Abstract

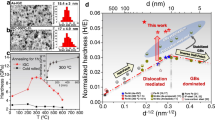

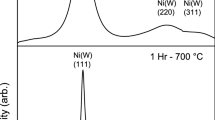

Conventionally, nanograined metals and alloys can be stabilized through segregating foreign elements at grain boundaries (GBs). Yet such an effect may be offset by formation of second phase at elevated temperatures. In this paper, by introducing minor W into a binary Ni-Mo alloy, we found precipitation of intermetallic phases was suppressed, enhancing thermal stability of the nanograined structure. Characterized faceted GBs and a high-fraction of Σ3 coincidence site lattice (CSL) boundaries illustrate that GB structures are relaxed by formation of copious annealing twins. Adding W reduces stacking fault energy of the solid solution and facilitates the thermally-triggered GB relaxation. Suppressed precipitation of the intermetallic phases may be attributed to depletion of solutes at relaxed GBs.

Similar content being viewed by others

References

Meyers, M. A.; Mishra, A.; Benson, D. J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 57, 427–556.

Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat. Rev. Mater. 2016, 7, 16019.

Shan, Z. W.; Stach, E. A.; Wiezorek, J. M. K.; Knapp, J. A.; Follstaedt, D. M.; Mao, S. X. Grain boundary-mediated plasticity in nanocrystalline nickel. Science 2004, 305, 654–657.

Rupert, T. J.; Gianola, D. S.; Gan, Y.; Hemker, K. J. Experimental observations of stress-driven grain boundary migration. Science 2009, 326, 1686–1690.

Weissmüller, J. Alloy effects in nanostructures. Nanostruct. Mater. 1993, 3, 261–272.

Kirchheim, R. Grain coarsening inhibited by solute segregation. Acta Mater. 2002, 50, 413–419.

Chookajorn, T.; Murdoch, H. A.; Schuh, C. A. Design of stable nanocrystalline alloys. Science 2012, 337, 951–954.

Hu, J.; Shi, Y. N.; Sauvage, X.; Sha, G.; Lu, K. Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 2017, 355, 1292–1296.

Hondros, E. D.; Seah, M. P. The theory of grain boundary segregation in terms of surface adsorption analogues. Metall. Trans. A 1977, 8, 1363–1371.

Kalidindi, A. R.; Schuh, C. A. Stability criteria for nanocrystalline alloys. Acta Mater. 2017, 132, 128–137.

Jiao, Z. B.; Schuh, C. A. Nanocrystalline Ag-W alloys lose stability upon solute desegregation from grain boundaries. Acta Mater. 2018, 767, 194–206.

Zheng, X. G.; Hu, J.; Li, J. X.; Shi, Y. N. Achieving ultrahigh hardness in electrodeposited nanograined Ni-based binary alloys. Nanomaterials (Basel) 2019, 9, 546.

Schuh, C. A.; Lu, K. Stability of nanocrystalline metals: The role of grain-boundary chemistry and structure. MRS Bull. 2021, 46, 225–235.

Zhou, X.; Li, X. Y.; Lu, K. Enhanced thermal stability of nanograined metals below a critical grain size. Science 2018, 340, 526–530.

Zhou, X.; Li, X. Y.; Lu, K. Size dependence of grain boundary migration in metals under mechanical loading. Phys. Rev. Lett. 2019, 122, 126101.

Li, X. Y.; Zhou, X.; Lu, K. Rapid heating induced ultrahigh stability of nanograined copper. Sci. Adv. 2020, 4, eaaz8003.

Xu, W.; Zhang, B.; Du, K.; Li, X. Y.; Lu, K. Thermally stable nanostructured Al-Mg alloy with relaxed grain boundaries. Acta Mater. 2022, 226, 117640.

Zhang, B. B.; Tang, Y. G.; Mei, Q. S.; Li, X. Y.; Lu, K. Inhibiting creep in nanograined alloys with stable grain boundary networks. Science 2022, 378, 659–663.

Porter, D. A.; Easterling, K. E.; Sherif, M. Y. Phase Transformations in Metals and Alloys, 3rd ed.; CRC Press: Boca Raton, 2009.

Rittner, J. D.; Seidman, D. N.; Merkle, K. L. Grain-boundary dissociation by the emission of stacking faults. Phys. Rev. B 1996, 53, R4241–R4244.

Meyers, M. A.; Murr, L. E. A model for the formation of annealing twins in F. C. C. metals and alloys. Acta Metall. 1978, 24, 951–962.

Merkle, K. L. Atomic-scale grain boundary relaxation modes in metals and ceramics. Microsc. Microanal. 1997, 3, 339–351.

Hu, J.; Shi, Y. N.; Lu, K. Thermal analysis of electrodeposited nano-grained Ni-Mo alloys. Scr. Mater. 2018, 754, 182–185.

Gallagher, P. C. J. The influence of alloying, temperature, and related effects on the stacking fault energy. Metall. Trans. 1970, 1, 2429–2461.

Shang, S. L.; Zacherl, C. L.; Fang, H. Z.; Wang, Y.; Du, Y.; Liu, Z. K. Effects of alloying element and temperature on the stacking fault energies of dilute Ni-base superalloys. J. Phys. Condens. Matter. 2012, 24, 505403.

Tiearney, T. C.; Grant, N. J. Measurement of structural parameters important in creep of Ni-Mo and Ni-W solid solutions. Metall. Trans. A 1982, 13, 1827–1836.

Zhao, W. Y.; Li, W.; Sun, Z. M.; Gong, S. K.; Vitos, L. Tuning the plasticity of Ni-Mo solid solution in Ni-based superalloys by ab initio calculations. Mater. Des. 2017, 124, 100–107.

Johnson, W. R.; Barrett, C. R.; Nix, W. D. The high-temperature creep behavior of nickel-rich Ni-W solid solutions. Metall. Trans. 1972, 3, 963–969.

Xie, X. S.; Chen, G. L.; McHugh, P. J.; Tien, J. K. Including stacking fault energy into the resisting stress model for creep of particle strengthened alloys. Scr. Metall. 1982, 16, 483–488.

Hu, J.; Zheng, X. G.; Shi, Y. N.; Lu, K. Effect of a mixture of saccharin and 2-butyne-1,4-diol on electrodeposition of nano-grained Ni-Mo alloys. J. Electrochem. Soc. 2017, 164, D348–D353.

Schloßmacher, P.; Yamasaki, T. Structural analysis of electroplated amorphous-nanocrystalline Ni-W. Mikrochim. Acta 2000, 132, 309–313.

Xing, W. T.; Kalidindi, A. R.; Amram, D.; Schuh, C. A. Solute interaction effects on grain boundary segregation in ternary alloys. Acta Mater. 2018, 161, 285–294.

Brooks, C. R.; Spruiell, J. E.; Stansbury, E. E. Physical metallurgy of nickel-molybdenum alloys. Int. Met. Rev. 1984, 29, 210–248.

Mahajan, S.; Pande, C. S.; Imam, M. A.; Rath, B. B. Formation of annealing twins in f.c.c. crystals. Acta Mater. 1997, 45, 2633–2638.

Ogata, S.; Li, J.; Yip, S. Ideal pure shear strength of aluminum and copper. Science 2002, 298, 807–811.

Qi, Y.; Mishra, R. K. Ab initio study of the effect of solute atoms on the stacking fault energy in aluminum. Phys. Rev. B 2007, 75, 224105.

Yu, X. X.; Wang, C. Y. The effect of alloying elements on the dislocation climbing velocity in Ni: A first-principles study. Acta Mater. 2009, 57, 5914–5920.

Cockayne, D. J. H.; Parsons, J. R.; Hoelke, C. W. A study of the relationship between lattice fringes and lattice planes in electron microscope images of crystals containing defects. Philos. Mag. A J. Theoret. Exp. Appl. Phys. 1971, 24, 139–153.

Ruff, A. W. Measurement of stacking fault energy from dislocation interactions. Metall. Trans. 1970, 7, 2391–2413.

Balk, T. J.; Hemker, K. J. High resolution transmission electron microscopy of dislocation core dissociations in gold and iridium. Philos. Mag. A 2001, 81, 1507–1531.

Cai, W.; Nix, W. D. Imperfections in Crystalline Solids; Cambridge University Press: Cambridge, 2016.

Vegard, L. Z. Formation of mixed crystals by solid-phase contact. J. Phys. 1921, 5, 393–395.

Massalski, T. B. Comments concerning some features of phase diagrams and phase transformations. Mater. Trans. 2010, 51, 583–596.

Mizutani, U. Hume-Rothery Rules for Structurally Complex Alloy Phases; CRC Press: Boca Raton, 2010.

Acknowledgements

The authors are grateful for financial support from the Ministry of Science and Technology of China (No. 2017YFA0204401), Liaoning Revitalization Talents Program (No. XLYC1808008), and Liaoning Science and Technology Development Program (No. 2021JH6/10500102).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zeng, D., Li, J., Shi, Y. et al. Thermally-triggered grain boundary relaxation in a nanograined Ni-Mo-W alloy. Nano Res. 16, 12800–12808 (2023). https://doi.org/10.1007/s12274-023-6186-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-023-6186-9