Abstract

The topmost challenge for Indian manufacturing industries is to reduce the pace of energy intensity to deal with environmental degradation and climate change problems. In this light, we examine the firm-specific determinants influencing energy intensity of Indian manufacturing firms and suggest measures to minimize the energy intensity. To do so, we use aggregate firm-level data ranging between 2010 and 2021 and employ panel quantile regression. We found that the determinants, namely LI, RMPMI, PMI, and OI, have a statistically positive and significant impact on energy intensity. Other factors such as RMSSI, PATI, TDI, SI, and LNTA were found to show mixed results. Besides, we observed RMPMI as the most dominant factor driving energy intensity among Indian manufacturing firms. The findings of this paper endorse effective policymaking pertaining to energy intensity for Indian manufacturing firms and necessitates the modifications in energy conservation regulations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Energy drives the engine of economic growth and is vital for the development of human civilization (Chalvatzis, 2019; Rasool et al. 2022; Pradhan et al. 2021; Wang et al. 2022). Because of its multipurpose use, it is regarded as the lifeblood of an economy. Several entities of an economy such as industries rely on energy to run its machines, and household units depend on energy to operate various appliances. Because it is the basic input for the production of goods and services in an economy, topic related to energy intensity (henceforth EI) remains a topmost priority for effective policymaking to deal with environmental degradation and climate change.

A plethora of literature expresses about the association between energy consumption and economic development and considers energy as an indicator of life quality. Some other studies hold that energy generation from conventional sources absorbed by industries contributes to CO2 emissions and can eventually lead to environmental degradation (Pradhan et al. 2022). Furthermore, many studies identify accelerated industrialization, growth in the demographic structure, increasing urbanization, technical progression, and socioeconomic growth as important contributors of an ever-increasing global demand for energy which accelerate environmental concerns (Zhang et al. 2014). More specifically, the fast pace of energy growth is spurred by rapid industrialization and urbanization (Reddy and Ray 2010). With the growing pace of industrialization, energy has also raised environmental concern of the global citizens in achieving the much needed sustainable development goals.

At times when the growth of an economy is entirely dependent on industrial production, the industrial sector must focus upon energy which is the fundamental source of every industrial activity. In connection with an increase in environmental concerns due to rapid industrialization, the notion of EI finds significant attention in order to achieve the goal of energy security while remaining environmentally friendly. Studies pertaining to EI hold importance because policymakers will be able to project the future energy requirement and this eventually affects the course of ensuing energy needs of an economy.

India is considered a potential candidate for a fresh investigation related to EI because of multiple reasons. India is the second largest emerging market and a home for more than 131 crores of population. With a rise in the population, the demand for energy is expected to boost in the future to meet the household and industrial demand. India is ranked third across the globe in terms of energy consumption (International energy agency 2021). Sahu (2009), also hold that Indian manufacturing sector is among the top consumer of commercial energy in the country. Because of a steady growth in energy consumption, India had to rely on fossil fuels such as coal, crude oil, and solid biomass which contribute to 80% of its energy demand (International energy agency 2021). Therefore, the country’s overdependence on fossil fuels also paved the way to recognize it as the third largest global emitter of carbon dioxide. Although the outbreak of COVID-19 pandemic halted the progression of India’s energy use, however, it again resumed the pace after the lockdown and shutdown measures by its government were taken off.

Against the backdrop of increasing awareness regarding environmental degradation, and growing demand of energy, we have explored the factors that contribute to the EI of Indian firms by drawing a voluminous firm-level data. We have contributed to the extant literature on energy economics, and energy management in multiple directions. First, this study is first of its kind to examine unexplored firm-specific factors inducing EI across Indian firms. Most of the studies related to EI (Zhang et al. 2014, 2020, 2022) and energy efficiency (Wang et al. 2021) are concentrated on China. Although there is ample literature on EI with respect to Indian context, however, this issue did not receive due attention after the implementation of the Energy Conservation Amendment Act, 2010. Also because India is the third largest contributor of CO2 emissions, a detailed study analysing the factors affecting EI holds significance. Recently, India has also announced to achieve the carbon neutrality targets by the year 2070 at the United Nations Climate Change Conference held at Glasgow. Such targets can only be met if environment related policymaking aims at reducing EI at firm level. Therefore, the current study is expected to untangle the nuances of global environmental issue through a local lens.

Second, we consider voluminous firm-level data including 8803 firms with 64,956 firm-year observations. Use of such a huge data adds insights about the ongoing energy consumption and helps to untangle the reasons of an increase in energy demand at firm level. Past literature did not analyse the EI issue using such a voluminous data in Indian context. For instance, Sahu and Sharma (2016) analyse the EI of Indian industries considering 947 firms, Haider et al. (2019) show empirical estimates of 67 firms, Haider and Mishra (2021) investigated the EI issue for 82 iron and steel companies, and Jain and Kaur (2021) recently probed the EI of 41 Indian metallic sector.

Third, departing from the prior studies, we have used a novel econometric method, i.e. panel quantile regression proposed by Powell (2022). This method is superior over other static panel data models which assume the linearity of the data. Empirical outcome of other methods provides robustness of the panel quantile regression results.

Finally, the outcome of this study is expected to offer policy inputs and guide the policymakers in taking corrective actions to deal with climate change and environmental issues. More specifically, the results of the current study suggest effective management of the corporate sector in addressing the EI and considering measures in enhancing the energy efficiency at firm level. The empirical findings of the study also endorse policy modifications in the Energy Conservation Amendment Act, 2010.

The remainder section of this thesis is divided into the following sections. In the “Policy relevance” section, we discuss the extant policies related to EI and efficiency and summarize the extensive studies on EI in the “Overview of the literature” section. The “Data and methodology” section discusses the data and methodology. In the “Results and discussions” section, we have interpreted the results of the empirical analysis. The “Conclusion and policy suggestions” section concludes the study and provides policy recommendations and discusses on future work.

Policy relevance

The prime motivation of this study is based on the recent announcement made by the Indian representatives in the Glasgow summit to achieve net-zero carbon emission by 2070. Hence, to meet this target, India proposed to ensure half of the energy needs sourced from renewables and pledged to cut the intensity of carbon emissions per unit of the domestic output by less than 45%.

Despite of several commitments made at the international forums, the country has taken a number of legislative measures in mitigating the EI. In the similar vein, the Energy Conservation Act (EC Act) was enacted in the year 2001 ensuring the reduction of EI. Again, a few modifications in the EC Act were proposed in the year 2010. With this amendment, the government holds the authority in implementing regulations related to energy efficiency and set several company specific criteria related to power consumption. Similarly, the government implemented the National Action Plan on Climate Change proposing eight national missions including “Enhanced Energy Efficiency” (NMEEE). Furthermore, as a part of NMEEE, the “Perform-Achieve-Trade” (PAT) scheme was launched by the Ministry of Power and the Bureau of Energy Efficiency (BEE) in 2007, in which eight most energy-intensive industries were identified as textile, iron and steel, paper and pulp, thermal power, fertilizer, cement, and chlor-alkali and were referred to as “designated consumers” (DC). These authorized consumers account for over 45% of India’s commercial energy usage (BEE). For each DC, individual plant-specific EI cutting goals were proposed, which were needed to be completed by the end of PAT cycle I, i.e. 2012–2013 to 2014–2015. Consumers who complete the goal will be issued a merchantable Energy Saving certificates (ESCerts), on the completion of PAT cycle I, while those who do not fulfil their goals will have to purchase ESCerts in order to continue production.

The sixth edition of the PAT sixth cycle has begun from the year 2020. As per the current edition of the PAT cycle, industries such as iron and steel, cement, pulp and paper, petroleum refinery, textiles, and commercial buildings (hotels) were the specific industries identified among the 135 DCs. The sixth edition of the PAT cycle has projected to save 1.277 MTOE. With a total of 1073 DCs covering 13 sectors, BEE has completed six PAT cycles until March 31, 2020. By March 2023, it is expected that overall energy savings of almost 26 MTOE will be realized, resulting in the avoidance of around 70 million tonnes of CO2.

Overview of the literature

Several prior studies explored about the determinants of EI pertaining to various sectors, regions, firms, and countries. Zhang et al. (2016) categorized six important factors of EI namely demographic features, economic factors, firm-specific attributes, openness, energy and environmental factors, and transportation factors. Considering the size of the extant literature, we have cited specific studies and the recent ones (see Table 1) pertaining to Indian context and documented the expected relationship between the potential independent variables on EI.

EI refers to the total amount of energy consumed or used per unit of output produced and is reciprocal to energy efficiency (Soni et al. 2017). The less the energy required to produce one unit of output or service, the higher is the energy efficiency. Therefore, EI refers to how effectively energy is utilized in an economy. Oak and Bansal (2017) probed the EI of Indian cement industries and found that EI of cement industries is declining. The results signify that cement industries are using the energy saving techniques. Reddy and Ray (2010) discuss about two ways of measuring EI of industries such as considering the ratio of energy use per unit of tangible output (physical EI) and the proportion of energy use to one unit of physical output expressed in monetary value (economic EI). Improving energy efficiency by lowering EI can be a key strategy for increasing competitiveness of energy-intensive industries. In the similar vein, Sahu and Narayanan (2010) use the general parametric Divisia method for the decomposition of the EI and found that the variations in EI across sectors influence the changes in the total EI of Indian manufacturing firms than the alterations in the production structure of the industries.

Many scholars claim several factors which can affect the EI at firm level. Among a few, labour is expected to affect the level of energy efficiency and economic performance of industries which are energy intensive (Subrahmanya 2006). Depending upon the labour productivity, impact of labour intensity on EI can either be positive (Soni et al. 2017) or else negative (Jain and Kaur 2021; Sahu and Sharma 2016). Sahu and Narayanan (2013) employ the random effect approach using the data from 1992 to 2000 and found a significant and positive association between labour intensity and EI for paper and pulp industries. Additionally, the authors consider the squared term of the labour intensity variable as an important factor in their empirical model. The findings of the squared term of the labour intensity variable show negative relationship with EI confirming an inverted U shape relationship between EI and labour intensity. Contrastingly, Jain and Kaur (2021) explored the EI of Indian metallic industries using MLM and pooled RE panel regression for the period 2007 to 2017. The authors found labour intensity as the most dominant factor for minimizing the EI. In another study, Subrahmanya (2006) probed the effect of labour productivity on EI and economic performance in Indian context. The author found a negative association between labour productivity and EI.

Previous studies also discuss the role of repair and maintenance of plant in affecting the EI. Repair and maintenance of plant and machinery intensity is directly associated with EI. Investments on the renovations, maintenance, and repair of plant and machinery indicate inefficiency. Therefore, machines and equipment that demand more maintenance will result in higher EI, indicating that the industry is seeking more energy for various operations (Sahu and Narayanan 2011; and Soni et al. 2017). Several extant literatures also suggest a positive relationship between repair intensity and EI (Golder 2011). Similarly, Sharma et al. (2019) inquired about the factors influencing EI of iron and steel industries and concluded that repair intensity is positively associated with EI.

The relationship between raw materials store and spares intensity on EI is uncertain. Increase in spending on better quality raw materials and spare parts reduces effort for the creation of final product, thereby enhancing the EI (Soni et al. 2017). On the other hand, investment in low-quality raw materials and its operations through energy reduces firms’ efficiency and total physical output. Sahu and Sharma (2016) also found a negative relationship between raw material intensity and EI revealing that firms investing in raw materials are energy efficient.

Net plant, machinery, and computer installation intensity (PMI) is directly related with EI because these inputs consume large amount of energy in a firm. Installation of plant, machinery, and computer necessitates energy, thereby increasing its consumption. Nevertheless, increase in investment on plant and machinery raises the level of firms’ efficiency (Soni et al. 2017).

The variable profit after tax intensity is negatively associated with EI because increase in firms’ profit tends to raise firms’ efficiency. Firms with relatively higher profit margin channelize funds to invest in new technologies, install efficient machineries, and undertake research and development activities. Therefore, previous studies hold an inverse relationship between profit intensity and EI (Soni et al. 2017). However, the relationship between profit margin and EI can be positive depending upon the type of firms’ operations in case if it is involved in energy-intensive activities.

Environmental scientists hold technological upgradation as the most preferred technique for improving energy efficiency of small businesses. Technological development intensity is inversely related with EI. If investment in technological development is higher, it will lead to higher energy efficiency of the firms, thereby reducing their EI (Soni et al. 2017; Oak and Bansal 2017). In the similar vein, Narayan and Sahu (2012) also show that import of updated embodied/disembodied technology and knowledge spillovers from overseas helps the firm to save more energy. However, past literature also cites financial constraints as a major impediment for small businesses in upgrading energy-efficient technology.

The variables outsourced intensity and software intensity are firm-specific determinants (Table 2). They can be either directly or indirectly related with EI depending on the firms’ structure and size (Soni et al. 2017).

The firm size is inversely related with EI, because larger companies have more resources to invest in better technology and update their operations, as well as the ability to work with overseas companies. So they can improve their EI with financial availability (Jain and Kaur 2021; Oak and Bansal 2017). Golder (2011) and Kumar (2003) also opine that a negative relationship between firm size and EI is due to economies of scale.

Overall literature related to EI and efficiency in Indian context is concentrated towards explaining the relationship between total factor productivity and EI (Sahu and Sharma 2016). Most of the studies related to EI offer mixed outcomes explaining the relationship among the potential firm-specific factors on EI. Therefore, a fresh investigation is imperative in such a changing scenario.

Data and methodology

In this section, we have described the data and methodology employed for empirical analysis.

Description of the data

The data used for the current study is subject to the availability of secondary data. The data was sourced from the Centre for Monitoring of Indian Economy (CMIE) Prowess IQ database. The study period is from the year 2010 to 2021. The reason for choosing this study period is because of the implementation of the Energy Conservation Amendment Act, 2010. We expect this to be an important policy change which would have considerable impact on energy consumption, pollution, and carbon emissions. We have chosen the firms which are listed in the BSE30 index as this is the oldest index reflecting the market performance of the Indian economy. We considered heterogeneity by including non-financial firms from diverse sectors namely power, construction, cement, textiles, chemical, metals, and paper and pulp industries. These sectors were further aggregated. The data was also filtered to omit any outlier and missing values in the dataset. After filtering the dataset, the total data accounts to 8803 firms for the period 2010 to 2021. The empirical analysis is performed using the STATA 16.0 software.

We used panel quantile regression proposed by Powell (2022) to examine the asymmetric effects of the factors affecting EI in Indian context. We estimated the following panel regression equation to examine the factors affecting EI:

where EIit is the regressand and is expressed as the proportion of expenditure on power and fuel to net sales. In the current study, we measure the economic EI because using physical EI will not be appropriate for a time series comparison of different products and also for the entire industries that produce different units of output across sectors. LIit denotes the ratio of salaries and wages to net sales, RMPMIit is represented as the proportion of expenditure on maintenance of plant and machineries to net sales, RMSSIit indicates as the ratio of expenditure on raw materials, and spares and stores to net sales, PMIit implies the ratio of expenses on plant and machinery, computers, and electrical assets to net sales, PATIit is the proportion of profit after tax to net sales, TDIit suggests technological development to net sales, OIit is expressed as the ratio of sum of outsourced professional jobs, outsourced manufacturing jobs, and consultancy fees to others as a proportion to net sales, SIit symbolizes the ratio of sum of IT-enabled services charges, software charges, and other professional services to net sales, and LNTAit signifies the firm size which is calculated by taking the natural logarithmic transformation of total assets of the firms.

The term µt symbolizes unobserved time-specific effect, whereas νi is represented as the unobserved firm-specific effect and φit is the overall error term of the model with a zero mean random disturbance with variance σv2. We chose the independent variables based on an extensive review of the literature and is justified dependent on its theoretical relevance. Besides, inclusion of the regressors is also dependent upon previous empirical studies and keeping in the view the degrees of freedom and precision of the results.

Methodology

We considered using panel quantile regression for the empirical analysis. The quantile regression for panel data is used to examine the non-linear or asymmetric nature of the data. Specifically, panel quantile regression developed by Powell (2022) introduced static panel data modelling using fixed effects.

The panel quantile regression is useful for determining the varied impacts of explanatory variables at several effect points of the conditional distribution of the outcome variable. Quantile panel data estimators with additive fixed effects have been developed in the growing econometrics literature (Koenker 2004; Lamarche 2010; Canay 2011; Galvao 2011). To investigate the determinants that influence EI in Indian manufacturing industries, we use a fixed effect panel quantile regression model. A panel quantile regression with fixed effects is defined as:

where \({z}_{\dot{i}}\) is the restricted quantile, \({\beta }_{i}\) denotes the individual specific fixed effect variable, \(\gamma ({S}_{n})\) is the general slope coefficients, which are the considered variables in the study, and \({y}_{it}\) is a n dimensional vector of independent determinants. The variables can depend on the quantile index S ∈ (0,1). To appraise the panel quantile regression model, Koenker (2004) considered unobserved fixed effects as variables to be mutually estimated with the covariate effects for different quantile. The inclusion of a penalty component in the minimization process allows this technique to explicitly handle the computational difficulty of estimating a large number of parameters. The fixed effects quantile regression estimator is explained in the following:

where T is the index for the number of observations per sectors, N is the index for quantiles, i is the index for sectors (M), \({\rho }_{sn}\) is the quantile loss function, and y is the matrix of independent variables. Furthermore, \({v}_{n}\) is the relative weight given to the Nth quantile, which controls for the contribution of the Nth quantile for the estimation of the fixed effect.

λ is the tuning constraint that decreases the specific effects to zero, to improve the estimation performance of the \(\gamma\). If the λ value is equal to zero, then the penalty term vanishes with the usual fixed effects estimator. However, if the λ value approaches to infinity, then we get an estimate of the model without distinct effects. With contempt of a huge frame of literature on the panel quantile regression with fixed effects, the progressive techniques are mainly concerned about the problems in estimating a huge number of fixed effects in a quantile framework, and considering incidental constraints probability when T is small. To stun this problem, Powell (2022) recommends a quantile regression estimator of panel data (QRPD) with non-additive fixed effects. The QRPD method with the existing quantile estimators with additive fixed effects (\({\beta }_{i}\)) provides estimates of the distribution of \({Z}_{it}\) given \({F}_{it}\) instead of \({Z}_{it}\)−\({\beta }_{i}\), due to the different structural quantile functions (SQF), though Powell (2022) claims that the latter is unsuitable in many empirical applications because observations persisting at the top of the (\({Z}_{it}\)−\({\beta }_{i}\)) distribution may be at the bottom of the \({Z}_{it}\) distribution. Accordingly, Powell’s (2022) method offers point estimates which can be construed in the same way as the ones coming from a cross-sectional regression. The fundamental model is described as:

where \({Z}_{it}\) is the EI, \({\gamma }_{k}\) is the parameter of variables, \({F}_{it}\) is the set of independent variables, and \({V}_{it}^{*}\) is the error term that may be a function of numerous disturbance terms, some invariant and some time-variant. The model is linear in parameters and \({F}_{it}\gamma (s)\) is strictly increasing with respect to s. In general, for the sth quantile of \({Z}_{it}\), the quantile regression relies on the conditional restriction:

Equation (5) shows that the probability of the outcome variable which is smaller than the quantile function and is the same for all \({F}_{it}\) and equal to s. The QRPD estimator of Powell (2022) permits this probability to differ by distinct and even within-individual as long as such variation is orthogonal to the instruments. Therefore, QRPD relies on a conditional restriction and an unconditional restriction letting \({F}_{i}\)= (\({F}_{it}\)…\({F}_{iT}\)):

Powell’s (2022) method develops the estimator in an innovation variable context given the innovations \({X}_{i}\) =(\({X}_{it}\),…,\({X}_{iT}\)). If the descriptive variables are exogenous (in which case \({F}_{i}\)=\({X}_{i}\)), many of the identification conditions are met trivially. The estimation uses the generalized method of moments (GMM), and the sample moments are defined as:

with

where

Using Eq. (9), the parameter set is defined as:

for all t. Then, the parameter is estimated as:

where \(\widehat{A}\) is some weighting matrix (\(\widehat{A}\) can be the identity matrix and can be estimated using the two-step GMM).

Results and discussions

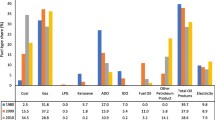

In this section, we discuss about the trends of EI across 8803 firms considered in the present study and interpret the results of the empirical analysis. EI across Indian firms exhibits a declining trend as it decreased from 0.069 in 2011 through 0.058 in 2021 (Fig. 1). The highest EI was recorded in the year 2011. Implementation of Energy Conservation Amendment Act in the year 2010 and consequent stringent environment policies explains this declining trend.

To explore the factors affecting the EI of Indian firms, we have conducted empirical analysis of the overall Indian firms. Similarly, the panel quantile regression results for 10th, 25th, 50th, 75th, and 90th quantile for the overall Indian manufacturing and power sector are documented in Table 6. Firms included in 10th quantile are considered less EI in comparison to 25th, 50th, 75th, and 90th quantile. So, the EI across firms increases and energy efficiency decreases with the rise in quantiles. Finally, we have also documented the results of the overall firms by employing the fixed effects regression model and Driscoll-Kraay standard error regression model with fixed effects for robustness of the main results obtained from panel quantile regression.

Table 3 presents the descriptive statistics of the variables used in the empirical analysis for the entire dataset. All variables have a positive mean value with low standard deviation value. Except for the variable RMSSI, the value of skewness is positive for all variables. Most of the variables have positive skewness, which implies that these variables are skewed to the right when compared to a normal distribution. All variables show a leptokurtic distribution. This demonstrates that these variables are vulnerable to extreme events.

The values of the correlation coefficient of the variables included in the empirical model are presented in Table 4. The correlation among the variable EI and RMSSI, PATI, TDI, OI, SI, and LNTA is negative. The correlation coefficients between EI and LI and RMPMI and PMI are all positive. The correlation coefficient of majority of the variables is low. Furthermore, a low mean value of the VIF indicates that the model is free from multicollinearity.

The panel unit root test for the whole dataset is shown in Table 5. When working with panel data, the unit root test is used to determine the stationarity of the model’s variables. We used the fisher ADF panel unit root test and the fisher PP panel unit root test to deal with unbalanced panel data with temporal gaps (Pradhan and Hiremath, 2020). These tests are recommended while dealing with unbalanced panel data that has time gaps. When both trend components and without trend components are included in the model, the fisher ADF and fisher PP panel unit root tests show that all variables are stationary in their level form.

In order to examine the non-linear relationship between the variables of interest with the EI, we employed the panel quantile regression. The results of panel quantile regression for overall firms are reported in Table 6. We found that the variable LI has a positive relationship on EI for all quantiles except the 50th quantile. This indicates that LI of aggregated firms tends to increase the EI. India is a labour surplus country (Mohan 2011) and most of the industries prefer to use a mixture of labour-intensive method and capital intensive method of production depending upon the industrial requirements. To tackle unemployment problems, several industrial units absorb labourers and many industrial operations are managed and controlled by labour manually. Also an increase in EI can also be equated with lower labour productivity and employment of less-skilled labourers in industrial sector. Therefore, employment of labour is also expected to increase the EI and reduce energy efficiency. Our result is in the consistent with Soni et al. (2017). Therefore, provision of proper training and skill development to the labourers might help in raising their technical know-how and assist in enhancing their efficiency, thereby reducing EI. The positive association between LI and EI is also validated when fixed effects regression and Driscoll-Kraay standard error regression model with fixed effects were employed (see Table 7).

In the long run, most of the machines demand maintenance because of wear and tear. Therefore, maintenance of the machines involves routine checks, testing, service, lubricating, and repairs on a periodic basis. It also involves the realignment or replacement of damaged parts. Repair and maintenance of plant and machinery intensity RMPMI is positively related to EI and it is significant for all the quantiles. This result is assisted by Soni et al. (2017); Sahu and Narayanan (2011); and Sharma et al. (2019). Hence, adoption of predictive maintenance instead of traditional maintenance will assist in reducing the maintenance cost, optimize the availability of machinery process and its efficiency, minimize unexpected failures, and provide a periodic preventive system for repair and maintenance of the machines (Mobley 2001). Therefore, this is indicative that in order to reduce EI, outdated plants equipped with traditional methods of production need to be replaced by modern technology. We found similar results when fixed effects regression and Driscoll-Kraay standard error regression model with fixed effects were conducted (see Table 7).

Raw materials, store, and spares are a part of inventory used for further processing of goods. Firms invest either in fixed assets or else in inventories. Increase in the employment of raw materials, stores, and spares is expected to scale up the business and firms’ operations and hence necessitates more energy. Therefore, the coefficient of RMSSI is positive for all quantiles. Surprisingly, we found contrasting results when fixed effects regression and Driscoll-Kraay standard error regression model with fixed effects were performed (see Table 7). Therefore, the results reveal an inconclusive outcome when the data was analysed using different models.

We use net plant, machinery, and computer installation intensity to probe the impact of the variable PMI on EI. All of these components raise the demand of energy use, thereby increasing the EI. Because the usage of information and communication technology augments energy consumption, the installation of computers also drives energy demand (Lange et al. 2020). The indicator PMI is directly related with EI and it is consistent for all the quantiles. The same finding is obtained by Soni et al. (2017) and the linear models such as fixed effects regression and Driscoll-Kraay standard error regression model with fixed effects (see Table 7).

Increase in profit after tax incentivizes less EI firms to reuse its profits for further production which subsequently enhance energy consumption. The association between PATI and EI is found to be negative and significant for all quantiles except 75th quantile. The inverse relation between PATI and EI is favoured by Sahu and Sharma (2016) and Sharma et al. (2019). This implies that additional profits of the firms are used or invested in fixed assets (such as updated technical machineries and plants) which help in reducing the energy use. Results from panel quantile regression are similar to the robustness results obtained from regression models in a linear framework (see Table 7).

The variable TDI is negative and significant for lower energy-intensive and higher energy-intensive firms which imply less and more intensive firms spending on technological development will be able to reduce EI. This clearly shows that less and highly energy-intensive firms use updated and less energy-intensive or more (energy saving) efficient technologies for production process. Using these technologies, they are able to reduce the use of the energy. Furthermore, for moderate EI firms, the variable TDI affects the EI positively. This is also evident from the empirical outcomes that moderate energy-intensive firms use conventional energy-oriented technologies which further drive the use of more energy. However, the outcome of the robustness results for the variable TDI is found to be statistically insignificant (see Table 7).

Any type of outsourced operations and consultancies also demands more energy. Therefore, the indicator OI is found to be positive and significant for all the quantiles except for moderate energy-intensive firms and highly energy-intensive firms. This result supports previous literature (Soni et al. 2017) and the findings of the robustness estimates (see Table 7). Several IT-enabled services charges, software charges, and other professional services are also expected to increase energy usage. Therefore, the variable SI is found to be negative for all quantiles except for highly energy-intensive firms which stipulates that increment in SI will lead to an increment in EI applicable for high energy-intensive firms as they are also not able to reduce the energy usage while using these services including other operations. Because of mixed results obtained from the robustness checks as compared with the panel quantile regression, the impact of SI on EI for Indian firms is inconclusive.

Less energy-intensive firms and high energy-intensive firms are able reduce energy use with the increase in firms’ size measured through its assets. However, the impact of factor LNTA is negligible for overall firms because the impact of LNTA is meagre on EI and hence inconclusive for the aggregated dataset. The outcome of the panel quantile regression results is congruent to the results reported in Table 7.

The results from the empirical analysis endorse effective policy suggestions concomitant to EI for the overall Indian firms. The current study presents the evidence of a declining EI among Indian manufacturing and power sector and calls for micro-prudential norms in order to assist the firms implement efficient energy technologies and make effective use of economies of scale. Our study also offers policy directives in strengthening the PAT scheme and Energy Conservation Amendment Act, 2010.

Conclusion and policy suggestions

India, being one of the world’s rapidly developing economies, witnesses increasing energy demand, spurred by the country’s speedy industrialization and urbanization. Because of increasing cut-throat competitive across economies, changes in the population structure, expanding urbanization, social development, and the desire to achieve and maintain self-reliance in specific sectors, the demand for energy, particularly commercial energy, is expected to create energy crisis that necessitates prompt action.

Against the backdrop of these pertinent issues related to energy demand and growing environmental degradation, the current study explores the determinants of EI in Indian manufacturing industries and power sector. To examine the relationship of firm-specific explanatory variables on EI, the panel quantile regression method is employed. This method determines the non-linear effects of the factors which influence the EI and the results from the panel quantile regression are validated from the outcome of fixed effects regression and Driscoll-Kraay regression with fixed effects estimates. The data used for the current study commences from the year 2010 through 2021, and was sourced from CMIE Prowess IQ database. Our results indicate that the variables RMPMI, RMSSI, and PMI induce EI of the overall firms. Additionally, we find that LNTA reduces EI wherein other variables show mixed outcomes when panel quantile regression was estimated. The robustness of the panel quantile regression outcomes was validated through the fixed effects and Driscoll-Kraay regression with fixed effects estimates. It is important to note that firm EI increases with the profit margin, and raw materials, plants, stores, and maintenance. Therefore, firms need to find out alternative ways to be more competitive by reducing the production costs, manage resources effectively, implement efficient modern technologies, and take advantage of economies of scale. Although the trends indicate a declining trend in EI in Indian context, however, continuous efforts are required at firm level to considerably reduce the greenhouse gas emissions and overdependence on fossil fuel energy to become carbon neutral by 2070.

References

Bhat JA, Haider S, Kamaiah B (2018) Interstate energy efficiency of Indian paper industry: a slack-based non-parametric approach. Energy 161:284–298

Canay IA (2011) A simple approach to quantile regression for panel data. Economet J 14(3):368–386

Chalvatzis KJ, Malekpoor H, Mishra N, Lettice F, Choudhary S (2019) Sustainable resource allocation for power generation: the role of big data in enabling interindustry architectural innovation. Technol Forecast Soc Chang 144:381–393

Chalvatzis KJ (2009) Electricity generation development of Eastern Europe: A carbon technology management case study for Poland. Renew Sust Energ Rev 13(6–7):1606–1612

Dasgupta S, Roy J (2015) Understanding technological progress and input price as drivers of energy demand in manufacturing industries in India. Energy Policy 83:1–13

Dasgupta S, Roy J (2017) Analysing energy intensity trends and decoupling of growth from energy use in Indian manufacturing industries during 1973–1974 to 2011–2012. Energ Effi 10(4):925–943

Galvao AF Jr (2011) Quantile regression for dynamic panel data with fixed effects. J Econom 164(1):142–157

Golder B (2011) Energy intensity of Indian manufacturing firms: effect of energy prices, technology and firm characteristics. Sci Technol Soc 16(3):351–372

Haider S, Mishra PP (2021) Does innovative capability enhance the energy efficiency of Indian Iron and Steel firms? A Bayesian stochastic frontier analysis. Energy Econ 95:105128

Haider S, Danish MS, Sharma R (2019) Assessing energy efficiency of Indian paper industry and influencing factors: a slack-based firm-level analysis. Energy Econ 81:454–464

International energy agency. (2021). Energy in India today. Is 2020 a turning point? India energy outlook. Available at: https://iea.blob.core.windows.net/assets/1de6d91e-e23f-4e02-b1fb-51fdd6283b22/India_Energy_Outlook_2021.pdf

Jain M, Kaur S (2021) Determinants of energy intensity trends in Indian metallic industry: a firm-level analysis. Vision 09722629211004293. Available at: https://journals.sagepub.com/doi/full/10.1177/09722629211004293

Koenker R (2004) Quantile regression for longitudinal data. J Multivar Anal 91(1):74–89

Kumar A (2003) Energy intensity: a quantitative exploration for Indian manufacturing. Available at: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=468440

Lamarche C (2010) Robust penalized quantile regression estimation for panel data. J Econom 157(2):396–408

Lange S, Pohl J, Santarius T (2020) Digitalization and energy consumption. Does ICT reduce energy demand? Ecol Econ 176:106760

Mobley RK (2001) Plant engineer's handbook. Elsevier. Available at: https://www.sciencedirect.com/book/9780750673280/plant-engineershandbook

Mohan Ram M, Gundimeda H, Kathuria V (2015) Does energy intensity affect labour productivity in Indian firms? Preliminary estimates. Energy Security and Development. Springer, New Delhi, pp 293–306

Mohan NC (2011) Why India is grappling with labour issues? Rediff.com. Available at: https://www.rediff.com/business/slide-show/slide-show-1-column-why-india-is-grappling-with-labour-issues/20111025.htm#1

Narayanan K, Sahu SK (2012) CO2 Emission and firm heterogeneity: A study of metals & metal based industries in India. Munich personal RePEc archive. Available at:https://core.ac.uk/download/pdf/213935156.pdf

Oak H, Bansal S (2017) Effect of perform-achieve-trade policy on energy efficiency of Indian industries by Hena Oak, Sangeeta Bansal: SSRN. Available at: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3412317

Pradhan AK, Rout S, Khan IA (2021) Does market concentration affect wholesale electricity prices? An analysis of the Indian electricity sector in the COVID-19 pandemic context. Util Policy 73:101305

Pradhan AK, Hiremath GS (2020) Why do Indian firms borrow in foreign currency? Margin. J Appl Econ Res 14(2):191–211

Pradhan AK, Sachan A, Sahu UK, Mohindra V (2022) Do foreign direct investment inflows affect environmental degradation in BRICS nations? Environ Sci Pollut Res 29(1):690–701

Powell, D. (2022). Quantile regression with nonadditive fixed effects. Empirical Economics, 1–17.

Rasool SF, Chin T, Wang M, Asghar A, Khan A, Zhou, L (2022) Exploring the role of organizational support, and critical success factors on renewable energy projects of Pakistan. Energy 243:122765

Reddy BS, Ray BK (2010) Decomposition of energy consumption and energy intensity in Indian manufacturing industries. Energy Sustain Dev 14(1):35–47

Sahu SK, Mehta D (2018) Determinants of energy and CO2 emission intensities: a study of manufacturing firms in India. Singapore Econ Rev 63(02):389–407

Sahu SK, Narayanan K (2010) Determinants of energy intensity in Indian manufacturing industries: a firm level analysis. Available at:https://mpra.ub.uni-muenchen.de/21646/

Sahu SK, Narayanan K (2011) Total factor productivity and energy intensity in Indian manufacturing: a cross-sectional study. Int J Energy Econ Policy 1(2):47–58

Sahu SK, Narayanan K (2013) Labour and energy intensity: a study of the pulp and paper industries in India. Human Capital and Development. Springer, India, pp 55–76

Sahu SK, Sharma H (2016) Productivity, energy intensity and output: a unit level analysis of the Indian manufacturing sector. J Quant Econ 14(2):283–300

Sahu SK, Bagchi P, Kumar A, Tan KH (2022) Technology, price instruments and energy intensity: a study of firms in the manufacturing sector of the Indian economy. Ann Oper Res 313(1):319–339

Sharma A, Roy H, Dalei NN (2019) Estimation of energy intensity in Indian iron and steel sector: a panel data analysis. Stat Transit 107

Soni A, Mittal A, Kapshe M (2017) Energy intensity analysis of Indian manufacturing industries. Resource-Efficient Technologies 3(3):353–357

Subrahmanya MB (2006) Labour productivity, energy intensity and economic performance in small enterprises: a study of brick enterprises cluster in India. Energy Convers Manage 47(6):763–777

Sahu, S. (2009). Trends and Patterns of Energy Consumption in India. Munich Personal RePEc Archive Working Papers. 11 August, 2009. Available at: https://mpra.ub.uni-muenchen.de/16753/

Wang S, Chen S, Zhang H (2021) Effect of income and energy efficiency on natural capital demand. Environ Sci Pollut Res 28(33):45402–45413

Wang B, Rasool SF, Zhao Y, Samma M, Iqbal J (2022) Investigating the nexus between critical success factors, despotic leadership, and success of renewable energy projects. Environ Sci Pollut Res 29(7):10388–10398

Zhang D, Cao H, Wei YM (2016) Identifying the determinants of energy intensity in China: a Bayesian averaging approach. Appl Energy 168:672–682

Zhang D, Li J, Ji Q (2020) Does better access to credit help reduce energy intensity in China? Evidence from Manufacturing Firms. Energy Policy 145:111710

Zhang H, Chen S, Wang S (2022) Impact of economic growth and labor productivity dispersion on energy intensity in China. Energy 242:123004

Zhang YJ, Liu Z, Zhang H, Tan TD (2014) The impact of economic growth, industrial structure and urbanization on carbon emission intensity in China. Nat Hazards 73(2):579–595

Author information

Authors and Affiliations

Contributions

Aman Kumar: writing—review and editing, data curation, and analysis. Arvind Mittal: conceptualization, supervision, writing—review and editing. Ashis Kumar Pradhan: software, validation, methodology, and analysis.

Corresponding author

Ethics declarations

Ethics approval

NA

Consent to participate

NA

Consent to publish

We give the consent for the publication of the material in the current research to the journal Environmental Science and Pollution Research.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Mittal, A. & Pradhan, A.K. Magnitude and determinants of energy intensity: evidence from Indian firms. Environ Sci Pollut Res 30, 3270–3281 (2023). https://doi.org/10.1007/s11356-022-22346-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22346-9