Abstract

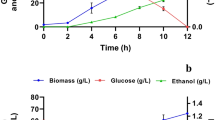

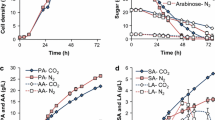

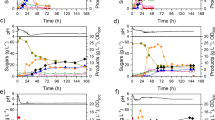

Solid-state fermentation, featured by water-saving, eco-friendly and high concentration product, is a promising technology in lignocellulosic ethanol industry. However, in solid-state fermentation system, large gas content inside the substrate directly leads to high oxygen partial pressure and inhibits ethanol fermentation. Z. mobilis can produce ethanol from glucose near the theoretical maximum value, but this ethanol yield would be greatly decreased by high oxygen partial pressure during solid-state fermentation. In this study, we applied N2 periodic pulsation process intensification (NPPPI) to ethanol solid-state fermentation, which displaced air with N2 and provided a proper anaerobic environment for Z. mobilis. Based on the water state distribution, the promotion effects of NPPPI on low solid loading and solid-state fermentation were analyzed to confirm the different degrees of oxygen inhibition in ethanol solid-state fermentation. During the simultaneous saccharification solid-state fermentation, the NPPPI group achieved 45.29% ethanol yield improvement and 30.38% concentration improvement compared with the control group. NPPPI also effectively decreased 58.47% of glycerol and 84.24% of acetic acid production and increased the biomass of Z. mobilis. By coupling the peristaltic enzymatic hydrolysis and fed-batch culture, NPPPI made the ethanol yield and concentration reach 80.11% and 55.06 g/L, respectively, in solid-state fermentation.

Similar content being viewed by others

References

Chen, H., & Qiu, W. (2010). Key technologies for bioethanol production from lignocellulose. Biotechnology Advances, 28(5), 556–562.

Zhu, Y., Kim, T. H., Lee, Y., Chen, R., & Elander, R. T. (2006). Enzymatic production of xylooligosaccharides from corn stover and corn cobs treated with aqueous ammonia. Applied Biochemistry and Biotechnology, 130(1-3), 586–598.

Himmel, M. E., Ding, S.-Y., Johnson, D. K., Adney, W. S., Nimlos, M. R., Brady, J. W., & Foust, T. D. (2007). Biomass recalcitrance: Engineering plants and enzymes for biofuels production. Science, 315, 804–807.

Hongzhang, C., & Liying, L. (2007). Unpolluted fractionation of wheat straw by steam explosion and ethanol extraction. Bioresource Technology, 98(3), 666–676.

Wyman, C. E. (2001). Twenty years of trials, tribulations, and research progress in bioethanol technology. Applied Biochemistry and Biotechnology, 91, 5–21.

Ballesteros, I., Ballesteros, M., Cabanas, A., Carrasco, J., Martin, C., Negro, M., Saez, F., & Saez, R. (1991). Selection of thermotolerant yeasts for simultaneous saccharification and fermentation (SSF) of cellulose to ethanol. Applied Biochemistry and Biotechnology, 28, 307–315.

Liu, Z.-H., & Chen, H. (2016). Periodic peristalsis enhancing the high solids enzymatic hydrolysis performance of steam exploded corn stover biomass. Biomass and Bioenergy, 93, 13–24.

Koppram, R., Tomás-Pejó, E., Xiros, C., & Olsson, L. (2014). Lignocellulosic ethanol production at high-gravity: Challenges and perspectives. Trends in Biotechnology, 32(1), 46–53.

Chen, H. (2013). Modern solid state fermentation. Dordrecht: Springer.

He, Q., & Chen, H. (2015). Comparative study on occurrence characteristics of matrix water in static and gas double-dynamic solid-state fermentations using low-field NMR and MRI. Analytical and Bioanalytical Chemistry, 407(30), 9115–9123.

Weiss, N. D., Felby, C., & Thygesen, L. G. (2019). Enzymatic hydrolysis is limited by biomass–water interactions at high-solids: Improved performance through substrate modifications. Biotechnology for Biofuels, 12(1), 3.

Zhao, Q., Wang, L. and Chen, H. (2019) Effect of novel pretreatment of steam explosion associated with ammonium sulfite process on enzymatic hydrolysis of corn straw. Applied biochemistry and biotechnology, 1-13.

Bai, F., Anderson, W., & Moo-Young, M. (2008). Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnology Advances, 26(1), 89–105.

Rogers, P., Lee, K., Skotnicki, M. and Tribe, D. (1982), In microbial reactions, springer, pp. 37-84.

Kremer, T. A., LaSarre, B., Posto, A. L., & McKinlay, J. B. (2015). N2 gas is an effective fertilizer for bioethanol production by Zymomonas mobilis. Proceedings of the National Academy of Sciences, 112, 2222–2226.

Bringer, S., Finn, R. K., & Sahm, H. (1984). Effect of oxygen on the metabolism of Zymomonas mobilis. Archives of Microbiology, 139(4), 376–381.

Kalnenieks, U. (2006). Physiology of Zymomonas mobilis: Some unanswered questions. Advances in Microbial Physiology, 51, 73–117.

Kirby, M. E., Mirza, M. W., Leigh, T., Oldershaw, L., Reilly, M., & Jeffery, S. (2019). Destruction of Staphylococcus aureus and the impact of chlortetracycline on biomethane production during anaerobic digestion of chicken manure. Heliyon, 5(11), e02749.

Metcalf, W. W., Zhang, J. K., & Wolfe, R. S. (1998). An Anaerobic, Intrachamber Incubator for Growth of Methanosarcina spp. on Methanol-Containing Solid Media. Applied & Environmental Microbiology, 64(2), 768–770.

Balish, E., Brown, J. F., & Wilkins, T. D. (1977). Transparent plastic incubator for the anaerobic glove box. Applied & Environmental Microbiology, 33(3), 525–527.

Zhao, Z.-M., Wang, L., & Chen, H.-Z. (2015). Variable pressure pulsation frequency optimization in gas double-dynamic solid-state fermentation (GDSSF) based on heat balance model. Process Biochemistry, 50(2), 157–164.

Chen, H.-Z., Xu, J., & Li, Z.-H. (2005). Temperature control at different bed depths in a novel solid-state fermentation system with two dynamic changes of air. Biochemical Engineering Journal, 23(2), 117–122.

Chen, H., Qin, L., Li, H., et al. Appl Biochem Biotechnol, 172, 2218–2226.

Liu, J., Li, D. B., & Yang, J. C. (2007). Operating characteristics of solid-state fermentation bioreactor with air pressure pulsation. Applied Biochemistry & Microbiology, 43, 234–239.

Chen, H. Z., Zhao, Z.-M., & Li, H.-Q. The effect of gas double-dynamic on mass distribution in solid-state fermentation. Enzyme & Microbial Technology, 58-59, 14–21.

Chen, H., Shao, M., & Li, H. (2014). Effects of gas periodic stimulation on key enzyme activity in gas double-dynamic solid state fermentation (GDD-SSF). Enzyme and Microbial Technology, 56, 35–39.

Ghose, T. (1987). Measurement of cellulase activities. Pure and Applied Chemistry, 59(2), 257–268.

Liu, Z.-H., & Chen, H.-Z. (2016). Periodic peristalsis releasing constrained water in high solids enzymatic hydrolysis of steam exploded corn Stover. Bioresource Technology, 205, 142–152.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., & Crocker, D. (2008). Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure, 1617, 1–16.

Olofsson, K., Rudolf, A., & Lidén, G. (2008). Designing simultaneous saccharification and fermentation for improved xylose conversion by a recombinant strain of Saccharomyces cerevisiae., 134, 112–120.

Liu, Z. H., & Chen, H. Z. (2015). Biomass–water interaction and its correlations with enzymatic hydrolysis of steam-exploded corn stover. ACS Sustainable Chemistry & Engineering, 4, 1274–1285.

Roberts, K. M., Lavenson, D. M., Tozzi, E. J., McCarthy, M. J., & Jeoh, T. (2011). The effects of water interactions in cellulose suspensions on mass transfer and saccharification efficiency at high solids loadings. Cellulose, 18(3), 759–773.

Zhao, J., & Chen, H. (2013). Correlation of porous structure, mass transfer and enzymatic hydrolysis of steam exploded corn stover. Chemical Engineering Science, 104, 1036–1044.

Wang, X., He, Q., Yang, Y., Wang, J., Haning, K., Hu, Y., Wu, B., He, M., Zhang, Y., & Bao, J. Advances and Prospects in Metabolic Engineering of Zymomonas mobilis. Metabolic Engineering, 50, 57 S1096717618300363.

Ishikawa, H., Nobayashi, H., & Tanaka, H. (1990). Mechanism of fermentation performance of Zymomonas mobilis under oxygen supply in batch culture. Journal of Fermentation and Bioengineering, 70(1), 34–40.

Tanaka, H., Ishikawa, H., Osuga, K., & Takagi, Y. (1990). Fermentative ability of Zymomonas mobilis under various oxygen supply conditions in batch culture. Journal of Fermentation and Bioengineering, 69(4), 234–239.

Xu, Z., Wang, Q., Jiang, Z., Yang, X.-x., & Ji, Y. (2007). Enzymatic hydrolysis of pretreated soybean straw. Biomass and Bioenergy, 31(2-3), 162–167.

Andreaus, J., Azevedo, H., & Cavaco-Paulo, A. (1999). Effects of temperature on the cellulose binding ability of cellulase enzymes. Journal of Molecular Catalysis B: Enzymatic, 7(1-4), 233–239.

Moreau, R. A., Powell, M. J., Fett, W. F., & Whitaker, B. D. (1997). News & Notes: The effect of ethanol and oxygen on the growth of zymomonas mobilis and the levels of hopanoids and other membrane lipids. Current Microbiology, 35(2), 124–128.

Bondesson, P.-M., & Galbe, M. (2016). Process design of SSCF for ethanol production from steam-pretreated, acetic-acid-impregnated wheat straw. Biotechnology for Biofuels, 9(1), 222.

Kim, Y., Hendrickson, R., Mosier, N. S., Ladisch, M. R., Bals, B., Balan, V., Dale, B. E., Dien, B. S., & Cotta, M. A. (2010). Effect of compositional variability of distillers’ grains on cellulosic ethanol production. Bioresource Technology, 101(14), 5385–5393.

Öhgren, K., Vehmaanperä, J., Siika-Aho, M., Galbe, M., Viikari, L., & Zacchi, G. (2007). High temperature enzymatic prehydrolysis prior to simultaneous saccharification and fermentation of steam pretreated corn Stover for ethanol production. Enzyme and Microbial Technology, 40(4), 607–613.

Wang, R., Unrean, P., & Franzén, C. J. (2016). Model-based optimization and scale-up of multi-feed simultaneous saccharification and co-fermentation of steam pre-treated lignocellulose enables high gravity ethanol production. Biotechnology for Biofuels, 9(1), 88.

Minihane, B. J., & Brown, D. E. (1986). Fed-batch culture technology. Biotechnology Advances, 4(2), 207–218.

Funding

This study was financially supported by the National Key Research and Development Program of China (Grant No.2018YFB1501702) and the Transformational Technologies for Clean Energy and Demonstration (Strategic Priority Research Program of the Chinese Academy of Sciences, Grant No.XDA 21060300).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, L., Wang, L. & Chen, H. High Productivity Ethanol from Solid-State Fermentation of Steam-Exploded Corn Stover Using Zymomonas mobilis by N2 Periodic Pulsation Process Intensification. Appl Biochem Biotechnol 192, 466–481 (2020). https://doi.org/10.1007/s12010-020-03318-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-020-03318-6