Abstract

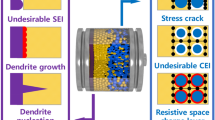

All solid-state lithium batteries (ASSLBs) overcome the safety concerns associated with traditional lithium-ion batteries and ensure the safe utilization of high-energy-density electrodes, particularly Li metal anodes with ultrahigh specific capacities. However, the practical implementation of ASSLBs is limited by the instability of the interface between the anode and solid-state electrolyte (SSE). To mitigate this, considerable research has been dedicated to achieving enhanced stability at the anode/SSE interface. Among the current strategies for enhancing interface performance, the concept of Li-alloy materials is extensively used and well functionalized in various scenarios, including Li alloys as anodes, Li-alloy interlayers and Li alloys in the anode. Despite the notable achievements of Li-alloy materials in ASSLBs, the functionality, practicality and working mechanism of Li-alloys have not been fully elucidated. This review commences by providing an exhaustive and in-depth examination of the fundamental kinetics, thermodynamics, and mechanics, highlighting Li-alloy materials. Subsequently, through a systematic interconnection of material properties and their practical applications, we undertake a comprehensive analysis of the operative principles governing Li alloys. This analytical approach allows a thorough evaluation of the viability and utility of Li alloys within the context of ASSLBs. Finally, this review concludes by succinctly summarizing the future prospects and inherent potential of Li-alloy materials for further advancing the field of ASSLBs.

Graphical Abstract

Copyright © 2022, American Chemical Society. d Schematic illustration of the interfacial Li transport process. e Evolutions of the diffusion coefficient and charge transfer impedance as a function of the Li content in LixIn and the GITT profile. Reprinted with permission from Ref. [71]. Copyright © 2021, AAAS

Copyright © 2021, AAAS. c Voltage and current profiles of the Li-Zn|LPSC|Li-Zn cell at step-increased current densities. Reprinted with permission from Ref. [41]. Copyright © 2022, The Royal Society of Chemistry. d Typical voltage profile of a symmetric Li|LPSC|Li cell. Reprinted with permission from Ref. [79]. Copyright © 2022, Nature Publishing Group

Copyright © 2012, Nature Publishing Group. b Comparison of Si and Ge during lithiation. Reprinted with permission from Ref. [95]. Copyright © 2013, American Chemical Society. c Gibbs free energy diagram of Li-Al alloys. Reprinted with permission from Ref. [89]. Copyright © 2020, Nature Publishing Group

Copyright © 2021, Elsevier

Copyright © 2022, Wiley-VCH. c AIMD simulation on the In/Li6PS5Cl interface. Reprinted with permission from Ref. [78]. Copyright © 2021, Nature Publishing Group

Copyright © 2021, Nature Publishing Group

Copyright © 2020, Nature Publishing Group

Copyright © 2012, American Chemical Society. b Li trapped in the Si anode during delithiation. Reprinted with permission from Ref. [176]. Copyright © 2019, AAAS. Calculated electrochemical reaction energy between Si and c 75Li2S-25P2S5 and d 70(0.75Li2S-0.25P2S5)-60LiI electrolytes, confirming the side reactions between the Li-Si anode and the sulfide electrolytes. Reprinted with permission from Ref. [178]. Copyright © 2023, The Royal Society of Chemistry

Copyright © 2022, Wiley-VCH. b Structure and c advantages of bipolar-stacked all-solid-state batteries. Reprinted with permission from Ref. [191]. Copyright © 2022, Wiley-VCH

Copyright © 2007, Wiley-VCH. b Schematic illustration of the contact between col-Si and SSEs and the 1D breathing behavior of the col-Si anode during lithiation. Reprinted with permission from Ref. [182]. Copyright © 2020, Wiley-VCH. c The 99.9% μSi anode and its lithiation process in an all-solid-state full battery. Reprinted with permission from Ref. [114]. Copyright © 2021, AAAS. d Mechanism of the hard carbon-stabilized LiSi anode. Reprinted with permission from Ref. [116]. Copyright © 2023, Nature Publishing Group

Copyright © 2021, American Chemical Society. b Cross-sectional SEM images of the LPSCl/Ag-Li interfaces in the full cell after the first cycle. Reprinted with permission from Ref. [56]. Copyright © 2021, Wiley-VCH. c Distribution of the Li+ flux simulated by the finite element method. d Schematic diagram of the working mechanism of the Li-Sn interface derived from in situ reactions between Li and the gc-Li3.2P0.8Sn0.2S4 electrolyte. Reprinted with permission from Ref. [225]. Copyright © 2021, Wiley-VCH

Copyright © 2020, Wiley-VCH. b Li stripping/plating behavior in the cell with the garnet-type SSE and the Li-Mg alloy anode. Reprinted with permission from Ref. [112]. Copyright © 2018, Wiley-VCH. c Effective Li diffusion coefficient of Li and Li-Mg alloys. The orange, gray and blue lines correspond to Li, Li0.95Mg0.5 and Li0.9Mg0.1, respectively. d Simulated Li utilization of the Li0.9Mg0.1 electrode as a function of current density at different temperatures. Reprinted with permission from Ref. [55]. Copyright © 2019, Wiley-VCH

Copyright © 2017, Wiley-VCH. b Preparation process of the LiSnC electrode. Comparison of the surface morphology of the c LiSnC electrode and d bare Li electrode after Li stripping. Reprinted with permission from Ref. [250]. Copyright © 2023, Elsevier

Similar content being viewed by others

References

Tarascon, J.M., Armand, M.: Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001). https://doi.org/10.1038/35104644

Armand, M., Tarascon, J.M.: Building better batteries. Nature 451, 652–657 (2008). https://doi.org/10.1038/451652a

Dunn, B., Kamath, H., Tarascon, J.M.: Electrical energy storage for the grid: a battery of choices. Science 334, 928–935 (2011). https://doi.org/10.1126/science.1212741

Nitta, N., Wu, F.X., Lee, J.T., et al.: Li-ion battery materials: present and future. Mater. Today 18, 252–264 (2015). https://doi.org/10.1016/j.mattod.2014.10.040

Zhang, J.G., Xu, W., Xiao, J., et al.: Lithium metal anodes with nonaqueous electrolytes. Chem. Rev. 120, 13312–13348 (2020). https://doi.org/10.1021/acs.chemrev.0c00275

Goodenough, J.B., Park, K.S.: The Li-ion rechargeable battery: a perspective. J. Am. Chem. Soc. 135, 1167–1176 (2013). https://doi.org/10.1021/ja3091438

Wang, Q., Lu, T.T., Xiao, Y.B., et al.: Leap of Li metal anodes from coin cells to pouch cells: challenges and progress. Electrochem. Energy Rev. 6, 22 (2023). https://doi.org/10.1007/s41918-023-00185-7

Li, Y.L., Feng, X.N., Ren, D.S., et al.: Thermal runaway triggered by plated lithium on the anode after fast charging. ACS Appl. Mater. Interfaces 11, 46839–46850 (2019). https://doi.org/10.1021/acsami.9b16589

Hou, J.X., Lu, L.G., Wang, L., et al.: Thermal runaway of Lithium-ion batteries employing LiN(SO2F)2-based concentrated electrolytes. Nat. Commun. 11, 5100 (2020). https://doi.org/10.1038/s41467-020-18868-w

Jiao, S.H., Ren, X.D., Cao, R.G., et al.: Stable cycling of high-voltage lithium metal batteries in ether electrolytes. Nat. Energy 3, 739–746 (2018). https://doi.org/10.1038/s41560-018-0199-8

Liu, H., Sun, X., Cheng, X.B., et al.: Working principles of lithium metal anode in pouch cells. Adv. Energy Mater. 12, 2202518 (2022). https://doi.org/10.1002/aenm.202202518

Manthiram, A., Yu, X.W., Wang, S.F.: Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2, 16103 (2017). https://doi.org/10.1038/natrevmats.2016.103

Yang, C.P., Fu, K., Zhang, Y., et al.: Protected lithium-metal anodes in batteries: from liquid to solid. Adv. Mater. 29, 1701169 (2017). https://doi.org/10.1002/adma.201701169

Yang, S.J., Hu, J.K., Jiang, F.N., et al.: Oxygen-induced thermal runaway mechanisms of Ah-level solid-state lithium metal pouch cells. ETransportation 18, 100279 (2023). https://doi.org/10.1016/j.etran.2023.100279

Zhao, Q., Stalin, S., Zhao, C.Z., et al.: Designing solid-state electrolytes for safe, energy-dense batteries. Nat. Rev. Mater. 5, 229–252 (2020). https://doi.org/10.1038/s41578-019-0165-5

Wu, J.H., Shen, L., Zhang, Z.H., et al.: All-solid-state lithium batteries with sulfide electrolytes and oxide cathodes. Electrochem. Energy Rev. 4, 101–135 (2021). https://doi.org/10.1007/s41918-020-00081-4

Su, H., Jiang, Z., Liu, Y., et al.: Recent progress of sulfide electrolytes for all-solid-state lithium batteries. Energy Mater 2, 205 (2022). https://doi.org/10.20517/energymater.2022.01

Vishnugopi, B.S., Kazyak, E., Lewis, J.A., et al.: Challenges and opportunities for fast charging of solid-state lithium metal batteries. ACS Energy Lett. 6, 3734–3749 (2021). https://doi.org/10.1021/acsenergylett.1c01352

Xiao, Y.H., Wang, Y., Bo, S.H., et al.: Understanding interface stability in solid-state batteries. Nat. Rev. Mater. 5, 105–126 (2019). https://doi.org/10.1038/s41578-019-0157-5

Wu, J.H., Liu, S.F., Han, F.D., et al.: Lithium/sulfide all-solid-state batteries using sulfide electrolytes. Adv. Mater. 33, 2000751 (2021). https://doi.org/10.1002/adma.202000751

Su, H., Liu, Y., Zhong, Y., et al.: Stabilizing the interphase between Li and Argyrodite electrolyte through synergistic phosphating process for all-solid-state lithium batteries. Nano Energy 96, 107104 (2022). https://doi.org/10.1016/j.nanoen.2022.107104

Han, F.D., Westover, A.S., Yue, J., et al.: High electronic conductivity as the origin of lithium dendrite formation within solid electrolytes. Nat. Energy 4, 187–196 (2019). https://doi.org/10.1038/s41560-018-0312-z

Porz, L., Swamy, T., Sheldon, B.W., et al.: Mechanism of lithium metal penetration through inorganic solid electrolytes. Adv. Energy Mater. 7, 1701003 (2017). https://doi.org/10.1002/aenm.201701003

Liu, H., Cheng, X.B., Huang, J.Q., et al.: Controlling dendrite growth in solid-state electrolytes. ACS Energy Lett. 5, 833–843 (2020). https://doi.org/10.1021/acsenergylett.9b02660

Liu, X.M., Garcia-Mendez, R., Lupini, A.R., et al.: Local electronic structure variation resulting in Li ‘filament’ formation within solid electrolytes. Nat. Mater. 20, 1485–1490 (2021). https://doi.org/10.1038/s41563-021-01019-x

Wang, C.H., Deng, T., Fan, X.L., et al.: Identifying soft breakdown in all-solid-state lithium battery. Joule 6, 1770–1781 (2022). https://doi.org/10.1016/j.joule.2022.05.020

Sun, M.H., Liu, T.F., Yuan, Y.F., et al.: Visualizing lithium dendrite formation within solid-state electrolytes. ACS Energy Lett. 6, 451–458 (2021). https://doi.org/10.1021/acsenergylett.0c02314

Kasemchainan, J., Zekoll, S., Spencer Jolly, D., et al.: Critical stripping current leads to dendrite formation on plating in lithium anode solid electrolyte cells. Nat. Mater. 18, 1105–1111 (2019). https://doi.org/10.1038/s41563-019-0438-9

Li, J.R., Su, H., Li, M., et al.: A deformable dual-layer interphase for high-performance Li10GeP2S12-based solid-state Li metal batteries. Chem. Eng. J. 431, 134019 (2022). https://doi.org/10.1016/j.cej.2021.134019

Umeshbabu, E., Zheng, B.Z., Zhu, J.P., et al.: Stable cycling lithium-sulfur solid batteries with enhanced Li/Li10GeP2S12 solid electrolyte interface stability. ACS Appl. Mater. Interfaces 11, 18436–18447 (2019). https://doi.org/10.1021/acsami.9b03726

Xu, R., Liu, F., Ye, Y.S., et al.: A morphologically stable Li/electrolyte interface for all-solid-state batteries enabled by 3D-micropatterned garnet. Adv. Mater. 33, 2104009 (2021). https://doi.org/10.1002/adma.202104009

Zhao, F.P., Sun, Q., Yu, C., et al.: Ultrastable anode interface achieved by fluorinating electrolytes for all-solid-state Li metal batteries. ACS Energy Lett. 5, 1035–1043 (2020). https://doi.org/10.1021/acsenergylett.0c00207

Wang, C.H., Zhao, Y., Sun, Q., et al.: Stabilizing interface between Li10SnP2S12 and Li metal by molecular layer deposition. Nano Energy 53, 168–174 (2018). https://doi.org/10.1016/j.nanoen.2018.08.030

Wan, H.L., Liu, S.F., Deng, T., et al.: Bifunctional interphase-enabled Li10GeP2S12 electrolytes for lithium-sulfur battery. ACS Energy Lett. 6, 862–868 (2021). https://doi.org/10.1021/acsenergylett.0c02617

Ji, X., Hou, S., Wang, P.F., et al.: Solid-state electrolyte design for lithium dendrite suppression. Adv. Mater. 32, 2002741 (2020). https://doi.org/10.1002/adma.202002741

Liu, Y., Su, H., Li, M., et al.: In situ formation of a Li3N-rich interface between lithium and argyrodite solid electrolyte enabled by nitrogen doping. J. Mater. Chem. A 9, 13531–13539 (2021). https://doi.org/10.1039/d1ta03343c

Bonnick, P., Muldoon, J.: The quest for the holy grail of solid-state lithium batteries. Energy Environ. Sci. 15, 1840–1860 (2022). https://doi.org/10.1039/d2ee00842d

Du, M.J., Liao, K.M., Lu, Q., et al.: Recent advances in the interface engineering of solid-state Li-ion batteries with artificial buffer layers: challenges, materials, construction, and characterization. Energy Environ. Sci. 12, 1780–1804 (2019). https://doi.org/10.1039/c9ee00515c

Chen, Y.M., Wang, Z.Q., Li, X.Y., et al.: Li metal deposition and stripping in a solid-state battery via Coble creep. Nature 578, 251–255 (2020). https://doi.org/10.1038/s41586-020-1972-y

Rioja, R.J., Liu, J.: The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 43, 3325–3337 (2012). https://doi.org/10.1007/s11661-012-1155-z

Huang, Y.L., Shao, B.W., Han, F.D.: Li alloy anodes for high-rate and high-areal-capacity solid-state batteries. J. Mater. Chem. A 10, 12350–12358 (2022). https://doi.org/10.1039/d2ta02339c

Shi, Z., Liu, M.L., Naik, D., et al.: Electrochemical properties of Li-Mg alloy electrodes for lithium batteries. J. Power Sources 92, 70–80 (2001). https://doi.org/10.1016/s0378-7753(00)00521-8

Pelton, A.D.: The Cu-Li (copper-lithium) system. Bull. Alloy Phase Diagr. 7, 142–144 (1986). https://doi.org/10.1007/BF02881552

Pelton, A.D.: The Ag-Li (silver-lithium) system. Bull. Alloy Phase Diagr. 7, 223–228 (1986). https://doi.org/10.1007/BF02868993

Nayeb-Hashemi, A.A., Clark, J.B., Pelton, A.D.: The Li-Mg (lithium-magnesium) system. Bull. Alloy Phase Diagr. 5, 365–374 (1984). https://doi.org/10.1007/BF02872951

Songster, J., Pelton, A.D.: The In-Li (indium-lithium) system. J. Phase Equilib. 12, 37–41 (1991). https://doi.org/10.1007/BF02663671

Sangster, J., Bale, C.W.: The Li-Sn (lithium-tin) system. J. Phase Equilib. 19, 70–75 (1998). https://doi.org/10.1361/105497198770342788

McAlister, A.J.: The Al-Li (aluminum-lithium) system. Bull. Alloy Phase Diagr. 3, 177–183 (1982). https://doi.org/10.1007/BF02892377

Gąsior, W., Onderka, B., Moser, Z., et al.: Thermodynamic evaluation of Cu-Li phase diagram from EMF measurements and DTA study. Calphad 33, 215–220 (2009). https://doi.org/10.1016/j.calphad.2008.10.006

Adams, B.D., Zheng, J.M., Ren, X.D., et al.: Accurate determination of coulombic efficiency for lithium metal anodes and lithium metal batteries. Adv. Energy Mater. 8, 1702097 (2018). https://doi.org/10.1002/aenm.201702097

Sun, M.H., Wei, J.K., Xu, Z., et al.: Electrochemical solid-state amorphization in the immiscible Cu-Li system. Sci. Bull. 63, 1208–1214 (2018). https://doi.org/10.1016/j.scib.2018.06.021

Jin, S., Ye, Y.D., Niu, Y.J., et al.: Solid-solution-based metal alloy phase for highly reversible lithium metal anode. J. Am. Chem. Soc. 142, 8818–8826 (2020). https://doi.org/10.1021/jacs.0c01811

Guo, B.C., Guo, P.Y., Zhao, G.H., et al.: A solid-solution-based Li-Mg alloy for highly stable lithium metal anodes. Sustain. Energy Fuels 6, 4137–4145 (2022). https://doi.org/10.1039/d2se00910b

Braga, M.H., Dębski, A., Terlicka, S., et al.: Experimental and ab initio study of the Ag-Li system for energy storage and high-temperature solders. J. Alloys Compd. 817, 152811 (2020). https://doi.org/10.1016/j.jallcom.2019.152811

Krauskopf, T., Mogwitz, B., Rosenbach, C., et al.: Diffusion limitation of lithium metal and Li-Mg alloy anodes on LLZO type solid electrolytes as a function of temperature and pressure. Adv. Energy Mater. 9, 1902568 (2019). https://doi.org/10.1002/aenm.201902568

Choi, H.J., Kang, D.W., Park, J.W., et al.: In situ formed Ag-Li intermetallic layer for stable cycling of all-solid-state lithium batteries. Adv. Sci. 9, 2103826 (2022). https://doi.org/10.1002/advs.202103826

Lee, Y.G., Fujiki, S., Jung, C., et al.: High-energy long-cycling all-solid-state lithium metal batteries enabled by silver-carbon composite anodes. Nat. Energy 5, 299–308 (2020). https://doi.org/10.1038/s41560-020-0575-z

Prasad, N.E., Ramachandran, T.R.: Phase diagrams and phase reactions in Al-Li alloys. In: Prasad, N.E., Gokhale, A.A., Wanhill, R.J.H. (eds.) Aluminum-Lithium Alloys, pp. 61–97. Butterworth-Heinemann, Boston (2014)

Pan, H., Zhang, M.H., Cheng, Z., et al.: Carbon-free and binder-free Li-Al alloy anode enabling an all-solid-state Li-S battery with high energy and stability. Sci. Adv. 8, eabn4372372 (2022). https://doi.org/10.1126/sciadv.abn4372

Huggins, R.A.: Lithium alloy negative electrodes. J. Power Sources 81(82), 13–19 (1999). https://doi.org/10.1016/s0378-7753(99)00124-x

Boukamp, B.A., Lesh, G.C., Huggins, R.A.: All-solid lithium electrodes with mixed-conductor matrix. J. Electrochem. Soc. 128, 725–729 (1981). https://doi.org/10.1149/1.2127495

Obrovac, M.N., Chevrier, V.L.: Alloy negative electrodes for Li-ion batteries. Chem. Rev. 114, 11444–11502 (2014). https://doi.org/10.1021/cr500207g

Taillades, G., Sarradin, J.: Silver: high performance anode for thin film lithium ion batteries. J. Power Sources 125, 199–205 (2004). https://doi.org/10.1016/j.jpowsour.2003.07.004

Beutl, A., Fürtauer, S., Flandorfer, H.: A novel apparatus for coulometric titrations in lithium containing systems. Thermochim. Acta 653, 8–15 (2017). https://doi.org/10.1016/j.tca.2017.03.025

Hänsel, C., Singh, B., Kiwic, D., et al.: Favorable interfacial chemomechanics enables stable cycling of high-Li-content Li-In/Sn anodes in sulfide electrolyte-based solid-state batteries. Chem. Mater. 33, 6029–6040 (2021). https://doi.org/10.1021/acs.chemmater.1c01431

Mayo, M., Morris, A.J.: Structure prediction of Li-Sn and Li-Sb intermetallics for lithium-ion batteries anodes. Chem. Mater. 29, 5787–5795 (2017). https://doi.org/10.1021/acs.chemmater.6b04914

Huo, H.Y., Janek, J.: Silicon as emerging anode in solid-state batteries. ACS Energy Lett. 7, 4005–4016 (2022). https://doi.org/10.1021/acsenergylett.2c01950

Pelton, A.D.: General phase diagram sections. In: Pelton, A.D. (ed.) Phase Diagrams and Thermodynamic Modeling of Solutions, pp. 103–131. Elsevier, Amsterdam (2019)

Li, Y.J., Li, J.P., Xiao, H., et al.: A novel 3D Li/Li9Al4/Li-Mg alloy anode for superior lithium metal batteries. Adv. Funct. Mater. 33, 2213905 (2023). https://doi.org/10.1002/adfm.202213905

Qu, J.L., Xiao, J.W., Wang, T.S., et al.: High rate transfer mechanism of lithium ions in lithium-tin and lithium-indium alloys for lithium batteries. J. Phys. Chem. C 124, 24644–24652 (2020). https://doi.org/10.1021/acs.jpcc.0c07880

Lu, Y., Zhao, C.Z., Zhang, R., et al.: The carrier transition from Li atoms to Li vacancies in solid-state lithium alloy anodes. Sci. Adv. 7, eabi5520 (2021). https://doi.org/10.1126/sciadv.abi5520

Ga̧sior, W., Moser, Z.: Chemical diffusion coefficients in solid Al-Li alloys at low Li concentrations. Scand. J. Metall. 31, 353–358 (2002). https://doi.org/10.1034/j.1600-0692.2002.00465.x

Jow, T.R., Liang, C.C.: Lithium-aluminum electrodes at ambient temperatures. J. Electrochem. Soc. 129, 1429–1434 (1982). https://doi.org/10.1149/1.2124178

Korblein, A., Heitjans, P., Stockmann, H.J., et al.: Diffusion processes in solid Li-Mg and Li-Ag alloys and the spin-lattice relaxation of 8Li. J. Phys. F: Met. Phys. 15, 561–577 (1985). https://doi.org/10.1088/0305-4608/15/3/011

Zhang, Y., Ravi Chandran, K.S., Jagannathan, M., et al.: The nature of electrochemical delithiation of Li-Mg alloy electrodes: neutron computed tomography and analytical modeling of Li diffusion and delithiation phenomenon. J. Electrochem. Soc. 164, A28–A38 (2016). https://doi.org/10.1149/2.0051702jes

Choi, Y.S., Scanlon, D.O., Lee, J.C.: Extending the performance limit of anodes: insights from diffusion kinetics of alloying anodes. Adv. Energy Mater. 11, 2003078 (2021). https://doi.org/10.1002/aenm.202003078

Ye, Y.D., Xie, H.Y., Yang, Y.H., et al.: Solid-solution or intermetallic compounds: phase dependence of the Li-alloying reactions for Li-metal batteries. J. Am. Chem. Soc. 145, 24775–24784 (2023). https://doi.org/10.1021/jacs.3c08711

Luo, S.T., Wang, Z.Y., Li, X.L., et al.: Growth of lithium-indium dendrites in all-solid-state lithium-based batteries with sulfide electrolytes. Nat. Commun. 12, 6968 (2021). https://doi.org/10.1038/s41467-021-27311-7

Zeng, D.W., Yao, J.M., Zhang, L., et al.: Promoting favorable interfacial properties in lithium-based batteries using chlorine-rich sulfide inorganic solid-state electrolytes. Nat. Commun. 13, 1909 (2022). https://doi.org/10.1038/s41467-022-29596-8

Shi, P., Cheng, X.B., Li, T., et al.: Electrochemical diagram of an ultrathin lithium metal anode in pouch cells. Adv. Mater. 31, 1902785 (2019). https://doi.org/10.1002/adma.201902785

Su, Y.B., Ye, L.H., Fitzhugh, W., et al.: A more stable lithium anode by mechanical constriction for solid state batteries. Energy Environ. Sci. 13, 908–916 (2020). https://doi.org/10.1039/c9ee04007b

Ye, L.H., Li, X.: A dynamic stability design strategy for lithium metal solid state batteries. Nature 593, 218–222 (2021). https://doi.org/10.1038/s41586-021-03486-3

Lee, G.H., Lee, S.G., Park, S.H., et al.: Interface engineering on a Li metal anode for an electro-chemo-mechanically stable anodic interface in all-solid-state batteries. J. Mater. Chem. A 10, 10662–10671 (2022). https://doi.org/10.1039/d1ta11066g

Cao, D.X., Sun, X., Li, Y.J., et al.: Long-cycling sulfide-based all-solid-state batteries enabled by electrochemo-mechanically stable electrodes. Adv. Mater. 34, 2200401 (2022). https://doi.org/10.1002/adma.202200401

Wu, X.H., Billaud, J., Jerjen, I., et al.: Operando visualization of morphological dynamics in all-solid-state batteries. Adv. Energy Mater. 9, 1901547 (2019). https://doi.org/10.1002/aenm.201901547

Liu, X.H., Zhong, L., Huang, S., et al.: Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6, 1522–1531 (2012). https://doi.org/10.1021/nn204476h

Liu, H.B., Sun, Q., Zhang, H.Q., et al.: The application road of silicon-based anode in lithium-ion batteries: from liquid electrolyte to solid-state electrolyte. Energy Storage Mater. 55, 244–263 (2023). https://doi.org/10.1016/j.ensm.2022.11.054

Hirai, K., Ichitsubo, T., Uda, T., et al.: Effects of volume strain due to Li-Sn compound formation on electrode potential in lithium-ion batteries. Acta Mater. 56, 1539–1545 (2008). https://doi.org/10.1016/j.actamat.2007.12.002

Li, H.Y., Yamaguchi, T., Matsumoto, S., et al.: Circumventing huge volume strain in alloy anodes of lithium batteries. Nat. Commun. 11, 1584 (2020). https://doi.org/10.1038/s41467-020-15452-0

Heligman, B.T., Manthiram, A.: Elemental foil anodes for lithium-ion batteries. ACS Energy Lett. 6, 2666–2672 (2021). https://doi.org/10.1021/acsenergylett.1c01145

Lee, S.W., McDowell, M.T., Berla, L.A., et al.: Fracture of crystalline silicon nanopillars during electrochemical lithium insertion. Proc. Natl. Acad. Sci. U. S. A. 109, 4080–4085 (2012). https://doi.org/10.1073/pnas.1201088109

Zhao, K.J., Pharr, M., Wan, Q., et al.: Concurrent reaction and plasticity during initial lithiation of crystalline silicon in lithium-ion batteries. J. Electrochem. Soc. 159, A238–A243 (2012). https://doi.org/10.1149/2.020203jes

Sun, F., Dong, K., Osenberg, M., et al.: Visualizing the morphological and compositional evolution of the interface of InLi-anode|thio-LISION electrolyte in an all-solid-state Li-S cell by in operando synchrotron X-ray tomography and energy dispersive diffraction. J. Mater. Chem. A 6, 22489–22496 (2018). https://doi.org/10.1039/c8ta08821g

Wu, H., Chan, G., Choi, J.W., et al.: Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotechnol. 7, 310–315 (2012). https://doi.org/10.1038/nnano.2012.35

Liang, W.T., Yang, H., Fan, F.F., et al.: Tough germanium nanoparticles under electrochemical cycling. ACS Nano 7, 3427–3433 (2013). https://doi.org/10.1021/nn400330h

Zhang, W.B., Schröder, D., Arlt, T., et al.: (Electro)chemical expansion during cycling: monitoring the pressure changes in operating solid-state lithium batteries. J. Mater. Chem. A 5, 9929–9936 (2017). https://doi.org/10.1039/c7ta02730c

Hänsel, C., Kumar, P.V., Kundu, D.P.: Stack pressure effect in Li3PS4 and Na3PS4 based alkali metal solid-state cells: the dramatic implication of interlayer growth. Chem. Mater. 32, 10501–10510 (2020). https://doi.org/10.1021/acs.chemmater.0c03444

Lim, H., Jun, S., Song, Y.B., et al.: Operando electrochemical pressiometry probing interfacial evolution of electrodeposited thin lithium metal anodes for all-solid-state batteries. Energy Storage Mater. 50, 543–553 (2022). https://doi.org/10.1016/j.ensm.2022.05.050

Obrovac, M.N., Christensen, L., Le, D.B., et al.: Alloy design for lithium-ion battery anodes. J. Electrochem. Soc. 154, A849 (2007). https://doi.org/10.1149/1.2752985

Han, S.Y., Lee, C., Lewis, J.A., et al.: Stress evolution during cycling of alloy-anode solid-state batteries. Joule 5, 2450–2465 (2021). https://doi.org/10.1016/j.joule.2021.07.002

Ham, S.Y., Yang, H.D., Nunez-cuacuas, O., et al.: Assessing the critical current density of all-solid-state Li metal symmetric and full cells. Energy Storage Mater. 55, 455–462 (2023). https://doi.org/10.1016/j.ensm.2022.12.013

Fan, X.L., Ji, X., Han, F.D., et al.: Fluorinated solid electrolyte interphase enables highly reversible solid-state Li metal battery. Sci. Adv. 4, eaau9245 (2018). https://doi.org/10.1126/sciadv.aau9245

Lepley, N.D., Holzwarth, N.A.W., Du, Y.J.A.: Structures, Li+ mobilities, and interfacial properties of solid electrolytes Li3PS4 and Li3PO4 from first principles. Phys. Rev. B 88, 104103 (2013). https://doi.org/10.1103/PhysRevB.88.104103

Nagao, M., Hayashi, A., Tatsumisago, M., et al.: In situ SEM study of a lithium deposition and dissolution mechanism in a bulk-type solid-state cell with a Li2S-P2S5 solid electrolyte. Phys. Chem. Chem. Phys. 15, 18600 (2013). https://doi.org/10.1039/c3cp51059j

Yi, J.G., Zhou, D., Liang, Y.H., et al.: Enabling high-performance all-solid-state lithium batteries with high ionic conductive sulfide-based composite solid electrolyte and ex-situ artificial SEI film. J. Energy Chem. 58, 17–24 (2021). https://doi.org/10.1016/j.jechem.2020.09.038

Jiang, Z., Li, Z.X., Wang, X.L., et al.: Robust Li6PS5I interlayer to stabilize the tailored electrolyte Li9.95SnP2S11.95F0.05/Li metal interface. ACS Appl. Mater. Interfaces 13, 30739–30745 (2021). https://doi.org/10.1021/acsami.1c07947

Liu, Y., Peng, H.L., Su, H., et al.: Ultrafast synthesis of I-rich lithium argyrodite glass-ceramic electrolyte with high ionic conductivity. Adv. Mater. 34, 2107346 (2022). https://doi.org/10.1002/adma.202107346

Hiratani, M.: Effect of a lithium alloy layer inserted between a lithium anode and a solid electrolyte. Solid State Ion. 28(29/30), 1406–1410 (1988). https://doi.org/10.1016/0167-2738(88)90394-3

Takada, K.: Solid state lithium battery with oxysulfide glass. Solid State Ion. 86(87/88), 877–882 (1996). https://doi.org/10.1016/0167-2738(96)00199-3

Notten, P., Roozeboom, F., Niessen, R., et al.: 3-D integrated all-solid-state rechargeable batteries. Adv. Mater. 19, 4564–4567 (2007). https://doi.org/10.1002/adma.200702398

Han, X.G., Gong, Y.H., Fu, K., et al.: Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat. Mater. 16, 572–579 (2017). https://doi.org/10.1038/nmat4821

Yang, C.P., Xie, H., Ping, W.W., et al.: An electron/ion dual-conductive alloy framework for high-rate and high-capacity solid-state lithium-metal batteries. Adv. Mater. 31, 1804815 (2019). https://doi.org/10.1002/adma.201804815

Park, R.J.Y., Eschler, C.M., Fincher, C.D., et al.: Semi-solid alkali metal electrodes enabling high critical current densities in solid electrolyte batteries. Nat. Energy 6, 314–322 (2021). https://doi.org/10.1038/s41560-021-00786-w

Tan, D.H.S., Chen, Y.T., Yang, H.D., et al.: Carbon-free high-loading silicon anodes enabled by sulfide solid electrolytes. Science 373, 1494–1499 (2021). https://doi.org/10.1126/science.abg7217

Wan, H.L., Wang, Z.Y., Zhang, W.R., et al.: Interface design for all-solid-state lithium batteries. Nature 623, 739–744 (2023). https://doi.org/10.1038/s41586-023-06653-w

Yan, W.L., Mu, Z.L., Wang, Z.X., et al.: Hard-carbon-stabilized Li-Si anodes for high-performance all-solid-state Li-ion batteries. Nat. Energy 8, 800–813 (2023). https://doi.org/10.1038/s41560-023-01279-8

Wan, J., Song, Y.X., Chen, W.P., et al.: Micromechanism in all-solid-state alloy-metal batteries: regulating homogeneous lithium precipitation and flexible solid electrolyte interphase evolution. J. Am. Chem. Soc. 143, 839–848 (2021). https://doi.org/10.1021/jacs.0c10121

Li, D.Q., Chu, F.L., He, Z.J., et al.: Single-material aluminum foil as anodes enabling high-performance lithium-ion batteries: the roles of prelithiation and working mechanism. Mater. Today 58, 80–90 (2022). https://doi.org/10.1016/j.mattod.2022.07.004

Kim, M.S., Deepika, N., Lee, S.H., et al.: Enabling reversible redox reactions in electrochemical cells using protected LiAl intermetallics as lithium metal anodes. Sci. Adv. 5, eaax5587 (2019). https://doi.org/10.1126/sciadv.aax5587

Kamaya, N., Homma, K., Yamakawa, Y., et al.: A lithium superionic conductor. Nat. Mater. 10, 682–686 (2011). https://doi.org/10.1038/nmat3066

Kato, Y., Hori, S., Saito, T., et al.: High-power all-solid-state batteries using sulfide superionic conductors. Nat. Energy 1, 16030 (2016). https://doi.org/10.1038/nenergy.2016.30

Wu, Z., Li, X.H., Zheng, C., et al.: Interfaces in sulfide solid electrolyte-based all-solid-state lithium batteries: characterization, mechanism and strategy. Electrochem. Energy Rev. 6, 10 (2023). https://doi.org/10.1007/s41918-022-00176-0

Nakamura, T., Amezawa, K., Kulisch, J., et al.: Guidelines for all-solid-state battery design and electrode buffer layers based on chemical potential profile calculation. ACS Appl. Mater. Interfaces 11, 19968–19976 (2019). https://doi.org/10.1021/acsami.9b03053

Zhu, Y.Z., He, X.F., Mo, Y.F.: Origin of outstanding stability in the lithium solid electrolyte materials: insights from thermodynamic analyses based on first-principles calculations. ACS Appl. Mater. Interfaces 7, 23685–23693 (2015). https://doi.org/10.1021/acsami.5b07517

Chen, S.J., Xie, D.J., Liu, G.Z., et al.: Sulfide solid electrolytes for all-solid-state lithium batteries: structure, conductivity, stability and application. Energy Storage Mater. 14, 58–74 (2018). https://doi.org/10.1016/j.ensm.2018.02.020

Wenzel, S., Weber, D.A., Leichtweiss, T., et al.: Interphase formation and degradation of charge transfer kinetics between a lithium metal anode and highly crystalline Li7P3S11 solid electrolyte. Solid State Ion. 286, 24–33 (2016). https://doi.org/10.1016/j.ssi.2015.11.034

Gao, J., Zhu, J.X., Li, X.L., et al.: Rational design of mixed electronic-ionic conducting Ti-doping Li7La3Zr2O12 for lithium dendrites suppression. Adv. Funct. Mater. 31, 2001918 (2021). https://doi.org/10.1002/adfm.202001918

Riegger, L.M., Schlem, R., Sann, J., et al.: Lithium-metal anode instability of the superionic halide solid electrolytes and the implications for solid-state batteries. Angew. Chem. Int. Ed. 60, 6718–6723 (2021). https://doi.org/10.1002/anie.202015238

Riegger, L.M., Otto, S.K., Sadowski, M., et al.: Instability of the Li7SiPS8 solid electrolyte at the lithium metal anode and interphase formation. Chem. Mater. 34, 3659–3669 (2022). https://doi.org/10.1021/acs.chemmater.1c04302

Il’ina, E.A., Lylin, E.D., Plekhanov, M.S.: Investigation of Li-In alloy application as anode for all-solid-state batteries. J. Phys.: Conf. Ser. 1967, 012012 (2021). https://doi.org/10.1088/1742-6596/1967/1/012012

Santhosha, A.L., Medenbach, L., Buchheim, J.R., et al.: The indium-lithium electrode in solid-state lithium-ion batteries: phase formation, redox potentials, and interface stability. Batter. Supercaps 2, 524–529 (2019). https://doi.org/10.1002/batt.201800149

Li, X.N., Liang, J.W., Chen, N., et al.: Water-mediated synthesis of a superionic halide solid electrolyte. Angew. Chem. Int. Ed. 58, 16427–16432 (2019). https://doi.org/10.1002/anie.201909805

Park, K.H., Kaup, K., Assoud, A., et al.: High-voltage superionic halide solid electrolytes for all-solid-state Li-ion batteries. ACS Energy Lett. 5, 533–539 (2020). https://doi.org/10.1021/acsenergylett.9b02599

Koç, T., Hallot, M., Quemin, E., et al.: Toward optimization of the chemical/electrochemical compatibility of halide solid electrolytes in all-solid-state batteries. ACS Energy Lett. 7, 2979–2987 (2022). https://doi.org/10.1021/acsenergylett.2c01668

Liu, Y., Su, H., Zhong, Y., et al.: Revealing the impact of Cl substitution on the crystallization behavior and interfacial stability of superionic lithium argyrodites. Adv. Funct. Mater. 32, 2207978 (2022). https://doi.org/10.1002/adfm.202207978

Yamada, Y., Furukawa, K., Sodeyama, K., et al.: Unusual stability of acetonitrile-based superconcentrated electrolytes for fast-charging lithium-ion batteries. J. Am. Chem. Soc. 136, 5039–5046 (2014). https://doi.org/10.1021/ja412807w

Zhang, W.D., Wu, Q., Huang, J.X., et al.: Colossal granular lithium deposits enabled by the grain-coarsening effect for high-efficiency lithium metal full batteries. Adv. Mater. 32, 2001740 (2020). https://doi.org/10.1002/adma.202001740

Yang, Q.F., Hu, J.L., Meng, J.W., et al.: C-F-rich oil drop as a non-expendable fluid interface modifier with low surface energy to stabilize a Li metal anode. Energy Environ. Sci. 14, 3621–3631 (2021). https://doi.org/10.1039/d0ee03952g

Liu, F.F., Wang, L.F., Zhang, Z.W., et al.: A mixed lithium-ion conductive Li2S/Li2Se protection layer for stable lithium metal anode. Adv. Funct. Mater. 30, 2001607 (2020). https://doi.org/10.1002/adfm.202001607

Chen, J., Fan, X.L., Li, Q., et al.: Electrolyte design for LiF-rich solid-electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nat. Energy 5, 386–397 (2020). https://doi.org/10.1038/s41560-020-0601-1

Ming, J., Cao, Z., Wahyudi, W., et al.: New insights on graphite anode stability in rechargeable batteries: Li ion coordination structures prevail over solid electrolyte interphases. ACS Energy Lett. 3, 335–340 (2018). https://doi.org/10.1021/acsenergylett.7b01177

Gao, T., Han, Y., Fraggedakis, D., et al.: Interplay of lithium intercalation and plating on a single graphite particle. Joule 5, 393–414 (2021). https://doi.org/10.1016/j.joule.2020.12.020

Lewis, J.A., Cavallaro, K.A., Liu, Y., et al.: The promise of alloy anodes for solid-state batteries. Joule 6, 1418–1430 (2022). https://doi.org/10.1016/j.joule.2022.05.016

Janek, J., Zeier, W.G.: A solid future for battery development. Nat. Energy 1, 16141 (2016). https://doi.org/10.1038/nenergy.2016.141

Randau, S., Weber, D.A., Kötz, O., et al.: Benchmarking the performance of all-solid-state lithium batteries. Nat. Energy 5, 259–270 (2020). https://doi.org/10.1038/s41560-020-0565-1

Sun, Y.L., Suzuki, K., Hori, S., et al.: Superionic conductors: Li10+δ[SnySi1−y]1+δP2−δS12 with a Li10GeP2S12-type structure in the Li3PS4-Li4SnS4-Li4SiS4 quasi-ternary system. Chem. Mater. 29, 5858–5864 (2017). https://doi.org/10.1021/acs.chemmater.7b00886

Huang, W.Z., Yoshino, K., Hori, S., et al.: Superionic lithium conductor with a cubic argyrodite-type structure in the Li-Al-Si-S system. J. Solid State Chem. 270, 487–492 (2019). https://doi.org/10.1016/j.jssc.2018.12.015

Wang, C.H., Liang, J.W., Kim, J.T., et al.: Prospects of halide-based all-solid-state batteries: from material design to practical application. Sci. Adv. 8, eadc9516 (2022). https://doi.org/10.1126/sciadv.adc9516

Liang, J.W., Li, X.N., Wang, S., et al.: Site-occupation-tuned superionic LixScCl3+x halide solid electrolytes for all-solid-state batteries. J. Am. Chem. Soc. 142, 7012–7022 (2020). https://doi.org/10.1021/jacs.0c00134

Kanno, R., Murayama, M., Inada, T., et al.: A self-assembled breathing interface for all-solid-state ceramic lithium batteries. Electrochem. Solid-State Lett. 7, A455 (2004). https://doi.org/10.1149/1.1809553

Liu, Y., Wang, C.C., Yoon, S.G., et al.: Aluminum foil negative electrodes with multiphase microstructure for all-solid-state Li-ion batteries. Nat. Commun. 14, 3975 (2023). https://doi.org/10.1038/s41467-023-39685-x

Zhong, C., Guo, C., Jin, X., et al.: Gradient electrodeposition enables high-throughput fabrication and screening of alloy anodes for high-energy lithium-ion batteries. Mater. Today Energy 18, 100528 (2020). https://doi.org/10.1016/j.mtener.2020.100528

Zhou, D.B., Liu, Z.J., Lv, X.K., et al.: Electrochemical studies of LiB compound as anode material for lithium-ion battery. Electrochim. Acta 51, 5731–5737 (2006). https://doi.org/10.1016/j.electacta.2006.03.023

Liu, X., Wu, X.Y., Chang, B.B., et al.: Recent progress on germanium-based anodes for lithium ion batteries: efficient lithiation strategies and mechanisms. Energy Storage Mater. 30, 146–169 (2020). https://doi.org/10.1016/j.ensm.2020.05.010

He, J., Wei, Y.Q., Zhai, T.Y., et al.: Antimony-based materials as promising anodes for rechargeable lithium-ion and sodium-ion batteries. Mater. Chem. Front. 2, 437–455 (2018). https://doi.org/10.1039/c7qm00480j

DeVries, L.E., Jackson, L.D., James, S.D.: Structure and anodic discharge behavior of lithium-boron alloys in the LiCl-KCl eutectic melt(II). J. Electrochem. Soc. 126, 993–996 (1979). https://doi.org/10.1149/1.2129222

Sanchez, P., Belin, C., Crepy, G., et al.: Preparation and characterization of lithium-boron alloys: electrochemical studies as anodes in molten salt media, and comparison with pure lithium-involving systems. J. Mater. Sci. 27, 240–246 (1992). https://doi.org/10.1007/BF00553862

Sanchez, P., Belin, C., Crepy, C., et al.: Electrochemical studies of lithium-boron alloys in non-aqueous media: comparison with pure lithium. J. Appl. Electrochem. 19, 421–428 (1989). https://doi.org/10.1007/BF01015246

Netz, A., Huggins, R.A., Weppner, W.: Investigations of a number of alternative negative electrode materials for use in lithium cells. Ionics 7, 433–439 (2001). https://doi.org/10.1007/BF02373580

Duan, B., Wang, W., Zhao, H., et al.: Li-B alloy as anode material for lithium/sulfur battery. ECS Electrochem. Lett. 2, A47–A51 (2013). https://doi.org/10.1149/2.005306eel

Weker, J.N., Liu, N., Misra, S., et al.: In situ nanotomography and operando transmission X-ray microscopy of micron-sized Ge particles. Energy Environ. Sci. 7, 2771–2777 (2014). https://doi.org/10.1039/c4ee01384k

Kennedy, T., Brandon, M., Ryan, K.M.: Advances in the application of silicon and germanium nanowires for high-performance lithium-ion batteries. Adv. Mater. 28, 5696–5704 (2016). https://doi.org/10.1002/adma.201503978

Chen, G.D., Sun, J.R., Li, J.D., et al.: Revealing capacity degradation of Ge anodes in lithium-ion batteries triggered by interfacial LiH. Angew. Chem. Int. Ed. 62, 2306141 (2023). https://doi.org/10.1002/anie.202306141

Weppner, W., Huggins, R.A.: Thermodynamic properties of the intermetallic systems lithium-antimony and lithium-bismuth. J. Electrochem. Soc. 125, 7–14 (1978). https://doi.org/10.1149/1.2131401

Weppner, W., Huggins, R.A.: Determination of the kinetic parameters of mixed-conducting electrodes and application to the system Li3Sb. J. Electrochem. Soc. 124, 1569–1578 (1977). https://doi.org/10.1149/1.2133112

Hou, H.S., Jing, M.J., Yang, Y.C., et al.: Sb porous hollow microspheres as advanced anode materials for sodium-ion batteries. J. Mater. Chem. A 3, 2971–2977 (2015). https://doi.org/10.1039/c4ta06476c

Guo, Y.G., Hu, J.S., Wan, L.J.: Nanostructured materials for electrochemical energy conversion and storage devices. Adv. Mater. 20, 2878–2887 (2008). https://doi.org/10.1002/adma.200800627

Kim, H., Cho, J.: Template synthesis of hollow Sb nanoparticles as a high-performance lithium battery anode material. Chem. Mater. 20, 1679–1681 (2008). https://doi.org/10.1021/cm703401u

Gong, H.X., Chen, Y.L., Chen, S.C., et al.: Fast-charging of hybrid lithium-ion/lithium-metal anodes by nanostructured hard carbon host. ACS Energy Lett. 7, 4417–4426 (2022). https://doi.org/10.1021/acsenergylett.2c02130

Ko, M., Chae, S., Ma, J., et al.: Scalable synthesis of silicon-nanolayer-embedded graphite for high-energy lithium-ion batteries. Nat. Energy 1, 16113 (2016). https://doi.org/10.1038/nenergy.2016.113

Son, Y., Ma, J., Kim, N., et al.: Quantification of pseudocapacitive contribution in nanocage-shaped silicon-carbon composite anode. Adv. Energy Mater. 9, 1803480 (2019). https://doi.org/10.1002/aenm.201803480

Lai, Y.Z., Li, H.Y., Yang, Q., et al.: Revisit the progress of binders for a silicon-based anode from the perspective of designed binder structure and special sized silicon nanoparticles. Ind. Eng. Chem. Res. 61, 6246–6268 (2022). https://doi.org/10.1021/acs.iecr.2c00453

Zhang, L., Wang, C.R., Dou, Y.H., et al.: A yolk-shell structured silicon anode with superior conductivity and high tap density for full lithium-ion batteries. Angew. Chem. Int. Ed. 58, 8824–8828 (2019). https://doi.org/10.1002/anie.201903709

Yang, Z., Jiang, M.X., Cui, C., et al.: In-situ cross-linking strategy for stabilizing the LEDC of the solid-electrolyte interphase in lithium-ion batteries. Nano Energy 105, 107993 (2023). https://doi.org/10.1016/j.nanoen.2022.107993

Lee, J., Jin, D., Kim, J.Y., et al.: Dry pre-lithiation for graphite-silicon diffusion-dependent electrode for all-solid-state battery. Adv. Energy Mater. 13, 2300172 (2023). https://doi.org/10.1002/aenm.202300172

Zhu, B., Liu, G.L., Lv, G.X., et al.: Minimized lithium trapping by isovalent isomorphism for high initial coulombic efficiency of silicon anodes. Sci. Adv. 5, eaax0651 (2019). https://doi.org/10.1126/sciadv.aax0651

Yang, Y.F., Wang, J.Y., Kim, S.C., et al.: In situ prelithiation by direct integration of lithium mesh into battery cells. Nano Lett. 23, 5042–5047 (2023). https://doi.org/10.1021/acs.nanolett.3c00859

Huang, Y.L., Shao, B.W., Wang, Y., et al.: Solid-state silicon anode with extremely high initial coulombic efficiency. Energy Environ. Sci. 16, 1569–1580 (2023). https://doi.org/10.1039/d2ee04057c

Zhan, X., Li, M., Li, S., et al.: Challenges and opportunities towards silicon-based all-solid-state batteries. Energy Storage Mater. 61, 102875 (2023). https://doi.org/10.1016/j.ensm.2023.102875

Shoji, M., Cheng, E.J., Kimura, T., et al.: Recent progress for all solid state battery using sulfide and oxide solid electrolytes. J. Phys. D Appl. Phys. 52, 103001 (2019). https://doi.org/10.1088/1361-6463/aaf7e2

Wang, Y.Y., Diao, W.Y., Fan, C.Y., et al.: Benign recycling of spent batteries towards all-solid-state lithium batteries. Chem. 25, 8975–8981 (2019). https://doi.org/10.1002/chem.201900845

Cangaz, S., Hippauf, F., Reuter, F.S., et al.: Enabling high-energy solid-state batteries with stable anode interphase by the use of columnar silicon anodes. Adv. Energy Mater. 10, 2001320 (2020). https://doi.org/10.1002/aenm.202001320

Han, F.D., Zhu, Y.Z., He, X.F., et al.: Electrochemical stability of Li10GeP2S12 and Li7La3Zr2O12 solid electrolytes. Adv. Energy Mater. 6, 1501590 (2016). https://doi.org/10.1002/aenm.201501590

Schwietert, T.K., Arszelewska, V.A., Wang, C., et al.: Clarifying the relationship between redox activity and electrochemical stability in solid electrolytes. Nat. Mater. 19, 428–435 (2020). https://doi.org/10.1038/s41563-019-0576-0

Wang, Y., Wu, Y.J., Wang, Z.X., et al.: Doping strategy and mechanism for oxide and sulfide solid electrolytes with high ionic conductivity. J. Mater. Chem. A 10, 4517–4532 (2022). https://doi.org/10.1039/d1ta10966a

Yu, T., Ke, B.Y., Li, H.Y., et al.: Recent advances in sulfide electrolytes toward high specific energy solid-state lithium batteries. Mater. Chem. Front. 5, 4892–4911 (2021). https://doi.org/10.1039/d1qm00474c

Trevey, J., Jang, J.S., Jung, Y.S., et al.: Glass-ceramic Li2S-P2S5 electrolytes prepared by a single step ball billing process and their application for all-solid-state lithium-ion batteries. Electrochem. Commun. 11, 1830–1833 (2009). https://doi.org/10.1016/j.elecom.2009.07.028

Dunlap, N.A., Kim, S., Jeong, J.J., et al.: Simple and inexpensive coal-tar-pitch derived Si-C anode composite for all-solid-state Li-ion batteries. Solid State Ion. 324, 207–217 (2018). https://doi.org/10.1016/j.ssi.2018.07.013

Piper, D.M., Yersak, T.A., Lee, S.H.: Effect of compressive stress on electrochemical performance of silicon anodes. J. Electrochem. Soc. 160, A77–A81 (2012). https://doi.org/10.1149/2.064301jes

Yamamoto, M., Terauchi, Y., Sakuda, A., et al.: Slurry mixing for fabricating silicon-composite electrodes in all-solid-state batteries with high areal capacity and cycling stability. J. Power Sources 402, 506–512 (2018). https://doi.org/10.1016/j.jpowsour.2018.09.070

Cao, D.X., Sun, X., Wang, Y., et al.: Bipolar stackings high voltage and high cell level energy density sulfide based all-solid-state batteries. Energy Storage Mater. 48, 458–465 (2022). https://doi.org/10.1016/j.ensm.2022.03.012

Zhang, W.B., Leichtweiß, T., Culver, S.P., et al.: The detrimental effects of carbon additives in Li10GeP2S12-based solid-state batteries. ACS Appl. Mater. Interfaces 9, 35888–35896 (2017). https://doi.org/10.1021/acsami.7b11530

Chen, C., Li, Q., Li, Y.Q., et al.: Sustainable interfaces between Si anodes and garnet electrolytes for room-temperature solid-state batteries. ACS Appl. Mater. Interfaces 10, 2185–2190 (2018). https://doi.org/10.1021/acsami.7b16385

Ke, X.Y., Wang, Y., Dai, L.M., et al.: Cell failures of all-solid-state lithium metal batteries with inorganic solid electrolytes: lithium dendrites. Energy Storage Mater. 33, 309–328 (2020). https://doi.org/10.1016/j.ensm.2020.07.024

Xiong, S.Z., Xu, X.Y., Jiao, X.X., et al.: Mechanical failure of solid-state electrolyte rooted in synergy of interfacial and internal defects. Adv. Energy Mater. 13, 2203614 (2023). https://doi.org/10.1002/aenm.202203614

Liu, J., Yuan, H., Liu, H., et al.: Unlocking the failure mechanism of solid state lithium metal batteries. Adv. Energy Mater. 12, 2100748 (2022). https://doi.org/10.1002/aenm.202100748

Kazyak, E., Garcia-Mendez, R., LePage, W.S., et al.: Li penetration in ceramic solid electrolytes: operando microscopy analysis of morphology, propagation, and reversibility. Matter 2, 1025–1048 (2020). https://doi.org/10.1016/j.matt.2020.02.008

Lu, Y., Zhao, C.Z., Hu, J.K., et al.: The void formation behaviors in working solid-state Li metal batteries. Sci. Adv. 8, eadd0510 (2022). https://doi.org/10.1126/sciadv.add0510

Lee, K., Kazyak, E., Wang, M.J., et al.: Analyzing void formation and rewetting of thin in situ-formed Li anodes on LLZO. Joule 6, 2547–2565 (2022). https://doi.org/10.1016/j.joule.2022.09.009

Shishvan, S.S., Fleck, N.A., McMeeking, R.M., et al.: Vacancy diffusion and its consequences for void growth at the interface of a stripping metal electrode and solid electrolyte. Electrochim. Acta 467, 143081 (2023). https://doi.org/10.1016/j.electacta.2023.143081

Ma, J., Zhang, S., Zheng, Y., et al.: Interelectrode talk in solid-state lithium-metal batteries. Adv. Mater. 35, 2301892 (2023). https://doi.org/10.1002/adma.202301892

Kang, J., Shin, H.R., Yun, J., et al.: Chemo-mechanical failure of solid composite cathodes accelerated by high-strain anodes in all-solid-state batteries. Energy Storage Mater. 63, 103049 (2023). https://doi.org/10.1016/j.ensm.2023.103049

Kato, A., Kowada, H., Deguchi, M., et al.: XPS and SEM analysis between Li/Li3PS4 interface with Au thin film for all-solid-state lithium batteries. Solid State Ion. 322, 1–4 (2018). https://doi.org/10.1016/j.ssi.2018.04.011

Kato, A., Hayashi, A., Tatsumisago, M.: Enhancing utilization of lithium metal electrodes in all-solid-state batteries by interface modification with gold thin films. J. Power Sources 309, 27–32 (2016). https://doi.org/10.1016/j.jpowsour.2016.01.068

Chen, B.T., Zhang, J.C., Zhang, T.R., et al.: Constructing a superlithiophilic 3D burr-microsphere interface on garnet for high-rate and ultra-stable solid-state Li batteries. Adv. Sci. 10, 2207056 (2023). https://doi.org/10.1002/advs.202207056

Jiang, J.L., Ou, Y.H., Lu, S.Y., et al.: In-situ construction of Li-Mg/LiF conductive layer to achieve an intimate lithium-garnet interface for all-solid-state Li metal battery. Energy Storage Mater. 50, 810–818 (2022). https://doi.org/10.1016/j.ensm.2022.06.011

Shi, K., Wan, Z.P., Yang, L., et al.: In situ construction of an ultra-stable conductive composite interface for high-voltage all-solid-state lithium metal batteries. Angew. Chem. Int. Ed. 59, 11784–11788 (2020). https://doi.org/10.1002/anie.202000547

Zhong, Y.R., Xie, Y.J., Hwang, S., et al.: A highly efficient all-solid-state lithium/electrolyte interface induced by an energetic reaction. Angew. Chem. Int. Ed. 59, 14003–14008 (2020). https://doi.org/10.1002/anie.202004477

Chen, Y., Qian, J., Hu, X., et al.: Constructing a uniform and stable mixed conductive layer to stabilize the solid-state electrolyte/Li interface by cold bonding at mild conditions. Adv. Mater. 35, 2212096 (2023). https://doi.org/10.1002/adma.202212096

Lee, K., Han, S., Lee, J., et al.: Multifunctional interface for high-rate and long-durable garnet-type solid electrolyte in lithium metal batteries. ACS Energy Lett. 7, 381–389 (2022). https://doi.org/10.1021/acsenergylett.1c02332

Deng, T., Ji, X., Zhao, Y., et al.: Tuning the anode-electrolyte interface chemistry for garnet-based solid-state Li metal batteries. Adv. Mater. 32, 2000030 (2020). https://doi.org/10.1002/adma.202000030

He, X.Z., Ji, X., Zhang, B., et al.: Tuning interface lithiophobicity for lithium metal solid-state batteries. ACS Energy Lett. 7, 131–139 (2022). https://doi.org/10.1021/acsenergylett.1c02122

Wang, T.R., Duan, J., Zhang, B., et al.: A self-regulated gradient interphase for dendrite-free solid-state Li batteries. Energy Environ. Sci. 15, 1325–1333 (2022). https://doi.org/10.1039/d1ee03604a

He, G., Li, Q.W., Shen, Y.L., et al.: Flexible amalgam film enables stable lithium metal anodes with high capacities. Angew. Chem. Int. Ed. 58, 18466–18470 (2019). https://doi.org/10.1002/anie.201911800

Fan, Y., Tao, T., Gao, Y.X., et al.: A self-healing amalgam interface in metal batteries. Adv. Mater. 32, 2004798 (2020). https://doi.org/10.1002/adma.202004798

Zhang, Q., Wu, L., Fan, M.J., et al.: A room temperature alloying strategy to enable commercial metal foil for efficient Li/Na storage and deposition. Energy Storage Mater. 34, 708–715 (2021). https://doi.org/10.1016/j.ensm.2020.10.028

Li, X.N., Liang, J.W., Li, X., et al.: High-performance all-solid-state Li-Se batteries induced by sulfide electrolytes. Energy Environ. Sci. 11, 2828–2832 (2018). https://doi.org/10.1039/c8ee01621f

Fan, X.L., Yue, J., Han, F.D., et al.: High-performance all-solid-state Na-S battery enabled by casting-annealing technology. ACS Nano 12, 3360–3368 (2018). https://doi.org/10.1021/acsnano.7b08856

Huo, H.Y., Chen, Y., Li, R.Y., et al.: Design of a mixed conductive garnet/Li interface for dendrite-free solid lithium metal batteries. Energy Environ. Sci. 13, 127–134 (2020). https://doi.org/10.1039/c9ee01903k

Krauskopf, T., Richter, F.H., Zeier, W.G., et al.: Physicochemical concepts of the lithium metal anode in solid-state batteries. Chem. Rev. 120, 7745–7794 (2020). https://doi.org/10.1021/acs.chemrev.0c00431

Pathak, R., Chen, K., Gurung, A., et al.: Fluorinated hybrid solid-electrolyte-interphase for dendrite-free lithium deposition. Nat. Commun. 11, 93 (2020). https://doi.org/10.1038/s41467-019-13774-2

Li, F., Tan, Y.H., Yin, Y.C., et al.: A fluorinated alloy-type interfacial layer enabled by metal fluoride nanoparticle modification for stabilizing Li metal anodes. Chem. Sci. 10, 9735–9739 (2019). https://doi.org/10.1039/c9sc01845j

Li, S., Yang, S.J., Liu, G.X., et al.: A dynamically stable mixed conducting interphase for all-solid-state lithium metal batteries. Adv. Mater. 36, 2307768 (2024). https://doi.org/10.1002/adma.202307768

Liang, X., Pang, Q., Kochetkov, I.R., et al.: A facile surface chemistry route to a stabilized lithium metal anode. Nat. Energy 2, 17119 (2017). https://doi.org/10.1038/nenergy.2017.119

Zhao, F.P., Alahakoon, S.H., Adair, K., et al.: An air-stable and Li-metal-compatible glass-ceramic electrolyte enabling high-performance all-solid-state Li metal batteries. Adv. Mater. 33, 2006577 (2021). https://doi.org/10.1002/adma.202006577

Liu, H., Zhu, Q.S., Wang, C., et al.: High air stability and excellent Li metal compatibility of argyrodite-based electrolyte enabling superior all-solid-state Li metal batteries. Adv. Funct. Mater. 32, 2203858 (2022). https://doi.org/10.1002/adfm.202203858

Ni, Y., Huang, C., Liu, H., et al.: A high air-stability and Li-metal-compatible Li3+2xXP1−xBixS4−1.5xO1.5x sulfide electrolyte for all-solid-state Li-metal batteries. Adv. Funct. Mater. 32, 2205998 (2022). https://doi.org/10.1002/adfm.202205998

Jiang, Z., Liu, Y., Peng, H.L., et al.: Enhanced air stability and interfacial compatibility of Li-argyrodite sulfide electrolyte triggered by CuBr co-substitution for all-solid-state lithium batteries. Energy Storage Mater. 56, 300–309 (2023). https://doi.org/10.1016/j.ensm.2023.01.018

Taklu, B.W., Su, W.N., Nikodimos, Y., et al.: Dual CuCl doped argyrodite superconductor to boost the interfacial compatibility and air stability for all solid-state lithium metal batteries. Nano Energy 90, 106542 (2021). https://doi.org/10.1016/j.nanoen.2021.106542

Xu, B.Y., Li, X.Y., Yang, C., et al.: Interfacial chemistry enables stable cycling of all-solid-state Li metal batteries at high current densities. J. Am. Chem. Soc. 143, 6542–6550 (2021). https://doi.org/10.1021/jacs.1c00752

Jia, W.S., Wang, Z.H., Li, J.Z., et al.: A dual-phase Li-Ca alloy with a patternable and lithiophilic 3D framework for improving lithium anode performance. J. Mater. Chem. A 7, 22377–22384 (2019). https://doi.org/10.1039/c9ta08798b

Chen, L., Fan, X.L., Ji, X., et al.: High-energy Li metal battery with lithiated host. Joule 3, 732–744 (2019). https://doi.org/10.1016/j.joule.2018.11.025

Wan, M.T., Kang, S.J., Wang, L., et al.: Mechanical rolling formation of interpenetrated lithium metal/lithium tin alloy foil for ultrahigh-rate battery anode. Nat. Commun. 11, 829 (2020). https://doi.org/10.1038/s41467-020-14550-3

Ding, X.L., Lu, X., Fu, Z.W., et al.: Temperature-dependent lithium storage behavior in tetragonal boron (B50) thin film anode for Li-ion batteries. Electrochim. Acta 87, 230–235 (2013). https://doi.org/10.1016/j.electacta.2012.09.017

Wu, C., Huang, H.F., Lu, W.Y., et al.: Mg doped Li-LiB alloy with in situ formed lithiophilic LiB skeleton for lithium metal batteries. Adv. Sci. 7, 1902643 (2020). https://doi.org/10.1002/advs.201902643

Chen, Z.R., Liang, Z.T., Zhong, H.Y., et al.: Bulk/interfacial synergetic approaches enable the stable anode for high energy density all-solid-state lithium-sulfur batteries. ACS Energy Lett. 7, 2761–2770 (2022). https://doi.org/10.1021/acsenergylett.2c01334

Wang, M.Q., Peng, Z., Luo, W.W., et al.: Improving the interfacial stability between lithium and solid-state electrolyte via dipole-structured lithium layer deposited on graphene oxide. Adv. Sci. 7, 2000237 (2020). https://doi.org/10.1002/advs.202000237

Park, S.H., Jun, D., Lee, G.H., et al.: Designing 3D anode based on pore-size-dependent Li deposition behavior for reversible Li-free all-solid-state batteries. Adv. Sci. 9, 2203130 (2022). https://doi.org/10.1002/advs.202203130

Ye, S.F., Chen, X.J., Zhang, R., et al.: Revisiting the role of physical confinement and chemical regulation of 3D hosts for dendrite-free Li metal anode. Nano Micro Lett. 14, 187 (2022). https://doi.org/10.1007/s40820-022-00932-3

Yan, K., Lu, Z.D., Lee, H.W., et al.: Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat. Energy 1, 16010 (2016). https://doi.org/10.1038/nenergy.2016.10

Wang, H.S., Cao, X., Gu, H.K., et al.: Improving lithium metal composite anodes with seeding and pillaring effects of silicon nanoparticles. ACS Nano 14, 4601–4608 (2020). https://doi.org/10.1021/acsnano.0c00184

Zhu, J.Q., Cai, D., Li, J.R., et al.: In-situ generated Li3N/Li-Al alloy in reduced graphene oxide framework optimizing ultra-thin lithium metal electrode for solid-state batteries. Energy Storage Mater. 49, 546–554 (2022). https://doi.org/10.1016/j.ensm.2022.05.001

Wan, H.L., Wang, Z.Y., Liu, S.F., et al.: Critical interphase overpotential as a lithium dendrite-suppression criterion for all-solid-state lithium battery design. Nat. Energy 8, 473–481 (2023). https://doi.org/10.1038/s41560-023-01231-w

Chen, L.H., Tong, R.A., Zhang, J.X., et al.: Reactive magnesium nitride additive: a drop-in solution for lithium/garnet wetting in all-solid-state batteries. Angew. Chem. Int. Ed. 62, 2305099 (2023). https://doi.org/10.1002/anie.202305099

Qiu, H.L., Tang, T.Y., Asif, M., et al.: Stable lithium metal anode enabled by lithium metal partial alloying. Nano Energy 65, 103989 (2019). https://doi.org/10.1016/j.nanoen.2019.103989

Huang, Y., Chen, B., Duan, J., et al.: Graphitic carbon nitride (g-C3N4): an interface enabler for solid-state lithium metal batteries. Angew. Chem. Int. Ed. 59, 3699–3704 (2020). https://doi.org/10.1002/anie.201914417

Wang, C.W., Xie, H., Zhang, L., et al.: Universal soldering of lithium and sodium alloys on various substrates for batteries. Adv. Energy Mater. 8, 1701963 (2018). https://doi.org/10.1002/aenm.201701963

Wang, T.S., Zhai, P.B., Legut, D., et al.: S-doped graphene-regional nucleation mechanism for dendrite-free lithium metal anodes. Adv. Energy Mater. 9, 1804000 (2019). https://doi.org/10.1002/aenm.201804000

Xu, Y., Zheng, H.Q., Yang, H., et al.: Thermodynamic regulation of dendrite-free Li plating on Li3Bi for stable lithium metal batteries. Nano Lett. 21, 8664–8670 (2021). https://doi.org/10.1021/acs.nanolett.1c02613

Li, J.R., Su, H., Jiang, Z., et al.: Domain-limited laminar lithium deposition behavior mediated by the design of hybrid anode for sulfide-based all-solid-state batteries. Acta Mater. 244, 118592 (2023). https://doi.org/10.1016/j.actamat.2022.118592

Liu, C., Chen, B.T., Zhang, T.R., et al.: Electron redistribution enables redox-resistible Li6PS5Cl towards high-performance all-solid-state lithium batteries. Angew. Chem. Int. Ed. 62, 2302655 (2023). https://doi.org/10.1002/anie.202302655

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant Nos. 51971201, U20A20126, 52073253, and 52103350). Y. Zhong acknowledges the support by the Zhejiang Provincial Natural Science Foundation of China (No. LY23E020009). X.L. Wang acknowledges the support by Development Program of Zhejiang Province (No. 2022C01071).

Funding

National Natural Science Foundation of China, 51971201, Jiangping Tu; U20A20126, Jiangping Tu; 52103350, Yu Zhong; 52073253, Xiuli Wang. Zhejiang Provincial Natural Science Foundation of China, LY23E020009, Yu Zhong. Development Program of Zhejiang Province, 2022C01071, Xiuli Wang.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical statement

We hereby declare that this manuscript is the result of all authors’ independent creation under the reviewer’s comments. Except for the quoted contents, this manuscript does not contain any research achievements that have been published or written by other individuals or groups. We are the only authors of this manuscript. The legal responsibility of this statement should be borne by the corresponding authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, J., Su, H., Liu, Y. et al. Li Alloys in All Solid-State Lithium Batteries: A Review of Fundamentals and Applications. Electrochem. Energy Rev. 7, 18 (2024). https://doi.org/10.1007/s41918-024-00221-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41918-024-00221-0