Abstract

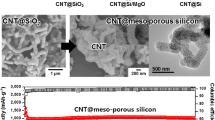

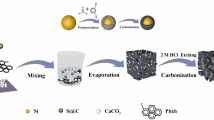

Silicon-based materials has attracted attention as a promising candidate for lithium-ion batteries (LIBs) with high energy density. However, severe volume variation, pulverization, and poor conductivity hindered the development of Si based materials. In this study, porous Si microparticles supported by carbon nanotubes (p-Si/CNT) are fabricated through simple molten salt assisted dealloying process at low temperature followed by acid treatment. The ZnCl2 molten salt not only provides the liquid environment to enhance the reaction, but also participates the dealloying process and works as template for porous structure when removes by acid treatment. Additionally, distribution of defect sites in CNTs also increases after molten salt process. Density function theory (DFT) calculations further prove the defects could improve the adsorption of Li+. The participation of CNTs can also contribute to the reaction kinetics and retain the integrity of the electrode. As expected, the p-Si/CNT anode manifests enhanced lithium-storage performance in terms of superior cycling stability and good rate capability. The p-Si/CNT//LiCoO2 full cell assembly further demonstrates its potential as a prospective anode for high-performance LIBs.

Similar content being viewed by others

References

Liu, J.; Bao, Z. N.; Cui, Y.; Dufek, E. J.; Goodenough, J. B.; Khalifah, P.; Li, Q. Y.; Liaw, B. Y.; Liu, P.; Manthiram, A. et al. Pathways for practical high-energy long-cycling lithium metal batteries. Nat. Energy 2019, 4, 180–186.

Zu, C. X.; Yu, H. G.; Li, H. Enabling the thermal stability of solid electrolyte interphase in Li-ion battery. InfoMat 2021, 3, 648–661.

Parekh, M. H.; Parikh, V. P.; Kim, P. J.; Misra, S.; Qi, Z. M.; Wang, H. Y.; Pol, V. G. Encapsulation and networking of silicon nanoparticles using amorphous carbon and graphite for high performance Li-ion batteries. Carbon 2019, 148, 36–43.

Zhang, Q. L.; Xi, B. J.; Xiong, S. L.; Qian, Y. T. Carbon coated SiO nanoparticles embedded in hierarchical porous N-doped carbon nanosheets for enhanced lithium storage. Inorg. Chem. Front. 2021, 8, 4282–4290.

Wang, L. B.; Lin, N.; Zhou, J. B.; Zhu, Y. C.; Qian, Y. T. Silicon nanoparticles obtained via a low temperature chemical “metathesis” synthesis route and their lithium-ion battery properties. Chem. Commun. 2015, 51, 2345–2348.

Zhou, J. B.; Liu, X. Y.; Cai, W. L.; Zhu, Y. C.; Liang, J. W.; Zhang, K. L.; Lan, Y.; Jiang, Z. H.; Wang, G. M.; Qian, Y. T. Wet-chemical synthesis of hollow red-phosphorus nanospheres with porous shells as anodes for high-performance lithium-ion and sodium-ion batteries. Adv. Mater. 2017, 29, 1700214.

Zhang, S. J.; Liu, C.; Wang, H. L.; Wang, H. P.; Sun, J. T.; Zhang, Y. M.; Han, X. P.; Cao, Y.; Liu, S.; Sun, J. A covalent P-C bond stabilizes red phosphorus in an engineered carbon host for high-performance lithium-ion battery anodes. ACS Nano 2021, 15, 3365–3375.

Liu, X. Y.; Zhang, L.; Liu, Z.; Zheng, Y. P.; Zhao, Y.; Yang, Y. C.; Zhang, Q. L.; Li, S. Y. Alkaliphilic Cu(OH)2 nanowires on copper foam for dendrite-free alkali metal anodes. J. Alloys Compd. 2022, 898, 162815.

Wei, C. L.; Fei, H. F.; An, Y. L.; Tao, Y.; Feng, J. K.; Qian, Y. T. Uniform Li deposition by regulating the initial nucleation barrier via a simple liquid-metal coating for a dendrite-free Li-metal anode. J. Mater. Chem. A 2019, 7, 18861–18870.

Feng, X. Y.; Wu, H. H.; Gao, B.; Świętosławski, M.; He, X.; Zhang, Q. B. Lithiophilic N-doped carbon bowls induced Li deposition in layered graphene film for advanced lithium metal batteries. Nano Res. 2022, 15, 352–360.

Sun, Y. M.; Liu, N.; Cui, Y. Promises and challenges of nanomaterials for lithium-based rechargeable batteries. Nat. Energy 2016, 1, 16071.

Hou, G. L.; Cheng, B. L.; Yang, Y. J.; Du, Y.; Zhang, Y. H.; Li, B. Q.; He, J. P.; Zhou, Y. Z.; Yi, D.; Zhao, N. N. et al. Multiscale buffering engineering in silicon-carbon anode for ultrastable Li-ion storage. ACS Nano 2019, 13, 10179–10190.

Chen, M.; Zhou, Q. N.; Zai, J. T.; Iqbal, A.; Tsega, T.; Dong, B. X.; Liu, X. J.; Zhang, Y. C.; Yan, C. Y.; Zhao, L. et al. High power and stable P-doped yolk-shell structured Si@C anode simultaneously enhancing conductivity and Li+ diffusion kinetics. Nano Res. 2021, 14, 1004–1011.

Han, Y.; Zhou, J.; Li, T. Q.; Yi, Z.; Lin, N.; Qian, Y. T. Molten-salt chemical exfoliation process for preparing two-dimensional mesoporous Si nanosheets as high-rate Li-storage anode. Nano Res. 2018, 11, 6294–6303.

Zhao, Y. M.; Yue, F. S.; Li, S. C.; Zhang, Y.; Tian, Z. R.; Xu, Q.; Xin, S.; Guo, Y. G. Advances of polymer binders for silicon-based anodes in high energy density lithium-ion batteries. InfoMat 2021, 3, 460–501.

Tian, Y.; An, Y. L.; Feng, J. K. Flexible and freestanding silicon/MXene composite papers for high-performance lithium-ion batteries. ACS Appl. Mater. Interfaces 2019, 11, 10004–10011.

Lin, N.; Han, Y.; Zhou, J.; Zhang, K. L.; Xu, T. J.; Zhu, Y. C.; Qian, Y. T. A low temperature molten salt process for aluminothermic reduction of silicon oxides to crystalline Si for Li-ion batteries. Energy Environ. Sci. 2015, 8, 3187–3191.

Zong, L. Q.; Zhu, B.; Lu, Z. D.; Tan, Y. L.; Jin, Y.; Liu, N.; Hu, Y.; Gu, S.; Zhu, J.; Cui, Y. Nanopurification of silicon from 84% to 99. 999% purity with a simple and scalable process. Proc. Natl. Acad. Sci. USA 2015, 112, 13473–13477.

Yi, Z.; Qian, Y.; Cao, C. H.; Lin, N.; Qian, Y. T. Porous Si/C microspheres decorated with stable outer carbon interphase and inner interpenetrated Si@C channels for enhanced lithium storage. Carbon 2019, 149, 664–671.

Sohn, M.; Lee, D. G.; Park, H. I.; Park, C.; Choi, J. H.; Kim, H. Microstructure controlled porous silicon particles as a high capacity lithium storage material via dual step pore engineering. Adv. Funct. Mater. 2018, 28, 1800855.

Ge, M. Y.; Lu, Y. H.; Ercius, P.; Rong, J. P.; Fang, X.; Mecklenburg, M.; Zhou, C. W. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon. Nano Lett. 2014, 14, 261–268.

An, W. L.; Gao, B.; Mei, S. X.; Xiang, B.; Fu, J. J.; Wang, L.; Zhang, Q. B.; Chu, P. K.; Huo, K. F. Scalable synthesis of ant-nestlike bulk porous silicon for high-performance lithium-ion battery anodes. Nat. Commun. 2019, 10, 1447.

Zhai, W.; Ai, Q.; Chen, L. N.; Wei, S. Y.; Li, D. P.; Zhang, L.; Si, P. C.; Feng, J. K.; Ci, L. J. Walnut-inspired microsized porous silicon/graphene core-shell composites for high-performance lithiumion battery anodes. Nano Res. 2017, 10, 4274–4283.

Yi, Z.; Lin, N.; Xu, T. J.; Qian, Y. T. TiO2 coated Si/C interconnected microsphere with stable framework and interface for high-rate lithium storage. Chem. Eng. J. 2018, 347, 214–222.

An, Y. L.; Tian, Y.; Wei, H.; Xi, B. J.; Xiong, S. L.; Feng, J. K.; Qian, Y. T. Porosity- and graphitization-controlled fabrication of nanoporous silicon@carbon for lithium storage and its conjugation with MXene for lithium-metal anode. Adv. Funct. Mater. 2020, 30, 1908721.

Chae, S.; Xu, Y. B.; Yi, R.; Lim, H. S.; Velickovic, D.; Li, X. L.; Li, Q. Y.; Wang, C. M.; Zhang, J. G. A micrometer-sized silicon/carbon composite anode synthesized by impregnation of petroleum pitch in nanoporous silicon. Adv. Mater. 2021, 33, 2103095.

Huang, Y. H.; Luo, J.; Peng, J.; Shi, M. H.; Li, X. X.; Wang, X. Y.; Chang, B. B. Porous silicon-graphene-carbon composite as high performance anode material for lithium ion batteries. J. Energy Storage 2020, 27, 101075.

Zhou, W. Y.; Lian, Q. H.; Huang, X. K.; Ding, W. Q.; Jiang, C. H.; Zou, Z. M.; Su, X. D. Introducing SiC/C dual-interface on porous silicon anode by a conventional exothermic displacement reaction for improved cycle performance. J. Power Sources 2021, 508, 230326.

Salvetat, J. P.; Bonard, J. M.; Thomson, N. H.; Kulik, A. J.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260.

Zeng, Y. F.; Huang, Y. D.; Liu, N. T.; Wang, X. C.; Zhang, Y.; Guo, Y.; Wu, H. H.; Chen, H. X.; Tang, X. C.; Zhang, Q. B. N-doped porous carbon nanofibers sheathed pumpkin-like Si/C composites as free-standing anodes for lithium-ion batteries. J. Energy Chem. 2021, 54, 727–735.

Liang, J. W.; Li, X. N.; Hou, Z. G.; Guo, C.; Zhu, Y. C.; Qian, Y. T. Nanoporous silicon prepared through air-oxidation demagnesiation of Mg2Si and properties of its lithium ion batteries. Chem. Commun. 2015, 51, 7230–7233.

Kresse, G.; Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 1996, 6, 15–50.

Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186.

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953–17979.

Perdew, J. P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865–3868.

Monkhorst, H. J.; Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188–5192.

Peng, X. D.; Xiong, C.; Lin, Y. K.; Zhao, C.; Zhao, T. S. Honeycomb-like hierarchical porous silicon composites with dual protection for ultrastable Li-ion battery anodes. SmartMat 2021, 2, 579–590.

Acres, R. G.; Ellis, A. V.; Alvino, J.; Lenahan, C. E.; Khodakov, D. A.; Metha, G. F.; Andersson, G. G. Molecular structure of 3-aminopropyltriethoxysilane layers formed on silanol-terminated silicon surfaces. J. Phys. Chem. C 2012, 116, 6289–6297.

Xu, K. Q.; Ben, L. B.; Li, H.; Huang, X. J. Silicon-based nanosheets synthesized by a topochemical reaction for use as anodes for lithium ion batteries. Nano Res. 2015, 8, 2654–2662.

Yuan, Y.; Chen, Z. W.; Yu, H. X.; Zhang, X. K.; Liu, T. T.; Xia, M. T.; Zheng, R. T.; Shui, M.; Shu, J. Heteroatom-doped carbon-based materials for lithium and sodium ion batteries. Energy Storage Mater. 2020, 32, 65–90.

Yang, Z. X.; Du, Y.; Hou, G. L.; Ouyang, Y. G.; Ding, F.; Yuan, F. L. Nanoporous silicon spheres preparation via a controllable magnesiothermic reduction as anode for Li-ion batteries. Electrochim. Acta 2020, 329, 135141.

An, Y. L.; Fei, H. F.; Zeng, G. F.; Ci, L. J.; Xiong, S. L.; Feng, J. K.; Qian, Y. T. Green, scalable, and controllable fabrication of nanoporous silicon from commercial alloy precursors for high-energy lithium-ion batteries. ACS Nano 2018, 12, 4993–5002.

Li, X. L.; Gu, M.; Hu, S. Y.; Kennard, R.; Yan, P. F.; Chen, X. L.; Wang, C. M.; Sailor, M. J.; Zhang, J. G.; Liu, J. Mesoporous silicon sponge as an anti-pulverization structure for high-performance lithium-ion battery anodes. Nat. Commun. 2014, 5, 4105.

Simon, P.; Gogotsi, Y.; Dunn, B. Where do batteries end and supercapacitors begin? Science 2014, 343, 1210–1211.

Pan, K.; Zou, F.; Canova, M.; Zhu, Y.; Kim, J. H. Systematic electrochemical characterizations of Si and SiO anodes for high-capacity Li-Ion batteries. J. Power Sources 2019, 413, 20–28.

Suh, S.; Choi, H.; Eom, K.; Kim, H. J. Enhancing the electrochemical properties of a Si anode by introducing cobalt metal as a conductive buffer for lithium-ion batteries. J. Alloys Compd. 2020, 827, 154102.

Zhang, H.; Zong, P.; Chen, M.; Jin, H.; Bai, Y.; Li, S. W.; Ma, F.; Xu, H.; Lian, K. In situ synthesis of multilayer carbon matrix decorated with copper particles: Enhancing the performance of Si as anode for Li-ion batteries. ACS Nano 2019, 13, 3054–3062.

Cai, W. L.; Song, Y. Z.; Fang, Y. T.; Wang, W. W.; Yu, S. L.; Ao, H. S.; Zhu, Y. C.; Qian, Y. T. Defect engineering on carbon black for accelerated Li-S chemistry. Nano Res. 2020, 13, 3315–3320.

Fan, X. F.; Zheng, W. T.; Kuo, J. L. Adsorption and diffusion of Li on pristine and defective graphene. ACS Appl. Mater. Interfaces 2012, 4, 2432–2438.

Zheng, J. M.; Ren, Z. Y.; Guo, P.; Fang, L.; Fan, J. Diffusion of Li+ ion on graphene: A DFT study. Appl. Surf. Sci. 2011, 258, 1651–1655.

Acknowledgements

The authors gratefully acknowledge the financial supports provided by the National Natural Science Foundation of China (Nos. U21A2077, 21971145, and 21871164), the Taishan Scholar Project Foundation of Shandong Province (No. ts20190908), the Natural Science Foundation of Shandong Province (Nos. ZR2021ZD05 and ZR2019MB024), and Young Scholars Program of Shandong University (No. 2017WLJH15).

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

12274_2022_4275_MOESM1_ESM.pdf

Synthesis of carbon nanotubes-supported porous silicon microparticles in low-temperature molten salt for high-performance Li-ion battery anodes

Rights and permissions

About this article

Cite this article

Zhang, Q., Xi, B., Chen, W. et al. Synthesis of carbon nanotubes-supported porous silicon microparticles in low-temperature molten salt for high-performance Li-ion battery anodes. Nano Res. 15, 6184–6191 (2022). https://doi.org/10.1007/s12274-022-4275-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-022-4275-9