Abstract

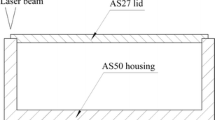

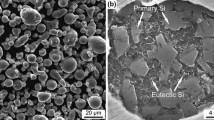

The electronic packaging shell with high silicon carbide aluminum-base composites was prepared by semi-solid thixoforming technique. The flow characteristic of the SiC particulate was analyzed. The microstructures of different parts of the shell were observed by scanning electron microscopy and optical microscopy, and the thermophysical and mechanical properties of the shell were tested. The results show that there exists the segregation phenomenon between the SiC particulate and the liquid phase during thixoforming, the liquid phase flows from the shell, and the SiC particles accumulate at the bottom of the shell. The volume fraction of SiC decreases gradually from the bottom to the walls. Accordingly, the thermal conductivities of bottom center and walls are 178 and 164 W·m−1·K−1, the coefficients of thermal expansion (CTE) are 8.2×10−6 and 12.6×10−6 K−1, respectively. The flexural strength decreases slightly from 437 to 347 MPa. The microstructures and properties of the shell show gradient distribution.

Similar content being viewed by others

References

XIONG De-gan, CHENG Hui, LIU Xi-cong, ZHAO Xun, BAO Xiao-heng, YANG Sheng-liang, DU Yong-guo. Advances in research on aluminum silicon carbide electronic packaging composites and components [J]. Materials Review, 2006, 20(3): 111–115. (in Chinese)

LIU Zheng-chun, WANG Zhi-fa, JIANG Guo-sheng. Advances in metal-matrix material for electronic packaging [J]. Ordnance Material Science and Engineering, 2010, 24(2): 49–54. (in Chinese)

OKUMUS S. C, ASLAN S, KARSLIOGLU R, GULTEKIN D, AKBULUT H. Thermal expansion and thermal conductivity behaviors of Al-Si/SiC/graphite hybrid metal matrix composites (MMCs) [J]. Materials Science, 2012, 18(4): 341–346.

KALAICHELVI V, KARTHIKEYAN R, SIVAKUMAR D, SRINIVASAN V. Tool wear classification using fuzzy logic for machining of Al/SiC composite material [J]. Modeling and Numerical Simulation of Material Science, 2012, 2: 28–36.

RAWAL S. Metal-matrix composites for space application [J]. The Journal of the Minerals Metals & Materials Society, 2001, 53(4): 14–17.

RAO B S, HEMAMBAR C, PATHAK A V, PATEL K J, RÖDEL J, JAYARAM V. Al/SiC carriers for microwave integrated circuits by a new technique of pressure less infiltration [J]. Ieee Transactions on Electronics Packaging Manufacturing, 2006, 29(1): 58–63.

ZHANG Dong-ming, ZHANG Lian-meng, GU Xiao-feng, YANG Jun. A preparation method of high conductivity electronic packaging shell with laser weld ability: China, CN200610125306.5 [P]. 2007-05-30. (in Chinese)

LLOYD D J. Particle reinforced aluminum and magnesium matrix composites [J]. International Materials Review, 1994, 39(1): l–23.

LEE J C, AHN J P, ZHONG L S. Methodology to design the interfaces in SiC/Al composites [J]. Metallurgical and Materials Transaction A, 2001, 32: 1541–1549

LONG S, BEFFORT O, CAYRON C, BONJOUR C. Microstructure and mechanical properties of a high volume fraction SiC particle reinforced AlCu4MgAg squeeze casting [J]. Material Science and Engineering, 1999, A269(1/2):175–185.

ZHAO Zhi-yuan. Aluminum and aluminum alloy grade and metallographic info search speed and technology innovation of metallographic examination and Application Guide [M]. Beijing: China Knowledge Press, 2005: 71–72. (in Chinese)

LU Gui-min, ZHI Li-qun. The current status of research on the constitutive relations of semi-solid metal thixoforming [J]. Automotive Engineering, 2009, 31(5): 430–434. (in Chinese).

WANG Kai-kun, KANG Yong-lin, SONG Pu-guang. Preparation of SiCp/A356 electronic packaging materials and its thixo-forging [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 988–992.

YU Zhi-hua, ZHANG Jian-yun, ZHOU Xian-liang, ZOU Ai-hua. Research and development on thermal conductivity of SiC/Al composites applied to electronic packaging [J]. Metallic Functional Materials, 2009, 16(1): 61–63. (in Chinese)

NAM T H, REQUENA G, DEGISCHER P. Thermal expansion behavior of aluminum matrix composites with densely SiC particles [J]. Composites A, 2008, 39: 856–865.

YANG Hui-juan, WANG zhi-fa, JIANG Guo-sheng, WANG Hai-shan, TANG Ren-zheng. Preparation of Kovar/Cu/Kovar laminates by rolling combination [J]. Rare Metals and Cemented Carbides, 2004, 32(2): 7–8. (in Chinese)

GEIGER A L, JACKSON M. Low-expansion MMCs boost avionics [J]. Advanced Materials & Processes, 1989, 136(7): 23–28.

LI Yan-xia, LIU Jun-you, LIU Guo-quan, JIA Qi-jin. Microstructure and properties of Al-65%Si alloy fabricated by a process of liquid and solid separation [J]. Transactions of Materials and Heat Treatment, 2012, 33(3): 40–45. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Mh., Liu, Jy., Jia, Cc. et al. Microstructure and properties of electronic packaging shell with high silicon carbide aluminum-base composites by semi-solid thixoforming. J. Cent. South Univ. 21, 4053–4058 (2014). https://doi.org/10.1007/s11771-014-2396-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2396-3