Abstract

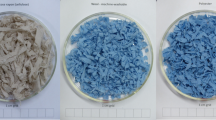

The paper discusses experimental techniques for pulping, bleaching, and creating manmade fibers based on Na-sulfite and Mg-bisulfite dissolving pulps utilizing a dry-jet wet spinning procedure with solutions in N-methylmorpholine-N-oxide. After pulping, Mg-bisulfite pulp had a cellulose yield of 46.1% and Na-sulfite pulp of 44.0%. For Na-sulfite and Mg-bisulfite pulps, the Kappa number was 14.1 and 15.6 units, respectively. According to TCF technology, the overall yield of the semi-finished product after bleaching was 33.5% for Na-sulfite pulp and 36.4% for Mg-bisulfite pulp. For Na-sulfite and Mg-bisulfite pulps, the α-cellulose content was 92% and 91%, respectively. Spinning solutions of various concentrations were obtained from the resulting cellulose, and their rheological behavior was determined. The fibers were spun using the dry-jet wet spinning technique from 14% cellulose solutions, and their morphology and structure were examined. The fibers’ revealed mechanical properties are superior to viscose fibers and on par with those of commercial Lyocell fiber analogs.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included within the article.

References

L. Alves, A. Ramos, E. Ferraz et al., Cellulose (2023). https://doi.org/10.1007/s10570-023-05495-z

A. Patti, D. Acierno, Polymers 14, 692 (2022). https://doi.org/10.3390/polym14040692

O.V. Ingruber, M.J. Kocurek, A. Wong. Pulp and Paper Manufacturing: Vol. 4. Sulfite Science & Technology, 3rd ed. (The Joint Textbook Committee of the Paper Industry, USA, 1985)

D. Mboowa1. Biomass Conversion and Biorefinery (2021) https://doi.org/10.1007/s13399-020-01243-6

Ek.M. Gellerstedt, G. Henriksson. Pulp and Paper Chemistry and Technology Vol. 1. (Walter de Gruyter GmbH & Co, Berlin, 2009) p. 308.

P. Niemz, A. Teischinger, D. Sandberg. Springer Handbook of Wood Science and Technology (Springer Nature, Switzerland AG, 2023) p.2069 https://doi.org/10.1007/978-3-030-81315-4

GOST 5982–84. Sulfite viscose cellulose. Specifications (1998)

C.W. Dence, D.W. Reeve, Pulp Bleaching: Principles and Practice (Tappi Press, USA, 1996), p.880

M. Miri, A. Ghasemian, H. Resalati, F. Zeinaly. International Journal of Carbohydrate Chemistry 1–8 (2015) https://doi.org/10.1155/2015/381242

R. Yudianti, A. Syampurwadi, H. Onggo, M. Karina, H. Uyama, J. Azuma. Polym. Advan. Technol 27, 1102–1107 (2016). https://doi.org/10.1002/pat.3782

M.M. Iovleva, Fibre Chem. 28, 61–64 (1996). https://doi.org/10.1007/BF01058275

X. Lu, X. Shen, Carbohyd. Polym.. Polym. 86(1), 239–244 (2011). https://doi.org/10.1016/j.carbpol.2011.04.042

S. Liu, L. Zhang, Cellulose 16(2), 189–198 (2009). https://doi.org/10.1007/s10570-008-9268-7

D. Majumdar, A. Bhanarkar, C. Rao, D. Gouda, Atmospheric Environment: X 13, 100157 (2022). https://doi.org/10.1016/j.aeaoa.2022.100157

I.I. Ponomarev, I.Y. Skvortsov, Y.A. Volkova, I.I. Ponomarev, L.A. Varfolomeeva, D.Y. Razorenov, K.M. Skupov, M.S. Kuzin, O.A. Materials, 12 (21), 3490- (2019) DOI: https://doi.org/10.3390/ma12213490

M.S. Kuzin, I.Y. Skvortsov, P.S. Gerasimenko, A.V. Subbotin, A.Y. Malkin, J. Mol. Liq. 392(2), 123516 (2023). https://doi.org/10.1016/j.molliq.2023.123516

I.Y. Skvortsov, A.D. Kalugina, E.G. Litvinova, A.Y. Malkin, V.S. Khotimskiy, V.G. Kulichikhin, J. Appl. Polym. Sci.Polym. Sci. 137(13), 48511 (2020). https://doi.org/10.1002/app.48511

H. Shen, T. Sun, J. Zhou. Macromol. Mater. Eng. 308, 2300089 (2023). https://doi.org/10.1002/mame.202300089

B. Azimi, H. Maleki, V. Gigante, R. Bagherzadeh, A. Mezzetta, M. Milazzo, L. Guazzelli, P. Cinelli, A. Lazzeri, S. Danti, Cellulose 29, 3079–3129 (2022). https://doi.org/10.1007/s10570-022-04473-1

S. Janjic, M. Kostic, P. Skundric, Journal of Natural Fibers 4(3), 23–36 (2007). https://doi.org/10.1300/j395v04n03_02

H. Zhang, Z.G. Wang, Z.N. Zhang, J. Wu, J. Zhang, J.S. He, Adv. Mater. 19, 698 (2007)

I.S. Makarov, L.K. Golova, M.I. Vinogradov, Yu.E. Egorov, V.G. Kulichikhin, Yu.M. Mikhailov, Russ. J. Gen. Chem. 91, 1807–1815 (2021). https://doi.org/10.1134/S1070363221090280

L.K. Golova, Rus. J. Gen. Chem. 46, 49–57 (2002)

L.K. Golova, Fibre Chem. 28(1), 5–16 (1996). https://doi.org/10.1007/BF01130691

L. Golova, V. Romanov, O. Balashova. Method for Producing a Solution for Spinning Fibers (RF Patent 1645308, 1992) http://patents.su/3-1645308-sposob-polucheniya-rastvora-dlya-formovaniya-volokon.html (accessed 9 March, 2018)

H.P. Fink, D. Hofmann, B. Philipp, Cellulose 2, 51–70 (1995). https://doi.org/10.1007/BF00812772

W. Gindl, J. Keckes, Polymer 46(23), 10221–10225 (2005). https://doi.org/10.1016/j.polymer.2005.08.040

S. Nomura, Y. Kugo, T. Erata, Cellulose 27, 3553–3563 (2020). https://doi.org/10.1007/s10570-020-03036-6

I.S. Makarov, L.K. Golova, L.K. Kuznetsova, M.V. Mironova, M.I. Vinogradov, M.V. Bermeshev, I.S. Levin, V.G. Kulichikhin, Fibre Chem. 51(1), 26–31 (2019). https://doi.org/10.1007/s10692-019-10041-4

D.L. Kaplan, Biopolymers from Renewable Resources (Springer Science & Business Media, USA, 2013), p.420

I. Dechant, R. Danz, W. Kimmer, R. Schmolke. Infrared spectroscopy of polymers (Translated from German by Arkhan-gelsky, V. Oleynik, E. Ed., Russia, 1976) p. 472.

F. Carrillo, X. Colom, J.J. Sunol, J. Saurina, Eur. Polymer J. 40(9), 2229–2234 (2004). https://doi.org/10.1016/j.eurpolymj.2004.05.003

G. N. Kukin, A. N. Solovyov, A. I. Koblyakov. Textile materials science (fibers and threads): Textbook for universities. 2nd ed., revised. and additional (Legprombytizdat, Russia, 1989) p.352.

I.S. Makarov, G.N. Bondarenko, L.K. Kuznetsova. Phys. Fi-brous Mater. Struct. Prop. High Technol. Mater. Smartex 1, 142–149 (2016)

N. Graupner, F. Sarasini, J. Mussig, Compos. B 194, 108041 (2020). https://doi.org/10.1016/j.compositesb.2020.108041

Funding

This work was carried out within the State Program of TIPS RAS.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sevastyanova, J.V., Makarov, I.S., Potashev, A.V. et al. Modern Technology for the Production of Hydrated Cellulose Fibers. Fibers Polym 25, 913–921 (2024). https://doi.org/10.1007/s12221-024-00485-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-024-00485-9