Abstract

Tomato pomace is an abundant lignocellulosic waste stream from industrial tomato processing and therefore a potential feedstock for production of renewable biofuels. However, little research has been conducted to determine if pretreatment can enhance release of fermentable sugars from tomato pomace. Ionic liquids (ILs) are an emerging pretreatment technology for lignocellulosic biomass to increase enzymatic digestibility and biofuel yield while utilizing recyclable chemicals with low toxicity. In this study, pretreatment of tomato pomace with the ionic liquid 1-ethyl-3-methylimidazolium acetate ([C2mim][OAc]) was investigated. Changes in pomace enzymatic digestibility were affected by pretreatment time and temperature. Certain pretreatment conditions significantly improved reducing sugar yield and hydrolysis time compared to untreated pomace. Compositional analyses suggested that pretreatment primarily removed water-soluble compounds and enriched for lignocellulose in pomace, with only subtle changes to the composition of the lignocellulose. While tomato pomace was effectively pretreated with [C2mim][OAc] to improve enzymatic digestibility, as of yet, unknown factors in the pomace caused ionic liquid pretreatment to negatively affect anaerobic digestion of pretreated material. This result, which is unique compared to similar studies on IL pretreatment of grasses and woody biomass, highlights the need for additional research to determine how the unique chemical composition of tomato pomace and other lignocellulosic fruit residues may interact with ionic liquids to generate inhibitors for downstream fermentation to biofuels.

Similar content being viewed by others

References

Brandt, A., Gräsvik, J., Hallett, J., & Welton, T. (2013). Deconstruction of lignocellulosic biomass with ionic liquids. Green Chemistry, 15, 550–583.

Dadi, A. P., Varanasi, S., & Schall, C. A. (2006). Enhancement of cellulose saccharification kinetics using an ionic liquid pretreatment step. Biotechnology and Bioengineering, 95, 904–910.

Gao, J., Chen, L., Yan, Z., & Wang, L. (2013). Effect of ionic liquid pretreatment on the composition, structure and biogas production of water hyacinth (Eichhornia crassipes). Bioresource Technology, 132, 361–364.

Haykir, N. I., Bahcegul, E., Bicak, N., & Bakir, U. (2013). Pretreatment of cotton stalk with ionic liquids including 2-hydroxy ethyl ammonium formate to enhance biomass digestibility. Industrial Crops and Products, 41, 430–436.

Zhao, H., Baker, G. A., & Cowins, J. V. (2010). Fast enzymatic saccharification of switchgrass after pretreatment with ionic liquids. Biotechnology Progress, 26, 127–133.

Li, C., Knierim, B., Manisseri, C., Arora, R., Scheller, H. V., Auer, M., Vogel, K. P., Simmons, B. A., & Singh, S. (2010). Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification. Bioresource Technology, 101, 4900–4906.

Li, C., Sun, L., Simmons, B., & Singh, S. (2013). Comparing the recalcitrance of eucalyptus, pine, and switchgrass using ionic liquid and dilute acid pretreatments. Bioenergy Research, 6, 14–23.

Li, Q., Jiang, X., He, Y., Li, L., Xian, M., & Yang, J. (2010). Evaluation of the biocompatibile ionic liquid 1-methyl-3-methylimidazolium dimethylphosphite pretreatment of corn cob for improved saccharification. Applied Microbiology and Biotechnology, 87, 117–126.

Fu, D., & Mazza, G. (2011). Optimization of processing conditions for the pretreatment of wheat straw using aqueous ionic liquid. Bioresource Technology, 102, 8003–8010.

Katinonkul, W., Lee, J.-S., Ha, S. H., & Park, J.-Y. (2012). Enhancement of enzymatic digestibility of oil palm empty fruit bunch by ionic-liquid pretreatment. Energy, 47, 11–16.

Feng, X., Wang, H., Wang, Y., Wang, X., & Huang, J. (2010). Biohydrogen production from apple pomace by anaerobic fermentation with river sludge. International Journal of Hydrogen Energy, 35, 3058–3064.

Wang, H., Wang, J., Fang, Z., Wang, X., & Bu, H. (2010). Enhanced bio-hydrogen production by anaerobic fermentation of apple pomace with enzyme hydrolysis. International Journal of Hydrogen Energy, 35, 8303–8309.

Fernandes Maria, C., Torrado, I., Carvalheiro, F., Dores, V., Guerra, V., Lourenço Pedro, M. L. and Duarte Luís, C. (2016). Bioethanol production from extracted olive pomace: dilute acid hydrolysis. Bioethanol, 2.

Zheng, Y., Lee, C., Yu, C., Cheng, Y.-S., Simmons, C. W., Zhang, R., Jenkins, B. M., & VanderGheynst, J. S. (2012). Ensilage and bioconversion of grape pomace into fuel ethanol. Journal of Agricultural and Food Chemistry, 60, 11128–11134.

Barrios-Masias, F. H., & Jackson, L. E. (2014). California processing tomatoes: morphological, physiological and phenological traits associated with crop improvement during the last 80 years. European Journal of Agronomy, 53, 45–55.

Matteson, G. C., & Jenkins, B. M. (2007). Food and processing residues in California: resource assessment and potential for power generation. Bioresource Technology, 98, 3098–3105.

Al-Wandawi, H., Abdul-Rahman, M., & Al-Shaikhly, K. (1985). Tomato processing wastes as essential raw materials source. Journal of Agricultural and Food Chemistry, 33, 804–807.

Torr, K. M., Love, K. T., Çetinkol, Ö. P., Donaldson, L. A., George, A., Holmes, B. M., & Simmons, B. A. (2012). The impact of ionic liquid pretreatment on the chemistry and enzymatic digestibility of Pinus radiata compression wood. Green Chemistry, 14, 778–787.

Sun, N., Rahman, M., Qin, Y., Maxim, M. L., Rodríguez, H., & Rogers, R. D. (2009). Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chemistry, 11, 646–655.

Qiu, Z., Aita, G. M., & Walker, M. S. (2012). Effect of ionic liquid pretreatment on the chemical composition, structure and enzymatic hydrolysis of energy cane bagasse. Bioresource Technology, 117, 251–256.

Shafiei, M., Zilouei, H., Zamani, A., Taherzadeh, M. J., & Karimi, K. (2013). Enhancement of ethanol production from spruce wood chips by ionic liquid pretreatment. Applied Energy, 102, 163–169.

da Costa Lopes, A., Joao, K., Morais, A. R., Bogel-Lukasik, E., & Bogel-Lukasik, R. (2013). Ionic liquids as a tool for lignocellulosic biomass fractionation. Sustainable Chemical Processes, 1, 3.

Gutowski, K. E., Broker, G. A., Willauer, H. D., Huddleston, J. G., Swatloski, R. P., Holbrey, J. D., & Rogers, R. D. (2003). Controlling the aqueous miscibility of ionic liquids: aqueous biphasic systems of water-miscible ionic liquids and water-structuring salts for recycle, metathesis, and separations. Journal of the American Chemical Society, 125, 6632–6633.

Van Soest, P. J. (1973). Collaborative study of acid-detergent fiber and lignin. Journal of the American Oil Chemists’ Society, 56, 781–784.

Van Soest, P. J., Robertson, J. B., & Lewis, B. A. (1991). Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 74, 3583–3597.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C. and Sluiter, J. (2012). Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedures (LAP), National Renewable Energy Laboratory (NREL), Golden, CO. Revised version Jul 2011.

Gancedo, M. C., & Luh, B. S. (1986). HPLC analysis of organic acids and sugars in tomato juice. Journal of Food Science, 51, 571–573.

Li, Q., He, Y.-C., Xian, M., Jun, G., Xu, X., Yang, J.-M., & Li, L.-Z. (2009). Improving enzymatic hydrolysis of wheat straw using ionic liquid 1-ethyl-3-methyl imidazolium diethyl phosphate pretreatment. Bioresource Technology, 100, 3570–3575.

Avelino, A., Avelino, H. T., Roseiro, J. C., & Collaço, M. T. A. (1997). Saccharification of tomato pomace for the production of biomass. Bioresource Technology, 61, 159–162.

Haddadin, M. S. Y., Abu-Reesh, I. M., Haddadin, F. A. S., & Robinson, R. K. (2001). Utilisation of tomato pomace as a substrate for the production of vitamin B12—a preliminary appraisal. Bioresource Technology, 78, 225–230.

Li, B., Asikkala, J., Filpponen, I., & Argyropoulos, D. S. (2010). Factors affecting wood dissolution and regeneration of ionic liquids. Industrial & Engineering Chemistry Research, 49, 2477–2484.

Shill, K., Padmanabhan, S., Xin, Q., Prausnitz, J. M., Clark, D. S., & Blanch, H. W. (2011). Ionic liquid pretreatment of cellulosic biomass: enzymatic hydrolysis and ionic liquid recycle. Biotechnology and Bioengineering, 108, 511–520.

Doherty, T. V., Mora-Pale, M., Foley, S. E., Linhardt, R. J., & Dordick, J. S. (2010). Ionic liquid solvent properties as predictors of lignocellulose pretreatment efficacy. Green Chemistry, 12, 1967–1975.

Klein-Marcuschamer, D., Simmons, B. A., & Blanch, H. W. (2011). Techno-economic analysis of a lignocellulosic ethanol biorefinery with ionic liquid pre-treatment. Biofuels, Bioproducts and Biorefining, 5, 562–569.

Del Valle, M., Cámara, M., & Torija, M.-E. (2006). Chemical characterization of tomato pomace. Journal of the Science of Food and Agriculture, 86, 1232–1236.

Lazos, E. S., & Kalathenos, P. (1988). Technical note: composition of tomato processing wastes. International Journal of Food Science and Technology, 23, 649–652.

Lenucci, M. S., Durante, M., Anna, M., Dalessandro, G., & Piro, G. (2013). Possible use of the carbohydrates present in tomato pomace and in byproducts of the supercritical carbon dioxide lycopene extraction process as biomass for bioethanol production. Journal of Agricultural and Food Chemistry, 61, 3683–3692.

Lee, S. H., Doherty, T. V., Linhardt, R. J., & Dordick, J. S. (2009). Ionic liquid-mediated selective extraction of lignin from wood leading to enhanced enzymatic cellulose hydrolysis. Biotechnology and Bioengineering, 102, 1368–1376.

da Costa Lopes, A. M., João, K. G., Rubik, D. F., Bogel-Łukasik, E., Duarte, L. C., Andreaus, J., & Bogel-Łukasik, R. (2013). Pre-treatment of lignocellulosic biomass using ionic liquids: wheat straw fractionation. Bioresource Technology, 142, 198–208.

Fu, D., Mazza, G., & Tamaki, Y. (2010). Lignin extraction from straw by ionic liquids and enzymatic hydrolysis of the cellulosic residues. Journal of Agricultural and Food Chemistry, 58, 2915–2922.

Magalhaes da Silva, S. P., da Costa Lopes, A. M., Roseiro, L. B., & Bogel-Lukasik, R. (2013). Novel pre-treatment and fractionation method for lignocellulosic biomass using ionic liquids. RSC Advances, 3, 16040–16050.

Saravanan, R. S., & Rose, J. K. C. (2004). A critical evaluation of sample extraction techniques for enhanced proteomic analysis of recalcitrant plant tissues. PROTEOMICS, 4, 2522–2532.

Sogi, D. S., Arora, M. S., Garg, S. K., & Bawa, A. S. (2002). Fractionation and electrophoresis of tomato waste seed proteins. Food Chemistry, 76, 449–454.

Gao, J., Chen, L., Yuan, K., Huang, H., & Yan, Z. (2013). Ionic liquid pretreatment to enhance the anaerobic digestion of lignocellulosic biomass. Bioresource Technology, 150, 352–358.

Benzing-Purdie, L. M., Ripmeester, J. A., & Ratcliffe, C. I. (1985). Effects of temperature on Maillard reaction products. Journal of Agricultural and Food Chemistry, 33, 31–33.

Einarsson, H., Snygg, B. G., & Eriksson, C. (1983). Inhibition of bacterial growth by Maillard reaction products. Journal of Agricultural and Food Chemistry, 31, 1043–1047.

Stecchini, M. L., Giavedoni, P., Sarais, I., & Lerici, C. R. (1991). Effect of Maillard reaction products on the growth of selected food-poisoning micro-organisms. Letters in Applied Microbiology, 13, 93–96.

Frankel, E. N. (1984). Lipid oxidation: mechanisms, products and biological significance. J Am Oil Chem Soc, 61, 1908–1917.

Novak, A. F., Solar, J. M., Mod, R. R., Magne, F. C., & Skau, E. L. (1969). Antimicrobial activity of some N-substituted amides of long-chain fatty acids. Applied Microbiology, 18, 1050–1056.

Nawar, W. W. (1969). Thermal degradation of lipids. Journal of Agricultural and Food Chemistry, 17, 18–21.

Acknowledgments

The authors thank the Campbell Soup Company for providing tomato pomace samples. This work was supported by the New Research Initiatives and Collaborative Interdisciplinary Research Grants program provided by the University of California, Davis Academic Senate Committee on Research and by the National Institute of Food and Agriculture (project number CA-D-FST-2236-RR).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Figure Supplementary Figure 1

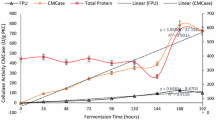

Representative plots of empirical data describing release of reducing sugars during enzymatic hydrolysis of pomace pretreated using different conditions and a washed pomace control (shapes) and corresponding fitted non-linear regression models (dashed lines) are given for select samples across the design space to indicate the goodness of fit. (PNG 139 kb)

Rights and permissions

About this article

Cite this article

Allison, B.J., Cádiz, J.C., Karuna, N. et al. The Effect of Ionic Liquid Pretreatment on the Bioconversion of Tomato Processing Waste to Fermentable Sugars and Biogas. Appl Biochem Biotechnol 179, 1227–1247 (2016). https://doi.org/10.1007/s12010-016-2061-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2061-4