Abstract

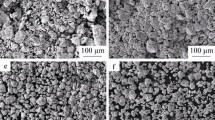

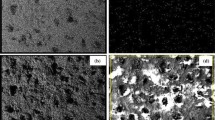

Elemental powder mixtures with the composition of Mo–12Si–10B–3Zr–0.3Y (at%) were milled in a planetary ball mill using hardened stainless-steel milling media under argon atmosphere. Effects of milling time, milling speed, process control agent, ball-to-powder ratio and milling ball size on the mechanical alloying processes were investigated from the points of morphology, internal structure, grain size, microstrain, phase constituent and dissolution of solute atoms. It is shown that under all conditions, the microstructural evolutions of mechanically milled powder particles are similar. The morphological evolution can roughly be divided into five stages: individual particle, irregular blocky composite particle, flake-shaped particle, agglomerate and single particle. The internal structure generally undergoes five stages: individual particle, coarse lamellar structure, fine lamellar structure, non-uniformly mixed structure and plum-pudding structure. Regardless of exceptional cases, the grain size of Moss decreases and its microstrain increases with the increase in milling time. Si and Zr atoms are dissolved into Mo gradually with the progress of milling. However, the evolutionary rates change significantly with milling conditions. The most significant influencing factor among different milling conditions is the input power from the mill to the powders, which plays a decisive role in the milling process.

Similar content being viewed by others

References

Dimiduk DM, Perepezko JH. Mo–Si–B alloys: developing a revolutionary turbine-engine material. MRS Bull. 2003;28(9):639.

Lemberg JA, Ritchie RO. Mo-Si-B alloys for ultrahigh-temperature structural applications. Adv Mater. 2012;24(26):3445.

Burk S, Gorr B, Trindade VB, Christ HJ. Effect of Zr addition on the high-temperature oxidation behaviour of Mo–Si–B alloys. Oxid Met. 2010;73(1–2):163.

Hochmuth C, Schliephake D, Völkl R, Heilmaier M, Glatzel U. Influence of zirconium content on microstructure and creep properties of Mo–9Si–8B alloys. Intermetallics. 2014;48:3.

Krüger M, Schliephake D, Jain P, Kumar KS, Schumacher G, Heilmaier M. Effects of Zr additions on the microstructure and the mechanical behavior of PM Mo–Si–B alloys. J Miner, Met Mater Soc. 2013;65(2):301.

Schneibel JH, Tortorelli PF, Ritchie RO, Kruzic JJ. Optimization of Mo–Si–B intermetallic alloys. Metall Mater Trans A. 2005;36(3):525.

Jehanno P, Boning M, Kestler H, Heilmaier M, Saage H, Krüger M. Molybdenum alloys for high temperature applications in air. Powder Metall. 2008;51(2):99.

Lemberg JA, Middlemas MR, Weingaertner T, Gludovatz B, Cochran JK, Ritchie RO. On the fracture toughness of fine-grained Mo–3Si–1B (wt%) alloys at ambient to elevated (1300 °C) temperatures. Intermetallics. 2012;20(1):141.

Majumdar S, Schliephake D, Gorr B, Christ HJ, Heilmaier M. Effect of yttrium alloying on intermediate to high-temperature oxidation behavior of Mo–Si–B alloys. Metall Mater Trans A. 2013;44(5):2243.

Majumdar S, Gorr B, Christ HJ, Schliephake D, Heilmaier M. Oxidation mechanisms of lanthanum-alloyed Mo–Si–B. Corros Sci. 2014;88:360.

Majumdar S, Burk S, Schliephake D, Krüger M, Christ HJ, Heilmaier M. A study on effect of reactive and rare earth element additions on the oxidation behavior of Mo–Si–B system. Oxid Met. 2013;80(3–4):219.

Burk S, Gorr B, Krüger M, Heilmaier M, Christ HJ. Oxidation behavior of Mo–Si–B–(X) alloys: macro- and microalloying (X = Cr, Zr, La2O3). J Miner, Met Mater Soc. 2011;63(12):32.

Sossaman T, Perepezko JH. Viscosity control of borosilica by Fe doping in Mo–Si–B environmentally resistant alloys. Corros Sci. 2015;98:406.

Jéhanno P, Heilmaier M, Saage H, Heyse H, Böning M, Kestler H, Schneibel JH. Superplasticity of a multiphase refractory Mo–Si–B alloy. Scripta Mater. 2006;55(6):525.

Yu JL, Li ZK, Zheng X, Zhang JJ, Liu H, Bai R, Wang H. Tensile properties of multiphase Mo–Si–B refractory alloys at elevated temperatures. Mater Sci Eng, A. 2012;532:392.

Rioult FA, Imhoff SD, Sakidja R, Perepezko JH. Transient oxidation of Mo–Si–B alloys: effect of the microstructure size scale. Acta Mater. 2009;57(15):4600.

Wang F, Shan AD, Dong XP, Wu JS. Microstructure and oxidation behavior of directionally solidified Mo–Mo5SiB2 (T2)-Mo3Si alloys. J Alloy Compd. 2008;462(1–2):436.

Krüger M, Franz S, Saage H, Heilmaier M, Schneibel JH, Jéhanno P, Böning M, Kestler H. Mechanically alloyed Mo–Si–B alloys with a continuous α-Mo matrix and improved mechanical properties. Intermetallics. 2008;16(7):933.

Majumdar S, Kumar A, Schliephake D, Christ HJ, Jiang X, Heilmaier M. Microstructural and micro-mechanical properties of Mo–Si–B alloyed with Y and La. Mater Sci Eng, A. 2013;573:257.

Gheisari K, Javadpour S, Oh JT, Ghaffari M. The effect of milling speed on the structural properties of mechanically alloyed Fe-45%Ni powders. J Alloy Compd. 2009;472(1–2):416.

Ragab M, Salem HG. Effect of milling energy on the structural evolution and stability of nanostructured Al-5.7wt% Ni mechanically alloyed eutectic alloy. Powder Technol. 2012;222:108.

Zhang LJ, Guo XP. Mechanical alloying behavior of Nb–Ti–Si-based alloy made from elemental powders by ball milling process. Rare Met. 2017;36(3):174.

Shao HP, Wang Z, Lin T, Ye Q, Guo ZM. Preparation of TiAl alloy powder by high-energy ball milling and diffusion reaction at low temperature. Rare Met. 2018;37(1):21.

Zhang JG, Bai Y, Dong H, Wu Q, Ye XC. Influence of ball size distribution on grinding effect in horizontal planetary ball mill. Adv Powder Technol. 2014;25(3):983.

Shaw L, Villegas J, Luo H, Zawrah M, Miracle D. Effects of process-control agents on mechanical alloying of nanostructured aluminum alloys. Metall Mater Trans A. 2003;34(1):159.

Ali M, Liwa M. Modification of parameters in mechanochemical synthesis to obtain alpha and beta-molybdenum disilicide. Adv Powder Technol. 2013;24(1):183.

Liu L, Padella F, Guo W, Magini M. Solid state reactions induced by mechanical alloying in metal-silicon (metal = Mo, Nb) systems. Acta Metall Mater. 1995;43(10):3755.

Abbasi AR, Shamanian M. Synthesis of Mo5SiB2 based nanocomposites by mechanical alloying and subsequent heat treatment. Mater Sci Eng, A. 2011;528(9):3295.

Yamauchi A, Yoshimi K, Kurokawa K, Hanada S. Synthesis of Mo–Si–B in situ composites by mechanical alloying. J Alloy Compd. 2007;434–435:420.

Bakhshi SR, Salehi M, Edris H, Borhani GH. Structural evaluation of Mo–Si–B multiphase alloy during mechanical alloying and heat treatment. Powder Metall. 2008;51(2):119.

Yang T, Guo XP, Luo YC. Microstructural evolution of mechanically alloyed Mo–Si–B–Zr–Y powders. Int J Refract Metal Hard Mater. 2016;56:35.

Williamson GK, Hall WH. X-Ray line broadening from filed aluminium and wolfram. Acta Metall. 1953;1(1):22.

Abdellaoui M, Gaffet E. The physics of mechanical alloying in a planetary ball mill: mathematical treatment. Acta Metall Mater. 1995;43(3):1087.

Magini M, Iasonna A. Energy transfer in mechanical alloying (overview). Mater Trans. 1995;36(2):123.

Maurice DR, Courtney TH. The physics of mechanical alloying: a first report. Metall Trans A. 1990;21A:289.

Gheiratmand T, Madaah Hosseini HR, Davami P, Ababei G, Song M. Mechanism of mechanically induced nanocrystallization of amorphous FINEMET ribbons during milling. Metall Mater Trans A. 2015;46(6):2718.

Burgio N, Iasonna A, Magini M, Martelli S, Padella F. Mechanical alloying of the Fe–Zr system. Correlation between input energy and end products. IL Nuovo Cimento. 1991; 13 D (4): 459.

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2017YFB0702903), the National Natural Science Foundation of China (Nos. 51431003 and U1435201) and the Research Fund of State Key Laboratory of Solidification Processing, China (No. 143-TZ-2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, T., Guo, XP. Mechanical alloying behaviors of Mo–Si–B-based alloy from elemental powders under different milling conditions. Rare Met. 38, 653–664 (2019). https://doi.org/10.1007/s12598-018-1111-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1111-1