Abstract

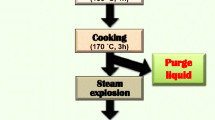

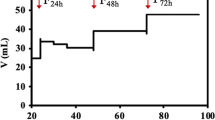

In this study on the valorization of hemicelluloses (a co-product generated during cellulosic bioethanol production), prehydrolyzates obtained from poplar woodchips pretreated in an industrial experimental steam-explosion pilot-plant facility were evaluated for the production of bioxylitol using the yeast, Candida guilliermondii FTI 20037, employing both batch and fed-batch fermentation modes in shake flasks on defined nutrient medium. The prehydrolyzates consisted of monosaccharides (pentose and hexose sugars) as well as xylo-oligosaccharides and undegraded hemicellulose. Xylose (31.6 ± 0.57 g/L) was the major sugar in the prehydrolyzates that also contained acetic acid and degradation products of lignin and sugars (phenolic and furanic compounds). Xylose in the prehydrolyzates could be further increased (106.4 ± 0.02 g/L) through an acid hydrolysis step (0.6 % (w/v) H2SO4). Compounds of a toxic nature in both the acid hydrolyzates and prehydrolyzates were removed by treatment with Amberlite IRA-400 resin (chloride form). Batch fermentation of pure xylose and poplar prehydrolyzate resulted in bioxylitol production of 9.9 ± 0.01 and 4.9 ± 0.17 g/L, respectively, indicating that the poplar prehydrolyzates exhibited an inhibitory effect on fermentation. After detoxification of the poplar prehydrolyzates, bioxylitol production increased to 8.9 ± 0.01 g/L. Fed-batch fermentation of the prehydrolyzate increased the bioxylitol production to 12.39 ± 0.33 g/L, while acid hydrolysis followed by detoxification resulted in a maximum bioxylitol production of 22.0 ± 0.01 g/L, a 348 % increase. The results demonstrated that acid hydrolysis and detoxification followed by fed-batch fermentation was an efficient way to produce bioxylitol from poplar prehydrolyzates.

Similar content being viewed by others

References

Devappa RK, Rakshit SK, Dekker RF (2015) Forest biorefinery: potential of poplar phytochemicals as value-added co-products. Biotechnol Adv 33:681–716

Etchells JP, Mishra LS, Kumar M, Campbell L, Turner SR (2015) Wood formation in trees is increased by manipulating PXY-regulated cell division. Curr Biol 25:1050–1055

Sannigrahi P, Ragauskas AJ, Tuskan GA (2010) Poplar as a feedstock for biofuels: a review of compositional characteristics. Biofuels Bioprod Bioref 4:209–226

Yang B, Wyman CE (2008) Pretreatment: the key to unlocking low cost cellulosic ethanol. Biofuel Bioprod Bioref 2:26–40

Li J, Gellerstedt G, Toven K (2009) Steam explosion lignins; their extraction, structure and potential as feedstock for biodiesel and chemicals. Bioresour Technol 100:2556–2561

Avellar BK, Glasser WG (1998) Steam-assisted biomass fractionation. I. Process considerations and economic evaluation. Biomass Bioenergy 14:205–218

Zheng Y, Zhao J, Xu F, Li Y (2014) Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog Energy Combust Sci 42:35–53

Devappa RK, Rakshit SK, Dekker RF (2015) Potential of poplar bark phytochemicals as value-added co-products from the wood and cellulosic bioethanol industry. Bioenerg Res 8:1235–1251

Vithanage LNG, Barbosa AM, Borsato D, Dekker RFH (2015) Value adding of poplar hemicellulosic prehydrolyzates: laccase production by Botryosphaeria rhodina MAMB-05 and its application in the detoxification of prehydrolyzates. Bioenerg Res 8:657–674

Werpy T, Petersen G (2004) Top value added chemicals from biomass. Volume I: results of screening for potential candidates from sugars and synthesis gas. Pacific Northwest National Laboratory, National Renewable Energy Laboratory, Office of Biomass Program, U.S. Department of Energy (DOE), Oak Ridge, TN (USA)

Rafiqul ISM, Sakinah AMM (2013) Process for the production of xylitol—a review. Food Rev Int 29:127–156

Biocore-Europe Site. Technical note on pentose sugars and their applications. http://www.biocore-europe.org/file/131220_Biocore_TN%2302_BD.pdf. Accessed 12 January 2015

de Albuquerque TL, da Silva Jr IJ, de Macedo GR (2014) Biotechnological production of xylitol from lignocellulosic wastes: a review. Process Biochem 49:1779–1789

Continuum Clean Energy Innovation at NREL. At $2.15 a gallon, cellulosic ethanol could be cost competitive.http://www.nrel.gov/continuum/sustainable_transportation/cellulosic_ethanol.cfm Accessed 12 March 2015

Mikkola JP, Vainio H, Salmi T, Sjöholm R, Ollonqvist T, Väyrynen J (2000) Deactivation kinetics of Mo-supported raney Ni catalyst in the hydrogenation of xylose to xylitol. Appl Catal A Gen 196:143–155

da Cunha MAA, Converti A, Santos JC, Ferreira STS, da Silva SS (2009) PVA-hydrolgel entrapped Candida guilliermondii for xylitol production from sugarcane hemicellulose hydrolysate. Appl Biochem Biotechnol 157:527–537

Zhuang J, Liu Y, Wu Z, Sun Y, Lin L (2009) Hydrolysis of wheat straw hemicellulose and detoxification of the hydrolysate for xylitol Production. Bioresources 4:674–686

Barbosa MFS, de Medeiros MB, de Mancilha IM, Schneider H, Lee H (1988) Screening of yeasts for production of xylitol from D-xylose and some factors which affect xylitol yield in Candida guilliermondii. J Ind Microbiol 3:241–251

El Baz AF, Shetaia YM, Elkhouli RR (2011) Kinetic behavior of Candida tropicals during xylitol production using semi-synthetic and hydrolysate based media. Afr J Biotechnol 10:16617–16625

Sirisansaneeyakul S, Wannawilai S, Chisti Y (2012) Repeated fed-batch production of xylitol by Candida magnoliae TISTR 5663. J Chem Biotechnol 88:1121–1129

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74:17–24

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Panagiotou G, Olsson L (2007) Effect of compounds released during pretreatment of wheat straw on microbial growth and enzymatic hydrolysis rates. Biotechnol Bioeng 96:250–258

Huang CF, Jiang YF, Guo GL, Hwang WS (2011) Development of a yeast strain for xylitol production without hydrolysate detoxification as part of the integration of co-product generation within the lignocellulosic ethanol process. Bioresour Technol 102:3322–3329

Kelly C, Jones O, Barnhart C, Lajoie C (2008) Effect of furfural, vanillin and syringaldehyde on Candida guilliermondii growth and xylitol biosynthesis. Appl Biochem Biotechnol 148:97–108

Mussatto SI, Santos JC, Roberto IC (2004) Effect of pH and activated charcoal adsorption on hemicellulosic hydrolysate detoxification for xylitol production. J Chem Technol Biotechnol 79:590–596

Marton JM, Felipe MGA, Silva JBA, Júnior AP (2006) Evaluation of the activated charcoals and adsorption conditions used in the treatment of sugarcane bagasse hydrolysate for xylitol production. Braz J Chem Eng 23:9–21

Moreno AD, Ibarra D, Fernández JL, Ballesteros M (2012) Different Laccase Detoxification strategies for ethanol production from lignocellulosic biomass by the thermotolerant yeast Kluyveromyces marxianus CECT 10875. Bioresour Technol 106:101–109

Li M, Meng X, Diao E, Du F (2012) Xylitol production by Candida tropicalis from corn cob hemicelluose hydrolysate in a two-stage fed-batch fermentation process. J Chem Technol Biotechnol 87:387–392

Payne R, Edmonds M (2005) Isolation of shikimic acid from star aniseed. J Chem Educ 82:599

Vogel HJ (1956) A convenient growth medium for Neurospora crassa (Medium N). Microbial Genet Bull 13:42–43

Gullón P, González-Muńoz MJ, van Gool MP, Schols HA, Hirsch J, Ebringerová, Parajó JC (2010) Production, refining, structural characterization and fermentability of rice husk xylooligosaccharides. J Agric Food Chem 58:3632–3641

Deutschmann R, Dekker RFH (2012) From plant biomass to bio-based chemicals: latest developments in xylan research. Biotechnol Adv 30:1627–1640

Villarreal MLM, Prata AMR, Felipe MGA, Almeida E, Silva JB (2006) Detoxification procedures of eucalyptus hemicellulose hydrolysate for xylitol production by Candida guilliermondii. Enzym Microb Technol 40:17–24

Arruda PV, Felipe MGA (2009) Role of glycerol addition on xylose-to-xylitol bioconversion by Candida guilliermondii. Curr Microbiol 58:274–278

Pereira RS, Mussatto SI, Roberto IC (2011) Inhibitory action of toxic compounds present in lignocellulosic hydrolysates on xylose to xylitol bioconversion by Candida guilliermondii. J Ind Microbiol Biotechnol 38:71–78

Ling H, Cheng K, Ge J, Ping W (2011) Statistical optimization of xylitol production from corncob hemicellulose hydrolysate by Candida tropicalis HDY-02. Nat Biotechnol 28:673–678

Yang F, Hanna MA, Sun R (2012) Value-added uses for crude glycerol—a byproduct of biodiesel production. Biotechnol Biofuels 5:13

Rodrigues RCB, Felipe MGA, Roberto IC, Vitolo M (2003) Batch xylitol production by Candida guilliermondii FTI 20037 from sugarcane bagasse hemicellulosic hydrolyzate at controlled pH values. Bioprocess Biosyst Eng 26:103–107

Mussatto SI, Dragone G, Roberto IC (2005) Kinetic behavior of Candida guilliermondii yeast during xylitol production from brewer’s spent grain hemicellulosic hydrolysate. Biotechnol Prog 21:1352–1356

Mussatto SI, Roberto IC (2003) Xylitol production from high xylose concentration: evaluation of the fermentation in bioreactor under different stirring rates. J Appl Microbiol 95:331–337

Boussarsar H, Rogé B, Mathlouthi M (2009) Optimization of sugarcane baggase conversion by hydrothermal treatment for the recovery of xylose. Bioresour Technol 100:6537–6542

Wang L, Yang M, Fan, X, Zhu X, Xu T, Yuan Q (2011) An environmentally friendly and efficient method for xylitol bioconversion with high-temperature-steaming hydrolysate by adapted Candia tropicalis 46:1619-1626

Rivas B, Domínguez JM, Domínguez H, Pararjó JC (2002) Bioconversion of posthydrolysed autohydrolysis liquors: an alternative for xylitol production from corn cobs. Enzym Microb Technol 31:431–438

Felipe MGA, Veira MV, Vitolo M, Mancilha IM, Roberto IC, Silva SS (1995) Effect of acetic acid on xylose fermentation to xylitol by Candida guilliermondii. J Basic Microbiol 35:171–177

Trin LTP, Kundu C, Lee J-W, Lee H-J (2014) An integrated detoxification process with electrodialysis and adsorption from the hemicellulose hydrolysates of yellow poplars. Bioresour Technol 161:280–287

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16

Rafiqul ISM, Sakinah AMM, Zularisam AW (2015) Inhibition by toxic compounds in the hemicellulosic hydrolysates on the activity of xylose reductase from Candida tropicalis. Biotechnol Lett 37:191–196

Cortez DV, Roberto IC (2010) Improved xylitol production in media containing phenolic aldehydes: application of response surface methodology for optimization and modeling bioprocess. J Chem Technol Biotechnol 85:33–38

Dominguez JM, Cao NJ, Krishnan MS, Gong CS, Tsao GT (1997) Xylitol production from hybrid poplar wood chips pretreated by the ammonia steeping process. Biotechnol Tech 11:339–341

Cho DH, Lee YJ, Um Y, Sang B-I, Kim YH (2009) Detoxification of model phenolic compounds in lignocellulosic hydrolysates with peroxidase for butanol production from Clostridium beijerinckii. Appl Microbiol Biotechnol 83:1035–1043

Rodrigues DCGA, da Silva SS, Felipe MGA (1999) Fed-batch culture of Candida guilliermondii FTI 20037 for xylitol production from sugar cane bagasse hydrolysate. Lett Appl Microbiol 29:359–363

Bura R, Vajzovic A, Doty SL (2012) Novel endophytic yeast Rhodotorula mucilaginosa strain PTD3 I: production of xylitol and ethanol. J Ind Microbiol Biotechnol 39:1003–1011

Acknowledgments

The authors gratefully acknowledge the financial support from the Centre for Research and Innovation in the Bioeconomy (CRIBE), Ontario, Canada (RFH Dekker). Dr. Regis Benech, Dr. Stephan Brey, and Greg Santavy of Greenfield Engineering and Technology (Research and Development), Chatham, ON (Canada) are thanked for providing the pilot plant-produced poplar prehydrolyzate samples. The authors gratefully acknowledge the technical expertise of Greg Kepka for assistance with the GC-MS analyses. Yue Sun (summer vacation student) and Magali Ferro (intern; Ecole Nationale Supérieure Agronomique de Toulouse, France) are thanked for their experimental contribution toward this work while at the Biorefining Research Institute during May–August 2013.

Conflict of Interest

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vithanage, L.N.G., Barbosa, A.M., Kankanamge, G.R.N. et al. Valorization of Hemicelluloses: Production of Bioxylitol from Poplar Wood Prehydrolyzates by Candida guilliermondii FTI 20037. Bioenerg. Res. 9, 181–197 (2016). https://doi.org/10.1007/s12155-015-9673-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9673-3