Abstract

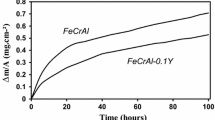

B2 FeAl intermetallic compounds modified with reactive elements (REs) including Sc and Y were fabricated by vacuum arc-melting, and the isothermal oxidation behavior of the RE-doped alloys at 1373 K was investigated. Both Sc and Y single-doping significantly decrease the alumina film growth rate of the alloys. The alumina film growth rate of Sc + Y co-doped alloy even further reduces compared to that of the Sc and Y single-doped alloys. The synergistic effect produced by Sc + Y co-doping on the growth behavior of alumina was discussed. It could be anticipated that the combined additions of Sc and Y which have matched chemical properties might decrease the alumina film growth rate more effectively and provide FeAl alloys with enhanced oxidation resistance.

Similar content being viewed by others

References

Ruan Y, Yan N, Zhu HZ, Zhou K, Wei B. Thermal performance determination of binary Fe–Al alloys at elevated temperatures. J Alloys Compd. 2017;701:676.

Ohtsu N, Nomura A, Oku M, Shishido T, Wagatsuma K. X-ray photoelectron spectroscopic studies on oxidation behavior of nickel and iron aluminides under oxygen atmosphere at low pressures. Appl Surf Sci. 2008;254:5336.

Zhang ZX, Li XY, Dong HS. Plasma-nitriding and characterization of FeAl40 iron aluminide. Acta Mater. 2015;86:341.

Airiskallio E, Nurmi E, Heinonen MH, Väyrynen IJ, Kokko K, Ropo M, Punkkinen MPJ, Pitkänen H, Alatalo M, Kollár J, Johansson B, Vitos L. High temperature oxidation of Fe–Al and Fe–Cr–Al alloys: the role of Cr as a chemically active element. Corros Sci. 2010;52:3394.

Brito P, Pinto H, Kostka A. The crystallographic template effect assisting the formation of stable α-Al2O3 during low temperature oxidation of Fe–Al alloys. Corros Sci. 2016;105:100.

Guilemany JM, Cinca N, Dosta S, Cano IG. FeAl and NbAl3 intermetallic-HVOF coatings: structure and properties. J Therm Spray Technol. 2009;18:536.

Lang FQ, Yu ZM, Gedevanishvili S, Deevi SC, Narita T. Cyclic oxidation behavior of Fe–40Al sheet. Intermetallics. 2004;12:451.

Liu CT, George EP, Maziasz PJ, Schneibel JH. Recent advances in B2 iron aluminide alloys: deformation, fracture and alloy design. Mater Sci Eng A. 1998;258:84.

Deevi SC, Sikka VK, Liu CT. Processing, properties, and applications of nickel and iron aluminides. Prog Mater Sci. 1997;42:177.

DeVan JH, Tortorelli PF. The oxidation-sulfidation behavior of iron alloys containing 16–40 at% aluminum. Corros Sci. 1993;35:1065.

Hou PY, Moskito J. Sulfur segregation to Al2O3–FeAl interfaces studied by field emission-Auger electron spectroscopy. Oxid Met. 2003;59(5):559.

Xu CH, Gao W, Gong H. Oxidation behaviour of FeAl intermetallics. The effects of Y and/or Zr on isothermal oxidation kinetics. Intermetallics. 2000;8:769.

Pint BA. Progress in understanding the reactive element effect since the Whittle and Stringer literature review. In: Proceedings of John Stringer Symposium on High Temperature Corrosion, ASM International; Novelty; 2003.9.

Whittle DP, Stringer J. Improvements in high temperature oxidation resistance by additions of reactive elements or oxide dispersions. Philos Trans R Soc Lond Ser A. 1980;295:309.

Wang L, Pan LL, Peng H, Guo HB, Gong SK. Cyclic oxidation behavior of Cr-/Si-modified NiAlHf coatings on single-crystal superalloy produced by EB-PVD. Rare Met. 2016;35(5):396.

Yan K, Guo HB, Peng H, Gong SK. Oxidation behaviour of electron beam physical vapour deposition β-NiAlHf coatings at 1100 °C in dry and humid atmospheres. Rare Met. 2016;35(7):513.

Xu CH, Gao W, Li S. Oxidation behaviour of FeAl intermetallics—the effect of Y on the scale spallation resistance. Corros Sci. 2001;43:671.

Wang HF, Zhang YD, Shahzad S, Liu WB, Yang ZG, Zhang C. High temperature oxidation performance of CoNiCrAl alloy with different Sc contents. Chin J Rare Met. 2016;40(9):857.

Xu CH, Gao W. Oxidation behaviour of FeAl intermetallics: effects of reactive elements on cyclic oxidation properties. Mater Sci Technol. 2001;17(3):324.

Li DQ, Guo HB, Peng H, Gong SK, Xu HB. Improved alumina scale adhesion of electron beam physical vapor deposited Dy/Hf-doped β-NiAl coatings. Appl Surf Sci. 2013;283:513.

Carling KM, Carter EA. Effects of segregating elements on the adhesive strength and structure of the α-Al2O3/β-NiAl interface. Acta Mater. 2007;55:2791.

Heuer AH, Hovis DB, Smialek JL, Gleeson B. Alumina scale formation: a new perspective. J Am Ceram Soc. 2011;94(S):146.

Pint BA. Experimental observations in support of the dynamic-segregation theory to explain the reactive-element effect. Oxid Met. 1996;45(1/2):1.

Janda D, Fietzek H, Galetz M, Heilmaier M. The effect of micro-alloying with Zr and Nb on the oxidation behavior of Fe3Al and FeAl alloys. Intermetallics. 2013;41:51.

Pint BA, Alexander KB. Grain boundary segregation of cation dopants in α-Al2O3 scales. J Electrochem Soc. 1998;145(6):1819.

Pint BA, More KL, Wright IG. The use of two reactive elements to optimize oxidation performance of alumina-forming alloys. Mater High Temp. 2003;20(3):375.

Li DQ, Guo HB, Wang D, Zhang T, Gong SK, Xu HB. Cyclic oxidation of β-NiAl with various reactive element dopants at 1200°C. Corros Sci. 2013;66:125.

Lan H, Zhang WG, Yang ZG. Investigation of Pt–Dy co-doping effects on isothermal oxidation behavior of (Co, Ni)-based alloy. J Rare Earths. 2012;30(9):928.

Guo HB, Li DQ, Zheng L, Gong SK, Xu HB. Effect of co-doping of two reactive elements on alumina scale growth of β-NiAl at 1200°C. Corros Sci. 2014;88:197.

Zhang YD, Zhang C, Wang HF, Yang ZG. Oxidation behaviour of CoNiCrAlY at 1000°C with Ce and Re additions. Chin J Rare Met. 2016;40(5):409.

Pint BA, More KL, Tortorelli PF. Optimizing the imperfect oxidation performance of iron aluminides. Mater Sci Forum. 2001;369–372(1):411.

Zheng YB, Wang F, Ai TT, Li C. Structural, elastic and electronic properties of B2-type modified by ternary additions FeAl-based intermetallics: first-principles study. J Alloys Compd. 2017;710:581.

Pint BA. The oxidation behavior of Y2O3-dispersed β-NiAl. Oxid Met. 2004;61(3/4):273.

Nowak K, Kupka M. High-temperature oxidation behaviour of B2 FeAl based alloy with Cr, Zr and B additions. Mater Chem Phys. 2012;132:902.

Monceau D, Pieraggi B. Determination of parabolic rate constants from a local analysis of mass-gain curves. Oxid Met. 1998;50(5/6):477.

Pint BA, Martin JR, Hobbs LW. 18O/SIMS characterization of the growth mechanism of doped and undoped α-Al2O3. Oxid Met. 1993;39(3/4):167.

Mennicke C, He MY, Clarke DR, Smith JS. The role of secondary oxide inclusions (“pegs”) on the spallation resistance of oxide films. Acta Mater. 2000;48:2941.

Guo HB, Zhang T, Wang SX, Gong SK. Effect of Dy on oxide scale adhesion of NiAl coatings at 1200°C. Corros Sci. 2011;53:2228.

Cotell CM, Yurek GJ, Hussey RJ, Mitchell DF, Graham MJ. The influence of grain-boundary segregation of Y in Cr2O3 on the oxidation of Cr metal. Oxid Met. 1990;34(3/4):173.

Cotell CM, Yurek GJ, Hussey RJ, Mitchell DF, Graham MJ. The influence of grain-boundary segregation of Y in Cr2O3 on the oxidation of Cr metal. II. Effects of temperature and dopant concentration. Oxid Met. 1990;34(3/4):201.

Acknowledgements

This research was financially supported by the Basic Research Program of State Grid (No. GCB17201500188).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, DQ., Zhou, LX., Zhu, KJ. et al. Isothermal oxidation behavior of scandium and yttrium co-doped B2-type iron–aluminum intermetallics at elevated temperature. Rare Met. 37, 690–698 (2018). https://doi.org/10.1007/s12598-018-1091-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1091-1