Abstract

Little is known about how firms change energy consumption over time. Yet, to meet global climate change targets, understanding how changes in firm investment impact environmental performance is important for policymakers and firms alike. To investigate the environmental performance of firms, we measure the energy consumption and efficiency of firms in the Netherlands’ manufacturing industries before and after large capital expenditures over the 2000 to 2008 period. Unique to this data set is that firm investment is decomposed into the following three streams: investment in buildings only, investment in equipment only, or a simultaneous investment in both buildings and equipment. We find that firms increase energy consumption when experiencing a simultaneous investment. However, after large capital expenditures, energy efficiency increases. Further decomposition by firm types suggests that the building capital investments of firms active in high-tech, energy-intensive, and low labor-intensive industries do not coincide with energy efficiency improvements while energy efficiency does increase with capital expenditures in equipment. From a policy perspective, it is important for regulators to understand firm investment and production processes, which help regulators understand when and where energy efficiency increases are feasible across firm types and expansionary production strategies. Firms, regulators, and other third parties may work together to develop an energy efficiency plan in line with investment strategies, including enhanced transparency by firms, energy efficiency subsidies, and R&D tax credits, for innovation. Targeted agreements may work to cooperatively improve energy performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Firm output in the industrial sector is very energy-intensive. In the US, industrial sector energy consumption in 2010 was 625 million tons of oil equivalent (TOE) or one third of total consumption (US Energy Information Administration 2014). Energy consumption in the EU is approximately 320 million TOE (European Environment Agency 2013). Policymakers have sought to change this energy intensity by incentivizing capital investments towards energy efficiency through stricter building codes and more stringent equipment standards in the industrial sector (Acemoglu et al. 2014; Acemoglu et al. 2009). Early results from Aroonruengsawat et al. (2012) and Jacobsen and Kotchen (2013) document that improvements in residential building codes—that impact new and redevelopment construction—decrease energy consumption by 4 to 6%. Papineau (2013) has shown similar results for commercial buildings. These studies suggest that policymakers could attain environmental goals by shifting energy codes towards a more progressive energy efficiency outcome through stimulating firms to conduct capital investments embodying recent general technological change in energy efficiency.

Firm environmental performance is often measured in the literature and by policymakers by looking at the output of firms across various toxicity-weighted pollutants—carbon, nitrate, and sulfate oxides. Overall, studies find that firms are decreasing their pollution over time (Cole et al. 2005; Earnhart 2004), but there are some sectors in which firms are not achieving the environmental goals (Gamper-Rabindran and Finger 2013). Prior work ascribes improvements in the energy efficiency and broader environmental performance of industrial firms to general capital-embodied technological progress, yet it tends to account for equipment capital investments exclusively (e.g., Lennox and Witajewski-Baltvilks 2017; Sterner 1990). Meanwhile, the literature on energy performance in buildings has documented evidence of increased property value and decreased energy consumption after new building development, but, importantly, these findings are divided from research investigating capital expenditures at the firm level (Eichholtz et al. 2010; Dalton and Fuerst 2018). Given the general omission of building structures at firm-level capital expenditure analysis, we do not know the drivers of energy consumption and whether investments or changes in buildings or equipment can impact the environmental performance of firms; is it equipment, buildings, or some combination of both? Hence, we bridge these two literatures and account for capital expenditures on building structures, equipment, and (or) the simultaneous investment in both. By taking a firm-level view of environmental performance that includes buildings and equipment as production factors, we identify firm-level challenges and capital expenditure areas where technological progress can help meeting environmental performance benchmarks.

To understand firm-level environmental performance, we employ a multi-period event study to measure the following outcomes. First, we investigate how the energy performance of firms active in the energy-intensive industrial sector develops around episodes of unusually large capital investments—so-called investment spikes (Power 1998). Specifically, we compare the energy consumption and energy efficiency of firms before, during, and after investment spikes in buildings or equipment or investment spikes in both capital types simultaneously. As such, the analysis allows us to assess whether and how upgrading the capital stock of industrial firms contribute towards attaining environmental goals concerning energy use and, thus, the emission of greenhouse gasses. Second, we assess how firms’ operational efficiency develops around these same capital investment spikes. By comparing the simultaneous development of firms’ energy performance and of their operational efficiency surrounding capital investment spikes, we investigate if environmental goals conflict with—or rather complement—competitive goals. As such, we add to the literature addressing whether firms are able to combine “lean and green” production techniques (e.g., King and Lenox 2001; Klassen and Whybark 1999; Telle and Larsson 2007).

We begin our analysis by developing a theoretical framework to guide our empirical analysis, which looks at firm investment spikes across time periods and the arbitrary timing in investment spike event patterns across firms to guide our empirical analysis of firm capital expenditures and energy performance. The framework also enables us to understand how energy efficiency is related to productivity of capital, price developments, and a change in production technology. To operationalize this model, we employ a micro-level panel data set provided by the Dutch Statistics (CBS) covering the period 2000–2008. The data set contains information concerning investment in buildings and equipment. In addition, it provides data on production statistics and the energy expenditures of firms. By identifying large capital expenditures, we pinpoint major events at the firm level (Power 1998).

Importantly, we distinguish between expenditures in buildings and equipment. Here, we allow for single expenditure events where the firm only adjusts one type of capital and for a simultaneous expenditure where the firm makes a large investment in both buildings and equipment. The purpose of discriminating between single and simultaneous expenditures is that the latter is more likely to reflect expansionary efforts of the firm whereas the former more likely refers to replacement of depreciated physical capital. Our identification scheme makes it possible to measure how energy performance of the firm behaves surrounding investment events. In addition, we examine firms in all sectors and, then, decompose firms into their innovation, labor, and energy intensities. This is particularly important for understanding and pinpointing problematic general sector trends and direct policy-making in specific sectors.

The main findings of our analysis are that when firms invest in both buildings and equipment simultaneously, energy consumption increases. This result signals that firms engaging in a simultaneous investment are expanding the scale of their operations. Overall, firm energy consumption is increasing with increased production. However, new buildings and new equipment tend to incorporate technology-consuming less energy. Importantly, after investment has taken place, firm energy efficiency improves. However, firm operational efficiency improves when investing in equipment, but it decreases when investing in buildings. In particular, firms operating in energy- and capital-intensive industries and high-tech industries face financial damage when investing in buildings, which is an area where policymakers, engineers, and firms can join to cooperatively identify energy efficiency solutions that are mindful of firm-level production demands, investment strategy, and energy efficiency requirements.

The paper proceeds as follows. In the following section, we provide a theoretical framework for firm capital expenditures that could impact energy performance. Then, we describe the data provided by CBS. In the next section, we explain our estimation strategy. Then, we depict our results for all sectors, provide an industry cluster analysis, analyze operational efficiency, and consider a specific industry. We end with a conclusion and policy recommendations on the link between firm investment, energy performance, and operational performance.

Theoretical framework

In this section, we start with a framework to guide our empirical analysis of firm-level energy consumption and energy performance. The empirical strategy we employ is based on the notion of investment spikes. These represent large capital expenditures. Our aim is to identify such large expenditures as these most likely reflect major retooling or expansionary efforts of firms. In Appendix 1, we present a model explaining the presence of investment lumps. Suppose now that at time t a firm uses two capital inputs—the stock of buildings is given by \( {K}_t^B \) and the stock of equipment is given by \( {K}_t^E \)—to produce a non-storable output. We abstract from labor to ease exposition of the model, without affecting the theoretical insights obtained. The expression \( F\left({A}_t,{K}_t^B,{K}_t^E\right)={p}_t{Y}_t-{p}_t^e{e}_t \) denotes net sales. We assume a Cobb–Douglas production technology with decreasing returns to scale, \( {Y}_t={\phi}_t{\left({K}_t^B\right)}^{\nu }{\left({K}_t^E\right)}^{\mu }{\left({e}_t\right)}^{\kappa } \), where Y, e, and ϕ denote production, energy use, and total factor productivity, respectively. The price of energy is given by \( {p}_t^e \). The structural parameters satisfy 0 < ν, μ, κ < 1. Energy is a fully flexible factor of production. The isoelastic demand function is given by \( {P}_t={\varphi}_t{\left({Y}_t\right)}^{-\frac{1}{\varepsilon }} \), where ε > 1. Then, \( F\left({A}_t,{K}_t^B,{K}_t^E\right)={\varphi}_t{\left({\phi}_t{\left({K}_t^B\right)}^{\nu }{\left({K}_t^E\right)}^{\mu }{\left({e}_t\right)}^{\kappa}\right)}^{1-\frac{1}{\varepsilon }}-{p}_t^e{e}_t \). The term \( {A}_t={\varphi}_t{\phi_t}^{1-\frac{1}{\varepsilon }} \) summarizes randomness in both total factor productivity and demand faced by the firm.

We expect that if at least one of the capital goods is subject to fixed adjustment costs, flexible input factors, like energy, will display a lumpy adjustment pattern as well (Abel and Eberly 1998). With more capital present in the firm, the (expected) marginal profit of energy usage is higher, assuming the production technology has not changed. Hence, the firm is likely to increase energy demand while investing in capital. This can be seen as follows. Assuming energy is a flexible input factor, it is set at the value maximizing \( {p}_t{Y}_t-{p}_t^e{e}_t={\varphi}_t{\left({\phi}_t{\left({K}_t^B\right)}^{\nu }{\left({K}_t^E\right)}^{\mu }{\left({E}_t\right)}^{\kappa}\right)}^{1-\frac{1}{\varepsilon }}-{p}_t^e{e}_t \). The first-order condition is given by

where \( K\left(1-\frac{1}{\varepsilon}\right)=K\left(\frac{\varepsilon -1}{\varepsilon}\right)<1 \). So, with more capital present, energy demand has to increase as well to restore equality of the first-order condition in Eq. (1). As observed previously, with fixed costs present, the model presented in Appendix 1 predicts investment lumps taking place. When capital is adjusted this way, energy demand will follow a very similar pattern accordingly. In our empirical analysis, we investigate the dynamics of energy usage in periods surrounding an investment spike.

Investment may not only affect the scale of a firm’s operations. It may also imply production technology changes when new capital enters the firm (Acemoglu 2015; Dunne et al. 1989; Hémous and Olsen 2013). For instance, upon investment, the parameters v, μ, and κof the Cobb–Douglas production function depicted previously may be altered, which potentially affects the optimal mix of input factors. Using Eq. (1) it is possible to show that

This means that innovation of energy efficiency given by \( \varDelta \ln \left({e}_t/{K}_t^c\right) \) is driven by developments in productivity of capital, \( {Y}_t/{K}_t^c \), price development, \( \varDelta \ln \left({p}_t\right)-\varDelta \ln \left({p}_t^e\right) \), and a change in production technology, Δ ln κ, ceteris paribus. One would expect that governmental efforts to induce firms investing in more energy-efficient buildings and equipment make that the parameter κ in the production function \( {Y}_t={\phi}_t{\left({K}_t^B\right)}^{\nu }{\left({K}_t^E\right)}^{\mu }{\left({e}_t\right)}^{\kappa } \) increases relative to the other two technology parameters ν and μ, implying the firm needs less energy to produce the same amount of output, and, in this case, energy use decreases relative to the use of capital for a given level of output.

We conclude from this discussion that capital investment can impact energy efficiency of a firm by inducing a change in the production technology and a change in the productivity of capital. From this theoretical framework, the empirical analysis will aim at revealing a broad picture of the dynamics of energy efficiency before, during, and after periods where large capital investment takes place.

Data description

The Netherlands is a country that provides a particularly rich data environment for analyzing building code standards. With respect to buildings, according to the Dutch building codes, firms need to comply with energy efficiency standards. In fact, in the last two decades, there were three policy instruments directed at the building sector in the Netherlands. Building codes and regulatory instruments were started in the Energy Performance Standard for Buildings in 1995. Further guidance, educational materials, and subsidies were developed in the Energy Performance advice and the More with Less Program (International Energy Agency 2014). Hence, if a building is redeveloped or developed, it must meet standards that secure energy efficiency improvements.

In regard to equipment, there were four voluntary approach agreements with energy-intensive manufacturers over the same time period. Notably, this includes The Energy Efficiency Benchmarking Covenant in 1999, which was later superseded by the Long-term Agreement on Energy Efficiency for enterprises participating in the EU Emissions Trading System. This covenant aims to enhance manufacturing energy efficiency in equipment (International Energy Agency 2014).

We aim to discern whether new buildings and equipment lead towards cleaner technology. A unique opportunity provided by Statistics Netherlands (CBS) data is that both firm investment and energy consumption data are collected at the firm level. Moreover, the data enables the decomposition of the type of capital investment, e.g., buildings and equipment. CBS collects data on production statistics and investment figures at the firm level on an annual basis. A random selection of all Dutch companies employing less than 50 people is sent questionnaires, and all firms with 50 or more employees receive the survey.Footnote 1 The data sets on production statistics and investments of the manufacturing sector are merged using a firm-specific identifier. We focus on regular firm investment intensity dynamics and not on extreme events, like divestments or mergers. For that reason, we construct a balanced panel. In this way, the panel conservatively controls for firm entry and exit, major (dis)investment decisions like mergers, acquisitions, bankruptcies, and/or geographic relocations. In addition, as we want to employ empirical data, imputed observations are disregarded. We also removed the 1% largest investment ratios to obtain the final data, in order to prevent our findings from being affected by extreme outliers. The panel data set isolates investment behavior for 2000 to 2008. We have chosen to limit our data up until 2008, as from 2009 onwards CBS used another operational definition of the unit of observation. We disregard years prior to 2000 as the balanced nature of the data would imply an additional loss of observations we like to avoid. Our data concern 652 firms, and the total number of firm-year observations equals 5868. This sample is representative of large firms, those with 50 or more employees in the Netherlands, and our data has close to 30% of the large firm sample.Footnote 2

Firms have been found to conduct investment in a lumpy fashion. Rather than smoothing investment over time, micro-level data have revealed that investment by firms is often concentrated in short time episodes. In this study, we will focus on such bursts of capital adjustment as these events represent major retooling or expansionary efforts of firms (Letterie et al. 2010). To investigate micro-level consequences of such events, various studies have proposed a definition of investment spikes. Some have employed an absolute spike definition. In that case, if the investment ratio is larger than an ad hoc value such as 0.2, the observation is referred to as an investment spike (see, for instance, Cooper et al. 1999; Sakellaris 2004). A drawback of the absolute spike definition is that it is not well-suited to capture sporadic bursts of investment. Furthermore, we have experienced that when using this absolute spike definition for buildings, we find rather few spikes. For that reason, we employ an event identification scheme for investments in both equipment and buildings, which does not suffer from these disadvantages. This classification method is referred to as a relative spike definition (Power 1998; Kapelko et al. 2015). This approach works as follows. Let the superscript z denote a certain type of capital good, i.e., equipment or buildings.Footnote 3 Power (1998) defines an investment spike as an instance where the investment ratio of a firm i in a certain year t, \( \frac{I_{it}^z}{K_{it}^z} \), exceeds the median investment ratio of that firm by a factor θ, where denotes investment in capital of type z and θ = 1.75.Footnote 4,Footnote 5 We adjust Power’s definition, as otherwise it would be too lax. The reason is that in our data, if a plant experiences the occurrence of 5 or more “zero investment years,” even the smallest investment in one of the remaining years would be classified as a spike. We aim for a more conservative and robust definition. Hence, our spike definition includes the constraint that the investment ratio also needs to exceed the depreciation rate for the asset in casu:

The depreciation rate is denoted by δz. A strictly positive number for depreciation tends to limit the number of spikes because of the restriction \( \frac{I_{it}^z}{K_{it}^z}>{\delta}^z \) in the spike definition. The depreciation rate for buildings is set at 0.02. We choose a conservative number for the commercial building sector in Europe (Bokhari and Geltner 2014; Chegut et al. 2014). As we employ Dutch data, the depreciation rate for equipment is 0.05 in line with Letterie and Pfann (2007). The depreciation rates we employ for buildings and equipment are consistent with the geometric depreciation approach employed by the US Bureau of Economic Analysis calculating the depreciation rate dividing the declining balance rate by the service life using the information provided by Görzig (2007) and van den Bergen et al. (2009).

Simultaneous investment spikes in both equipment and buildings signal significant expansion. To measure unusual expansionary events at the level of the firm, we include a simultaneous investment spike variable:

So, the variable \( {S}_{it}^C \) identifies the event of a simultaneous spike.

A set of descriptive statistics for the investment spikes (in buildings, equipment, or a combination of both) is provided in Table 1. We observe that the frequency of spikes is 8 and 11% for buildings and equipment, respectively. Simultaneous spikes occur in 3% of the data. The mean investment rate for equipment during simultaneous spikes is higher than in the absence of a spike in buildings, hinting at an expansionary effort of the firm.

In Table 2, we depict the mean and standard deviation of energy usage, energy efficiency, and operational efficiency under the scenarios of (a) all observations, (b) no investment spikes, and in case of (c) single spikes in buildings, (d) single spikes in equipment, and (e) simultaneous spikes. Note that we have deflated production values and energy expenses by the annual production and energy Producer Price Indices (PPIs) available at Statistics Netherlands (CBS) Statline online data center. The base year is 2000. The dependent variables we use in the empirical analysis are in natural logs.

Table 2 reveals that firms not experiencing a spike at all are relatively small as measured by the level of production and number of workers. Also, firms only conducting a large investment in buildings tend to be rather small. Firms that are involved with large investments in equipment are larger on average. Firms just conducting major investments in buildings do not use a lot of energy, compared to firms investing in equipment.

With respect to energy efficiency, we see from the bottom part of Table 2 that firms engaging in equipment spikes are more efficient in energy usage as reflected by energy consumption divided by the capital stock of equipment. In contrast, firms displaying building spikes are more efficient in energy usage as reflected by energy consumption divided by the capital stock of buildings. Firms not conducting major investment episodes typically belong to the least energy efficient groups, by all measures. Finally, we analyze the variable operational efficiency as measured by the ratio of cost to sales. Note that the cost variable does not include investment expenditures. It appears that our measure of operational efficiency is relatively stable and independent of the investment profile of the firm.

To identify high- and low-tech industry categories in Dutch manufacturing, we follow Raymond et al. (2006). A low-tech firm is characterized by a low propensity to engage in innovation-seeking activities, like R&D and innovation subsidy achievement. Following Raymond et al., wood-based industries are characterized as distinctively non-innovative. Labor and energy intensity industry groupings are based on Ramirez et al. (2005). Table 3 identifies how the sample firms are classified by innovation, energy, and labor intensity. High-tech and low-tech sectors represent 39 and 45% of the sample, respectively. High-tech firms are predominantly active in the Oil and coal, Chemicals, Transportation, and Machines and apparatuses sectors. High, medium, and low labor-intensive industries reflect 22, 30, and 49% of the sample, respectively. Low labor-intensive industries are split almost evenly between high-tech and low-tech industries. High, medium, and low energy-intensive firms represent 47, 21, and 33% of the sample data, respectively. Energy-intensive firms can be found in industries like Food, drinks, and tobacco, Paper and pulp, Oil, coal, and chemicals, Non-metallic minerals, and Metals.

Table 4 provides summary statistics on how the variables of interest vary across sectors if we break them down according to innovation intensity, energy intensity, and labor intensity. The bottom part of the table shows that, on average, firms with the highest energy consumption operate in sectors characterized by low innovation intensity, high energy intensity and medium/low labor intensity. Typically, in high-tech industries, one can find the most energy-efficient firms. Firms in sectors with high labor intensity, on average, display high energy efficiency as measured by low energy consumption per unit of buildings. In contrast, firms characterized by low labor intensity on average score high on energy efficiency as indicated by a low consumption of energy per unit of equipment.

Methodology

The goal of this study is to obtain insights into the dynamics of energy consumption and efficiency surrounding events of major investment efforts conducted by firms. Our analysis is descriptive and non-parametric rather than structural and enables us to observe investment activity across capital types. Our methodology is in line with a common approach in the capital investment literature, when the objective is to obtain descriptive evidence of firm behavior in times of major investment episodes. Hence, we closely follow Sakellaris (2004), Letterie et al. (2004), and Nilsen et al. (2009) and first identify events of large capital adjustments by firms. We use these events and look into what is happening with firm-level energy metrics in periods during and surrounding these events. One way of looking at this event type of methodology identified by investment spikes is that such episodes reflect that a firm was hit by a large shock. The investment spike in itself represents the response of the firm to the shock. Alternatively, the firm may have been subject to a series of smaller shocks to which the firm has not responded yet due to the presence of fixed capital adjustment costs, for instance. The large investment event reflects that the firm has taken action now (Sakellaris 2004).

We start investigating the dynamics of energy usage and energy efficiency surrounding investment spikes for firm-level dependent variables—as denoted by DVit—using the following empirical model:

where μi is a firm-specific effect, αt is a year-dummy vector capturing potential macro-economic developments, and εit denotes an idiosyncratic error. Our approach resembles an event study (Wooldridge 2013) where the goal is to estimate the effect of an event, a policy program change, or introduction, for instance, on an outcome variable of interest. Typically, such studies allow for exogenous treatment variables such that causal inferences can be made. In our study, the assumption of strict exogeneity of the events, which are identified by the occurrence of investment episodes, is violated. Hence, our estimates should be interpreted carefully with regard to causality. They provide us with a description of dynamic patterns of plant-level energy metrics surrounding major capital adjustments in plants.

The vector \( {X}_{it}^z \) captures the event for both capital types (i.e., buildings where z = B and equipment where z = E) as well as for a simultaneous spike episode (where z = C) in case a simultaneous investment spike in buildings and equipment takes place (i.e., where \( {S}_{it}^B={S}_{it}^E=1 \)). For more detail on the construction of the elements in the vector \( {X}_{it}^z \), we refer to Appendix 3. The parameter estimates for vector \( {X}_{it}^E \)\( \left({X}_{it}^B\right) \) identify adjustment of DVit in periods surrounding spike event in equipment (buildings) only. Likewise, coefficients of \( {X}_{it}^C \) measure adjustment of DVit surrounding simultaneous spikes in both buildings and equipment.

Estimating Eq. (5) yields regression coefficients captured by the vector βz with six elements for independent variables \( {X}_{it}^z,z\in \left\{B,E,C\right\} \). They identify the adjustment of the dependent variable DVit for firms i that are experiencing a spike in buildings, a spike in equipment, or a combined spike. These estimates measure the difference between a firm conducting a major investment and a firm that is not experiencing a spike. Due to the fixed-effects specification, the estimates identify the within variation of the dependent variable across various investment experiences of the firms. As the dependent variables are in natural logarithms, from the coefficients in the vector βz, percentage differences can be calculated in the dependent variable between firms that are and firms that are not in the situation described by an element \( {X}_{it}^z \). For example, consider as a dependent variable the natural logarithm of energy consumption in year t. Suppose the parameter estimate for \( {X}_{4 it}^C \) equals 0.01. Then, a firm that simultaneously invested in equipment and structures in the previous year, i.e., period t − 1, experiences energy consumption approximately 1% higher in year t than a firm that did not conduct a simultaneous spike in the previous year, correcting for firm-specific heterogeneity.

As long as an investment spike is observed in the timeframe 2000–2008, we also define all those other elements of the vector \( {X}_{it}^z \) that can be observed subject to data availability. As an example, for an investment spike in equipment in the year 2007, we set \( {X}_{1i2005}^E \), \( {X}_{2i2006}^E \), \( {X}_{3i2007}^E \), and \( {X}_{4i2008}^E \) equal to 1, but, logically, they do not define \( {X}_{5i2009}^E \) and \( {X}_{6i2010}^E \), as they fall outside of our observation window. Let us now say in reality that a firm experienced an investment spike in 2009. In that case, \( {X}_{1i2007}^E \) and \( {X}_{2i2008}^E \) should be equal to 1. However, they are held to 0 in our data, because we do not observe 2009. This measurement error will likely bias the findings downward to zero. Hence, this adds some conservativeness to our conclusions.

Hausman tests on all models indicate that all dependent variables required a fixed-effects specification. The models are estimated using fixed effects, within estimators. Within estimators are more efficient than first differencing, assuming i.i.d. idiosyncratic error terms εit. Since we do not (for example) include any lagged variables in the regression, this is a safe assumption after averaging out the fixed effects. Note, we do not intend to estimate a model obtaining causal insights. We rather aim at describing dynamic patterns of some key firm-level variables. We abstract from time-invariant variables as they are omitted from the model due to differencing fixed effects.

Results

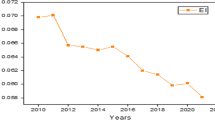

In Table 5, we present our results reflecting the dynamics of firm-level energy performance metrics surrounding investment spikes for the full sample. Based on these results, we constructed Figs. 1 and 2. These figures depict how three energy performance metrics behave around specific investment events for the full sample. We observe that energy consumption tends to increase by around 7% when a firm experiences a simultaneous spike. This result is statistically significant. Energy usage displays no major changes in case firms conduct a single spike in either buildings or equipment. As depicted in Fig. 2, Energy Consumption per Capital Stock of Buildings, energy efficiency does improve by 4% after three or more years when a firm experiences a spike in buildings. Figure 2, Energy Consumption per Capital Stock of Equipment, shows that three or more years after either a simultaneous spike or a single spike in equipment, the firm’s energy efficiency improves by even 12%. Strikingly, before these spikes, the energy efficiency metrics indicate relatively low performance, suggesting that the firms’ production processes have become less energy efficient potentially due to working at full capacity or due to aging. Thus, we see from Fig. 1 that firms use more energy after conducting major investment efforts in both buildings and equipment simultaneously. However, Fig. 2 reveals that they do use the energy more efficiently after the investments have taken place. Even though the scale of operations tends to increase, especially in case of a simultaneous spike, firms produce using more energy-efficient processes. In fact, in the case of a single spike in buildings, the energy consumption per unit of buildings decreases. Furthermore, if a single or simultaneous spike occurs, including equipment, energy usage per unit of equipment decreases.

Recall that Eq. (2) informs us that \( \varDelta \ln \left({e}_t/{K}_t^c\right)=\varDelta \ln \left(Y/{K}_t^c\right)+\varDelta \ln \left({p}_t\right)-\varDelta \ln \left({p}_t^e\right)+\varDelta \ln \kappa \). From Table 5, we infer that three or more years after a simultaneous spike \( \varDelta \ln \left({e}_t/{K}_t^c\right)=-0.127 \). Results not published here but available from the authors upon request reveal that in our data \( \varDelta \ln \left({Y}_t/{K}_t^c\right)=-0.120 \) three or more years after a simultaneous spike. Hence, \( \varDelta \ln \left({p}_t^e\right)-\varDelta \ln \left({p}_t\right)\approx \varDelta \ln \kappa \). As we are considering the period of 2000–2008 in the Netherlands, producer prices in manufacturing industries have increased by 30% and energy prices by 130% in 9 years. This means that for a firm that has conducted a simultaneous spike during one of the early years of the sample approximately Δ ln κ ≈ 1. This is probably an optimistic estimate of technological progress concerning energy use in the firm’s production function. Nevertheless, based on this number, we conclude that production technology has become more energy efficient in cases where a firm experienced a simultaneous spike. Similar findings hold if we would use results concerning energy efficiency and productivity of equipment (buildings) three or more years after a single spike in equipment (buildings).Footnote 6

Industry cluster analysis

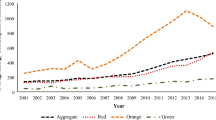

The table in Appendix Table 8 presents the results of our analysis conducted on sample breakdowns by innovation, labor, and energy intensity to obtain a more granular insight. Based on these results, we constructed Figs. 3, 4 and 5. In Fig. 3, we depict the results distinguishing firms by innovation intensity. In this discussion, we disregard the separate Wood sectors as these yield few statistically significant results in terms of what happens after the various spike events. We see from Fig. 3 that our findings for the full sample are largely in line with those for the Low Tech sectors. In these sectors, energy usage increases substantially by approximately 10% after a simultaneous spike. According to the table in Appendix Table 8, energy efficiency improves three or more years after investing in equipment (single or simultaneous spike). Firms in High Tech sectors do also improve energy efficiency when investing in equipment (single or simultaneous spike). This does increase overall usage of energy significantly by about 5% after three or more years, but this number is substantially lower than what we observe for the Low Tech sectors.

In Fig. 4, we present our results distinguishing firms by energy intensity. We observe that similar to our results based on the full sample, energy efficiency improves when investing in equipment (single and simultaneous spike) in essentially all sectors. Only in High Energy Intensity sectors a simultaneous spike does not yield a statistically significant result for three or more years after the spike, though the sign and size of the coefficient are in the right direction. However, we see that in High Energy Intensity sectors, after a simultaneous spike, energy usage increases afterwards. In Medium and Low Energy Intensity sectors, we do not observe this pattern. Instead, in the Medium Energy Intensity sectors, it is major investments in buildings that are associated with higher energy usage.

In Fig. 5, we depict our results breaking down sectors by labor intensity. We see that energy efficiency improves three or more years after investing in equipment (single and simultaneous spikes) except for the Medium Labor Intensity sectors where those improvements are not visible after simultaneous spikes. Nevertheless, in the Medium Labor Intensity sectors, we do observe an increase in energy usage three or more years afterwards. Strikingly, we find that in the Low Labor Intensive sectors after single spikes in buildings and equipment, energy usage expands.

In sum, we find some differences across various types of industries as distinguished by innovation, energy, and labor intensity. However, the result that major investments involving equipment (single and simultaneous spikes) are correlated with better energy efficiency is largely robust across sectors. The result that simultaneous spikes are associated with higher energy usage is found most strongly in Low Tech, High Energy Intensity, and Medium Labor Intensity sectors.

Operational efficiency

In Table 6, we report how efficiency of the firm evolves surrounding major investment events for the full sample, as well as for the sample breakdowns by technology, labor, and energy intensity. In case of simultaneous spikes, we observe that the total cost to sales ratio does not change significantly. Operational efficiency tends to improve three or more years after an investment spike in equipment only, though investments in buildings do the opposite. In the full sample, operational efficiency does not get worse by more than 1%.

Operational efficiency in oil and coal and chemicals

According to Table 6, sectors that are harmed most in terms of operational efficiency by investment in buildings are high-tech industries, industries with low labor intensity, and those with high energy intensity. With these categories in mind, Table 3 informs that firms operating in Oil and coal and in Chemicals face a statistically significant financial disincentive to invest in buildings. Operational efficiency decreases by more than 1.5 percentage points in such capital-intensive industries. This is confirmed by a separate analysis reported in Table 7 that we conducted for these sectors. Operational efficiency decreases by 3.4% after three or more years after a spike in buildings when we group the observations for Oil and coal and Chemicals. This result is statistically significant. For these sectors, we find that upon investment, energy use does increase; however, only a single investment spike in equipment does so according to conventional statistical significance levels. Likewise, previous literature identified that in Chemicals, firms increased energy consumption after participating in voluntary energy efficiency equipment programs (Gamper-Rabindran and Finger 2013). Nevertheless, our results suggest that, also, in these industries Δ ln κ > 0, implying that investment is associated with higher energy efficiency. We conclude that the sectors mentioned in this paragraph may enhance environmental performance by investing in appropriate capital goods. Nevertheless, appropriate financial incentives to do so seem absent.

Conclusion

Climate change and energy efficiency are core twenty-first century challenges, and firms have an important role to play in increasing environmental performance by decreasing the emission of toxic pollutants and decreasing energy consumption. How firms could go about making these changes requires a more thoughtful understanding of firm-level environmental performance. Moreover, there is limited evidence on how changes in firm-level investment activities impact firm-level environmental performance outcomes. For firms, investment events are periods where they can develop a plan for financial and environmental performance through the human and physical capital expenditures that they will make. Large investment spikes reflect cash flow resources that influence changes in the productivity of firms which can impact employment costs and operational costs and influence the production of manufactured goods. At the same time, these factors can impact firms’ cost efficiency and energy consumption from equipment, buildings, or the simultaneous use of both. In this way, we investigate how energy performance of Dutch manufacturing firms over the 2000 to 2008 period evolves in the time surrounding investment spikes in capital. Our contribution is to identify whether these investment spikes have an impact on energy consumption, assess whether or not firms improved energy efficiency in anticipation of the investment event or after an investment outlay occurred, and identify the capital types for which environmental performance is correlated with investment spikes.

From our multi-period event study, we find that when firms engage in large simultaneous investments in both buildings and equipment, energy consumption levels increase considerably by 6.4% in the first year after the spike and continue to rise to an average 7.4% after 3 or more years. For this result, we may be able to interpret a simultaneous capital expenditure as a signal of expansionary or replacement activities, and it potentially implies that when firms engage in growth activities, there is correlation with energy consumption growth overall. This result correlates with expectations that when firms expand production, they increase their use of resources and materials, but it does not necessarily point to poor environmental performance from the building or equipment capital itself. In fact, we find that, in cases of major investment spikes, energy efficiency improves. Moreover, we find that these investments do not correlate with an increase in the total cost per sales after an investment is made. Notably, investments in equipment improve the operational efficiency by approximately 2% after three years from the investment spike. This suggests that industrial firms can increase energy efficiency while increasing operational efficiency—the so-called “doing well by doing good.”

We find that after investments, energy efficiency in equipment improves. Our results for the overall sample imply that less energy is needed to produce a certain level of output once a firm invests. We show that after three years from the investment outlay, energy efficiency increases by about 12%. Though energy efficiency improves after installing new equipment capital, we observe some evidence of operational efficiency decreasing subsequent to investment in buildings in high technology, high energy, and low labor industries by 1.7, 1.6, and 1.9%, respectively. Especially for firms operating in capital-intensive industries like Oil & Coal and Chemicals, there is a shift in the operational efficiency of buildings.

Our results document a positive correlation with environmental performance after investment spike activity. Anecdotally, there is evidence of success in the industrial sector to meet energy efficiency performance targets. As an example, Prologis is a global industrial real estate company that is committed to decreased energy consumption to improve financial performance.Footnote 7 However, from a policy perspective, lagged firm awareness, poor environmental performance knowledge on behalf of firms, poor equipment and (or) building standards knowledge, or lagged policy implementation may lead to decreased planning for environmental performance at the time of investment spikes. Thus, more common policy approaches like voluntary agreements with firms may not be of much help in this context, but third-party verification, planning agreements or enforceable penalties when firms do not perform, subsidies, or R&D tax credits could potentially yield better results (Earnhart 2004; Cole et al. 2005; Gamper-Rabindran and Finger 2013).

Currently, CBS data does not enable us to identify the effect of energy efficiency standards or codes in our results by understanding the interventions made with building plans or types of equipment purchases, and, more generally, there are limitations around observing expansionary events by firms or the types of energy sources, whether they be clean, dirty, or offset with carbon credits that they consume in their production process. In addition, we do not observe substitution of activities between plants that belong to the same company. Future research may also seek to observe expansionary investment in BRIC economies. However, our results have allowed us to observe that there is a correlation between energy-related metrics and firms who have purchased new equipment capital. For policymakers to take note, we observe that growing firms become more energy efficient. Firms conducting large investments are planning for a future cash flow that is promising and invest in equipment where they expect to yield a profit-maximizing positive financial return from such decisions. Furthermore, it is financially healthy firms having cash flow streams and/or access to the capital markets that are capable of investments at this magnitude. Sometimes, firms need to finance capital improvement expenditures themselves due to capital market imperfections (Fazzari et al. 1988), but in the EU’s current Horizon 2020 program, there are numerous avenues to apply for financing and subsidies that support the purchase of new energy-efficient equipment and building technologies. Potentially, in the long run, as the manufacturing sector switches towards clean technology, then energy-efficient firm production could replace firm production that is both less successful and energy inefficient. In the aggregate, technological progress in equipment and buildings with an aim towards energy efficiency may be improved by replacement of unsuccessful firms by more energy-efficient competitors (Acemoglu et al. 2014; Acemoglu et al. 2009).

In this way, policymakers should continue to recognize, convene, and set standards towards industrial environmental performance. Environmental goals can be attained by advancing standards for materials, equipment, building codes, and the emissions of pollutants without significant financial repercussions to firms. This view is consistent with studies observing that “lean and green” go hand in hand. Investing in environmental technology enhances manufacturing performance (Klassen and Whybark 1999; Telle and Larsson 2007), and lean production processes are complementary to environmental performance (King and Lenox 2001). Future research is required to understand whether it is such evolutionary developments in industries that allow countries to become less dependent on energy in the aggregate.

Notes

Sampling strategies and collection methods of Statistics Netherlands can be obtained from: http://www.cbs.nl/nl-NL/menu/themas/industrie-energie/methoden/dataverzameling/korte-onderzoeksbeschrijvingen/productie-statistiek.htm (in Dutch only).

One limitation of our data is that they do not allow us to disentangle or identify substitution or transfer of activities, etc., between plants within one firm.

In our data, there is a separate variable for (total; i.e., including buildings and equipment) leasing expenses for the individual firms. We only considered acquisitions in our analysis. However, especially in the Dutch manufacturing sector, leasing expenses are only a fraction of total expenses/investment in new capital. In the full sample of manufacturing firms’ investments in 2000, firms show mean building investments of 20.38, mean equipment investments of 82.21, and mean total leasing expenses of only 2.41 (all figures in thousands of Euro).

See Appendix 2 for a description of how the capital stock is constructed.

Studies have employed absolute and/or relative spike definitions (Nilsen and Schiantarelli 2003; Letterie et al. 2004). We have experimented with all types. For instance, we have also investigated an absolute spike definition of 0.2 for equipment and 0.1 for buildings. Using this approach is providing similar results. Power (1998) tested three different values of θ, a low (1.75), medium (2.5), and high (3.25) threshold. She found that results obtained using various investment spike definitions were not really sensitive to the chosen value of θ. In our data, results for the different levels of θ are also robust to the definition employed. We have also experimented with various rates of depreciation for buildings and equipment, again indicating our results are robust. Results are available upon request.

It is clear that smaller businesses are underrepresented in our sample. This is due to the specific sampling method used by CBS. We have for firms employing fewer than 50 fte a number of observations of N = 1063 and for firms employing 50 fte or more N = 4805. In terms of performance, small and larger firms are quite comparable. For instance, for the variable Total Costs/Sales, the means of the two groups does not significantly differ from each other. In terms of our regression findings, we see that the patterns described for the overall sample are quite similar between smaller and larger firms, although statistical significance is mainly observed among the subsample of larger businesses. This is likely due to the relatively small sample of smaller firms. The main observations (1) firms increasing energy consumption after large simultaneous investments in buildings and equipment, (2) energy efficiency improving after large simultaneous investments, and (3) operational efficiency improving after investments in equipment, yet decreasing after investments in buildings are similar in both subsamples, although again not always accompanied with statistical significance in the small firm subsample. Results are available upon request.

Prologis is a large industrial real estate investment trust operating in North America, Europe, and Asia. They were, recently, acknowledged by the Green Real Estate Sustainability Benchmark for their ten years of superior energy consumption in the sector. See also https://www.prologis.com/logistics-industry-feature/prologis-earns-perfect-10-2017-sustainability-benchmark, accessed 08/28/2018.

Fixed costs have been assumed to be proportional to the scale of the firm measured by the stock of capital. We abstract from this scaling. For the arguments developed using the current model, this assumption is innocuous.

References

Abel, A. B., & Eberly, J. C. (1994). A unified model of investment under uncertainty. American Economic Review, 84, 1369–1384.

Abel, A. B., & Eberly, J. C. (1998). The mix and scale of factors with irreversibility and fixed costs of investment. Carnegie Rochester Conference Series on Public Policy, 48, 101–135.

Acemoglu, D. (2015). How the machines replace labor? Paper presented at the annual meeting of the Allied Social Science Associations. Boston: American Economic Association.

Acemoglu, D., Aghion, P., Bursztyn, L., and Hemous, D. (2009). The environment and directed technical change (no. w15451). National Bureau of Economic Research.

Acemoglu, D., Akcigit, U., Hanley, D. & Kerr, W. (2014). Transition to clean technology (no. w20743). National Bureau of Economic Research.

Aroonruengsawat, A., Auffhammer, M., & Sanstad, A. H. (2012). The impact of state level building codes on residential electricity consumption. Energy Journal-Cleveland, 33, 31.

Asphjell, M. K., Letterie, W., Nilsen, Ø. A., & Pfann, G. A. (2014). Sequentiality versus simultaneity: interrelated factor demand. Review of Economics and Statistics, 96, 986–998.

Bloom, N. (2009). The impact of uncertainty shocks. Econometrica, 77, 623–685.

Bokhari, S. & Geltner, D. (2014). Characteristics in commercial and multi-family property: an investment perspective. In: Center for real estate working paper series.

Chegut, A., Eichholtz, P. M., & Rodrigues, J. M. (2014). Spatial dependence in international office markets. Journal of Real Estate Finance and Economics, 51, 317–350.

Cole, M. A., Elliott, R. J., & Shimamoto, K. (2005). Industrial characteristics, environmental regulations and air pollution: an analysis of the UK manufacturing sector. Journal of Environmental Economics and Management, 50(1), 121–143.

Cooper, R. W., & Haltiwanger, J. C. (2006). On the nature of capital adjustment costs. The Review of Economic Studies, 73(3), 611–633.

Cooper, R. W., Haltiwanger, J. C., & Power, L. (1999). Machine replacement and business cycle: lumps and bumps. American Economic Review, 89(4), 921–946.

Dalton, B., & Fuerst, F. (2018). The ‘green value’ proposition in real estate. In: Routledge handbook of sustainable real estate.

Dunne, T., Roberts, M. J., & Samuelson, L. (1989). Firm turnover and gross employment flows in the US manufacturing sector. Journal of Labor Economics, 7, 48–71.

Earnhart, D. (2004). Regulatory factors shaping environmental performance at publicly-owned treatment plants. Journal of Environmental Economics and Management, 48(1), 655–681.

Eichholtz, P., Kok, N., & Quigley, J. M. (2010). Doing well by doing good? Green office buildings. American Economic Review, 100(5), 2492–2509.

European Environment Agency (2013). Final energy consumption by sector (CSI 027/ENER 016). http://www.eea.europa.eu/data-and-maps/indicators/final-energy-consumption-by-sector-5/assessment. Accessed 9 July 2014.

Gamper-Rabindran, S., & Finger, S. R. (2013). Does industry self-regulation reduce pollution? Responsible care in the chemical industry. Journal of Regulatory Economics, 43(1), 1–30.

Görzig, B., (2007). Depreciation in EU member states: empirical and methodological differences. EU KLEMS project.

Hamermesh, D., & Pfann, G. (1996). Adjustment costs in factor demand. Journal of Economic Literature, 34, 1264–1292.

Hémous, D., & Olsen, M. (2013). The rise of the machines: automation, horizontal innovation and income inequality. In Paper presented at the annual meeting of the Allied Social Science Associations. Boston: American Economic Association.

International Energy Agency. (2014). Energy policies of IEA countries. The Netherlands. 2014 review: OECD/IEA.

Jacobsen, G. J., & Kotchen, M. J. (2013). Are building codes effective at saving energy? Evidence from residential billing data in Florida. Review of Economics and Statistics, 95, 34–49.

Kapelko, M., Oude Lansink, A., & Stefanou, S. E. (2015). Analyzing the impact of investment spikes on dynamic productivity growth. Omega, 54, 116–124.

King, A. A., & Lenox, M. J. (2001). Lean and green? An empirical examination of the relationship between lean production and environmental performance. Production and Operations Management, 10(3), 244–256.

Klassen, R. D., & Whybark, D. C. (1999). The impact of environmental technologies on manufacturing performance. Academy of Management Journal, 42(6), 599–615.

Lennox, J. A., & Witajewski-Baltvilks, J. (2017). Directed technical change with capital-embodied technologies: implications for climate policy. Energy Economics, 67, 400–409.

Letterie, W. A., & Pfann, G. A. (2007). Structural identification of high and low investment regimes. Journal of Monetary Economics, 54, 797–819.

Letterie, W., Pfann, G. A., & Polder, J. M. (2004). Factor adjustment spikes and interrelation: an empirical investigation. Economics Letters, 85, 145–150.

Letterie, W., Pfann, G. A., & Verick, S. (2010). On lumpiness in the replacement and expansion of capital. Oxford Bulletin of Economics and Statistics, 72(3), 263–281.

Nilsen, Ø. A., & Schiantarelli, F. (2003). Zeros and lumps in investment: empirical evidence on irriversibilities and nonconvexities. Review of Economics & Statistics, 85(4), 1021–1037.

Nilsen, Ø. A., Raknerud, A., Rybalka, M., & Skjerpen, T. (2009). Lumpy investments, factor adjustments, and labor productivity. Oxford Economic Papers, 61, 104–127.

Papineau, M. (2013). Energy codes and the landlord-tenant problem. UC Berkeley: Fisher Center for Real Estate and Urban Economics. Retrieved from: https://escholarship.org/uc/item/46c518h9.

Power, L. (1998). The missing link: technology, investment, and productivity. Review of Economics and Statistics, 80, 300–313.

Ramirez, C. A., Patel, M., & Blok, K. (2005). The non-energy intensive manufacturing sector. An energy analysis relating to the Netherlands. Energy, 30, 749–767.

Raymond, W., Mohnen, P., Palm, F., & Schim van der Loeff, S. (2006). A classification of Dutch manufacturing based on a model of innovation. De Economist, 154, 85–105.

Sakellaris, P. (2004). Patterns of firm adjustment. Journal of Monetary Economics, 51, 425–450.

Sterner, T. (1990). Energy efficiency and capital embodied technical change: the case of Mexican cement manufacturing. Energy Journal, 11(2), 155–167.

Telle, K., & Larsson, J. (2007). Do environmental regulations hamper productivity growth? How accounting for improvements of plants' environmental performance can change the conclusion. Ecological Economics, 61(2), 438–445.

US Energy Information Administration (2014). AEO2014 early release overview. Report number DOE/EIA 0383ER (2014).

van den Bergen, D., de Haan, M., de Hey, R. & Horsten, M. (2009). Measuring capital in the Netherlands. In: Statistics Netherlands discussion paper (09036).

Verdolini, E., & Galeotti, M. (2011). At home and abroad: an empirical analysis of innovation and diffusion in energy technologies. Journal of Environmental Economics and Management, 61(2), 119–134.

Wooldridge, J. M. (2013). Introductory econometrics—a modern approach (5th ed.). Boston: Cengage Learning.

Acknowledgements

We thank Maarten Brinkerink, David Geltner, Rogier Holtermans, Øivind Nilsen, Lyndsey Rolheiser, and seminar participants at Maastricht University and MIT for useful comments during the early stages of the project resulting in this paper. In addition, we are grateful to the referees of this journal for their suggestions on how to improve this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1. An investment model explaining spikes

Investment data often also feature rather small expenditures. The model presented does not account for these. However, it can be adjusted easily to capture these small investment as well without influencing the main results (Letterie and Pfann 2007). The value of the firm is given by:

The term Et(.) indicates that expectations are taken with respect to information available at time t. The discount rate β satisfies 0 < β < 1. Upon investment, the firm incurs adjustment costs given by:

The function I(.) assumes the value 1 if the condition in the brackets is satisfied and is equal to zero otherwise. The adjustment cost function allows for convex costs. Their size is reflected by the parameters bB and bE. Convex costs make large capital expenditures expensive and, hence, provide an incentive to firms to smooth investment over time. The prices of the capital investment are \( {p}_t^B \) and \( {p}_t^E \), where for c ∈ {B, E}, \( {p}_t^c={p}^{c+}\ \mathrm{I}\left({I}_t^c>0\right)+{p}^{c-}\ I\left({I}_t^c<0\right) \). The purchase price for a unit of capital c is pc+. When the firm sells one unit of capital, the price received is pc−. As investment is partially irreversible, the purchase price of capital is higher than the resale price: pc+ > pc−. Fixed costs are given by αB and αE. In the model, these costs are independent of the size of the investment expenditure. In practice, such costs may capture increased managerial attention or the loss of productivity due to the installation and adoption of new equipment, for instance (Hamermesh and Pfann 1996). Various empirical studies have found convincing empirical evidence for this type of cost (see, for example, Cooper and Haltiwanger 2006; Bloom 2009; Asphjell et al. 2014).Footnote 8 We also assume these to be symmetric for simplicity. In fact, they are independent of whether capital demand is positive or negative.

Investment in buildings and equipment is denoted by \( {I}_t^B \) and \( {I}_t^E \), respectively. By conducting investment, the optimal size of the capital stocks, \( {K}_{t+1}^B \) and \( {K}_{t+1}^E \), is reached. The parameters δB and δE denote capital depreciation rates of buildings and equipment, respectively. Hence, capital is governed by:

where c ∈ {B, E}. The firm decides upon \( {I}_t^B \) and \( {I}_t^E \) by maximizing Eq. (6) subject to Eq. (8). The shadow values of an additional unit of capital are given by:

where c ∈ {B, E} and \( {\lambda}_t^c \) measures the value change of the firm if the constraint in Eq. (8) is relaxed or if, equivalently, capital is increased by one unit. From Eq. (9), it can be seen that the shadow values represent the expected present discounted value of the marginal profit of capital minus the marginal adjustment costs in future periods. For c ∈ {B, E}, we find that the first-order condition for investment is:

According to Abel and Eberly (1994), factor demand equals:

The firm determines whether to change the stock of capital for c ∈ {B, E} by evaluating:

At the left-hand side of Eq. (12), we see the expected benefits of investing. At the right-hand side, the cost associated with the firm’s decisions is depicted. The expression \( {\lambda}_t^c{I}_t^c \) approximates the benefits due to which we obtain a closed-form solution. This expression holds exactly in a continuous time framework with one production factor. Substituting Eq. (11) in Eq. (12), we observe that adjusting the stock of capital is profitable if \( \frac{1}{2{b}^c}{\left({\lambda}_t^c-{p}_t^c\right)}^2{K}_t^c\ge {\alpha}^c\ge 0 \). Hence, changing the amount of capital c ∈ {B, E} occurs if

This equation reveals that if the net benefits of adjusting capital do not go above a certain threshold, the firm abstains from adjusting. The thresholds are due to the presence of fixed adjustment costs αB and αE, for instance. Investment becomes less likely, all else equal, with larger fixed costs. Importantly, larger fixed costs also increase the size of the investment. In fact, with a larger threshold, the left-hand side of Eq. (13) must be higher, and this expression affects the size of investment as can be seen from Eq. (11).

Appendix 2. Construction of capital stock variables

We construct the starting value of a firm’s capital stock for buildings and for equipment as follows. The initial capital stock for a firm is the contemporaneous ratio of firm to industry output multiplied by the industry’s capital stock of an asset. More specifically, for a given firm i in period t, the firm’s capital stock, i.e., \( {K}_{it}^c \) is calculated using \( {K}_{it}^c={K}_{jt}^c\cdotp \frac{Y_{it}}{Y_{jt}} \), where j denotes the industry a firm is operating in, Yit (Yjt) depicts output of firm i (industry j) in year t, \( {K}_{it}^c \)Kjt denotes the capital stock of asset c of company i (industry j) at the beginning of year t. The industry-level data are obtained from the Statline online data center of the Statistics Netherlands (CBS). To construct the starting values of the capital stock series, data from the year prior to the start of the sample are collected. Hence, these series start in the year 2000.

The capital stock for the remaining years is determined by the perpetual inventory method. Importantly, in the analysis, we employ real investment and capital figures. The nominal numbers have been deflated using producer price indices on buildings or equipment assets. The nominal numbers refer to investments done in the book year.

Appendix 3. Construction of the matrices \( {X}_{it}^z \)

The matrices are defined as follows:

The parameter vector βz contains six elements; one for each of the components in \( {X}_{it}^z \). The vectors in Eqs. (14) to (16) are designed in such a way that they can track the dynamics of the dependent variables in the time period surrounding a certain spike event. This works as follows: The vector \( {X}_{it}^z \) consists of six elements \( {X}_{hit}^z,h\in \left\{1,...,6\right\} \) for z ∈ {B, E, C}. The variables \( {X}_{hit}^z,h\in \left\{1,...,6\right\},z\in \left\{B,E,C\right\} \) allow for identifying what happens to the firm’s energy metrics between two years prior to and two years post a certain firm investment spike event.

Let us consider the example of spikes in building investments. For example, the coefficient of \( {X}_{1 it}^B \) measures the change in the dependent variable two years before a spike in buildings occurs. The variable takes the value 1 if a spike occurs in year t + 2 for investment in buildings (but not in equipment) and no spikes in buildings occur in years t and t + 1. In all other conditions, it takes the value 0. The parameter estimate for variable \( {X}_{2 it}^B \) measures the change in DVit one year before a spike in buildings. The variable takes the value 1 if a spike in buildings occurs in year t + 1 (but not in equipment) and no spikes in buildings occur in year t; alternatively, it assumes the value 0. To measure changes in the dependent variable at the time of a spike, we employ \( {X}_{3 it}^B \). It assumes the value 1 if a spike in buildings occurs in year t, and there is no spike in equipment in t. It will be 0 otherwise. The variables \( {X}_{4 it}^B \) and \( {X}_{5 it}^B \) are similar to \( {X}_{2 it}^B \) and \( {X}_{1 it}^B \), though they indicate a spike in year t − 1 (t − 2) rather than t + 1 (t + 2). Thus, these variables identify what happens one and two years after a spike event, respectively. Finally, using \( {X}_{6 it}^B \), we capture the change in DVit after three or more years. The variable takes the value 1 if a spike occurs before year t − 2, but not in t − 2, t – 1, and t. The vectors \( {X}_{it}^E \) and \( {X}_{it}^C \) are analogous to \( {X}_{it}^B \).

Appendix 4

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Brinkerink, J., Chegut, A. & Letterie, W. Energy performance and capital expenditures in manufacturing industries. Energy Efficiency 12, 2011–2038 (2019). https://doi.org/10.1007/s12053-019-09779-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-019-09779-x