Abstract

9.5Cr–1.5MoCoVNbNB heat-resistant steel has been designed for use at 620 ℃ in ultra-supercritical power plants and has been acknowledged as the most promising martensitic heat-resistant steel for turbine rotors. With the addition of 100 ppm B, the resulting precipitates and inclusions endow the steel with improved properties. However, the direct observation and quantitative analysis of B distribution in 9.5Cr–1.5MoCoVNbNB heat-resistant steel are lacking. Herein, the distribution of B in 9.5Cr–1.5MoCoVNbNB heat-resistant steel was analyzed. The results of secondary ion mass spectroscopy (SIMS) revealed that B segregated at the boundaries after tempering, and those of atom probe tomography (APT) revealed that B atoms were evenly distributed in M23C6 carbide particles during aging at 620 ℃. The coarsening of M23C6 carbides was found to be a process of alloy element redistribution. The BN inclusions might be detrimental during the tensile rupture fracture because the fish-eye fracture mode was observed. Cavity coalescence mainly occurs around type-B dimples (without BN particles).

Graphical Abstract

Similar content being viewed by others

References

K. Yagi, F. Abe, Creep-resistant Steels, in Encyclopedia of Materials: Science and Technology, 2nd edn., ed. by K.H. Jürgen Buschow et. al (Pergamon, Oxford, 2001). https://doi.org/10.1016/B0-08-043152-6/00335-1

A. Fedoseeva, N. Dudova, R. Kaibyshev, Creep strength break down and microstructure evolution in a 3%Co modified P92 steel. Mater. Sci. Eng. A 654, 1–12 (2016). https://doi.org/10.1016/j.msea.2015.12.027

M.M. Li, W.Y. Chen, Microstructure-based prediction of thermal aging strength reduction factors for grade 91ferritic-martensitic steel. Mater. Sci. Eng. A 798, 140116 (2020). https://doi.org/10.1016/j.msea.2020.140116

D. Rojas, J. Garcia, O. Prat, G. Sauthoff, A.R. Kaysser-Pyzalla, 9%Cr heat resistant steels: alloy design, microstructure evolution and creep response at 650 °C. Mater. Sci. Eng A 528, 5164–5176 (2011). https://doi.org/10.1016/j.msea.2011.03.037

R. Viswanathan, W. Bakker, Materials for ultrasupercritical coal power plants: turbine materials: part II. J. Mater. Eng. Perform. 10, 96–101 (2001). https://doi.org/10.1361/105994901770345402

Y.Q. Zhang, J.F. Gu, L.Z. Han, Elemental redistribution and precipitation reactions of 9Cr1.5Mo1CoB (FB2) steel during tempering. Mater. Charact. 171, 110778 (2020). https://doi.org/10.1016/j.matchar.2020.110778

J. Moon, T.H. Lee, S.D. Kim, C.H. Lee, J.H. Jang, J.H. Shin et al., Isothermal transformation of austenite to ferrite and precipitation behavior in 9Cr-1.5Mo-1.25Co-0.1 C-VNb heat-resistant steel. Mater. Charact. 170, 110677 (2020). https://doi.org/10.1016/j.matchar.2020.110677

Y.Q. Zhang, J.F. Gu, L.Z. Han, G. Shen, C.W. Li, Thermal decomposition characteristics of retained austenite and its influence on impact toughness of B-containing 9Cr1Mo1Co(FB2) steel during the two-step tempering. J. Mater. Res. Technol. 12, 2462–2475 (2021). https://doi.org/10.1016/j.jmrt.2021.03.105

H.F. Yin, G. Yang, J.Q. Zhao, H.S. Bao, Mo-rich Laves phase in a 9.5Cr–1.5MoCoVNbNB heat-resistant steel during long-term aging at 620 °C. Mater. Charact. 182, 111588 (2021). https://doi.org/10.1016/j.matchar.2021.111588

F. Abe, Precipitate design for creep strengthening of 9%Cr tempered martensite steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 9(1), 1–16 (2008). https://doi.org/10.1088/1468-6996/9/1/013002

V.T. Paul, S. Saroja, M. Vijayalakshmi, Microstructural stability of modified 9Cr–1Mo steel during long term exposures at elevated temperatures. J. Nucl. Mater. 378(3), 273–281 (2008). https://doi.org/10.1016/j.jnucmat.2008.06.033

K. Maruyama, K. Sawada, J. Koike, Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int. 41(6), 641–653 (2001). https://doi.org/10.2355/isijinternational.41.641

J. Takahashi, K. Ishikawa, K. Kawakami, M. Fujioka, N. Kubota, Atomic-scale study on segregation behavior at austenite grain boundaries in boron- and molybdenum-added steels. Acta Mater. 133, 41–54 (2017). https://doi.org/10.1016/j.actamat.2017.05.021

G. Zeiler, R. Bauer, A. Putschoegl, Experiences in manufacturing of forgings for power generation application. La Metall. Ital. 6, 33–40 (2010)

P. Yan, Z.D. Liu, H.S. Bao, Y.Q. Weng, W. Liu, Effect of microstructural evolution on high-temperature strength of 9Cr-3 W-3Co martensitic heat resistant steel under different aging conditions. Mater. Sci. Eng. A A588, 22–28 (2013). https://doi.org/10.1016/j.msea.2013.09.033

A. Shirzadi, S. Jackson, Structural Alloys for Power plants (Woodhead Publishing, Cambridge, 2014)

F. Liu, H.R. Fors Dan, A. Golpayegani, H.O. Andrén, G. Wahnström, Effect of boron on carbide coarsening at 873K (600 °C) in 9 to 12pct chromium steels. Metall. Mater. Trans. A 43, 4053–4062 (2012). https://doi.org/10.1007/s11661-012-1205-6

Y.J. Li, D. Ponge, P. Choi, D. Raabe, Segregation of boron at prior austenite grain boundaries in a quenched martensitic steel studied by atom probe tomography. Scr. Mater. 96, 13–16 (2015). https://doi.org/10.1016/j.scriptamat.2014.09.031

T. Osanai, N. Sekido, M. Yonemura, K. Maruyama, M. Takeuchi, K. Yoshimi, Evolution of boron segregation during tempering in B doped 9% Cr ferritic steel. Mater. Charact. 177, 111192 (2021). https://doi.org/10.1016/j.matchar.2021.111192

X. Xu, J.A. Siefert, J.D. Parker, R.C. Thomson, Localised creep cavitation on boron nitride in the heat affected zone of 9%Cr tempered martensitic steel welds. Mater. Design 196, 109046 (2020). https://doi.org/10.1016/j.matdes.2020.109046

L.T. Li, R. Maclachlan, M.A.E. Jepson, R. Thomson, Microstructural evolution of boron nitride particles in advanced 9Cr power plant steels. Metall. Mater. Trans. A 44, 3411–3418 (2013). https://doi.org/10.1007/s11661-013-1642-x

K. Sakuraya, H. Okada, F. Abe, BN type inclusions formed in high Cr ferritic heat resistant steel. Energy Mater. 1, 158–166 (2013). https://doi.org/10.1179/174892406X160624

M. Albu, P. Mayr, F.M. Martin, G. Kothleitner, The influence of boron on the microstructure of a 9 wt% cr ferritic steel. Mater. High Temp. 28(2), 120–125 (2011). https://doi.org/10.3184/096034011X13059091965585

T. Fujishiro, T. Hara, G. Shigesato, Effect of Mo on γ to α transformation and precipitation behavior in b-added steel. Tetsu-to-Hagane 101(5), 300–307 (2015). https://doi.org/10.2355/tetsutohagane.101.300

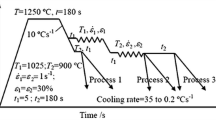

H.F. Yin, W.Q. Ge, F.S. Yin, J.Q. Zhao, G. Yang, H.S. Bao, L. Zhou, Effect of stress on the nucleation and evolution of Mo-rich Laves phase in 9.5Cr–1.5MoCoVNbNB heat-resistant steel during tensile rupture at 620°C. Mater. Charact. 196, 112565 (2023). https://doi.org/10.1016/j.matchar.2022.112565

T. Horiuchi, M. Igarashi, F. Abe, Improved utilization of added B in 9Cr heatresistant steels containing W. ISIJ Int. 42, S67–S71 (2002). https://doi.org/10.2355/isijinternational.42.Suppl_S67

C.R. Das, S.K. Albert, J. Swaminathan, A.K. Bhaduri, B.S. Murty, Effect of boron on creep behaviour of inter-critically annealed modified 9Cr-1Mo steel. Procedia Eng. 55(12), 402–407 (2013). https://doi.org/10.1016/j.proeng.2013.03.271

Y. Kimura, K. Kato, Y.W. Chai, Effects of Si on Phase stability and precipitation behavior of C14 laves phase (Fe,Cr). MRS Adv. 4(25–26), 1–7 (2019). https://doi.org/10.1557/adv.2019.112

G. Da Rosa, P. Maugis, A. Portavoce, J. Drillet, N. Valle, E. Lentzen et al., Grain-boundary segregation of boron in high-strength steel studied by nano-SIMS and atom probe tomography. Acta Mater. 182, 226–234 (2020). https://doi.org/10.1016/j.actamat.2019.10.029

Q.L. Yong, Secondary-Phase in Steel (Metallurgical Industry Press, Beijing, 2006)

X. Wang, Q. Xu, S.M. Yu, L. Hu, H. Liu, Y.Y. Ren, Laves-phase evolution during aging in fine grained heat-affected zone of a tungsten-strengthened 9% cr steel weldment. J. Mater. Process. Technol. 219, 60–69 (2015). https://doi.org/10.1016/j.jmatprotec.2014.12.007

A. Umantsev, G.B. Olson, Ostwald ripening in multicomponent alloys. Scr. Metall. Mater. 29, 1135–1140 (1993). https://doi.org/10.1016/0956-716X(93)90191-T

J. Ågren, M.T. Clavaguera-Mora, J. Golcheski, G. Inden, H. Kumar, C. Sigli, Workshop on applications of computational thermodynamics: Schloβ Ringberg. Calphad 24, 41–54 (2000). https://doi.org/10.1016/S0364-5916(00)00014-6

J. Hald, L. Korcakova, Precipitate stability in creep resistant ferritic steels-experimental investigations and modelling. ISIJ Int. 43, 420–427 (2003). https://doi.org/10.2355/isijinternational.43.420

M. Yoshizawa, M. Igarashi, T. Nishizawa, Effect of tungsten on the Ostwald ripening of M23C6 carbides in martensitic heat resistant steel. Trans. Iron Steel Inst. Jpn. 91, 272–277 (2005). https://doi.org/10.2355/tetsutohagane1955.91.2_272

F. Abe, Behavior of boron in 9Cr heat resistant steel during heat treatment and creep deformation. Key Eng. Mater. 345–346, 569–572 (2007). https://doi.org/10.4028/www.scientific.net/KEM.345-346.569

D. Kang, N. Kim, H. Lee, Effect of aging on the corrosion resistance of 2209 duplex stainless steel weldments. Met. Mater. Int. 25, 740–750 (2019). https://doi.org/10.1007/s12540-018-0206-4

H.F. Yin, J.Q. Zhao, W.Q. Ge, H.S. Bao, L. Zhou, F.S. Yin, Y. Zhang, Cavity growth behavior and fracture mechanism of 9.5Cr–1.5MoCoVNbNB heat-resistant steel during long-term tensile rupture at 620 °C. Mater. Charact. 203, 113130 (2023). https://doi.org/10.1016/j.matchar.2023.113130

K. Han, H. Ding, X. Fan, W. Li, Y. Lv, Y. Feng, Study of the creep cavitation behavior of P91 steel under different stress states and its effect on hightemperature creep properties. J. Mater. Res. Technol. 20, 47–59 (2022). https://doi.org/10.1016/j.jmrt.2022.07.032

T.L. Anderson, Fracture Mechanics Fundamentals and Applications (Taylor and Francis Group, Abingdon, 2017)

Acknowledgements

This work was financially supported by the National Key Research and Development Program No. 2021YFB3704100.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yin, H., Zhao, J., Bao, H. et al. Distribution of Boron in 9.5Cr–1.5MoCoVNbNB Martensitic Heat-Resistant Steel Studied by Secondary Ion Mass Spectroscopy and atom Probe Tomography. Met. Mater. Int. 30, 990–1001 (2024). https://doi.org/10.1007/s12540-023-01563-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01563-y