Abstract

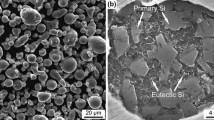

Silicon/aluminum (Si/Al) composite is a kind of lightweight electronic packaging material that received a lot of attention in the past 20 years. In this paper, a series of Si/Al composites with lowered coefficient of thermal expansion (CTE) and high thermal conductivity were produced by powder metallurgy (PM). The Si/Al composites are fully dense and have fine Si particles uniquely distributed within pure Al matrix. Three 50%Si/Al composites were designed to have strength in the range of 185–290 MPa to meet different demands, while the other properties keep invariable. Fracture toughness of the composites is measured to be 9–10 MPa·m1/2. The composites were machined to 50%Si/Al housings and 27%Si/Al lids. Both the hermeticities of housings before and after laser-beam-welding sealing are determined. The measured leak rate of composites and sealed housings is in magnitude order of 1 × 10−10 and 1 × 10−9 Pa·m3·s−1, respectively, suggesting high hermeticity. The good hermeticity is attributed to the full dense materials, good weldability, and extremely low weld porosity. The present Si/Al composites are expected to be extensively used in highly hermetic electronic packages.

Similar content being viewed by others

References

Zweben C. Advances in composite materials for thermal management in electronic packaging. JOM. 1998;50(6):47.

Tong XC. Advanced Materials for Thermal Management of Electronic Packaging. New York: Springer; 2011. 1.

Hunt WH. Particulate reinforced MMCs. In: Kelly A, Zweben C, editors. Comprehensive Composite Materials, Vol. 3. Metal Matrix Composites. Amsterdam: Elsevier Science; 2000. 12.

Chen YY, Chung DDL. Silicon-aluminium network composites fabricated by liquid metal infiltration. J Mater Sci. 1994;29(23):6069.

Sangha SPS, Jacobson DM, Ogilvy A, Azema M, Arun Junai A, Botter E. Novel aluminum-silicon alloys for electronics packaging. Eng Sci Educ J. 1997;10:195.

Jacobson DM. Spray-formed silicon–aluminum. Adv Mater Process. 2000;157(3):36.

Ogilvy A, Shannon GJ. Hermetic Welding of Osprey CE Alloys Using Nd YAG Pulsed Lasers. Pasadena: Pasadena Convention Center; 2004. 1.

Weinshanker S, Ogilvy A, Leatham AG, Sangha S. Advanced Space and Defense Microelectronic Devices Enabled by Ultra-Lightweight Osprey CE Alloys. Washington: Sandvik Osprey Ltd.; 2006. 1.

Xiu ZY, Zhu DZ, Zhang Q, Wu GH. Study on properties of high reinforcement-content aluminum matrix composite for electrical packaging. In: 6th International Conference on Electronic Packaging Technology, Shenzhen. 2005. 203.

Chien CW, Lee SL, Lin JC, Jahn MT. Effects of sip size and volume fraction on properties of Al/Sip composites. Mater Lett. 2002;52(4–5):334.

Zhang QG, Zhang HX, Gu MY, Jin YP. Studies on the fracture and flexural strength of Al/Sip composite. Mater Lett. 2004;58(27–28):3545.

Sumitomo Electronics Industries Ltd. Low thermal expansion PM aluminum alloy for electronic applications. Met Powder Rep. 1990;45(9):589.

Itoh Y, Odani Y, Akechi K, Kuroishi N. Aluminum–silicon alloy heatsink for semiconductor devices. US Patent; 4926242. 1990.

Feng X, Zheng QZ, Li SC, Yang PY. Properties of Si–Al electronic packaging materials fabricated by hot pressing. Chin J Rare Met. 2005;29(1):11.

Chien CW, Lee SL, Lin JC. Processing and properties of high volume fraction aluminium/silicon composites. Mater Sci Technol. 2003;19(9):1231.

Department of Defense. MIL-STD-883H, Test method standard, seal, method 1014.13. 2010.

Liu YQ, Wei SH, Fan JZ, Ma ZL, Zuo T. Mechanical properties of a low-thermal-expansion aluminum/silicon composite produced by powder metallurgy. J Mater Sci Technol. 2014;30(4):417.

Wei YG. Research on producing, microstructure and properties of spray-formed Si–Al alloys used for electronic packaging. Beijing: General Research Institute for Norferrous Metals; 2006. 25.

Zhu XJ, Liu G. Control of laser welding cracks in the alloy 4J42 packages. Hybrid Microelectron Technol. 2010;21(2–3):79.

Song YQ. Laser seal welding technology for microwave modules of aluminium alloy package. Electron Process Technol. 2012;33(3):148.

Acknowledgements

This study was financially supported by the National Basic Research Program of China (No. 2012CB619600).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, YQ., Fan, JZ., Hao, XX. et al. Advanced hermetic electronic packaging based on lightweight silicon/aluminum composite produced by powder metallurgy technique. Rare Met. 39, 1307–1313 (2020). https://doi.org/10.1007/s12598-016-0833-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0833-1