Abstract

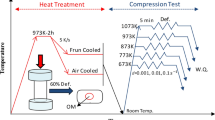

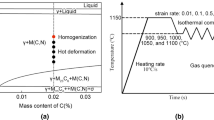

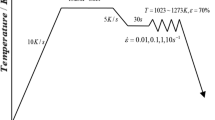

The hot deformation behavior of pure nickel with coarse, columnar grains in the temperature range of 950–1150 °C at intervals of 50 °C and in the strain rate range of 0.001–10.000 s−1 at intervals of one order of magnitude was investigated by isothermal hot compressive testing with the compression ratio of 70%. The results reveal that the strain rate and the temperature strongly affect the flow stress during hot deformation and that flow stress increases with the increase in strain rate while decreases with temperature increasing. Moreover, the relationship among flow stress, strain rate and temperature can be represented by the Zener–Hollomon parameter with the calculated apparent activation energy of 312.403 kJ·mol−1, and the variation of activation energy is sensitive to strain rate rather than temperature. In addition, the dynamic recrystallization (DRX) analysis reveals that the DRX behavior of nickel is evidently affected by both deformation temperature and strain rate and that the distinct mechanisms of nucleation are the bulging of serrated grain boundaries and the development of twinning.

Similar content being viewed by others

References

Manonukul A, Dunne FPE. Initiation of dynamic recrystallization under inhomogeneous stress states in pure copper. Acta Mater. 1999;47(17):4339.

Sommitsch C, Mitter W. On modelling of dynamic recrystallisation of fcc materials with low stacking fault energy. Acta Mater. 2006;54(2):357.

Galindo-Nava EI, Rae CMF. Microstructure evolution during dynamic recrystallisation in polycrystalline nickel superalloys. Mater Sci Eng A. 2015;636(6):434.

Sakai T. Dynamic recrystallization microstructures under hot working conditions. J Mater Process Technol. 1995;53(1):349.

Sakai T, Ohashi M. Dislocation substructures developed during dynamic recrystallisation in polycrystalline nickel. Mater Sci Technol. 1990;6(12):1251.

Chen S, Gottstein G. Dislocation structures in nickel during high temperature low cycle fatigue at large cumulative strains. J Mater Sci. 1989;24(11):4094.

Luton MJ, Sellars CM. Dynamic recrystallization in nickel and nickel-iron alloys during high temperature deformation. Acta Metall. 1969;17(8):1033.

Srinivasan N, Prasad Y. Characterisation of dynamic recrystallisation in nickel using processing map for hot deformation. Mater Sci Technol. 1992;8(3):206.

Mataya MC. Simulating microstructural evolution during the hot working of alloy 718. JOM. 1999;51(1):18.

Shen G, Semiatin SL, Shivpuri R. Modeling microstructural development during the forging of Waspaloy. Metall Mater Trans A. 1995;26(7):1795.

Semiatin SL, Weaver DS, Kramb RC, Fagin PN, Glavicic MG, Goetz RL, Frey ND, Antony MM. Deformation and recrystallization behavior during hot working of a coarse-grain, nickel-base superalloy ingot material. Metall Mater Trans A. 2004;35(2):679.

Hou XL, Li Y, Lv P, Cai J, Ji L, Guan QF. Hot deformation behavior and microstructure evolution of a Mg–Gd–Nd–Y–Zn alloy. Rare Met. 2016;35(7):532.

Li FL, Fu R, Feng D, Tian ZL. Hot workability characteristics of Rene88DT superalloy with directionally solidified microstructuremelt-spun. Rare Met. 2015;34(1):51.

Ponge D, Gottstein G. Necklace formation during dynamic recrystallization: mechanisms and impact on flow behavior. Acta Mater. 1998;46(1):69.

Dudova N, Belyakov A, Sakai T, Kaibyshev R. Dynamic recrystallization mechanisms operating in a Ni–20% Cr alloy under hot-to-warm working. Acta Mater. 2010;58(10):3624.

Beladi H, Cizek P, Hodgson PD. On the characteristics of substructure development through dynamic recrystallizationmelt-spun. Acta Mater. 2010;58(9):3531.

Haghdadi N, Zarei-Hanzaki A, Abedi HR. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strainmelt-spun. Mater Sci Eng A. 2012;535(2):252.

Lin YC, Chen MS, Zhong J. Numerical simulation for stress/strain distribution and microstructural evolution in 42CrMo steel during hot upsetting processmelt-spun. Comput Mater Sci. 2008;43(4):1117.

Lin YC, Xia YC, Chen XM, Chen MS. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain ratemelt-spun. Comput Mater Sci. 2010;50(1):227.

Zeng Z, Jonsson S, Zhang Y. Constitutive equations for pure titanium at elevated temperaturesmelt-spun. Mater Sci Eng A. 2009;505(S1–2):116.

Sellars CM, McTegart WJ. On the mechanism of hot deformation. Acta Metall. 1966;14(9):1136.

Salehi AR, Serajzadeh S, Yazdipour N. A study on flow behavior of A-286 superalloy during hot deformation. Mater Chem Phys. 2007;101(1):153.

Han Y, Liu G, Zou D, Liu R, Qiao G. Deformation behavior and microstructural evolution of as-cast 904L austenitic stainless steel during hot compression. Mater Sci Eng A. 2013;565(10):342.

Haghdadi N, Zarei-Hanzaki A, Abedi HR, Sabokpa O. The effect of thermomechanical parameters on the eutectic silicon characteristics in a non-modified cast A356 aluminum alloymelt-spun. Mater Sci Eng A. 2012;549(7):93.

Rokni MR, Zarei-Hanzaki A, Roostaei AA, Abolhasani A. Constitutive base analysis of a 7075 aluminum alloy during hot compression testingmelt-spun. Mater Des. 2011;32(10):4955.

Lin YC, Li QF, Xia YC, Li LT. A phenomenological constitutive model for high temperature flow stress prediction of Al–Cu–Mg alloymelt-spun. Mater Sci Eng A. 2012;534(1):654.

Liu Y, Hu R, Li J, Kou H, Li H, Chang H, Fu H. Characterization of hot deformation behavior of Haynes230 by using processing maps. J Mater Process Technol. 2009;209(8):4020.

Prasad Y, Sasidhara S, Sikka VK. Characterization of mechanisms of hot deformation of as-cast nickel aluminide alloy. Intermetallics. 2000;8(9):987.

Ueki M, Horie S, Nakamura T. Factors affecting dynamic recrystallization of metals and alloys. Mater Sci Technol. 1987;3(5):329.

Schaffer JP, Saxena A, Antolovich SD. The Science and Design of Engineering Materials. Chicago: Irwin; 1995. 864.

Wierzbinski S, Korbel A, Jonas JJ. Structural and mechanical aspects of high temperature deformation of polycrystalline nickel. Mater Sci Technol. 1992;8(2):153.

Wang Y, Shao WZ, Zhen L, Yang L, Zhang XM. Flow behavior and microstructures of superalloy 718 during high temperature deformation. Mater Sci Eng A. 2008;497(1):479.

Wang Y, Shao WZ, Zhen L, Zhang XM. Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718melt-spun. Mater Sci Eng A. 2008;486(1):321.

Wusatowska-Sarnek AM, Miura H, Sakai T. Nucleation and microtexture development under dynamic recrystallization of copper. Mater Sci Eng A. 2002;323(1):177.

Li D, Guo Q, Guo S, Guo S, Peng H, Wu Z. The microstructure evolution and nucleation mechanisms of dynamic recrystallization in hot-deformed Inconel 625 superalloy. Mater Des. 2011;32(2):696.

Montheillet F, Thomas JP. Dynamic Recrystallization of Low Stacking Fault Energy Metals. Netherlands: Springer; 2004. 357.

Poelt P, Sommitsch C, Mitsche S, Walter M. Dynamic recrystallization of Ni-base alloys—experimental results and comparisons with simulations. Mater Sci Eng A. 2006;420(1):306.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51271076 and 51474101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, WL., Lai, SZ., Teng, J. et al. Flow behavior and microstructural evolution in nickel during hot deformation. Rare Met. 38, 675–682 (2019). https://doi.org/10.1007/s12598-017-0877-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0877-x