Abstract

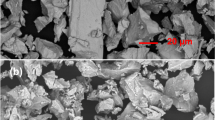

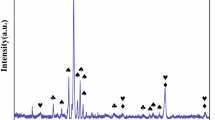

Nb–24Ti–18Si–2Al–2Hf–4Cr and Nb–24Ti–18Si–2Al–2Hf–8Cr alloys were prepared by arc melting in a water-cooled crucible under argon atmosphere. Microstructural characteristics and oxidation resistance of the alloys at 1250 °C were investigated. The results show that, when the Cr content is 4 at%, the microstructures consist of (Nb,Ti)SS and Nb5Si3; as Cr content increases to 8 at%, C14 Laves phase Cr2Nb is formed. The isothermal oxidation tests show that the oxidation kinetics of the two alloys follow similar features. The weight gains of the two alloys after oxidation at 1250 °C for 100 h are 235.61 and 198.50 mg·cm−2, respectively. During oxidation, SiO2, TiO2, Nb2O5 and CrNbO4 are formed at first. Then, Ti2Nb10O29 is formed after oxidation for 20 min and begins to change into TiNb2O7 as the oxidation proceeds. SiO2 is formed as solid state at first but later evolves into glassy state to improve the cohesion of the scale. After oxidation for 100 h, oxidation products consist of SiO2, TiNb2O7, Nb2O5 and CrNbO4.

Similar content being viewed by others

References

Yao CF, Guo XP, Guo HS. Microstructural characteristics of integrally directionally solidified Nb–Ti–Si base ultrahigh temperature alloy with crucibles. Acta Metallurgica Sinica. 2008;44(5):579.

Chan KS. Alloying effects on the fracture toughness of Nb-based silicides and Laves phases. Mater Sci Eng A. 2005;409(1–2):257.

Bewlay BP, Jackson MR, Lipsitt HA. The balance of mechanical and environmental properties of a multi-element niobium-niobium silicide-based in situ composite. Metall Mater Trans. 1996;27(12):3801.

Subramanian PR, Parthasarathy TA, Mendiratta MG, Dimiduk DM. Compressive creep behavior of Nb5Si3. Scripta Mater. 1995;32(8):1227.

Jackson MR, Rowe RG, Skelly DW. Oxidation of some intermetallic compounds and intermetallic matrix composites. MRS Proceedings, Vol. 364. Sacramento: Cambridge University Press; 1994. 1339.

Zhao JC, Peluso LA, Jackson MR, Tan Lizhen. Phase diagram of the Nb–Al–Si ternary system. J Alloy Compd. 2003;360(1):183.

Bewlay BP, Jackson MR, Zhao JC, Subramanian PR, Mendiratta MG, Lewandowski JJ. Ultrahigh-temperature Nb-silicide-based composites. MRS Bull. 2003;28(09):646.

Subramanian PR, Mendiratta MG, Dimiduk DM. The development of Nb-based advanced intermetallic alloys for structural applications. JOM. 1996;48(1):33.

Yao DZ, Cai R, Zhou CG, Sha JB, Jiang HR. Experimental study and modeling of high temperature oxidation of Nb-base in situ composites. Corros Sci. 2009;51(2):364.

Moricca MP, Varma SK. Isothermal oxidation behaviour of Nb–W–Cr alloys. Corros Sci. 2010;52(9):2964.

Bewlay BP, Jackson MR, Gigliotti MFX. Niobium silicide high temperature in situ composites. In: Westbrook JH, Fleischer RL, editors. Intermetallic Compounds, Principles and Practice, vol. 3. Chichester: Wiley; 2002. 541.

Subramanian PR, Mendiratta MG, Dimiduk DM. Advanced intermetallic alloys—beyond gamma titanium aluminides. Mater Sci Eng. 1997;239(4):1.

Bewlay BP, Jackson MR, Zhao JC, Subramanian PR. A review of very-high-temperature Nb-silicide-based composites. Metall Mater Trans. 2003;34(10):2043.

Brossmann U, Oehring M, Appel F, Hemker K J, Dimiduk D M, Clemens H. Structural Intermetallics. In: R Darolia, John J Lewandowski, CT Liu, PL Martin, DB Miracle, MV Nathal, editors. Warrendale: TMS; 2001. 99.

Guo JM, Guo XP, Song SG. Oxidation behavior of Nb-Ti-Si base multielement alloys at 1250 °C. Acta Metall Sin. 2008;44(5):574.

Wan W, Zhou CG. Hot corrosion behaviour of Nbss/Nb5Si3 in situ composites in the mixture of Na2SO4 and NaCl melts. Corros Sci. 2013;74(6):345.

Cockeram BV, Rapp RA. Oxidation-resistant boron-and germanium-doped silicide coatings for refractory metals at high temperature. Mater Sci Eng. 1995;192:980.

Zheng HZ, Lu SQ, Zhu JY, Liu GM. Effect of Al additions on the oxidation behavior of Laves phase NbCr2 alloys at 1373 and 1473 K. Int J Refract Met Hard Mater. 2009;27(3):659.

Alvarez D, Varma SK. Characterization of microstructures and oxidation behavior of Nb–20Si–20Cr–5Al alloy. Corros Sci. 2011;53(6):2161.

Kubaschewski. Oxidation of Metals and Alloys. 2nd ed. London: Butterworths, Academic Press; 1962. 321.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51101005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hong, Z., Zhang, H., Weng, JF. et al. Oxidation behavior of Nb–24Ti–18Si–2Al–2Hf–4Cr and Nb–24Ti–18Si–2Al–2Hf–8Cr hypereutectic alloys at 1250 °C. Rare Met. 36, 168–173 (2017). https://doi.org/10.1007/s12598-015-0600-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0600-8