Abstract

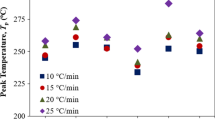

The solidification paths of Al-Zn-Mg-Cu alloys and its precipitation behavior are analyzed using software package JMatPro 6.0 for material property simulation of Al-base alloys. The microstructures of the experimental alloys are analyzed; the experimental results of microstructural analysis are in agreement with the thermodynamic prediction. Through orthogonal experimental method, this paper designs the composition of Al-Zn-Mg-Cu alloys by studying the variation of η (MgZn2) phase, S (Al2CuMg) phase, T (AlZnMgCu) phase amount and precipitation temperatures with different Zn, Mg and Cu contents. It is found that with the optimum mass fraction of Zn of 6.7%, Mg of 2.2%–2.5% and Cu of 1.6%–2.0%, the mass fraction of η phase can be up to 8.7%–9.22% and that of S phase and T phase can be lower than 0.5%.

Similar content being viewed by others

References

Starink M J, Wang S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys [J]. Acta Materialia, 2003, 51(17):5131–5150.

Starink M J, Li X M. A model for the electrical conductivity of peak aged and overaged Al-Zn-Mg-Cu alloys [J]. Metallurgical and Materials Transactions A, 2003, 34A(4):899–911.

Li X M, Starink M J. Identification and analysis of intermetallic phases in overaged Zr-containing and Crcontaining Al-Zn-Mg-Cu alloys [J]. Journal of Alloys and Compounds, 2011, 509(2):471–476.

Guo Z, Saunders N, Miodownik A P, et al. Modelling of materials properties and behaviour critical to casting simulation [J]. Materials Science and Engineering A, 2005, 413–414:465–469.

Saunders N, Guo Z, Li X, et al. Using JMatPro to model materials properties and behavior [J]. Journal of the Minerals, Metals and Materials Society, 2003, 55(12):60–65.

Saunders N, Miodownik A P. CALPHAD-calculation of phase diagrams: A comprehensive guide, pergamon materials series [M]. Oxford: Elsevier, 1998.

Park J K, Ardell A J. Precipitate microstructure of peak-aged 7075 Al [J]. Scripta Metallurgical, 1988, 22(7):1115–1119.

Yu J J, Li X M. Modelling of the precipitated phases and properties of Al-Zn-Mg-Cu alloys [J]. Journal of Phase Equilibria and Diffusion, 2011, 32(4):350–360.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Jj., Li, Xm. & Yu, Xq. Thermodynamic analyse on equilibrium precipitation phases and composition design of Al-Zn-Mg-Cu alloys. J. Shanghai Jiaotong Univ. (Sci.) 17, 286–290 (2012). https://doi.org/10.1007/s12204-012-1270-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-012-1270-4