Abstract

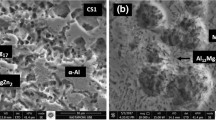

The precipitation and dissolution kinetics of cast and solutionized Al–6.2wt%Cu–0.6wt%Mg alloys microalloyed with varying contents of Sn was investigated. Differential scanning calorimetry (DSC) was performed from 50 to 550 °C at four different heating rates. Exothermic peak within intermediate temperature range of 200–300 °C of DSC heating cycle represented the precipitation reaction. Endothermic drift at elevated temperatures corresponded to melting of alloy phases. Peak temperatures increased with increase in heating rate, indicating precipitation reaction to be kinetically controlled. The kinetic rate equation governing exothermic precipitation peaks was modelled using a new analytical technique. Activation energy and kinetic parameters were determined for the alloys, and effect of Sn concentrations was investigated. Functional forms of mole fraction transformed were optimized. Predicted transformation rate calculated using the kinetic rate equation and evaluated kinetic parameters, was successfully compared with experimental data with fairly good accuracy. To identify possible precipitating crystalline phase(s), X-ray diffraction (XRD) analysis was performed on age-hardened alloys. DSC and XRD results were further corelated with microstructural characterization of morphology and composition of different phases, as studied by SEM and EDS analysis. Microalloying with Sn up to 0.06 wt% was observed to kinetically favor the precipitation reaction, as evident from increased growth in θ-crystal size, increased volume fraction of microstructural θ-phase, decrease in peak temperature and lower values of activation energy. Trace additions of Sn revealed considerable potential to control precipitation kinetics, activation energy, precipitating phases, and respective microstructural evolution of the investigated Al–Cu–Mg alloy system.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not Applicable.

References

Elagin VI (2007) Ways of developing high-strength and high-temperature structural aluminium alloys in the 21st century. Met Sci Heat Treat 49:427–434

Ron C, Alcan C, Banbury C (1994) Aluminum: physical properties, characteristics and alloys. Euro. Alum. Asst., pp 1–60

Rambabu P, Prasad NE, Kutumbarao VV, Wanhill RJH (2017) Aluminium alloys for aerospace applications. Aerospace Mater Mater Technologies 1:29–52

ASM Handbook Committee, Metals Handbook Properties and Selection: Non-Ferrous Alloys and Special Purpose Materials (1990) 2nd edn. ASM International, pp 507–563

Banerjee S, Robi PS, Srinivasan A, Lakavath PK (2010) Effect of trace additions of Sn on microstructure and mechanical properties of Al-Cu-Mg alloys. Mater Des 31:4007–4015

Miao WF, Laughlin DE (2000) Effects of Cu content and presaging on precipitation characteristics in aluminium alloy 6022. Metal Mater Trans A 31:361–371

Wilm A (1906) German patent, Patent no: DRP244554

Hornbogen E (2012) Hundred years of precipitation hardening. J Light Met 1:127–132

Callister WD (1997) Material science and engineering: an introduction, 4th edn. Wiley, New York, pp 211–215

Unlu N, Gable BM, Shiflet GJ, Starke EA (1990) The effect of cold work on the precipitation of Ω and θ’ in a ternary Al-Cu-Mg alloy. Metall Mater Trans A 24:307

Chakrabarti DJ, Cheong BK, Laughlin DE (1998) Precipitation strengthening of aluminium alloys AA6111 Auto. Alloys II:27–44

Reich L, Ringer SP, Hono K (1999) Origin of the initial rapid age-hardening in an Al-1.7at.%Mg-1.1at.% Cu alloy. Philos Mag Lett A 79:639–644

Gaber A, Gaffar MA, Mostafa MS, Zeid EFA (2007) Precipitation kinetics of Al–1.12 Mg2Si–0.35 Si and Al–1.07 Mg2Si–0.33 Cu alloys. J Alloys Compd 429:167–175

Gupta AK, Lloyd DJ (1999) Study of precipitation kinetics in a super puity A1-0.8 Pct Mg-0.9 Pct Si alloy using differential scanning calorimetry. Metall Mater Trans A 30A:879

Luo A, Lloyd DJ, Gupta A, Youdelis WV (1993) Precipitation and dissolution kinetics in Al-Li-Cu-Mg alloy 8090. Acta Metall Mater 41:769–776

Hutchinson CR, Ringer SP (2000) Precipitation processes in Al-Cu-Mg alloys microalloyed with Si. Metall Mater Trans A 31:2721–2723

Bassani P, Gariboldi E, Ripamonti D (2008) Thermal analysis of Al-Cu-Mg-Si alloy with Ag/Zr additions. J Therm Anal Calorim 91:29–35

Papazian JM (1981) Calorimetric studies of precipitation and dissolution kinetics in aluminum alloys 2219 and 7075. Metall Trans A 12:269

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702

Donoso E (1985) Calorimetric study of the dissolution of Guinier-Preston zones and η′ phase in Al-4.5at.%Zn-1.75at.%Mg. Mater Sci Eng 74:39

Varschavsky A, Donoso E (1983) Non-isothermal short-range-order kinetics of binary alloys as influenced by solute-vacancy complexes. Thermochim Acta 69:341

Johnson WA, Mehl KF (1939) Calorimetric study of precipitation kinetics of Al-Cu-Mg and Al-Cu-Mg-0.06 wt% Sn alloys. Trans TMS AIME 135:416

Avrami M (1941) Kinetics of phase change I general theory. J Chem Phys 9:177

Clout A, Buanz ABM, Timothy JP, Reinhard C (2016) Anal Chem 88:10111–10117

Raju PN, Rao KS, Reddy GM, Kamaraj M, Rao KP (2007) Microstructure and high temperature stability of age-hardenable AA2219 aluminium alloy modified by Sc, Mg and Zr additions. Mater Sci Eng A 464:192–201

Miao LX, Lin PQ, Ge LC, Bin HY, Bin LW, Jie LW (2009) Microstructure and mechanical properties of Al-Cu-Mg-Mn-Zr alloy with trace amounts of Ag. Mater Sci Eng A 525:128–132

Vietz JT, Polmear IJ (1966) The influence of small additions of silver on the ageing of aluminium alloys. J Inst Met 94(12):410–418

Li W, Cui S, Han J, Xu C (2006) Effect of silicon on the casting properties of Al-5.0%Cu alloy. Rare Met 25:133–135

Mohamed AMA, Samuel FH, Samuel AM, Doty HW, Valtierra S (2008) Influence of Tin addition on the microstructure and mechanical properties of Al-Si-Cu-Mg and Al-Si-Mg casting alloys. Metall Mater Trans A 39:490–501

Wang J, Yi D, Su X, Yin F (2008) Influence of deformation ageing treatment on microstructure and properties of aluminium alloy 2618. Mater Chart 59:965–968

Miao WF, Laughlin DE (2000) Effects of Cu content and presaging on precipitation characteristics in aluminium alloy 6022. Metall Mater Trans A 31:361–371

Banerjee S (2011) Mechanical properties and high temperature deformation behaviour of Al-Cu-Mg alloys microalloyed with Tin, Doctoral Thesis, IIT Guwahati, Assam, pp 1–176

Maksimovic V, Slavicazec V, Jovanovic MT (2003) The effect of microalloying with silicon and germanium on microstructure and hardness of a commercial aluminium alloy. J Serb Chem Soc 68(11):893–901

Mondolfo LF (1976) Aluminum alloys St. Prop. Butterworths, London

Bhowmick S (2019) DSC and XRD analysis of Al-Cu alloys microalloyed with Cd, M.Tech Thesis, Tezpur University, Assam, pp 1–60

Mandal PK, Robi PS (2018) Influence of microalloying with silver on microstructure and mechanical properties of Al-Cu alloy. Mater Sci Eng A 722:99–111

Gogoi S (2017) Effect of rolling and age-hardening on the mechanical properties of microalloyed 2219Al alloy, M.Tech Thesis, Tezpur University, Assam, pp 1–176

Banerjee S, Robi PS, Srinivasan A, Lakavath PK (2010) High temperature deformation behaviour of Al–Cu–Mg alloys micro alloyed with Sn. Mater Sci Eng A 527:2498

Banerjee S, Robi PS, Srinivasan A (2012) Prediction of hot deformation behavior of Al–59%Cu–05%Mg alloys with trace additions of Sn. J Mater Sci 47(2):929

Banerjee S, Robi PS, Srinivasan A (2012) Deformation processing maps for control of microstructure in Al-Cu-Mg alloys microalloyed with Sn. Metall Mater Trans A 43A:3834

Banerjee S, Bhadra R, Gogoi S, Dutta RS (2020) Investigating weldability in microalloyed Al alloys. In: Biswal BB et al (eds) Adv. Mech. Eng., p. 271

Banerjee S, Gogoi S (2016) Influence of trace addition of CD on the hardness and impact properties of 2219 Al alloy. J Basis Appl Eng Research (JBAER) 3(13):1202

Sercombe TB, Schaffer GB (1999) On the use of trace additions of Sn to enhance sintered 2xxx series Al powder alloys. Mater Sci Eng A 268:32–39

Silcock JM, Flower HM (2002) Comments on a comparison of early and recent work on the effect of trace additions of Cd, In, or Sn on the nucleation and growth of θ’ in Al-Cu alloys. Scr Mater 46:389–394

Ringer SP, Raviprasad K (2000) Effects of microalloying with Sn on the precipitation process of Al-3.5Cu-0.4Mg (wt%) alloys. Mater Forum 24:59–63

Polmear IJ, Hardy HK (1952) Some metallographic observations on aged aluminium-copper alloys. J Inst Met 81:427–430

Hardy HK (1951) The ageing characteristics of ternary aluminium-copper alloys with cadmium, indium or tin. J Inst Met 80:483–492

Hirosawa S, Sato T, Kamio A, Flower HM (2000) Classification of the role of microalloying elements in phase decomposition of Al based alloys. Acta Mater 48:1797–1806

Acknowledgements

The authors are thankful to the Department of Mechanical Engineering and Department of Physics, Indian Institute of Technology (IIT) Guwahati, for the useful assistance in various experimental procedures. Authors further express their gratitude to the Department of Physics and Sophisticated Analytical Instrumentation Centre (SAIC), Tezpur University, for analyzing XRD results.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Banerjee, S., Robi, P.S., Srinivasan, A. et al. Effect of trace additions of Sn on precipitation kinetics and microstructural phases of Al–Cu–Mg alloys. Reac Kinet Mech Cat 135, 1853–1874 (2022). https://doi.org/10.1007/s11144-022-02234-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02234-6