Abstract

The demand for lithium-ion batteries (LIBs) with high mass-specific capacities, high rate capabilities and long-term cyclabilities is driving the research and development of LIBs with nickel-rich NMC (LiNixMnyCo1−x−yO2, \(x \geqslant 0.5\)) cathodes and graphite (LixC6) anodes. Based on this, this review will summarize recently reported and widely recognized studies of the degradation mechanisms of Ni-rich NMC cathodes and graphite anodes. And with a broad collection of proposed mechanisms on both atomic and micrometer scales, this review can supplement previous degradation studies of Ni-rich NMC batteries. In addition, this review will categorize advanced mitigation strategies for both electrodes based on different modifications in which Ni-rich NMC cathode improvement strategies involve dopants, gradient layers, surface coatings, carbon matrixes and advanced synthesis methods, whereas graphite anode improvement strategies involve surface coatings, charge/discharge protocols and electrolyte volume estimations. Electrolyte components that can facilitate the stabilization of anodic solid electrolyte interfaces are also reviewed, and trade-offs between modification techniques as well as controversies are discussed for a deeper understanding of the mitigation strategies of Ni-rich NMC/graphite LIBs. Furthermore, this review will present various physical and electrochemical diagnostic tools that are vital in the elucidation of degradation mechanisms during operation to supplement future degradation studies. Finally, this review will summarize current research focuses and propose future research directions.

Graphic Abstract

The demand for lithium-ion batteries (LIBs) with high mass specific capacities, high rate capabilities and longterm cyclabilities is driving the research and development of LIBs with nickel-rich NMC (LiNixMnyCo1−x−yO2, x ≥ 0.5) cathodes and graphite (LixC6) anodes. Based on this, this review will summarize recently reported and widely recognized studies of the degradation mechanisms of Ni-rich NMC cathodes and graphite anodes. And with a broad collection of proposed mechanisms on both atomic and micrometer scales, this review can supplement previous degradation studies of Ni-rich NMC batteries. In addition, this review will categorize advanced mitigation strategies for both electrodes based on different modifications in which Ni-rich NMC cathode improvement strategies involve dopants, gradient layers, surface coatings, carbon matrixes and advanced synthesis methods, whereas graphite anode improvement strategies involve surface coatings, charge/discharge protocols and electrolyte volume estimations. Electrolyte components that can facilitate the stabilization of anodic solid-electrolyte interfaces (SEIs) are also reviewed and tradeoffs between modification techniques as well as controversies are discussed for a deeper understanding of the mitigation strategies of Ni-rich NMC/graphite LIBs. Furthermore, this review will present various physical and electrochemical diagnostic tools that are vital in the elucidation of degradation mechanisms during operation to supplement future degradation studies. Finally, this review will summarize current research focuses and propose future research directions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to significant advantages such as high energy densities, high galvanic potentials, wide temperature ranges, no memory effects and long service lifespans, lithium-ion batteries (LIBs) have been widely employed in various applications, including in the fields of communication, aviation and transportation. Overall, the chemistries of LIBs are constantly evolving, and in terms of cathode materials, LiNixMnyCo1−x−yO2 (NMC) layered oxides have received increasing attention due to their enhanced specific capacity and thermal stability [1]. As compared with LiMO2 (M = Ni, Mn, or Co) cathodes, NMC-based cathodes also possess the combined merits of three transition metals in which nickel can offer high specific capacities, whereas Co and Mn can provide layered structures and enhanced structural integrity. In addition, NMC-based cathodes can outperform lithium iron phosphate (LFP) cathodes in many areas, particularly in terms of operational voltage in which LFP-based LIBs can only output voltages below 3.4 V [2] and suffer from high rates of self-discharge. Moreover, materials such as Li2MnO3 and lithium titanate do not possess great industrial potential as cathodes due to short lifespans and high costs. Here, NMC-based cathode materials are much cheaper to produce (~ USD 23 per kg for NMC111) as suggested by researchers using a co-precipitation method [3], and the increase in NMC-based material prices from January 2017 to March 2018 (~ 43% for NMC532 and NMC622, and ~ 27% for NMC811) [4] indicates that more research is being directed to the field of NMC-based cathode materials due to their commercial potential.

Following the initial commercial success of LiNi1/3Mn1/3Co1/3O2 (NMC333 or NMC111), NMC-based LIBs have become the mainstream with gradual improvements in NMC technology through the steady increase in the nickel content in each generation of cathode materials. And because Ni can cycle between Ni2+/3+ and Ni3+/4+ redox couples without large variations in voltage during the charge/discharge process, layer-structured Ni-rich NMC (LiNixMnyCo1−x−yO2, \(x \geqslant 0.5\)) cathodes [e.g., LiNi0.5Mn0.3Co0.2O2 (NMC532), LiNi0.6Mn0.2Co0.2O2 (NMC622) and the most recent LiNi0.8Mn0.1Co0.1O2 (NMC811)] have been developed. Here, the main advantage of Ni-rich materials is their high discharge capacity (200–220 mAh g−1), which represents a large increase in energy density (~ 800 Wh kg−1) as compared with conventional LiCoO2 (~ 570 Wh kg−1) and LiMn2O4 spinel (~ 440 Wh kg−1) materials [5]. In addition, increasing the Ni content is the most effective method to enhance capacity in the current state-of-the-art LIBs without requiring advanced and novel battery chemistries. As a result, researchers are reviewing recent progress achieved in the development of Ni-rich cathode materials in an attempt to provide important clues for the future design of Ni-rich cathodes [6].

However, although increasing Ni percentages can allow for enhanced Ni-rich NMC-based battery performances as compared with other NMC combinations in terms of capacity, capacity fading becomes severely pronounced. To address this, significant efforts have been made to elucidate the mechanisms of capacity fading and associated growth of impedance [7, 8], as well as to find remedies [9,10,11,12]. And in recent decades, numerous studies and reviews have been published worldwide [13,14,15] in which various testing protocols [16], research methodologies, models [17,18,19] and physical characterizations [9, 20] have been used to interpret the behavior of NMC-based cathodes with or without modifications. Here, studies based on microscopy [21], crystallography [22], mass spectroscopy [23], gas measurements [24] and calorimetry [8] have revealed that parasitic reactions [7], cation mixing (leading to restructured surface regions) [25], active material dissolution [26] and oxygen release [23, 25] are primary factors responsible for cathode degradation at the atomic scale. In addition, scanning electron microscopy (SEM) [13] together with computational studies [27] has revealed that intergranular cracking can weaken connections between primary particles. Despite these findings, the majority of recently published studies are insufficient and only partially cover the processes through which degradation occurs. For example, Liu et al. [28] reviewed surface layers and surface chemistries during Ni-rich NMC-based LIB operations and presented cationic doping and metal oxide coating as recent research progress, whereas Myung et al. [29] in their review only provided a brief developmental history of NMC and NCA-based LIBs with a focus on the categorization of gradient layers and core–shell structures as remedies. A more recent and detailed review conducted by Hou et al. [30] covered more mitigation topics varying from ion substitution and electrolyte additives to gradient layers; however, to the best of our knowledge, no review has presented a comprehensive collection of mitigation methods or has categorized them based on characteristics. Similarly, controversies in mitigation strategies and trade-offs need to be considered, such as the selection of dopants or coating materials, all of which have yet to be discussed. Based on this, these vacancies in the literature will be covered in this review to assist in the further investigation of Ni-rich NMC-based LIBs.

Apart from the cathode, graphite—the anode material that has received the most attention in LIBs due to its high mass-specific capacity and economic advantages [26, 31, 32]—can function collaboratively with NMC-based cathodes to provide promising performances in coin cells [20, 33], pouch cells [9, 34], pouch bags [11] and T-cells [35]. Based on this, this review will also provide a complete picture of the aging of graphite anodes that can affect both electrodes in battery cells based on degradation mechanisms and effective mitigation strategies. Furthermore, the solid electrolyte interface (SEI) is a film that forms on graphite anode surfaces during initial charging [36,37,38,39] and thickens in subsequent cycles, which can protect and impede anodes and is vital in the discussion of the aging behaviors of graphite anodes. Therefore, detailed mechanisms of anode SEIs are also reviewed to supplement previously published reviews.

To further investigate the degradation mechanisms of LIBs, multiple physical methods have been used in both electrochemical tests and physical characterizations [e.g., electrochemical impedance spectroscopy (EIS) to characterize the resistance of electron transfer and surface films]. Conventional and modern physical characterization methods have also been utilized to reveal surface morphology, element compositions, crystal lattice dimensions and reaction processes, and are also important to the interpretation of the degradation of Ni-rich NMC/graphite LIBs. Based on this, these diagnostic tools will also be presented in this review.

To fully present the evolution of electrode performances in Ni-rich NMC/graphite LIBs, degradation mechanisms based on various experiments and recent mitigation strategies in which cell conditions were evaluated separately or as a whole are presented in this review. And overall, this review will provide a summary of the recent advances in Ni-rich NMC-based batteries and can supplement pioneering reviews published previously.

2 Degradation Mechanisms

Ni-rich NMC-based materials are some of the most promising cathode candidates for next-generation LIBs due to high capacities and large voltage windows. Despite impressive progress in the development of advanced materials and fabrication processes, the development of high-capacity electrodes with long-term stability and prolonged cycle lifespans remains an important challenge. To address this, the understanding of underlying degradation mechanisms presented in this review can serve as a starting point to learn and improve the performance of Ni-rich NMC-based cathodes. In addition, the information included in this review can provide valuable insights into the creation of new devices with improved efficiency and productivity. And for the sake of completeness in the understanding of degradation mechanisms in LIB full cells, parasitic reactions on NMC-based cathode surfaces, the aging of graphite anodes as well as SEI formation and aging are also briefly presented in this section.

2.1 Ni-Rich NMC-Based Cathodes

The degradation of Ni-rich NMC LIBs involves different types of capacity loss, including initial capacity loss (ICL), sudden capacity loss (SCL) and gradual capacity loss (GCL), all of which are accompanied by impedance growth. And in the case of GCL, which is the most frequently investigated process, a major cause is the loss of Li and transition metals on cathode surfaces. In general, the majority of degradation mechanisms for Ni-rich NMC-based cathodes can be indexed to the same mechanism independent of Ni/Mn/Co ratios because they share similar crystal and microspherical structures. Here, adjustments (typically increases in Ni) to the relative amounts of Ni, Mn and Co can result in augmented performances as well as various negative features. For example, enhanced mass-specific capacity can be achieved but at the expense of rate capability and structural stability. In addition, researchers have also reported higher electronic conductivity and reduced polarization [40] in which the varied polarization as compared with the portion of Ni is caused by the higher eg orbital of Ni over the t2g orbital of Co [41]. Researchers have also shown that the reduced Mn content can result in faster degradation through surface reconstruction [42] and that the increased Ni content can result in increased cation mixing due to the bulk diffusion of Ni2+ into the Li-layer and increased parasitic reactions as the valence of surface Ni increases toward highly reactive Ni4+. Overall, cathode performances can be impacted by various factors that interact with each other, and therefore, this section will discuss degradation mechanisms in detail.

2.1.1 Surface Degradation During Cell Operation

Lattice Expansion/Contraction

NMC oxide possesses an \( R\bar{3}m \) structure (rhombohedral symmetry) with a Li-layer on the 3a site, an NMC layer on the 3b site and an oxygen layer on the 6c site [7] and can usually be indicated in the splitting of (110) and (108) peaks and of (006) and (102) peaks. For example, the expansion and contraction of the c-axis (14.21 Å) of NMC811 lattices can be observed by using in situ XRD measurements in the cell voltage windows of 3.0–4.0 V and 4.0–4.4 V, in which (003) peaks can decrease from 18.96° (3.0 V) and subsequently rise to 19.09° (4.4 V) [7, 10, 43]. This can also be observed for the movement of (104), (015) and (108) peaks. Here, researchers suggest that the expansion of the c-axis is due to the repulsive force generated from MO6 slabs, which are positively charged in a highly delithiated state, whereas the loss of electrons can shrink the radius of transition metal ions to reduce the a-axis [44]. In addition, the (110) peak can shift to higher angles in experiments, suggesting that the a-axis can contract during charging due to the smaller radius of transition metal ions at elevated valences [45]. Researchers have also reported that the a-axis of NMC811 lattices remains constant at potentials exceeding 4.3 V [10] and that a steep drop of the c-axis occurs at potentials exceeding 4.2 V in which the drop becomes steeper as the Ni content increases [7, 20, 43]. Here, researchers proposed that this drop is due to the fact that the repulsion between O2− layers decreases with more covalent M–O bonding at higher delithiated states [46, 47] (Fig. 1a, b). Furthermore, studies have also confirmed two pathways (Fig. 1c2, c3) involved in the delithiation of Ni-rich NMC-based cathodes [40, 48], including oxygen dumbbell hopping and tetrahedral site hopping, in which at the beginning of charging, Li can exit through oxygen dumbbell hopping until a certain degree of delithiation is reached and continue through tetrahedral site hopping due to increased energy barriers as caused by Li–O bonds during delithiation.

The c-axis (a1), the a-axis (a2) and potential (a3) of an NMC 811 cell as a function of specific capacity. The c-axis (b1) and the a-axis (b2) as a function of cell potential during the second cycle and dQ/dV of the second cycle as a function of cell potential (b3) (Reprinted with permission from Ref. [7]. Copyright © The Author(s) 2015. Published by ECS). c1 Lattice of an NMC layered structure. c2 Tetrahedral site pathway and c3 oxygen dumbbell pathway for Li-ion diffusion in an NMC layered structure (Reprinted with permission from Ref. [48]. Copyright © 2015 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim)

Surface Reconstruction to Fm3m Rocksalt

Surface reconstruction of the particles of NMC-based cathodes can initiate if delithiation exceeds 70% as shown in NMC111 [49]. In addition, increasing the Ni content can lead to increased portions of Ni3+ (usually Ni ions with higher valences) in the total amount of Ni. Furthermore, elemental Ni partially located in the transition metal layer as Ni2+ (0.69 Å) possesses a similar radius to Li+ (0.76 Å) [50], and Li+ and Ni2+ can exchange positions in a delithiated state through Ni2+ diffusion to the octahedral sites of Li+ (energetically favorable) through a neighboring tetrahedral site (Fig. 1c) [42, 51]. Here, the degree of Ni2+ migration can be evaluated by calculating the c/a ratio of the NMC lattice because this migration reduces the c/a ratio. And based on XRD measurements, ratios of I003 to I104 can decrease to less than 1.2 after significant cation mixing and can therefore serve as an indicator of the degree of cation mixing [52]. Moreover, researchers reported that cation disorder can lower spacing between atomic layers in the lattice of the NMC-based cathodes, hinder Li+ movement and reduce the amount of active Ni and Li [53]. In the case of higher Ni percentage cathodes, Mn4+ can partially be replaced by Ni, which increases the valence of Ni and therefore lowers the possibility of Ni atoms migrating to 3a sites [8]. However, because the total amount of Ni also increases, Ni2+ migration still occurs to a larger extent. To minimize Ni2+ migration, researchers reported that mitigation methods can be used to modify cathodes [54]. Furthermore, a disordered spinel structure (Fd3m) due to non-ideal cation mixing [55] can form if LIBs are charged to high voltages (e.g., 4.8 V) [21, 56,57,58,59,60] and consists of a LiM2O4 spinel structure and a M3O4 spinel structure if Co migration into tetrahedral sites occurs [42] (Fig. 2a). Xiong et al. [61] and Eom et al. [62] also reported that spinel phases can be formed on charged cathodes stored at 90 °C for a week. Moreover, researchers found that migrated Mn and Co possess high valences and smaller radii for movement and more vacancies in the Li-layer in a highly delithiated state [63]. Researchers also reported that long-term cycling to 4.2 V (NMC 622) [64] can result in phase changes to an Fm3m structure consisting of Ni2+, Mn2+ and Co2+ with lowered valence states as compared with a spinel structure [63, 65] and ion-insulating [56, 63, 66] (a cubic rocksalt phase) (Fig. 2b). Here, the conversion from a layered structure to a cubic rocksalt phase (usually confirmed by HRTEM/EELS [9]) can release O2 into the cell, which can react with electrolytes to generate CO2 and result in increased electrode interfacial resistances due to kinetic barriers in the Li+ insertion/desertion process [50]. To address this, researchers reported that NMC811 cathodes pretreated with ramping to 4.5 V limited the growth of the rocksalt layer in subsequent cycles and can serve as a pillar structure to stabilize the lattice and isolate the surface of NMC particles [67]. Furthermore, researchers reported that the oxidation states of Mn and Co decrease in the surface layer/region of NMC811 and NMC442 after cycling [9, 63].

a Schematic of phase transition and possible TM cation migration pathways in charged NMC cathode materials during thermal decomposition (Reprinted with permission from Ref. [42]. Copyright © 2014, American Chemical Society). b Degradation mechanisms of LiNi0.5Co0.2Mn0.3O2 after cycle tests under two upper cutoff voltage conditions (4.5 V and 4.8 V) (Reprinted with permission from Ref. [56]. Copyright © 2013 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim). c Differential capacity plot of three different NMC/graphite cells recorded at 0.1 C-rate (3rd cycle) with marked phase transformations (Reprinted with permission from Ref. [25]. Copyright © The Author(s) 2017. Published by ECS). d Schematic of H1–H2–H3 phase transformation from the perspective of local environments in different views along the c-axis (up) and the a-axis (bottom) (Reprinted with permission from Ref. [69]. Copyright © 2018, Elsevier B.V. All rights reserved.)

Phase Transformations

Two hexagonal phases of NMC811 can coexist on the surface of particles if freshly prepared in which the evolution of one phase is irreversible and vanishes after initial charging (with lattice constants remaining at the initial value), whereas the second phase is reversible (except for a small difference between charging and discharging above 4.2 V). Here, the fading of the (110) peak at 65.12° can track the conversion of the region in which the two hexagonal phases coexist and are converted to a single phase [7]. In addition, the broadening of the (003) peak during cycling as recorded by using in situ XRD measurements is of great interest in which researchers [25] suggested that this phenomenon was due to the creation of a second phase in the potential range of 3.8–4.0 V (H2, evolved from the monoclinic phase in contrast to the phase H1 following the stoichiometric composition) that possesses less Li. Researchers also reported that this process occurred earlier with higher Ni portions (Fig. 2c) and that at higher voltages, the conversion from H2 to H3 occurs with impedance growth (volume contraction) only for NMC811 (or NMCs with Ni portions larger than 80%) [25]. Researchers have also found that the phase transition from H2 to H3 can lead to (003) peaks shifting to higher degrees [68] and that Li-reordering (Li diffusing into Ni4+-rich sites) can further convert H3 to H3-2 [69] in which the fast shrinkage of the c-axis at potentials above 4.15 V is a clear indication of this phase transition. Moreover, the generated microregion of NiO2 in the intralayer of the NMC811 lattice as a result of the phase transition from H2 to H3 can lead to the irreversible transformation of the NMC811 structure [45] and this phase transition becomes severer as Ni portions further increase to extreme numbers as indicated by rising peaks of the differential capacity curve centered at 4.15 V [68]. Here, the fading of this peak leads to capacity fade and is referred to as the “deleterious effect.” Furthermore, phase changes to a second hexagonal phase for other NMC-based cathodes have yet to be clarified. (Fig. 2d illustrates crystal lattice evolution during delithiation.)

Surface Stabilizer

In general, NMC-based cathodes with more Mn content tend to possess better cycling stability [13, 70], whereas NMC-based cathodes with more Ni content are believed to be incapable of reaching high cutoff voltages due to the lack of Mn4+ as a structure stabilizer [65]. Apart from Ni2+, structural instability also applies to Mn3+, although with the high Ni content, Mn migration is not considered to be significant. Here, due to low octahedral site stability energy, NMC-based cathodes possess a tendency to form spinel-structured LiMn2O4 on surfaces [71] and Mn4+ possesses a similar tendency to migrate to the Li-layer [33, 71] and decrease capacity. Nevertheless, diffused Mn4+ on particle surfaces can stabilize structures during long-term cycling [50].

2.1.2 Impurities and Parasitic Reactions

Surface Impurities

To maintain a layered structure, excessive Li is used for Ni-rich NMC-based cathodes. However, side reactions of Li with water vapor and CO2 in air can lead to LiOH and Li2CO3 in which exposure to air can result in a reconstructed surface layer 3 nm thick (evidenced by STEM) that thickens if cycled [9]. A surface layer with similar impacts can also form as cathodes come into contact with electrolytes [65]. Here, researchers suggest that this reconstructed layer can be tuned through different synthesis methods of the cathode powder [63] and that in the case of NMC111, surface impurities can also grow on top of cathode particles as resistive films over the same time period for uncycled Ni-rich NMC-based LIBs [35] that contain mainly insulating hydroxides and carbonates as revealed through Raman spectroscopy (Fig. 3a). Here, the circumstances in which Li2CO3 (Eq. 1) or NiCO3 is favored remain unclear [35, 72, 73]. Researchers also reported that high humidity can lead to more hydroxide (e.g., LiOH) on NMC622 [72] and that surface impurities can affect cell impedances in subsequent cycles through reactions with electrolytes to form a Li+ diffusion inhibiting layer.

a Raman spectra of fresh and stored NMC111 and NMC811 electrodes before cycling, measured in air within ~ 1 h with the samples not treated prior to measurements (Reprinted with permission from Ref. [35]. Copyright © The Author(s) 2018. Published by ECS). b Positions of various redox couples relative to the top of the oxygen 2p band (Reprinted with permission from Ref. [14], https://pubs.acs.org/doi/10.1021/acscentsci.7b00288. Copyright © 2017, American Chemical Society. Further permissions related to this figure should be directed to ACS). c Proposed electrooxidation and chemical oxidation pathways for ethylene carbonate (EC) and their potential dependence (Reprinted with permission from Ref. [25]. Copyright © The Author(s) 2017. Published by ECS). d Schematic of the different issues facing Ni-rich NMC materials: (1) SEI formation and reactivity of Ni4+; (2) Li/Ni displacement and formation of disordered phases; (3) microcracks in secondary particles (Reprinted with permission from Ref. [13]. Copyright © The Author(s) 2016. Published by ECS)

NMC Dissolution

The dissolution of NMC materials can also result in capacity attenuation [26, 74] because it can decrease Li+ insertion sites and is triggered by the products of electrolyte decomposition such as HF from the reaction of PF5 with H2O (Eqs. 2, 3) [31]. In addition, higher voltages can accelerate the dissolution of NMC111 due to the release of more acidic components as a result of rapid electrolyte decomposition [75]. Despite these findings, effects on Ni-rich NMC have yet to be reported. The dissolution of NMC materials can also cause a concurrent issue involving the production of resistive MFx as a side product on the surface of NMC particles. Moreover, the dissolution of transition metals can pose a threat to anodes through electrodeposition [32, 76], catalysis of solvent reduction [77] and formation of inorganic layers in SEIs [78], all of which can impede Li+ intercalation and reduce capacity [79]. Here, Mn3+ disproportion into Mn2+ and Mn4+ was proposed to explain Mn dissolution [26, 75] as previously reported in Li–Mn–O spinel structures [80, 81] and various electrolytes have been utilized to form protective surface films containing carbon on electrodes to isolate surfaces from electrolytes [33].

Self-redox Reaction

At highly delithiated states, the valence of transition metals increases, and because the low-spin Co3+/4+:t2g band overlaps with the 2p band of O2− (Fig. 3b), electron transfer from O2− to Co3+/4+ can occur and reduce oxidized transition metal ions, thus releasing O2 into battery cells [82]. Oxygen release based on this also occurs at the first charging period in which O2− reduces transition metals oxidized to 4+ (similar effects on Ni4+ also exist and dominate oxygen release in Ni-rich NMC-based cathodes) [14, 42].

Parasitic Reaction: Effects of Ni4+

Highly delithiated (highly charged) states tend to generate large amounts of Ni4+ that can react with electrolytes. (No reaction schemes have been proposed.) This side reaction can significantly thicken cathode–electrolyte interfaces (CEIs) and reduce the number of available Li+ [14, 83], thus increasing impedance [13]. Researchers have also investigated gas evolution (CO2) from NMC532 cathodes using DEMS [84], and isothermal calorimetry (IMC) results have shown that at highly delithiated states above 4.2 V, the further removal of Li from NMC811 cathodes can result in decreased entropy and endothermic heat flow [7] in which rapidly increasing heat flow indicates that the highly delithiated cathode is very reactive with the electrolyte and can therefore cause capacity fading. In addition, researchers also found that remaining at a highly delithiated state can cause significant electrolyte oxidation as well as other side reactions [9].

Parasitic Reaction: CO2generation

Large Ni4+ portions at higher voltages can cause increased CO2 evolution at increased upper cutoff voltages [85] in which cathodes with higher Ni content suffer more from parasitic reactions with Ni4+ that are a source of emitted CO2. In addition, because highly reactive oxygen can be produced through O2− from self-redox reactions, surface reconstructions and highly delithiated cathodes (ca. > 80%) [86], CO and CO2 can also be traced back to the reaction between O2 and alkyl carbonate electrolytes (Eq. 4) [24, 25]. Alternatively, sweeping to higher voltages can also cause the electrochemical decomposition of electrolytes to produce CO2 (Eq. 5, Fig. 3c) [23, 24, 87]. Furthermore, Gasteiger et al. [88] have experimentally shown three other mechanisms that may contribute to CO2 emission, including solvent hydrolysis (if trace amounts of OH− exist), electrolyte impurity oxidation and HF reacting with lithium carbonate as a surface impurity. Moreover, the decomposition of lithium carbonate has also proven to be a source of CO2 [89, 90]. Researchers have also suggested that NMC-based cathodes with Ni-rich surfaces behave differently than other cathodes with different portions of Ni [7]. For example, the degradation of NMC811 cells was studied by using different electrolyte additives including VC and PES211 to suppress side reactions and it was revealed that NMC442/graphite cells and NMC111/graphite cells showed better performances with PES211, whereas NMC811/graphite cells aged slower with VC (with slower capacity fading and impedance growth) [79]. Here, PES was also reported to be a viable additive for the suppression of gas evolution [91] and impedance growth during cycling to higher voltages (above 4.3 V), and rocksalt surface layers formed with the use of VC but not with PES211, concluding that electrolyte additives can significantly affect the rate of parasitic reactions and that parasitic reactions were the main reason for capacity fading [7, 92].

2.1.3 Other Issues

Initial Capacity Loss

Initial capacity loss is strongly linked to the loss of available Li and the growth of impedance in anodes due to SEI formation. Here, researchers have reported that NMC-based cathodes cannot return to their fully lithiated states after initial cycling [26] in which separate mechanisms have been proposed, including parasitic reactions consuming Li+ [93] and the sluggishness of Li+ diffusion into the few vacancies of the Li-layer [94] (circumstantially proved by Gasteiger et al. [26]). In addition, researchers have also suggested that initial capacity loss is related to the C-rate because it is kinetically influenced. Furthermore, partial losses of available cathodic Li occur to compensate for losses of anodic Li+ to SEIs [26], and other losses of Li in the cycling period can be attributed to parasitic reactions including the immobilization of Li in the SEI and enlarged polarization, which become significant at higher cutoff potentials [26, 95].

Cracking of Secondary Particles

Reduced performances due to the cracking of spherical secondary particles have been extensively reported and are of significant concern [96]. Here, the expansion and contraction of the c-axis during repeated cycling at above 4.2 V can lead to microstrains on particles in cathodes, leading to the generation of microcracks in the core of primary particles with some initially generated cracks being able to close in subsequent cycles [68]. These cracks can cause poor connection between particles and micropores and even the cracking of secondary particles [13], all of which contribute to degradation at the microscale. To address this, Lim et al. [27] have used first-principle calculations to study these cracks generated by gaps between primary particles and found that they were a result of anisotropic and average contractions. In addition, researchers reported that these cracked particles possessed enlarged surface areas and therefore increased the possibility of parasitic reactions [13]. Moreover, these microcracks were also found to partially originate from the gas evolution of NMC particles [13] (Fig. 3d), and recent studies on coated NMC (76 14 10) suggested that the infiltration of liquid electrolytes into the gap between primary particles can also cause cracking [97]. Alternatively, various NMCs have also been found with no cracking by using SEM [7, 20]. Here, Dahn et al. [20] suggested that the shell of core–shell structured NMC cathodes (a Mn-rich shell and a Ni-rich core) was resistant to cracking due to the absence of compressive stress on the core and tensile stress on the shell. Based on all of this, numerous mitigation methods including carbon matrixes and gradient layers have been proposed to resolve cracking at the microscale (further details in Sect. 4.1).

The Effects of Temperature

Studies have shown that cell degradation can accelerate at elevated temperatures above 30 °C and that at low C-rate cycling, cell degradation is mainly affected by the time in which cells are placed under high temperatures and not by cycling [98]. Long-term operation of LIB cells can produce large amounts of heat. And although this released heat may even be useful in cold weather conditions, heat emissions are a major issue of Ni-rich NMC-based LIBs due to thermal instability [33] in which thermal runaways can occur if NMC-based cathodes react with LiPF6 from the electrolyte and limit the commercial and practical use of these battery packs. To improve thermal stability, coatings such as SiO2 [62], TiO2 [99] and Li2ZrO3 [100] have been chosen to prevent contact between cathodes and electrolytes, and an ALD-coated NMC532 with Al2O3 has even been reported [101] to resolve the issue of uneven coatings and prevent the failure of cathode separation from electrolytes.

2.2 Graphite Anode

Similar to the cracking of NMC secondary particles, cracking can also occur in graphite anodes due to Li intercalation/deintercalation, which can expand and contract the distance between graphite layers [102]. In addition, recent research indicated that unit cell expansion (13.2% in total) during Li intercalation is neither continuous nor linear, but staged (Fig. 4a–e) [103]. Here, Li intercalation from C6 (Li-free graphite) to LiC24 (Stage 2L) showed no in-plane ordering of intercalated Li, whereas from 2L to LiC12 (Stage 2), the ordering of Li appeared and the lattice can be assigned to the space group P6/mmm. Furthermore, in the transition from Stage 2 to LiC6 (Stage 1), total volume change suddenly increases as the amount of x exceeds 0.6 in LixC6 (where Stage 1 appears as Li presents in every interlayer). These results showed that optimal composition was between 20 and 80% charged in which Stage 2 stably exists or extends into.

Crystal structures of a graphite (space group P63/mmc) and two major Li intercalation compounds, b LiC12 and c LiC6 (space group P6/mmm). Different stacking of graphene layers with d the AB sequence in graphite and e the AA sequence in LiC12 and LiC6 (Reprinted with permission from Ref. [103]. Copyright © 2018, American Chemical Society). f Schematic of SEI formation and degradation on graphite anodes (Reprinted with permission from Ref. [31]. Copyright © 2005, Elsevier B.V. All rights reserved.)

Furthermore, “dead lithium,” which is Li-ions electrochemically plated onto the surface of graphite anodes, is the principal reason for capacity fading, especially at final stages [104]. This phenomenon occurs on graphite surfaces that possess limited mass transport, slow diffusion within the graphite or low charge transfer speeds [105] and is strongly promoted by low temperatures/large polarizations (including high electrolyte resistances induced by high temperatures) during lithiation as well as the properties of the graphite electrode (e.g., morphology [102], loading). And as Li+ intercalation is replaced by Li plating, issues such as dendrite growth become more pronounced, leading to increased impedance and more importantly, potential safety hazards due to internal short circuiting. To avoid this, the limits of charging currents and the state of charge need to be established to maintain polarization in optimal ranges [106]. However, large polarizations also need to be adopted to minimize charging durations to meet industrial application demands. Here, researchers reported that the reduction of graphite thicknesses and improvements in porosity can decrease charge transfer impedances [105, 107].

2.3 SEI

Electrolytes used in LIBs contain two main components including Li salt and organic solvents. Here, the use of additives as film-forming agents can allow for stable SEIs and, in general, the concentration of Li salt is maintained at 0.8–1.3 M to optimize electrolyte viscosity and ion conductivity. As compared with cathodes, the potential of LIB anodes is low and can trigger electrolyte reduction (SEI formation), which can cause Li loss during initial charging (Fig. 4f) [31]. However, because SEIs are electronically insulating, further reductions of electrolytes do not occur in which formed SEIs are usually 10–50 nm thick and are conductive to Li+ ions. Researchers have extensively studied the constituents of passivating SEIs on graphite anodes and have reported that lithium ethylene dicarbonate (LEDC, Eq. 6, Fig. 5a–d) [108] was the main component of SEIs formed with ethylene carbonate (EC) solvent [109] apart from electronically insulating LiF and gaseous products (H2 and C2H4). Propylene carbonate (PC) as a solvent has also been well investigated due to its thermal stability and wide voltage windows. Furthermore, DFT calculations have shown that stable SEI films can be produced by oligomers of SEI film components (SFCs) [108], which are first created through solvent decomposition. LiF is also a product of almost all common Li salts such as LiPF6 (the only commercially available salt), LiBF4, LiTFSi, LiTSi, etc., in which researchers reported that the amount of LiF produced from LiBF4 was large and would result in the formation of a grainy film instead of a smooth film.

DFT-MD snapshots of electrode/electrolyte interphases with Li2EDC: a adhesion structure of one Li2EDC monomer on a graphite electrode, b dissolution structure of one Li2EDC molecule in EC solvent, c adhesion structure of 12 Li2EDC molecule aggregates on a graphite anode, d dissolution structure of 12 Li2EDC molecule aggregates in EC solvent (Reprinted with permission from Ref. [108]. Copyright © The Author(s) 2015. Published by ECS). e Proposed mechanism for the continuous decomposition of SEI and electrolytes as monitored by C2H4 evolution for a preformed electrode with a Mn2+-containing electrolyte: (1) absorption of Mn2+ ions into the SEI; (2) reduction of Mn2+ ions in the SEI and deintercalation of Li+ from graphite; (3) re-oxidation of Mn0 to Mn2+; (4) recurrent electrolyte reduction; (5) the catalytic cycle of electrolyte decomposition (Reprinted with permission from Ref. [38]. Copyright © The Author(s) 2018. Published by ECS)

As aging continues during cycling, researchers believe that the inorganic portions of SEIs also increase as LiF (can be used as an indicator of SEI maturation) is produced through LiPF6 reacting with lithium carbonates (Eqs. 7, 8) [37].

After SEI formation, the resistance of anodes/SEIs toward divalent transition metal ions such as Ni2+, Co2+, Cu2+ and Mn2+ (relatively more impactive) is significantly enhanced, preventing the reduction of EC solvent by these ions. However, formed SEIs remain targets to many reductive substances in which reductive decomposition can degrade SEIs (Li2CO3 and C2H4 are produced as a result) and expose thermodynamically unstable graphite anodes to reactive environments [38]. Here, if the exposure of graphite anodes occurs, a series of damage can occur on the graphite anode, including the intercalation of solvated Li+, which leads to larger sizes and the potential risk of the breaking of the graphite layer. In addition, Mn2+ has been reported to be able to penetrate SEIs and reside in the inner area between the SEI and the anode through the exchange of positions with Li+ ions located in the SEI [110]. Furthermore, the recurrent generation of C2H4 suggests that Mn2+ is a destructive substance to both solvents and graphite anodes in which accumulated Mn2+ near graphite can function as a catalyst, suggesting that it is reduced at the surface of the anode but can reduce EC afterward, leading to thickened SEI films and the immobilization of active Li (Fig. 5e) [110]. In addition, the reduction of Mn2+ can cause the gradual transfer of active Li+ to SEIs or the conversion of active Li+ into compounds deposited onto graphite anodes, both of which lower storage capacity [38]. Researchers have also proposed another mechanism of Li+ that suggests that even monolayer Mn2+ can impede the movement of Li+ through the graphite and the SEI [111]. As for PF5, it is produced from the decomposition of various electrolytes and can trigger the open-ring polymerization of EC, which further increases SEI decomposition along with the production of HF [112]. Moreover, the damage/repair process caused by gaseous PF5 consumes active Li-ions until Li-ions are depleted in the system [113]. Researchers have reported, however, that this degradation can be mitigated through the addition of Lewis-basic additives. The presence of H2O in electrolytes can also reduce the production of C2H4 (usually used as an indicator of EC reduction) and promote H2 production. Here, the existence of SEIs can reduce the reduction of trace amounts of water that usually generate H2 and CO2 [114].

An automotive scale NMC pouch cell was also analyzed by Dahn group using ultra-high precision cycling technologies, and it was revealed that the performance of graphite anodes was decisive and that corresponding capacity fading (proportional to t1/2) was related to SEI thickness and was inversely proportional to the rate of SEI growth, suggesting that the gradual lowering of SEI thickening rates can lead to stable SEIs [115, 116]. Here, alternative relationships proposed for SEI growth need to take stability as a factor into consideration [117].

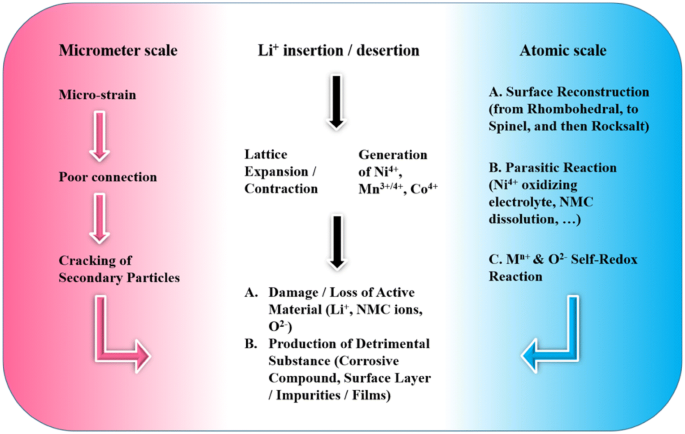

2.4 Summary

Overall, the degradation of Ni-rich NMC-based cathodes originates from the insertion/desertion of Li+ during charge/discharge in which the expansion and contraction of crystal lattices (primary particles) gradually generates tension, leading to the cracking of secondary particles (Fig. 6). Electrolyte infiltration as well as oxygen release can further deteriorate this issue. On an atomic scale, Ni4+ can accumulate during charging because delithiation can elevate the valence state of Ni together with high-valence Mn and Co ions. And due to smaller radii, easier diffusion can lead to surface reconstruction (from rhombohedral to rocksalt), which can further inhibit Li+ insertion/desertion. Moreover, increased voltage levels of high-valence ions can trigger side reactions such as the oxidization/decomposition of electrolytes and the further dissolution of NMC materials. Electrochemical potentials of electron-depleted Co and Ni can also fall below the fermi level of O2−, leading to the transfer of electrons from O2− to transition metal ions and the release of O2 into systems, which can also cause electrolyte decomposition. Throughout the operation of Ni-rich NMC-based LIBs, four types of unwanted substances exist on the surface of cathodic particles, including other phases, surface impurities (carbonates and hydroxide), rocksalt structures and surface films. To sum up, aging effects on both micrometer and atomic scales can result in two common outcomes in which the first is the chemical (through chemical reactions) and mechanical (through the breakage of crystallites) damage/loss of active materials and the second is the production of detrimental substances on electrode particle surfaces, including surface films (both SEIs and CEIs), surface impurities and surface layers. And although many differences in the performance of various Ni-rich NMC-based cathodes have been discovered, these remain unexplained. Therefore, future studies should focus on the interpretation of different aging behaviors in NMCs with or without mitigation methods.

As for graphite anodes, degradation primarily occurs due to the plating of Li dendrites and the cracking of layered graphitic structures. In addition, SEIs tend to thicken during cell operation as EC solvent is reduced electrochemically. Furthermore, transition metals, especially Mn2+ from dissolved NMC, can cause significant capacity loss due to massive damage to SEIs. A comprehensive list of identified degradation mechanisms for Ni-rich NMC-based cathodes, graphite anodes, SEIs and CEIs is presented in Table 1. Here, the degradation mechanisms of SEIs are categorized based on anodes and the degradation mechanisms of CEIs are categorized based on cathodes because certain degradation mechanisms may involve both electrode materials and interfaces.

3 Diagnostic Tools

3.1 Electrochemical Techniques

Throughout the development of LIBs, a variety of electrochemical methods have been employed to test, analyze and diagnose LIBs. To provide a comprehensive overview, these methods are categorized into three groups, including charge/discharge tests, cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS).

3.1.1 Charge/Discharge Tests

Charge/discharge tests include basic electrochemical characterizations that can be used to determine the voltage at which a certain reaction (including Li+ insertion/desertion reactions that generate current in external circuits and side reactions that negatively impact cell performance) occurs and that can be used to evaluate the reversibility of cycling performances. Data from these charge/discharge tests can be analyzed by using many methods and can provide useful information on cell performance, reaction and reversibility, degradation and associated mechanisms.

Voltage versus capacity

Charge/discharge curves are common and useful plots contained in almost every published study in the field of batteries. These plots are usually displayed in the format of voltage versus capacity (normalized by the mass of the active material) for a clear understanding of total capacity within a voltage range and capacity loss for certain cycles, including initial capacity loss (ICL), sudden capacity loss (SCL), gradual capacity loss (GCL) and voltage versus time. In some studies, the horizontal axis is changed to the content of Li in NMC compounds for easier comparison with physical characterization results in terms of lattice parameters/structures. Furthermore, the reversibility of cycling can be interpreted through these curves in which the presence of a reaction that can reconstruct the cathode at a certain voltage can be clearly predicted if the curve does not repeat itself in the next cycle after reaching that point [35]. Moreover, a small but important feature (a small peak) often found in the charge/discharge curve at the beginning of the initial charging can indicate the existence of impurities (most probably nickel hydroxide and nickel carbonate) during storage (a typical example showing the reaction of surface impurities of NMC811 after long-term storage during cycling is illustrated in Fig. 7a) [35]. Finally, the polarization of battery cells can be estimated by comparing the voltage levels of different cycles at fixed capacities.

a Charge/discharge curves of the 1st, the 2nd and the 3rd cycles of NMC811-Li (Reprinted with permission from Ref. [35]. Copyright © The Author(s) 2018. Published by ECS). b The c-lattice constant and differential capacity as a function of cell voltage for NMC811 (LiNi0.8Mn0.1Co0.1O2) (3–4.4 V) (Reprinted with permission from Ref. [20]. Copyright © 2016, American Chemical Society). c Cyclic voltammetry of the first three cycles of an NMC 811/Li coin cell (Reprinted with permission from Ref. [33]. Copyright © 2018, Elsevier B.V. All rights reserved.). d The Nyquist plot of NMC 811 (The inset: the equivalent circuit model used for data fitting). e The Nyquist plot of SiO2-coated NMC 811 (Reprinted with permission from Ref. [123]. Copyright © 2015, Elsevier B.V. All rights reserved.)

Differential Capacity Curve

Differential capacity curves are another kind of plots derived from charge/discharge curves [7, 20, 118]. These curves are also referred to as the incremental capacity and can be obtained by plotting \( \frac{{{\text{d}}Q}}{{{\text{d}}V}} \) versus voltage. (For similar reasons mentioned above, the vertical axis is converted to \( \frac{{{\text{d}}x}}{{{\text{d}}V}} \) in some cases, as shown in Fig. 7b.) The main use of these curves is to cross-check features already shown in charge/discharge curves at certain voltages but can also provide other information. Here, the most important feature revealed based on differential capacity curves for Ni-rich NMC-based cathodes is the phase transition in which three peaks can be identified in both charging and discharging processes, indicating phase transition from H1 (hexagonal) to M (monoclinic), and subsequently to H2 and H3 (see Sect. 2.1.1) as Li is extracted from the cathode [45]. In addition, differential capacity curves can be plotted with in situ X-ray diffraction results to correlate phases to corresponding lattice parameters [119]. Moreover, the loss of available Li between graphite layers or in the Li-rich layers of cathodes can be revealed through the fading of these peaks. And by integrating peak areas and calculating the ratio of these peak areas to the total charge/discharge capacities for each cycle, trends in the pathways/steps of Li transfer can be implied (e.g., more dominating, remaining the same or fading). Furthermore, the position of peak potential is indicative of cell impedance in which positive shifting during cycling implies an increasing cell impedance. Similarly, a differential voltage plot (\( \frac{{{\text{d}}V}}{{{\text{d}}Q}} \) vs. Q) can be used to show the fluctuation of voltage during charge/discharge and is also linked to phase transitions [98].

Maximum Capacity

To determine maximum capacity and associated fading, electromotive force (EMF) data [120] can be derived from the discharge curve of the same cell at different C-rates. Here, comparisons of EMF curves with charge/discharge curves can reveal the impact of C-rates on cell degradation. In addition, discharge capacities at each time slot during discharge can be plotted versus corresponding C-rates and a trendline fitting of all data points taken at the same voltage can be drawn and extrapolate to the Q-axis, thus revealing the relationship between maximum capacity Qmax and voltage. Moreover, maximum capacity fading plots based on EMF curves can be used to determine capacity loss (irreversible capacity loss ∆Qir) at different C-rates. Differential voltage curves can also be applied to EMF, and \( \frac{{{\text{d}}V_{\text{EMF}} }}{{{\text{d}}Q}} \) can be regarded as a nondestructive method in which peak shifting is indicative of cell degradation and can reveal anode material decay and voltage slippage effects [121].

Capacity Fading

Capacity fading curves can provide more macroscopic views of capacity loss during long-term cycling and can be derived from capacity fading plots in which cell capacity at different conditions is displayed. And because electrode materials and aging conditions vary significantly in difference battery systems, the speed of capacity fading can also vary significantly. Therefore, the degree of cell aging needs to be normalized in which the vertical axis of capacity fading curves is sometimes converted to represent normalized capacity. A modified version has also been recently presented [16] to investigate the effects of the amount of Li+ ions entering/exiting Li-layers in cathodes rather than focusing on the number of alterations. Here, an accumulative discharge capacity fading plot can be drawn and used to compare capacity fading in different currents, which can provide insights into the possible relationships between the amount of Li+ transferred and structure deformations.

Based on capacity fading plots, the number of electrons consumed by side reactions (both at the cathode and at the anode) can be measured by subtracting the discharge capacity by the corresponding charge capacity. Here, a charge efficiency (CE) plot focusing on the degree of side reactions is commonly used in which the charge efficiency of an anode can be calculated by \( \frac{{Q_{{{\text{discharge}},n}} }}{{Q_{{{\text{charge}},n}} }} \), because it describes the percentage of electrons charged to the anode that can be used to release Li+ (remaining electrons consumed by side reactions during charging), whereas the number of electrons that can be discharged from the cathode can be calculated by \( \frac{{Q_{{{\text{charge}}, n + 1}} }}{{Q_{{{\text{discharge}}, n}} }} \). And in general, the two percentages should be around 100% (CEanode is a bit less, but CEcathode is a bit more); however, the existence of kinetic barriers may cause enlarged differences.

To study impedance growth during cycling, average polarization plots combined with discharge voltage decay plots can be obtained and can reveal capacity retention behaviors by measuring ∆Vave increases, which can indicate impedance growth through cell degradation as well as potential kinetic barriers of Li+ insertion/desertion [9].

3.1.2 Cyclic Voltammetry

As a supplementary method, cyclic voltammetry (CV) can be used to determine the reversibility of charge/discharge in electrodes by measuring the difference in charge/discharge peak potentials, which is related to major delithiation/lithiation processes (Fig. 7c) [33]. As such, CV can assist in the investigation of transition metal oxidation and reduction in which the plot of the initial CV can differ from subsequent cycles due to the formation of SEIs during the first delithiation. In addition, upper cutoff voltages can also be determined by using CV [122].

3.1.3 Electrochemical Impedance Spectroscopy

Electrochemical impedance spectroscopy (EIS) is another common method to investigate cell impedance evolution and degradation mechanisms and involves the application of AC sinusoidal waves (voltage or current) to target cells. Here, AC sinusoidal waves are applied at an amplitude with different frequencies because semicircles in resulting Nyquist plots can overlap with each other if represented processes occur in the same frequency range. In addition, half-cell EIS can be carried out with either 2-electrode symmetric cells (e.g., Swagelok 2-electrode symmetric configuration cells) or 3-electrode cells by installing a reference electrode in which the resulting EIS curve often involves a vertical short tail, two depressed semicircles (only if a half cell is tested) and a long tail at a certain degree to the horizontal axis from high to low frequencies. Here, the short tail usually appears at extremely high frequencies, indicating the inductance of cables, which is rarely seen in test results. Solution resistances can also be measured at the intercept of the short tail with the real (Z) axis and therefore can be represented by a resistor. As for the first semicircle at high frequencies (usually a small one), this is indicative of the resistance of the CEI, and as the CEI continuously reacts (thickening and decomposing), the impedance cannot be taken as merely resistive. The second semicircle can be attributed to charge transfer at the cathode. (Double-layer capacitance is generated because of voltage decay across the interface.) In typical EIS curves, these semicircles can appear as depressed due to surface roughness (unevenness), which can cause varied capacitance from point to point. To address this, a resistor in parallel with a constant phase element (CPE) can be used to model each process. As for the long tail attached to the two semicircles in the EIS curve, this is related to mass-transfer resistance and therefore can be represented by using a Warburg element. During aging, both semicircles commonly increase (Fig. 7d, e), indicating large cell polarizations and thickened CEIs; however, with remedial efforts, the increase in both resistances (linked to both semicircles) can usually be reduced. For example, researchers have reported that impedance growth of surface films and charge transfer can be significantly reduced through a SiO2-layer coating of NMC811 (Fig. 7e) [123].

3.2 Physical Techniques

3.2.1 Crystal Lattice and Particle Morphology

X-ray Diffraction

In situ and ex situ XRD methods are the most frequently used physical characterization methods to determine lattice parameters and crystal structures. Here, in situ XRD can be used to measure the evolution of lattice parameters (both a-axis and c-axis) of NMC-based cathodes during cycling [43]. For example, the use of in situ XRD can evidence the shrinking of the a-axis to a constant value and the expansion and rapid shrinking of the c-axis during delithiation in Ni-rich NMC cathodes through the shifting of (003) and (006) peaks to a lower angle together with the shifting of the (101) peak to a higher angle (Fig. 8a). In addition, in situ XRD can allow for the comparison of the lattice shrinkage percentage of the a-axis to that of the c-axis, leading to the conclusion that lattice shrinkage is anisotropic and that lattice parameters are linked to corresponding phases (H1, M, H2, H3). In situ XRD can also be used to test the thermal stability of NMC cathodes and show temperature-resolved (TR) results [42] similar to voltage-resolved results. For example, TR-XRD results of heated NMC-based cathodes can be used to examine thermal stability in which researchers found that the structures of all NMC cathodes tested experienced surface reconstruction from rhombohedral to spinel (first the LiMn2O4 type and later the Mn3O4 type) and subsequently to rocksalt structure (Fig. 8b). In another study, in situ XRD plots were combined with gas chromatography–mass spectroscopy (GC–MS) data to reveal the relationship between the Li content and evolved gas from NMC-based cathodes [90].

a In situ XRD patterns of an NMC 811 cathode over a voltage range from 3.330 to 4.298 V during the first charge (Reprinted with permission from Ref. [43]. Copyright © 2015 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim). b Contour plots of TR-XRD patterns at the selected 2θ range for charged b1 NMC433, b2 NMC532, b3 NMC622 and b4 NMC811 (Reprinted with permission from Ref. [42]. Copyright © 2014, American Chemical Society). c Ex situ XRD patterns of NMC-811 and Li2MnO3-coated (10% and 30%) NMC-811 (Reprinted with permission from Ref. [45]. Copyright © 2016, American Chemical Society)

Ex situ XRD with Rietveld refinement is easier to conduct than in situ XRD but conveys less information because it can only illustrate the crystal structure of NMC-based cathodes. For ex situ XRD data, more peaks can be seen if a bulk phase of impurities or coating materials is formed on the surface of cathode materials. Here, the ratio of I003–I104 in the ex situ XRD data indicates the degree of cation mixing and can be used to determine the ameliorative performance of a mitigation method in which ratios lower than 1.2 represent significant cation mixing. Moreover, the peak splitting of (110)/(108) and (006)/(102) represents a well-layered hexagonal structure (Fig. 8c) [45] and the evolution of the full width at half maximum (FWHM) of peaks represents change in crystallinity. Surface species can also cause peak shifting [e.g., (003) of NMC622] if stored [72], or generate new peaks, and therefore, ex situ XRD can also be used to cross-check the existence of impurities.

Microscopy and Electron Diffraction

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) can be used to reveal microscopic structures of NMC-based cathodes and assess structural damage [124]. In addition, diameters of primary and secondary particles can be measured from obtained images together with the thickness of any surface coating layers [100]. Here, aggregates of primary particles, i.e., secondary particles, are usually observed in electron microscopy images possessing elongated or even needle-like shapes before degradation, whereas microcracks on secondary particles can usually be seen after repeated cycling, which can cause the breakage of particles. As a result, the spherical shape of secondary particles is usually distorted, and subfigures of SEM images obtained from samples aged under different conditions are usually displayed together for comparison. Another indispensable microscopic method is high-resolution transmission electron microscopy (HRTEM), which can reveal microregions of Fm3m NiO and spinel structures and allow for the distance between atomic layers to be clearly marked (Fig. 9a shows a surface reconstruction region on a NMC-based cathode and an electron diffraction pattern of selected spots) [56, 70]. A drawback of HRTEM, however, is that it is unable to distinguish between phases with similar structures and lattice parameters [50].

HRTEM images and FFTs after 50 cycles under 3.0–4.8 V conditions. a1 Lattice image of the surface region where a2–a5 correspond to the FFTs of regions 1–4, respectively. (11-1)C is the diffraction spot of the rocksalt phase of the metal monoxide (Reprinted with permission from Ref. [56]. Copyright © 2013 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim). b1 Low-magnification STEM-HAADF image of one surface primary particle of the x = 0.10 sample. b2 Corresponding X-ray spectrum from the highlighted area in (a). b3 High-resolution STEM-HAADF image showing the lattice structure from the highlighted area in (b1) (Reprinted with permission from Ref. [124]. Copyright © 2016, Elsevier B.V. All rights reserved.). c XPS data for lithiated FCG-Mn-F Li(Ni0.60Co0.15Mn0.25)O2: c1 Ni 2p, c2 Co 2p and c3 Mn 2p (Reprinted with permission from Ref. [127]. Copyright © 2013, American Chemical Society)

Electron diffraction is a useful tool to characterize phases and microregions in NMC lattice crystals and includes selected area electron diffraction (SAED) and nano-beam electron diffraction (NBED, in which a condenser lens and an upper objective lens are used to achieve nano-beams of electrons). Here, Kang et al. [56] have used electron diffraction to measure the space group of NMC-based cathodes with the zone axis at the bulk and surface regions of a NMC particle. In addition, electron diffraction is usually conducted separately on different regions of particles such as surface regions, transitional regions and bulk regions. Here, the existence of secondary phases can be confirmed based on obtained patterns in which spinel structures can lead to an additional spot (Fig. 9a2–a5), whereas Fm3m space groups will show two strong diffraction spots that indicate the formation of rocksalt phases with high symmetry. Phase conversion can also be tracked and compared by using HAADF-STEM results [9].

High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) measurements can provide array images of transition metal atoms located from the bulk to the surface of NMC particles and spectra of electron energy loss spectroscopy (EELS). Here, orderly arrays of atoms can clearly display layered structures of the crystal lattices of NMC (Fig. 9b) [63, 124, 125]. Here, the degree of surface reconstruction can be determined based on changes in atom patterns and a clear boundary between reconstructed and unreconstructed phases can be traced. In addition, region thicknesses can also be measured based on HAADF-STEM images.

3.2.2 Chemical Analysis

Elemental Analysis

Elemental analysis is necessary for the physical characterization of NMC-based LIBs and the composition of NMC-based cathodes as well as the investigation of impurities and remedial coatings/dopants. In addition, the semiquantitative properties of various elemental analyses are useful in the quantification of relative increases/decreases of certain elements during operation or storage. Here, energy-dispersive spectroscopy (EDS) mapping analysis can illustrate elemental distributions (Li, transition metals, C, etc.) semiquantitatively on cathode particle surfaces. For example, the dissolution of these surfaces through attack with HF can be evidenced by the increase in F element signals and the loss of transition metals.

Alternatively, electron-probe X-ray microanalysis (EPMA) accompanied with SEM can allow for the examination of transition metal element concentrations within different regions of NMC particles with a spatial resolution of ~ 0.3 μm and can often be used to determine the concentration gradient layer of modified-NMC particles [126]. Researchers have also reported that the average composition of Ni, Mn and Co can be measured using atomic absorption spectroscopy (AAS) [126].

X-ray photoelectron spectroscopy (XPS) is another elemental analysis method that can detect the chemical and electronic states of transition metals and oxygen in NMC cathodes as well as elemental carbon from current collectors and binders [73]. Here, the 2p orbitals of Ni, Mn and Co and the 1s orbital of O can be captured to reveal oxidation states by checking the peak positions of 2p1/2 and 2p3/2 (Fig. 9c) [127]. For example, the binding energies of Ni 2p3/2 in NiO and in Ni2O3 were found to be located at 854.0 and 856.0 eV, respectively [50]. In addition, the shift in oxidation states can be clearly shown by changes in peak positions, and changes in the amount of Ni can be deduced from the increase in peak area and intensity. Moreover, the use of cycle-dependent XPS can allow for the change of valence states to be attributed to a certain range of cycles, whereas a decrease in XPS peaks can indicate the loss of elements or the coverage of elements with surface impurities. Furthermore, XPS can enable the identification of new substances on cathode surfaces that evolve during storage or operation [35]. As for organic elements including C (1s), O (1s), F (1s), N (1s) and S (2p) that are contained in the components of SEI layers, XPS can also be used to track the existence of these elements in different molecules versus voltage [128].

To validate XPS data, X-ray absorption spectroscopy (XAS) can be used as a supplementary technique to monitor transition metal valence changes during charge/discharge and include extended X-ray absorption fine structure (EXAFS) and X-ray absorption near edge structure (XANES) [129]. For example, stronger Ni2+ signals over Ni4+ in NMC532 at 4.5 V reveal that the redox reaction of Ni4+ with electrolytes can occur, which reduces Ni4+ to Ni2+ [130]. And due to the viability of XAS in the examination of transition metal concentrations and oxidation states, XAS has also been widely utilized for anodic elemental analysis (e.g., transition metals deposited on graphite anodes) under various cycling conditions [113], leading to the discovery that the massive dissolution of Mn can occur if NMC111/graphite cells are charged above 4.6 V [76].

Electron energy loss spectroscopy (EELS) is another elemental analysis method that can investigate elemental energy loss and possesses three modes, including auger electron yield (AEY), total electron yield (TEY) and total fluorescence yield (TFY), each of which provides information from different depths (1–2 nm, 2–5 nm and 50 nm, respectively). Due to smaller probing depths, EELS signals reflect information on the top layer of cathodes [63], and the shift in energy loss peaks from time to time or from the bulk to the surface can indicate shifts in oxidation states of elements, in which lower energy losses translate to lower oxidation states of transition metals [9]. In general, each EELS curve consists of two peaks, including a pre-edge peak and a primary peak. Here, the pre-edge peak of oxygen is thought to be caused by the transition of electrons from the 1s to the unoccupied 2p state, which can hybridize with the 3d orbitals of transitional metals [66]. Alternatively, the primary peak originates from the transition of electrons from the 1s to the 2p state of O or to the 4sp state of transition metals. Moreover, area-integrated EELS data can be compared to check the homogeneity of NMC particles [63].

Electron paramagnetic resonance (EPR) spectroscopy can also be applied to NMC materials such as NMC622 to investigate the effects of doping with Al and Fe on cation mixing in which the change of the Ni2+ line indicates the redistribution of Ni within the structure. Hubert Gasteiger’s group have also demonstrated Li plating onto graphite anodes quantitatively and in real time by using operando EPR [106] quantified the amount of Li-ions not available for future cycling. Despite these uses, EPR cannot provide more detailed structural information, which requires other physical characterization methods [131].

Inductively coupled plasma–atomic emission spectroscopy (ICP-AES or ICP) is a cutting-edge technique that can provide relatively precise information on the amounts of Li [132], transition metals [133,134,135] and impurities in examined samples in which concentrations can be indicated by the intensity of characteristic waves emitted from excited atoms or ions. In addition, changes in the elemental composition of electrodes or powder samples due to operation or modification can be reflected in ICP-AES data and the results (in ppm) are often compared with theoretical values or results obtained by using other elemental analysis tools to observe differences. Researchers have also combined ICP with mass spectroscopy in studies. For example, ICP-MS was used to reveal significant increases in the Ni content on graphite anodes related to the dissolution of Ni from NMC 811 cathodes [136] and was also used to conduct a series of Li content measurements in sampled electrolytes, including sample preparation procedures [137], in which the results were pre-calibrated with known Li concentrations and proved the credibility of the ICP-MS method.

Gas Measurement

Ex situ gas measurements have been adopted by many researchers in the study of LIBs in which the volume of evolved gas is measured as the cell is charged to certain voltage levels [9, 85]. Gas evolution under other conditions can also be measured, including the addition of electrolyte additives or under different compositions of Ni, Mn and Co. And if combined with mass spectroscopy, the content of emitted gas can be identified (usually including H2, C2H4, CO and CO2) and allows for volume or moles versus voltage to be plotted with various curves related to different gases [24]. Furthermore, online electrochemical mass spectroscopy (OEMS) is a tool that can facilitate the detection of gas in real time and can quantify the amount of H2, CO2 and O2 from different mass to charge ratios [23, 90] in which gas evolution (e.g., O2) is related to cathode surface reconstruction (if aimed at cathodic processes) through comparisons of voltage profiles (or SOC) (Fig. 10a). Similarly, anodic processes with gas evolution can also be tracked by using OEMS. Researchers have also combined differential electrochemical mass spectrometry (DEMS) with differential electrochemical infrared spectroscopy (DEIRS) to identify and quantify gases emitted from NMC 532/graphite cells [84] and found that potential-resolved gas evolution partially originates from SEI formation. And if combined with thermogravimetry (TG), the mass loss of cells can be correlated to oxygen evolution from NMC-based cathodes heated to a certain temperature, showing that the majority of weight loss can be attributed to oxygen release as they both rapidly rise to around 175 °C [85].

a Specific charge and CO2 and O2 evolution rate profiles versus cathode potential during the first and the second charges of four NMC-based cathodes (Reprinted with permission from Ref. [90]. Copyright © 2017, American Chemical Society). b DSC traces and c TGA curves of electrochemically delithiated FCG Li0.25(Ni0.54Co0.16Mn0.30)O2, Li0.25(Ni0.5Co0.2Mn0.3)O2 and Li0.27(Ni1/3Co1/3Mn1/3)O2 charged to 4.3 V (Reprinted with permission from Ref. [140]. Copyright © 2014 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim). d Self-heating rate as a function of temperature for delithiated NMC electrode samples reacting with electrolytes in accelerating rate calorimeter experiments (Reprinted with permission from Ref. [8]. Copyright © 2018, American Chemical Society). e Isothermal calorimetry measurements of heat flow of extracted polarization, entropy and parasitic reactions (Reprinted with permission from Ref. [7]. Copyright © The Author(s) 2015. Published by ECS)

Impurities and Organics

Raman spectroscopy can be used to determine the existence of surface impurities that can cause capacity fading such as nickel carbonate, lithium carbonate and nickel hydroxide [35]. Because of this, Raman spectroscopy is a useful tool in the identification of impurities produced during long-term storage (Fig. 3a). Similarly, Fourier transformed infrared spectroscopy (FT-IR) can be used to identify impurities on cathode surfaces [72] or organic coatings [138]. For example, the O–H stretching mode from LiOH possesses a characteristic band between 3650 and 3200 cm−1 in corresponding FT-IR spectra, whereas 1450 and 870 cm−1 are regarded as characteristic peaks of the C=O mode originating from Li2CO3 [61]. Raman spectra of NMC-based cathodes can also be voltage dependent to monitor band shifts of A1g and Eg of Ni, Mn and Co. Moreover, FT-IR and Raman spectroscopy are widely used in the characterization of anodic graphite and SEIs because they can identify substances forming SEI layers such as lithium alkyl carbonates and therefore can reveal reaction mechanisms involved in the SEI formation process and present differences in mechanisms if multiple electrolyte additives are used [139].

3.2.3 Thermal Stability

Differential scanning calorimetry (DSC) is a method that utilizes microcalorimeters to measure heat flow from cells (W g−1) in which the thermal stability of NMC-based cathodes with/without electrolyte contact is recorded to reveal heat flow from the NMC-based cathode as it is heated to a certain temperature [33, 140]. For example, in two NMC-based cathodes and LiNi0.7Mn0.3O2 with a concentration gradient layer, one major peak can be found for each DSC curve centering at a certain temperature in which a higher onset temperature of the DSC peak indicates better thermal stability (Fig. 10b) [126]. In addition, exothermic peaks can be integrated to calculate the amount of heat released, which can translate into the degree to which corresponding reactions occur [99]. Here, the application of common mitigation methods usually results in smaller exothermic peak areas and higher onset temperatures [100]. However, small endothermic peaks can also be seen for some cases, indicating the decomposition of Li salt in the electrolyte [101]. In addition, TG is often combined with DSC to record mass loss during the heating of NMC-based cathodes (Fig. 10c), including processes such as the addition of carbon matrixes to remedy cathode degradation [141] or the release of oxygen due to surface reconstruction [140], or through the loss of surface impurities and adsorbed species [72].

Accelerating rate calorimetry (ARC) is another method adopted by researchers to measure self-heating rates (SHRs) versus temperature [8, 142]. For example, in the comparison of the SHR of 4 types of Ni-rich NMC-based cathodes (Fig. 10d), the onset temperature of a rapidly increasing SHR marks the upper limit of the temperature range for the safe operation of a cell [7] in which cathodes with higher SHR onset temperatures are considered to be better LIB cathodes for industrial applications. Isothermal microcalorimetry (IMC) has also been used to examine heat flow induced by polarization, entropy and parasitic reactions versus the state of charge of NMC811 and has revealed that heat flow originating from parasitic reactions can increase sharply if the relative SOC rises from 0 to 1 at certain voltages (Fig. 10e) [7].

3.2.4 Advanced Physical Characterization

Many advanced physical characterization methods have also been used by researchers to study LIBs. For example, 3D transmission X-ray tomography mapping [92] can be used to determine the distribution of transition metals in NMC particles in which 3D mappings can allow for elemental analysis within cross-sections at different depths. Surface potential mappings of NMC-based cathodes can also be conducted by using Kelvin probe atomic force microscopy (AFM) [143] in which smaller surface potentials can allow for easier electron transfer from cathodes and therefore smaller polarizations. The use of nano-secondary-ion mass spectrometry (nano-SIMS) analysis can provide good spatial resolution (less than 50 nm) for elemental mapping [144]. And with higher resolution, different phases can be identified by comparing the ratios of Mn to Ni along a direction across the particle. In situ neutron powder diffraction (NPD) can also be used to obtain more accurate results of lattice parameters as compared with in situ XRD [145], in which although the energy of neutrons is lower than X-rays, the penetration depth is higher. In situ NPD can also be used to determine the d-spacing of anodic graphite during Li intercalation and therefore the amounts of LiC6, LiC12 and LiC24 [44]. Despite these advantages, researchers have reported that hydrogen-containing species can attenuate neutrons. As for prompt gamma activation analysis (PGAA), this method can be used to quantify the amount of transition metals deposited onto graphite anodes by placing the sample in a neutron beam and collecting signals [26]. The use of PGAA allowed researchers to discover that cycling and high cutoff voltages can promote transition metal deposition onto graphite anodes.

4 Mitigation Strategies for Ni-Rich NMC-Based Cathodes and Graphite Anodes

4.1 Ni-Rich NMC-Based Cathodes

Ni-rich NMC-based cathodes suffer significantly more from capacity loss and impedance growth as compared with low Ni content NMC-based cathodes such as NMC111. This is because large amounts of Ni4+ on cathode surface regions can trigger side reactions and Ni2+ can cause cation mixing. In addition, excessive Li is usually added in the preparation of NMC-based cathodes and tends to accumulate on the surface of particles and react with electrolytes to convert to lithium carbonate and hydroxide. Furthermore, the continuous charging and discharging of these cathodes can cause the cracking of secondary particles.