Abstract

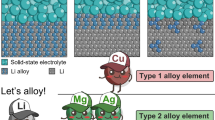

Lithium metal is one of the most promising anodes to develop high energy density and safe energy storage devices due to its highest theoretical capacity (3860 mAh·g−1) and lowest electrochemical potential, demonstrating great potential to fulfill unprecedented demand from electronic gadgets, electric vehicles, and grid storage. Despite these good merits, lithium metal suffers from low Coulombic efficiency and dendritic growth, leading to internal short-circuiting of the cell and raising safety concerns about employing lithium metal as an anode. Recently, lithium-tin (Li-Sn) alloys, among other lithium alloys, have emerged as a potential alternative to lithium metal to efficiently suppress the lithium dendrite formation and reduce interfacial resistance for safer and longer-lasting lithium batteries. Accordingly, this work first reviews the fundamentals of Li-Sn alloys, and critically analyzes the failure mechanisms of pristine Li-metal anode and how Li-Sn alloys could overcome those challenges. The subsequent section examines various strategies to synthesize Li-Sn bulk and protection film alloys, followed by an evaluation of symmetric cell performance. Furthermore, the comparative electrochemical performance of full cells against different cathodes and solid electrolytes provides an overview of the present research. Subsequently, advanced characterization techniques were discussed to visualize lithium dendrites directly and quantify the mechanical performance of Li-Sn alloys. Last but not the least, the state-of-the-art progress of applying M-Sn (M = Na and Mg) beyond lithium batteries was summarized. In closing, this work identifies the critical challenges and provides future perspectives on Li-Sn alloy for lithium batteries and beyond.

Similar content being viewed by others

References

Larcher, D.; Tarascon, J. M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29.

Shahsavari, A.; Akbari, M. Potential of solar energy in developing countries for reducing energy-related emissions. Renew. Sust. Energ. Rev. 2018, 90, 275–291.

Sahu, B. K. Wind energy developments and policies in China: A short review. Renew. Sust. Energy Rev. 2018, 81, 1393–1405.

Khare, V.; Nema, S.; Baredar, P. Solar-wind hybrid renewable energy system: A review. Renew. Sust. Energy Rev. 2016, 58, 23–33.

Gong, J. L.; Li, C.; Wasielewski, M. R. Advances in solar energy conversion. Chem. Soc. Rev. 2019, 48, 1862–1864.

Manthiram, A. An outlook on lithium ion battery technology. ACS Cent. Sci. 2017, 3, 1063–1069.

Goodenough, J. B. Energy storage materials: A perspective. Energy Stor. Mater. 2015, 1, 158–161.

Palacín, M. R.; de Guibert, A. Why do batteries fail? Science 2016, 351, 1253292.

Dunn, B.; Kamath, H.; Tarascon, J. M. Electrical energy storage for the grid: A battery of choices. Science 2011, 334, 928–935.

Tang, Y. X.; Zhang, Y. Y.; Li, W. L.; Ma, B.; Chen, X. D. Rational material design for ultrafast rechargeable lithium-ion batteries. Chem. Soc. Rev. 2015, 44, 5926–5940.

Armand, M.; Tarascon, J. M. Building better batteries. Nature 2008, 451, 652–657.

Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430.

Tarascon, J. M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2021, 414, 359–367.

Mizushima, K.; Jones, P. C.; Wiseman, P. J.; Goodenough, J. B. LixCoO2 (0 < x < −1): A new cathode material for batteries of high energy density. Mater. Res. Bull. 1980, 15, 783–789.

Thackeray, M. M.; David, W. I. F.; Bruce, P. G.; Goodenough, J. B. Lithium insertion into manganese spinels. Mater. Res. Bull. 1983, 18, 461–472.

Padhi, A. K.; Nanjundaswamy, K. S.; Masquelier, C.; Okada, S.; Goodenough, J. B. Effect of structure on the Fe3+/Fe2+ redox couple in iron phosphates. J. Electrochem. Soc. 1997, 144, 1609–1613.

Janek, J.; Zeier, W. G. A solid future for battery development. Nat. Energy 2016, 1, 16141.

Bruce, P. G.; Freunberger, S. A.; Hardwick, L. J.; Tarascon, J. M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 2012, 11, 19–29.

Chen, Y. H.; Freunberger, S. A.; Peng, Z. Q.; Fontain, O.; Bruce, P. G. Charging a Li-O2 battery using a redox mediator. Nat. Chem. 2013, 5, 489–494.

Pang, Q.; Liang, X.; Kwok, C. Y.; Nazar, L. F. Advances in lithium-sulfur batteries based on multifunctional cathodes and electrolytes. Nat. Energy 2016, 1, 16132.

Zhai, P. Y.; Peng, H. J.; Cheng, X. B.; Zhu, L.; Huang, J. Q.; Zhu, W. C.; Zhang Q. Scaled-up fabrication of porous-graphene-modified separators for high-capacity lithium-sulfur batteries. Energy Stor. Mater. 2017, 7, 56–63.

Xu, W.; Wang, J. L.; Ding, F.; Chen, X. L.; Nasybulin, E.; Zhang, Y. H.; Zhang, J. G. Lithium metal anodes for rechargeable batteries. Energy Environ. Sci. 2014, 7, 513–537.

Kolosnitsyn, V. S.; Karaseva, E. V. Lithium-sulfur batteries: Problems and solutions. Russ. J. Electrochem. 2008, 44, 506–509.

Kim, J.; Lee, D. J.; Jung, H. G.; Sun, Y. K.; Hassoun, J.; Scrosati, B. An advanced lithium-sulfur battery. Adv. Funct. Mater. 2013, 23, 1076–1080.

Whittingham, M. S. Electrical energy storage and intercalation chemistry. Science 1976, 192, 1126–1127.

Lin, D. C.; Liu, Y. Y.; Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 2017, 12, 194–206.

Brandt, K. Historical development of secondary lithium batteries. Solid State Ionics 1994, 69, 173–183.

Busche, M. R.; Drossel, T.; Leichtweiss, T.; Weber, D. A.; Falk, M.; Schneider, M.; Reich, M. L.; Sommer, H.; Adelhelm, P.; Janek, J. Dynamic formation of a solid-liquid electrolyte interphase and its consequences for hybrid-battery concepts. Nat. Chem. 2016, 8, 426–434.

Gallagher, K. G.; Geobel, S.; Greszler, T.; Mathias, M.; Oelerich, W.; Eroglu, D.; Srinivasan, V. Quantifying the promise of lithiumair batteries for electric vehicles. Energy Environ. Sci. 2014, 7, 1555–1563.

Tikekar, M. D.; Choudhury, S.; Tu, Z. Y.; Archer, L. A. Design principles for electrolytes and interfaces for stable lithium-metal batteries. Nat. Energy 2016, 1, 16114.

Cheng, X. B.; Zhang, R.; Zhao, C. Z.; Wei, F.; Zhang, J. G.; Zhang, Q. A review of solid electrolyte interphases on lithium metal anode. Adv. Sci. 2016, 3, 1500213.

Wang, D.; Zhang, W.; Zheng, W. T.; Cui, X. Q.; Rojo, T.; Zhang, Q. Towards high-safe lithium metal anodes: Suppressing lithium dendrites via tuning surface energy. Adv. Sci. 2017, 4, 1600168.

Cheng, X. B.; Zhang, R.; Zhao, C. Z.; Zhang, Q. Toward safe lithium metal anode in rechargeable batteries: A review. Chem. Rev. 2017, 117, 10403–10473.

Mukhopadhyay, A.; Jangid, M. K. Li metal battery, heal thyself. Science 2018, 359, 1463.

Li, L.; Basu, S.; Wang, Y. P.; Chen, Z. Z.; Hundekar, P.; Wang, B. W.; Shi, J.; Shi, Y. F.; Narayanan, S.; Koratkar, N. Self-heating-induced healing of lithium dendrites. Science 2018, 359, 1513–1516.

Ramakumar, S.; Deviannapoorani, C.; Dhivya, L.; Shankar, L. S.; Murugan, R. Lithium garnets: Synthesis, structure, Li+ conductivity, Li+ dynamics and applications. Prog. Mater. Sci. 2017, 88, 325–411.

Amardeep; Kobi, S.; Mukhopadhyay, A. Mg-doping towards enhancing the composition-phase-structural stability of Li-La-zirconate based cubic garnet upon exposure to air. Scr. Mater. 2019, 162, 214–218.

Sastre, J.; Futscher, M. H.; Pompizi, L.; Aribia, A.; Priebe, A.; Overbeck, J.; Stiefel, M.; Tiwari, A. N.; Romanyuk, Y. E. Blocking lithium dendrite growth in solid-state batteries with an ultrathin amorphous Li-La-Zr-O solid electrolyte. Commun. Mater. 2021, 2, 76.

Kobi, S.; Amardeep; Vyas, A.; Bhargava, P.; Mukhopadhyay, A. Al and Mg co-doping towards development of air-stable and Li-ion conducting Li-La-zirconate based solid electrolyte exhibiting low electrode/electrolyte interfacial resistance. J. Electrochem. Soc. 2020, 167, 120519.

Cao, D. X.; Sun, X.; Li, Q.; Natan, A.; Xiang, P. Y.; Zhu, H. L. Lithium dendrite in all-solid-state batteries: Growth mechanisms, suppression strategies, and characterizations. Matter 2020, 3, 57–94.

Yu, Z. J.; Zhang, X. Y.; Fu, C. K.; Wang, H.; Chen, M.; Yin, G. P.; Huo, H.; Wang, J. J. Dendrites in solid-state batteries: Ion transport behavior, advanced characterization, and interface regulation. Adv. Energy Mater. 2021, 11, 2003250.

Peled, E. The electrochemical behavior of alkali and alkaline earth metals in nonaqueous battery systems—The solid electrolyte interphase model. J. Electrochem. Soc. 1979, 126, 2047–2051.

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 2004, 104, 4303–4418.

Rehnlund, D.; Lindgren, F.; Böhme, S.; Nordh, T.; Zou, Y. M.; Pettersson, J.; Bexell, U.; Boman, M.; Edström, K.; Nyholm, L. Lithium trapping in alloy forming electrodes and current collectors for lithium based batteries. Energy Environ. Sci. 2017, 10, 1350–1357.

Liang, X.; Pang, Q.; Kochetkov, I. R.; Sempere, M. S.; Huang, H.; Sun, X. Q.; Nazar, L. F. A facile surface chemistry route to a stabilized lithium metal anode. Nat. Energy 2017, 2, 17119.

Gu, X. X.; Dong, J.; Lai, C. Li-containing alloys beneficial for stabilizing lithium anode: A review. Eng. Rep. 2021, 3, e12339.

Arrebola, J. C.; Caballero, A.; Gómez-Cámer, J. L.; Hernán, L.; Morales, J.; Sánchez, L. Combining 5 V LiNi0.5Mn1.5O4 spinel and Si nanoparticles for advanced Li-ion batteries. Electrochem. Commun. 2009, 11, 1061–1064.

Kuksenko, S. P. Aluminum foil as anode material of lithium-ion batteries: Effect of electrolyte compositions on cycling parameters. Russ. J. Electrochem. 2013, 49, 67–75.

Winter, M.; Besenhard, J. O. Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochim. Acta 1990, 45, 31–50.

Amardeep, A.; Shende, R. C.; Gandharapu, P.; Wani, M. S.; Mukhopadhyay, A. Faceted antimony particles with interiors reinforced with reduced graphene oxide as high-performance anode material for sodium-ion batteries. ACS Appl. Mater. Interfaces 2022, 14, 45296–45307.

Kamali, A. R.; Fray, D. J. Tin-based materials as advanced anode materials for lithium ion batteries: A review. Rev. Adv. Mater. Sci. 2011, 27, 14–24.

Zhang, W. J. A review of the electrochemical performance of alloy anodes for lithium-ion batteries. J. Power Sources 2011, 196, 13–24.

Zhang, P. P.; Ma, Z. S.; Jiang, W. J.; Wang, Y.; Pan, Y.; Lu, C. S. Mechanical properties of Li-Sn alloys for Li-ion battery anodes: A first-principles perspective. AIP Adv. 2016, 6, 015107.

Zhuang, H. F.; Zhao, P.; Li, G. D.; Xu, Y.; Jia, X. B. Li-LiAl alloy composite with memory effect as high-performance lithium metal anode. J. Power Sources 2020, 455, 227977.

Lou, J.; Chen, K. H.; Yang, N. C.; Shuai, Y.; Zhu, C. J. Improved cycle stability of LiSn alloy anode for different electrolyte systems in lithium battery. Nanomaterials 2021, 11, 300.

Il’ina, E. A.; Druzhinin, K. V.; Lyalin, E. D.; Plekhanov, M. S.; Talankin, I. I.; Antonov, B. D.; Pankratov, A. A. Li-In alloy: Preparation, properties, wettability of solid electrolytes based on Li7La3Zr2O12. J. Mater. Sci. 2022, 57, 1291–1301.

Yan, K.; Lu, Z. D.; Lee, Y. W.; Xiong, F.; Hsu, P. C.; Li, Y. Z.; Zhao, J.; Chu, S.; Cui, Y. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 2016, 1, 16010.

Xue, P.; Liu, S. R.; Shi, X. L.; Sun, C.; Lai, C.; Zhou, Y.; Sui, D.; Chen, Y. S.; Liang J. J. A hierarchical silver-nanowire-graphene host enabling ultrahigh rates and superior long-term cycling of lithium-metal composite anodes. Adv. Mater. 2018, 30, 1804165.

Zhu, M. Q.; Li, B.; Li, S. M.; Du, Z. G.; Gong, Y. J.; Yang, S. B. Dendrite-free metallic lithium in lithiophilic carbonized metal-organic frameworks. Adv. Energy Mater. 2018, 8, 1703505.

Chen, C.; Yang, Y. F.; Shao, H. X. Enhancement of the lithium cycling capability using Li-Zn alloy substrate for lithium metal batteries. Electrochim. Acta 2014, 137, 476–483.

Park, C. M.; Kim, J. H.; Kim, H.; Sohn, H. J. Li-alloy based anode materials for Li secondary batteries. Chem. Soc. Rev. 2010, 39, 3115–3141.

Chen, T.; Kong, W. H.; Zhao, P. Y.; Lin, H. N.; Hu, Y.; Chen, R. P.; Yan, W.; Jin, Z. Dendrite-free and stable lithium metal anodes enabled by an antimony-based lithiophilic interphase. Chem. Mater. 2019, 31, 7565–7573.

Weppner, W.; Huggins, R. A. Thermodynamic properties of the intermetallic systems lithium-antimony and lithium-bismuth. J. Electrochem. Soc. 1978, 125, 7–14.

Sun, J.; Zeng, Q. C.; Lv, R. T.; Lv, W.; Yang, Q. H.; Amal, R.; Wang, D. W. A Li-ion sulfur full cell with ambient resistant Al-Li alloy anode. Energy Storage Mater. 2018, 15, 209–217.

Liu, Y.; Hudak, N. S.; Huber, D. L.; Limmer, S. J.; Sullivan, J. P.; Huang, J. Y. In situ transmission electron microscopy observation of pulverization of aluminum nanowires and evolution of the thin surface Al2O3 layers during lithiation-delithiation cycles. Nano Lett. 2011, 11, 4188–4194.

Krauskopf, T.; Mogwitz, B.; Rosenbach, C.; Zeier, W. G.; Janek J. Diffusion limitation of lithium metal and Li-Mg alloy anodes on LLZO type solid electrolytes as a function of temperature and pressure. Adv. Energy Mater. 2019, 9, 1902568.

Kong, L. L.; Wang, L.; Ni, Z. C.; Liu, S.; Li, G. R.; Gao, X. P. Lithium-magnesium alloy as a stable anode for lithium-sulfur battery. Adv. Funct. Mater. 2019, 29, 1808756.

Besenhard, J. O.; Yang, J.; Winter, M. Will advanced lithium-alloy anodes have a chance in lithium-ion batteries? J. Power Sources 1997, 68, 87–90.

Gao, Y.; Yi, R.; Li, Y. C.; Song, J. X.; Chen, S. R.; Huang, Q. Q.; Mallouk, T. E.; Wang, D. H. General method of manipulating formation, composition, and morphology of solid-electrolyte interphases for stable Li-alloy anodes. J. Am. Chem. Soc. 2017, 139, 17359–17367.

Iwamura, S.; Nishihara, H.; Ono, Y.; Morito, H.; Yamane, H.; Nara, H.; Osaka, T.; Kyotan, T. Li-rich Li-Si alloy as a lithium-containing negative electrode material towards high energy lithium-ion batteries. Sci. Rep. 2015, 5, 8085.

Gandharapu, P.; Mukhopadhyay, A. Deformation and stresses during alkali metal alloying/dealloying of Sn-based electrodes. Appl. Mech. Rev. 2022, 74, 060802.

Ying, H. J.; Han, W. Q. Metallic Sn-based anode materials: Application in high-performance lithium-ion and sodium-ion batteries. Adv. Sci. 2017, 4, 1700298.

Mou, H. Y.; Xiao, W.; Miao, C.; Li, R.; Yu, L. M. Tin and tin compound materials as anodes in lithium-ion and sodium-ion batteries: A review. Front. Chem. 2020, 8, 141.

Smith, J. F.; Moser, Z. Thermodynamic properties of binary lithium systems—A review. J. Nucl. Mater. 1976, 59, 158–174.

Sangster, J.; Bale, C. W. The Li-Sn (lithium-tin) system. J. Phase Equilib. 1998, 19, 70.

Yin, F. C.; Su, X. P.; Li, Z.; Wang, J. H. Thermodynamic assessment of the Li-Sn (lithium-tin) system. J. Alloys Compd. 2005, 393, 105–108.

Gasior, W.; Moser, Z.; Zakulski, W. Thermodynamic studies and the phase diagram of the Li-Sn system. J. Non-Cryst. Solids 1996, 205–207, 379–382.

Guidotti, R. A.; Masset, P. J. Thermally activated (“thermal”) battery technology: Part IV. Anode materials. J. Power Sources 2008, 183, 388–398.

Wen, C. J.; Huggins, R. A. Thermodynamic study of the lithium-tin system. J. Electrochem. Soc. 1981, 128, 1181–1187.

Redlich, O.; Kister, A. T. Algebraic representation of thermodynamic properties and the classification of solutions. Ind. Eng. Chem. 1948, 40, 345–348.

Masing, G.; Tammann, G. Über das Verhalten von Lithium zu Natrium, Kalium, Zinn, Cadmium und Magnesium. Z. Anorg. Chem. 1910, 67, 183–199.

Grube, G.; Meyer, E. Elektrische Leitfähigkeit und Zustandsdiagramm bei binären Legierungen. Z. Elektrochem. Angew. Phys. Chem. 1934, 40, 771–777.

Hirai, K.; Ichitsubo, T.; Uda, T.; Miyazaki, A.; Yagi, S.; Matsubara, E. Effects of volume strain due to Li-Sn compound formation on electrode potential in lithium-ion batteries. Acta Mater. 2008, 56, 1539–1545.

Yu, C.; Liu, J. Y.; Lu, H.; Chen, J. M. Ab initio calculation of the properties and pressure induced transition of Sn. Solid State Commun. 2006, 140, 538–543.

Kubaschewski, O.; Alcock, C. B. Metallurgical Thermochemistry, 5th ed.; Pergamon Press: Oxford, 1979.

Chou, C. Y.; Kim, H.; Hwang, G. S. A comparative first-principles study of the structure, energetics, and properties of Li-M (M = Si, Ge, Sn) alloys. J. Phys. Chem. C 2011, 115, 20018–20026.

Zhang, P. P.; Ma, Z. S.; Wang, Y.; Zou, Y. L.; Lei, W. X.; Pan, Y.; Lu, C. S. A first principles study of the mechanical properties of Li-Sn alloys. RSC Adv. 2015, 5, 36022–36029.

Hansen, D. A.; Chang, L. J. Crystal structure of Li2Sn5. Acta Cryst. 1969, B25, 2392–2395.

Lupu, C.; Mao, J. G.; Rabalais, J. W.; Guloy, A. M.; Richardson, J. W. X-ray and neutron diffraction studies on “Li4.4Sn”. Inorg. Chem. 2003, 42, 3765–3771.

Boukamp, B. A.; Lesh, G. C.; Huggin, R. A. All-solid lithium electrodes with mixed-conductor matrix. J. Electrochem. Soc. 1981, 128, 725–729.

Gao, X. J.; Yang, X. F.; Jiang, M.; Zheng, M.; Zhao, Y.; Li, R. Y.; Ren, W. F.; Huang, H.; Sun, R. C.; Wang, J. T. et al. Fast ion transport in Li-rich alloy anode for high-energy-density all solid-state lithium metal batteries. Adv. Funct. Mater. 2022, 2209715.

Wen, C. J.; Huggins, R. A. Chemical diffusion in intermediate phases in the lithium-tin system. J. Solid State Chem. 1980, 35, 376–384.

Liu, B.; Zhang, J. G.; Xu, W. Advancing lithium metal batteries. Joule 2018, 2, 833–845.

Ji, L. W.; Lin, Z.; Alcoutlabi, M.; Zhang, X. W. Recent developments in nanostructured anode materials for rechargeable lithium-ion batteries. Energy Environ. Sci. 2011, 4, 2682–2699.

Harry, K. J.; Hallinan, D. T.; Parkinson, D. Y.; MacDowell, A. A.; Balsara, N. P. Detection of subsurface structures underneath dendrites formed on cycled lithium metal electrodes. Nat. Mater. 2014, 13, 69–73.

Yang, C. P.; Fu, K.; Zhang, Y.; Hitz, E.; Hu, L. B. Protected lithium-metal anodes in batteries: From liquid to solid. Adv. Mater. 2017, 29, 1701169.

Li, B.; Wang, Y.; Yang, S. B. A material perspective of rechargeable metallic lithium anodes. Adv. Energy Mater. 2018, 8, 1702296.

Cohen, Y. S.; Cohen, Y.; Aurbach, D. Micromorphological studies of lithium electrodes in alkyl carbonate solutions using in situ atomic force microscopy. J. Phys. Chem. B 2000, 104, 12282–12291.

Lin, D. C.; Liu, Y. Y.; Chen, W.; Zhou, G. M.; Liu, K.; Dunn, B.; Cui, Y. Conformal lithium fluoride protection layer on three-dimensional lithium by nonhazardous gaseous reagent freon. Nano Lett. 2017, 17, 3731–3737.

Aryanfar, A.; Brooks, D. J.; Colussi, A. J.; Hoffmann, M. R. Quantifying the dependence of dead lithium losses on the cycling period in lithium metal batteries. Phys. Chem. Chem. Phys. 2014, 16, 24965–24970.

Aurbach, D.; Zinigrad, E.; Cohen, Y.; Teller, H. A short review of failure mechanisms of lithium metal and lithiated graphite anodes in liquid electrolyte solutions. Solid State Ionics 2002, 148, 405–416.

Chen, K. H.; Wood, K. N.; Kazyak, E.; LePage, W. S.; Davis, A. L.; Sanchez, A. J.; Dasgupta, N. P. Dead lithium: Mass transport effects on voltage, capacity, and failure of lithium metal anodes. J. Mater. Chem. A 2017, 5, 11671–11681.

López, C. M.; Vaughey, J. T.; Dees, D. W. Morphological transitions on lithium metal anodes. J. Electrochem. Soc. 2009, 156, A726–A729.

Lu, D. P.; Shao, Y. Y.; Lozano, T.; Bennett, W. D.; Graff, G. L.; Polzin, B.; Zhang, J. G.; Engelhard, M. H.; Saenz, N. T.; Henderson, W. A. et al. Failure mechanism for fast-charged lithium metal batteries with liquid electrolytes. Adv. Energy Mater. 2015, 5, 1400993.

Yang, C. P.; Xie, H.; Ping, W. W.; Fu, K.; Liu, B. Y.; Rao, J. C.; Dai, J. Q.; Wang, C. W.; Pastel, G.; Hu, L. B. An electron/ion dual-conductive alloy framework for high-rate and high-capacity solid-state lithium-metal batteries. Adv. Mater. 2019, 31, 1804815.

Zhu, Y. H.; Han, Y.; Wang, H.; Guo, Q. P.; Jiang, H. Z.; Sun, W. W.; Xie, W.; Zheng, C. M.; Xie, K. Effect of conductor materials in lithium composite anode on plating and stripping of lithium. Ionics 2020, 26, 3307–3314.

Tu, Z. Y.; Choudhury, S.; Zachman, M. J.; Wei, S. Y.; Zhang, K. H.; Kourkoutis, L. F.; Archer, L. A. Fast ion transport at solid-solid interfaces in hybrid battery anodes. Nat. Energy 2018, 3, 310–316.

Zhao, J.; Zhou, G. M.; Yan, K.; Xie, J.; Li, Y. Z.; Liao, L.; Jin, Y.; Liu, K.; Hsu, P. C.; Wang, J. Y. et al. Air-stable and freestanding lithium alloy/graphene foil as an alternative to lithium metal anodes. Nat. Nanotechnol. 2017, 12, 993–999.

Wang, C. W.; Xie, H.; Zhang, L.; Gong, Y. H.; Pastel, G.; Dai, J. Q.; Liu, B. Y.; Wachsman, E. D.; Hu, L. B. Universal soldering of lithium and sodium alloys on various substrates for batteries. Adv. Energy Mater. 2018, 8, 1701963.

Huang, Y. L.; Shao, B. W.; Han, F. D. Li alloy anodes for high-rate and high-areal-capacity solid-state batteries. J. Mater. Chem. A 2022, 10, 12350–12358.

Jiang, Z. P.; Jin, L.; Han, Z. L.; Hu, W.; Zeng, Z. Q.; Sun, Y. L.; Xie, J. Facile generation of polymer-alloy hybrid layers for dendrite-free lithium-metal anodes with improved moisture stability. Angew. Chem. 2019, 131, 11496–11500.

Pathak, R.; Chen, K.; Gurung, A.; Reza, K. M.; Bahrami, B.; Pokharel, J.; Baniya, A.; He, W.; Wu, F.; Zhou, Y.; Xu, K.; Qiao, Q. Q. Fluorinated hybrid solid-electrolyte-interphase for dendrite-free lithium deposition. Nat. Commun. 2020, 11, 93.

Zhang, Z. B.; Luo, H.; Liu, Z. Y.; Wang, S. H.; Zhou, X. F.; Liu, Z. P. A chemical lithiation induced Li4.4Sn lithiophilic layer for anode-free lithium metal batteries. J. Mater. Chem. A 2022, 10, 9670–9679.

Choudhury, S.; Tu, Z. Y.; Stalin, S.; Vu, D.; Fawole, K.; Gunceler, D.; Sundararaman, R.; Archer, L. A. Electroless formation of hybrid lithium anodes for fast interfacial ion transport. Angew. Chem., Int. Ed. 2017, 56, 13070–13077.

Xu, Y.; Zhao, S. Y.; Zhou, G. M.; Chen, W.; Zhou, F.; Rong, Z.; Wu, Y.; Li, J.; Guo, J. H.; Zhang, Y. G. Solubility-dependent protective effects of binary alloys for lithium anode. ACS Appl. Energy Mater. 2020, 3, 2278–2284.

Touja, J.; Louvain, N.; Stievano, L.; Monconduit, L.; Berthelot, R. An overview on protecting metal anodes with alloy-type coating. Batteries Supercaps 2021, 4, 1252–1266.

Xia, S. X.; Zhang, X.; Liang, C.; Yu, Y.; Liu, W. Stabilized lithium metal anode by an efficient coating for high-performance Li-S batteries. Energy Storage Mater. 2020, 24, 329–335.

Li, S. H.; Wang, C.; Yu, J. M.; Han, Y. Y.; Lu, Z. D. Understanding the role of conductive polymer in thermal lithiation and battery performance of Li-Sn alloy anode. Energy Storage Mater. 2019, 20, 7–13.

Zhang, Y.; Wang, C. W.; Pastel, G.; Kuang, Y. D.; Xie, H.; Li, Y. J.; Liu, B. Y.; Luo, W.; Chen, C. J.; Hu, L. B. 3D wettable framework for dendrite-free alkali metal anodes. Adv. Energy Mater. 2018, 8, 1800635.

Xu, Q. S.; Yang, X. F.; Rao, M. M.; Lin, D. C.; Yan, K.; Du, R. A.; Xu, J. T.; Zhang, Y. G.; Ye, D. Q.; Yang, S. H. et al. High energy density lithium metal batteries enabled by a porous graphene/MgF2 framework. Energy Storage Mater. 2020, 26, 73–82.

Han, Z. Y.; Zhang, C.; Lin, Q. W.; Zhang, Y. B.; Deng, Y. Q.; Han, J. W.; Wu, D. C.; Kang, F. Y.; Yang, Q. H.; Lv, W. A protective layer for lithium metal anode: Why and how. Small Methods 2021, 5, 2001035.

Liao, K. M.; Wu, S. C.; Mu, X. W.; Lu, Q.; Han, M.; He, P.; Shao, Z. P.; Zhou, H. S. Developing a “water-defendable” and “dendrite-free” lithium-metal anode using a simple and promising GeCl4 pretreatment method. Adv. Mater. 2018, 30, 1705711.

Wan, M. T.; Kang, S. J.; Wang, L.; Lee, H. W.; Zheng, G. W.; Cui, Y.; Sun, Y. M. Mechanical rolling formation of interpenetrated lithium metal/lithium tin alloy foil for ultrahigh-rate battery anode. Nat. Commun. 2020, 11, 829.

Sun, B.; Lang, J. L.; Liu, K.; Hussain, N.; Fang, M. H.; Wu, H. Promoting a highly stable lithium metal anode by superficial alloying with an ultrathin indium sheet. Chem. Commun. 2019, 55, 1592–1995.

Ma, Y. T.; Wang, L. L.; Fu, S. Y.; Luo, R.; Qu, W. J.; Hu, X.; Chen, R. J.; Wu, F.; Li, L. In situ formation of a Li-Sn alloy protected layer for inducing lateral growth of dendrites. J. Mater. Chem. A 2020, 8, 23574–23579.

Huggins, R. A. Lithium alloy negative electrodes. J. Power Sources 1999, 81–82, 13–19.

Hiratani, M.; Miyauchi, K.; Kudo, T. Effect of a lithium alloy layer inserted between a lithium anode and a solid electrolyte. Solid State Ionics 1988, 28–30, 1406–1410.

Ikeda, K.; Terada, S.; Mandai, T.; Ueno, K.; Dokko, K.; Watanabe, M. Lithium-tin alloy/sulfur battery with a solvate ionic liquid electrolyte. Electrochemistry 2015, 83, 914–917.

Dokko, K.; Tachikawa, N.; Yamauchi, K.; Tsuchiya, M.; Yamazaki, A.; Takashima, E.; Park, J. W.; Ueno, K.; Seki, S.; Serizawa, N. et al. Solvate ionic liquid electrolyte for Li-S batteries. J. Electrochem. Soc. 2013, 160, A1304–A1310.

Ma, M. Y.; Lu, Y.; Yan, Z. H.; Chen, J. In situ synthesis of a bismuth layer on a sodium metal anode for fast interfacial transport in sodium-oxygen batteries. Batteries Supercaps 2019, 2, 663–667.

Wang, J. W.; Fan, F. F.; Liu, Y.; Jungjohann, K. L.; Lee, S. W.; Mao, S. X.; Liu, X. H.; Zhu, T. Structural evolution and pulverization of tin nanoparticles during lithiation-delithiation cycling. J. Electrochem. Soc. 2014, 161, F3019–F3024.

Li, J. C.; Yang, F. Q.; Ye, J.; Cheng, Y. T. Whisker formation on a thin film tin lithium-ion battery anode. J. Power Sources 2011, 196, 1474–1477.

Wang, C. S.; Appleby, A. J.; Little, F. E. Electrochemical study on nano-Sn, Li4.4Sn and AlSi0.1 powders used as secondary lithium battery anodes. J. Power Sources 2001, 93, 174–185.

Zheng, X. Y.; Fu, H. Y.; Hu, C. C.; Xu, H.; Huang, Y.; Wen, J. Y.; Sun, H. B.; Luo, W.; Huang, Y. H. Toward a stable sodium metal anode in carbonate electrolyte: A compact, inorganic alloy interface. J. Phys. Chem. Lett. 2019, 10, 707–714.

Kumar, V.; Eng, A. Y. S.; Wang, Y.; Nguyen, D. T.; Ng, M. F.; Seh, Z. W. An artificial metal-alloy interphase for high-rate and long-life sodium-sulfur batteries. Energy Storage Mater. 2020, 29, 1–8.

Chen, Q. W.; He, H.; Hou, Z.; Zhuang, W. M.; Zhang, T. X.; Sun, Z. Z.; Huang, L. M. Building an artificial solid electrolyte interphase with high-uniformity and fast ion diffusion for ultralong-life sodium metal anodes. J. Mater. Chem. A 2020, 8, 16232–16237.

Singh, N.; Arthur, T. S.; Ling, C.; Matsui, M.; Mizuno, F. A high energy-density tin anode for rechargeable magnesium-ion batteries. Chem. Commun. 2013, 49, 149–151.

Lv, R. J.; Guan, X. Z.; Zhang, J. H.; Xia, Y. Y.; Luo, J. Y. Enabling Mg metal anodes rechargeable in conventional electrolytes by fast ionic transport interphase. Natl. Sci. Rev. 2020, 7, 333–341.

Ramireddy, T.; Kali, R.; Jangid, M. K.; Srihari, V.; Poswal, H. K.; Mukhopadhyay, A. Insights into electrochemical behavior, phase evolution and stability of Sn upon K-alloying/de-alloying via in situ studies. J. Electrochem. Soc. 2017, 164, A2360–A2367.

Jangid, M. K.; Sonia, F. J.; Kali, R.; Ananthoju, B.; Mukhopadhyay, A. Insights into the effects of multi-layered graphene as buffer/interlayer for a-Si during lithiation/delithiation. Carbon 2017, 111, 602–616.

Sun, F.; Zhou, D.; He, X.; Osenberg, M.; Dong, K.; Chen, L. B.; Mei, S. L.; Hilger, A.; Markötter, H.; Lu, Y. et al. Morphological reversibility of modified Li-based anodes for next-generation batteries. ACS Energy Lett. 2020, 5, 152–161.

Ye, M. H.; Jin, X. T.; Nan, X. X.; Gao, J.; Qu, L. T. Paraffin wax protecting 3D non-dendritic lithium for backside-plated lithium metal anode. Energy Storage Mater. 2020, 24, 153–159.

Leng, J.; Liang, H. M.; Wang, H. Y.; Xiao, Z. Q.; Wang, S. T.; Zhang, Z. T.; Tang, Z. L. A facile and low-cost wet-chemistry artificial interface engineering for garnet-based solid-state Li metal batteries. Nano Energy 2022, 101, 107603.

Kepler, K. D.; Vaughey, J. T.; Thackeray, M. M. LixCu6Sn5 (0 < x < 13): An intermetallic insertion electrode for rechargeable lithium batteries. Electrochem. Solid-State Lett. 1999, 2, 307–309.

Acknowledgments

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC), Mitacs Accelerate, Canada Foundation for Innovation (CFI), B.C. Knowledge Development Fund (BCKDF), Fenix Advanced Materials, and the University of British Columbia (UBC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amardeep, A., Freschi, D.J., Wang, J. et al. Fundamentals, preparation, and mechanism understanding of Li/Na/Mg-Sn alloy anodes for liquid and solid-state lithium batteries and beyond. Nano Res. 16, 8191–8218 (2023). https://doi.org/10.1007/s12274-023-5448-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-023-5448-x