Abstract

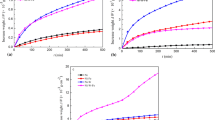

Amorphous NiP and NiCrP alloy coatings were prepared on copper substrates by electrodeposition. The thermal stability of the obtained coatings were evaluated by the onset temperature of phase transformation identified with differential scanning calorimetry measurements, and their high temperature oxidation resistances were characterized by the oxidation kinetics curve and the oxidation activation energy. The mechanism of the doping effect of Cr element on crystallization temperature and oxidation resistance of the alloy coatings were discussed based on X-ray diffraction analysis. The results show that the crystallization temperature of NiP amorphous alloy was \(344^{\circ }\hbox {C}\), and the oxidation activation energy was calculated to be \(1.54 \times 10^{\mathrm {3}}\hbox { J mol}^{\mathrm {-1}}\). As for NiCrP alloy coating with a Cr content of 1.8 wt%, the crystallization temperature increased to \(403.8^{\circ }\hbox {C}\) and the calculated oxidation activation energy was \(3.53 \times 10^{\mathrm {4}}\hbox { J mol}^{\mathrm {-1}}\), 2.29 times higher than the NiP coating. The remarkably enhanced high-temperature oxidation resistance of NiCrP alloy coating can be attributed to the compact metal oxide film formed on the surface.

Similar content being viewed by others

References

Brenner A and Riddel G 1964 J. Res. Natl. Bur. Stand.37 1

Brenner A and Riddel G 1974 J. Res. Natl. Bur. Stand.39 385

Li H, Chen H and Dong S 1998 Appl. Surf. Sci.125 115

Novakovic J, Vassiliou P and Samara K 2006 Surf. Coat.Technol.201 895

Song G-M, Wu Y and Xu Q 2010 J. Power Sources195 3913

Wang A, Zhao C and He A 2016 J. Alloys Compd.656 729

Xie J, Yang C and Duan M 2018 Ceram. Int.44 5459

Honghong S and Jiaming J 2002 Trans. Chin. Soc. Agric. Mach.1 29

Myshkin N K, Grigoriev A Y and Gutsev D M 2013 Trans. Tech. Publ.527 92

Yang Q, Lv C and Huang Z 2018 Int. J. Hydrog. Energy43 7872

Yu Y D, Wei G Y and Guo H F 2012 Surf. Eng.28 30

Balaraju J N, Manikandanath N T and Grips V K W 2012 Surf. Coat. Technol.206 2682

Hou P Y and Stringer J 1987 J. Electrochem. Soc.134 1836

Hussey R J and Graham M J 1996 Oxid. Met.45 349

Wang C Y, Zhou Y M and Zhang F L 2009 J. Alloys Compd.476 884

Wu N, Li Y and Wang J 2012 J. Mater. Process. Technol.212 794

Zhang B P, Habazaki H and Kawashima A 1991 Corros. Sci.32 433

Kumar P S and Nair P K 1996 J. Mater. Process. Technol.56 511

Wang Y and Lu K 2001 Sci. China Ser. E (Tech. Sci.)44 33

Choi B Y, Liang J and Gao W 2005 Met. Mater. Int.11 499

Erlinda V O, Daniel O B, Daniel E B, Silvina E F and Pablo R D 2017 Environ. Sci. Pollut. Res.24 27366

Suwanwatana W, Yarlagadda S and Gillespie J J W 2003 J. Mater. Sci.38 565

Lai Z H, Wu Y K and Guo K X 1984 Acta Phys. Sin.33 1182

Maeda K, Ikari T and Akashi Y 1994 J. Mater. Sci.29 1449

Acknowledgements

This work was supported by the National Key Laboratory Independent Research funding support project of China (Grant no. 20181-6).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Y.Q., Yu, J.K., Yang, H.B. et al. Improved thermal stability and oxidation resistance of electrodeposited NiCrP amorphous alloy coatings. Bull Mater Sci 43, 98 (2020). https://doi.org/10.1007/s12034-020-2067-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-2067-y