Abstract

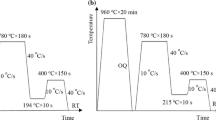

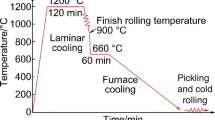

Five quenching temperatures were designed to investigate the relationship between volume fraction of retained austenite and microstructure, mechanical properties of a medium carbon quenching and partitioning (Q&P) steel. It is normally accepted that the optimal mechanical property of Q&P steels is obtained by quenching at optimum temperature, which corresponds to the maximum amount of retained austenite. However, the present work clarified that maximum volume fraction of retained austenite in Q&P steels is indeed unrelated to the optimum mechanical property of steels. The microstructure consisting of coarse martensite laths, dispersive bainite and thin retained austenite films was obtained by quenching at fine martensite start temperature (FMs), resulting in the optimum comprehensive mechanical property of Q&P steel with the better elongation at the expense of slightly smaller yield strength and tensile strength.

Graphic Abstract

Similar content being viewed by others

References

J.G. Speer, D.K. Matlock, B.C. De Cooman, J.G. Schroth, Acta Mater. 51, 2611 (2003)

J.G. Speer, D.V. Edmonds, F.C. Rizzo, D.K. Matlock, Curr. Opin. Solid State Mater. Sci. 8, 219 (2004)

J.G. Speer, E. De Moor, K.O. Findley, D.K. Matlock, B.C. De Cooman, D.V. Edmonds, Metall. Mater. Trans. A. 42, 3591 (2011)

S.G. Liu, S.S. Dong, F. Yang, L. Li, B. Hu, F.H. Xiao, Mater. Des. 56, 37 (2014)

E.J. Seo, L. Cho, Y. Estrin, B.C. De Coomana, Acta Mater. 113, 124 (2016)

D.V. Edmonds, K. He, M.K. Miller, F.C. Rizzo, A. Clarke, D.K. Matlock, Mater. Sci. Forum. 539, 4819 (2007)

D.H. Kim, J.G. Speer, H.S. Kim, B.C.D. Cooman, Metall. Mater. Trans. A. 40, 2048 (2009)

M.J. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, J. Sietsma, Acta Mater. 59, 6059 (2011)

E.J. Seo, L. Cho, B.C. De Cooman, Metall. Mater. Trans. A. 46, 27 (2014)

I. de Diego-Calderón, P. Rodriguez-Calvillo, A. Lara, J.M. Molina-Aldareguia, R.H. Petrov, D. De Knijf, Mater. Sci. Eng. A. 641, 215 (2015)

X.F. Huang, W.L. Liu, Y.Y. Huang, H. Chen, W.G. Huang, J. Mater. Process. Technol. 222, 181 (2015)

R. Jafari, S. Kheirandish, S. Mirdamadi, 6th International Biennial Conference on Ultrafine Grained and Nanostructured Materials: (UFGNSM2017). American Institute of Physics Conference Series. (2018).

M. Liu, G. Xu, G.H. Chen, J. Jia, Z.Y. Chen, Z.L. Xiong, Metall. Mater. Trans. A. (2019). https://doi.org/10.1007/s11661-019-05543-z

J.Y. Tian, G. Xu, Z.Y. Jiang, X.L. Wan, H.J. Hu, Q. Yuan, Steel Res. Int. (2018). https://doi.org/10.1002/srin.201800474

M. Liu, G. Xu, J.Y. Tian, Q. Yuan, M.X. Zhou, H.J. Hu, Steel Res. Int. (2019). https://doi.org/10.1002/srin.201900159

J.Y. Tian, G. Xu, M.X. Zhou, H.J. Hu, Steel Res. Int. (2017). https://doi.org/10.1002/srin.201700469

C.Y. Wang, J. Shi, W.Q. Cao, H. Dong, Mater. Sci. Eng. A. 527, 3442 (2010)

M.X. Zhou, G. Xu, L. Wang, B. He, Trans. Indian Inst. Met. 70, 1447 (2017)

M. Hillert, J. ÅGren, Scr. Mater. 50, 697 (2004)

J.G. Speer, D.K. Matlock, B.C.D. Cooman, J.G. Schroth, Scr. Mater. 52, 83 (2005)

D.P. Koistinen, R.E. Marburger, Acta Metall. 7, 59 (1959)

E.S. Machlin, M. Cohen, Trans. Metall. Soc. AIME. 191, 746 (1951)

R.E. Cech, D. Turnbull, JOM. 8, 124 (1956)

L. Liu, B.B. He, G.J. Cheng, H.W. Yen, M.X. Huang, Scr. Mater. 150, 1 (2018)

S.M.C.V. Bohemen, M.J. Santofimia, J. Sietsma, Scr. Mater. 58, 488 (2008)

C.H. Song, H. Yu, J. Lu, T. Zhou, Steel Res. Int. 90, 1800482 (2019)

F.R. Xiao, L. Bo, Y.Y. Shan, K. Yang, Mater Charact. 54, 417 (2005)

K. Sugimoto, N. Usui, M. Kobayashi, ISIJ Int. 32, 1311 (1992)

J. Wang, S. Van Der Zwaag, Metall. Mater. Trans. A. 32, 1527 (2001)

J.Y. Tian, G. Xu, M.X. Zhou, H.J. Hu, Z.L. Xue, J. Iron Steel Res. Int. 26, 846 (2019)

B. Hwang, Y.G. Kim, S. Lee, Y.M. Kim, N.J. Kim, J.Y. Yoo, Metall. Mater. Trans. A. 36, 2107 (2005)

O. Williams, V. Randle, P. Spellward, J. Cowan, Mater. Sci. Technol. 16, 1372 (2000)

C.H. Song, Univ. Sci. Technol. Beijing. (2018) (In Chinese)

Acknowledgements

The authors gratefully acknowledge the financial supports from the National Natural Science Foundation of China (NSFC) (Nos.51874216 and 51704217), the Major Projects of Technology Innovation of Hubei Province (No.2017AAA116) and the Hebei Joint Research Fund for Iron and Steel (E2018318013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, M., Wang, J., Zhang, Q. et al. Optimized Properties of a Quenching and Partitioning Steel by Quenching at Fine Martensite Start Temperature. Met. Mater. Int. 27, 2473–2480 (2021). https://doi.org/10.1007/s12540-020-00726-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00726-5