Abstract

Energy efficiency is considered an important indicator after the efficiency term is one framework of economic planning. The review results show that the gained energy is completely different in industries due to the production line, raw material, used fuel, system automation, application of thermodynamic rules, and energy recovery applications. The thermal parameters of the machining system are the main indicators to determine the system's efficiency. Dynamic behavior, effectiveness, and thermal capacity limitation are some parameters used for the optimization of machining energy efficiency. The temperature, pressure, flow rate, and other operating conditions as a function of time are the physical quantities to determine the dynamic behavior. The machining tools are intensive energy-consuming types of equipment and mostly consume electricity in manufacturing industries.

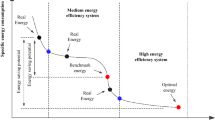

The general approach for cost-effective planning is to set a complete energy-efficient system. Mass, energy, and exergy analyses are the general bases for the efficiency consideration of heat generation. But the easiest and most expeditious energy recovery is observed in effective machining like micromechanical systems and hybrid systems, up to 20% of overall losses can be recovered. If the general usage of steam to produce electricity is considered, controlling the existing configuration will improve energy efficiency by applying quantitative optimization of the electricity usage. This quantity can be increased by an extra 20%. To optimize the entire cogeneration or trigeneration machining system, a holistic approach is needed that improves the system's energy efficiency by up to 65%. The energy efficiency is increased in the range from 3 to 35% by innovative EMS. Air leaks are causing the highest energy losses in CA systems. More than 90% energy efficiency can be achieved with an appropriate CAES system mostly in isothermal and high-pressure conditions for machining purposes. Moreover, the recovered energy will mitigate GHGs. And it is strict that, any developing plan of countries which contains an energy efficiency strategy, is necessary to sustain a habitable earth.

Graphical abstract

Similar content being viewed by others

Data availability

The data presented in this study are available on request from the corresponding author.

Abbreviations

- cp-g :

-

Exhaust gas average specific heat

- Ebiomass :

-

Biomass input

- Ecoal :

-

Coal input

- Ecooling :

-

Cooling output

- Eheating :

-

Heating output

- Ei :

-

Total electricity demand (annual) (GJ/yr)

- Ein,i :

-

Exergy input to a component (kW)

- Eout,k :

-

Exergy output to a component (kW)

- ESy :

-

Electricity savings (measure y for x) (GJ/yr)

- EX :

-

Exergy (J)

- Exbiomass :

-

Exergies of biomass (kW)

- EXC :

-

Exergy values for cooling

- Excoal :

-

Exergies of coal (kW)

- Excompair :

-

Exergy values for compressed air

- EXgt :

-

Exergy (the net power output of gas turbine)

- EXH :

-

Exergy values for heating (kW)

- EXhot water :

-

Output exergy of the hot water (kW)

- EXin :

-

Input exergy of the system (kW)

- Exsewage :

-

Exergies of sewage (kW)

- EXst :

-

Exergy of power output of steam turbine (kW)

- Fy :

-

Fuel thermal content (kWh)

- H:

-

Hot

- h:

-

Enthalpy (specific) (kJ/kg)

- h1 :

-

Enthalpy of compressed air (kJ/kg)

- h2s :

-

Isentropic enthalpy of compressed air (kJ/kg)

- hf :

-

Enthalpy of fuel (kJ/kg)

- in:

-

Inlet

- \(\dot{{\text{I}}}\) :

-

Irreversibility or exergy loss (kW)

- k:

-

Heat transfer coefficient (W/mK)

- L:

-

Thickness (m)

- mc :

-

Coal consumption rate (kg/s)

- mcoal :

-

Mass flow rates of coal (kg/s)

- msevage :

-

Mass flow rates of sevage (kg/s)

- mw :

-

Waste consumption rate (kg/s)

- \(\dot{{\text{m}}}\) :

-

Mass flow rate (kg/s)

- \({\dot{{\text{m}}}}_{{\text{f}}}\) :

-

Flow rate of the fuel (kg/s)

- \({\dot{{\text{m}}}}_{{\text{g}}}\) :

-

Exhaust gas mass flow rate (kg/s)

- n:

-

Number of modules

- out:

-

Outlet

- P:

-

Air pressure (Pa)

- PC :

-

Power consumption of compressor (kW)

- PE :

-

Available extra power for the CAES (MW)

- Pgt :

-

Gas turbine power (MW)

- Pin :

-

Input power (W)

- Pnet :

-

Net power output (W)

- Pout :

-

Power output (W)

- PP :

-

Power output of pneumatic energy (W)

- Pst :

-

Steam turbine power (MW)

- Ptot,net :

-

Net total power output (kW)

- Pw,net :

-

Net power output of the waste (kW)

- Q:

-

Heat load

- QC :

-

Cooling air output (W)

- Qc :

-

Energy input of the coal (kW)

- Qcompair :

-

Compressed air output (W)

- Qexh :

-

Exhaust heat from gas turbine (MW)

- Qgain :

-

Energy gain (W)

- QH :

-

Heating air output (W)

- Qp :

-

Primary energy (kW)

- Qsf :

-

Steam flow energy (kW)

- Qw :

-

Energy input of the waste (kW)

- \(\dot{\text{Q}}\) :

-

Heat transfer (kW)

- \({\dot{\text{Q}}}_{1}\) :

-

Heat addition (the steam per cycle) (kW)

- \({\dot{{\text{Q}}}}_{2}\) :

-

Heat rejection (the steam per cycle) (kW)

- \({\dot{{\text{Q}}}}_{{\text{b}}}\) :

-

Recovered thermal power (kW)

- \({\dot{{\text{Q}}}}_{{\text{L}}}\) :

-

Heat recovered by LPE

- \({\dot{{\text{Q}}}}_{{\text{loss}}}\) :

-

Sum of heat Losses (W)

- \({\dot{{\text{Q}}}}_{{\text{out}}}\) :

-

Sum of useful heat outputs (W)

- \({\dot{{\text{Q}}}}_{{\text{s}}\&{\text{w}}}\) :

-

Transferred heat to the steam and water (kW)

- \({\dot{{\text{Q}}}}_{{\text{tot}}}\) :

-

Heat losses sum & useful heat outputs (W)

- q:

-

Heat flux (W/m2)

- qc,net :

-

The coal net caloric values (kJ/kg)

- qcoal :

-

Lower caloric values of coal (kJ/kg)

- qsevage :

-

Lower caloric values of sevage (kJ/kg)

- qw,net :

-

The waste net caloric values (kJ/kg)

- Si :

-

Total value of the boiler losses (%)

- T:

-

Temperature in unit °C

- \(\dot{\text{U}}\) :

-

Heat loss increment due to the saved steam (kW)

- V:

-

Volume of air (m3)

- W:

-

Power production by the cogeneration (kW)

- \({\dot{\text{W}}}_{\text{c}}\) :

-

Compressor set total work (kW)

- We :

-

The expander produced output work (kW)

- Win,j :

-

Supplied work (kW)

- Wnet :

-

Net power output (kW)

- Wout,l :

-

Work output (kW)

- Wp :

-

Pump set total work (kW)

- X:

-

Faulty samples

- X*:

-

Normal samples

- \(\alpha \) :

-

Portion of electricity demand by industrial motors

- \({\upbeta }_{{\text{i}}}\) :

-

Portion of system x in total electricity

- \({\upgamma }_{{\text{x}}}\) :

-

Portion of total electricity demand by system x

- ∆Tlift :

-

Temperature lift (°C)

- \({\upvarepsilon }_{{\text{c}}}\) :

-

Compression ratio

- \({\upeta }_{{\text{comp}}}\) :

-

Compressor efficiency

- \({\upeta }_{{\text{con}}}\) :

-

Conversion efficiency

- \({\upeta }_{{\text{el}}}\) :

-

Electrical efficiency

- \({\upeta }_{{\text{en}}}\) :

-

Energy efficiency

- \({\upeta }_{{\text{en}},{\text{tot}}}\) :

-

Total energy efficiency

- \({\upeta }_{{\text{en}},{\text{w}}}\) :

-

Waste-to-electricity efficiency

- \({\upeta }_{{\text{ex}}}\) :

-

Exergy efficiency

- \({\upeta }_{{\text{gt}}}\) :

-

Gas turbine efficiency

- \({\upeta }_{{\text{i}}}\) :

-

Standard efficiency

- \({\upeta }_{{\text{j}}}\) :

-

Increased efficiency

- \({\upeta }_{{\text{L}}}\) :

-

Low efficiency motor

- \({\upeta }_{{\text{Q}}}\) :

-

Thermal efficiency

- \({\upeta }_{{\text{RT}}}\) :

-

Round trip efficiency

- \({\upeta }_{{\text{s}}}\) :

-

Isentropic efficiency of the PM

- \({\upeta }_{{\text{st}}}\) :

-

Steam turbine efficiency

- \({\uptau }_{{\text{y}}}\) :

-

Share of total electricity demand by measure y

- ψ:

-

Specific exergy (kW/kg)

- A:

-

Area (m.2)

- B:

-

The replaced equipment age (years)

- C:

-

Cold

- D:

-

Lifetime of the equipment (years)

- d:

-

Adiabatic index

- CA:

-

Compressed air systems

- CAES:

-

Compressed air energy storage system

- CAP:

-

Chilled ammonia process

- CART:

-

Classification and regression tree

- CCHP:

-

Combined cooling, heating and power

- CFL:

-

Compact fluorescent light

- CFPP:

-

Coal-fired power plant

- CHP:

-

Combined heat and power

- CO2 :

-

Carbon dioxide

- COP:

-

Coefficient of performance

- CWSP:

-

Coal-water slurries containing petrochemicals

- DLFLN:

-

Double linear fast learning network

- EEM:

-

Energy efficiency measures

- EI:

-

Energy-relevant investment

- EMDS:

-

Electric motor driven systems

- EMR:

-

Energetic macroscopic representation

- EMS:

-

Electric motor systems

- EEM:

-

Energy efficiency measures:

- ERG:

-

Exhaust gas recirculation

- EUF:

-

Energy utilization factor

- FWH:

-

Feedwater heater

- GHGs:

-

Greenhouse gases

- GSHP:

-

Ground source heat pump

- HHV:

-

Higher heating value

- HTI:

-

Heat transfer intensification

- I-CAES:

-

Energy storage of isothermal compressed air

- IEE:

-

Improvement in energy efficiency

- LAES:

-

Liquid air energy storage

- LHV:

-

Lower heating value

- LPE:

-

Low-pressure economizer:

- MCHP:

-

Combined heat and power in micro sacle:

- MEA:

-

Monoethanolamine:

- NGCC:

-

Natural gas combined cycle

- NOx :

-

Nitrogen oxides

- NPV:

-

Net present value

- PM:

-

Pneumatic motor

- SO2 :

-

Sulfur dioxide

- TCO2ER:

-

Trigeneration CO2 emission reduction

- TDV:

-

Temperature driving force

- TI:

-

Total investment

- TRNSYS:

-

Transient System Simulation Tool

References

Republic of Turkey. Regulation on ıncreasing efficiency in the use of energy resources and energy, 2011. The Law No: 5627 Published in the Official Gazette Issue No. 28097 of October 27, (2011).

Batouta, K.I., Aouhassi, S., Mansouri, K.: Energy efficiency in the manufacturing ındustry-a tertiary review and a conceptual knowledge-based framework. Energy Rep. 9, 4635–4653 (2023). https://doi.org/10.1016/j.egyr.2023.03.107

Chen, H., He, L., Chen, J., Yuan, B., Huang, T., Cui, Q.: Impacts of clean energy substitution for polluting fossil-fuels in terminal energy consumption on the economy and environment in China. Sustainability 11, 6419–6438 (2019). https://doi.org/10.3390/su11226419

Ratanakuakangwan, S., Morita, H.: An efficient energy planning model optimizing cost, emission, and social impact with different carbon tax scenarios. Appl. Energy 325, 119792 (2022). https://doi.org/10.1016/j.apenergy.2022.119792

Yuquan Meng, Y., Yang, Y., Chung, H., Lee, P.H., Shao, C.: Enhancing sustainability and energy efficiency in smart factories: a review. Sustainability 10, 4779 (2018). https://doi.org/10.3390/su10124779

Raza, M.A., Aman, M.M., Abro, A.G., Shahid, M., Ara, D., Waseer, T.A., Tunio, M.A., Soomro, S.A., Tunio, N.A., Haider, R.: Modelling and development of sustainable energy systems. AIMS Energy. 11(2), 256–270 (2023). https://doi.org/10.3934/energy.2023014

Republic of Turkey. The eleventh development plan, decision on aproval 2019. The Law No: 3067 Published in the Official Gazette Issue No. 1225 of July 18, (2019).

Mushafiq, M., Arisar, M.M.K., Tariq, H., Czapp, S.: energy efficiency and economic policy: comprehensive theoretical, empirical, and policy review. Energies 16(5), 2381–2403 (2023). https://doi.org/10.3390/en1605238

Phylipsen, G.J.M., Blok, K., Worrell, E.: International comparisons of energy efficiency-methodologies for the manufacturing industry. Energy Policy 25, 715–725 (1997). https://doi.org/10.1016/S0301-4215(97)00063-3

Narciso, D.A.C., Martins, F.G.: Application of machine learning tools for energy efficiency in industry: a review. Energy Rep. 6, 1181–1199 (2020). https://doi.org/10.1016/j.egyr.2020.04.035

Olayinka, O.S., Oladele, A.T.: Energy audit of manufacturing and processing industries in Nigeria: a case study of food processing ındustry and distillation & bottling company. Am. J. Energy Res. 3, 36–44 (2013). https://doi.org/10.12691/ajer-1-3-1

Vorayos, N., Vorayos, N., Jaitiang, T.: Energy-environmental performance of Thai’s cement industry. Energy Rep. 6, 460–466 (2020). https://doi.org/10.1016/j.egyr.2019.11.103

Branca, T.A., Fornai, B., Colla, V., Pistelli, M.I., Faraci, E.L., Cirilli, F., Schroder, A.J.: Industrial symbiosis and energy efficiency in european process industries: a review. Sustainability 13(16), 9159 (2021). https://doi.org/10.3390/su13169159

Gvozdenac, D.D., Uroševıć, B.D.G., Morvaj, Z.K.: Energy efficiency limitations. Therm. Scı. 23, 1669–1682 (2019). https://doi.org/10.2298/TSCI180723411G

Wang, H., Zhong, R.Y., Liu, G., Mu, W., Tian, X., Leng, D.: An optimization model for energy-efficient machining for sustainable production. J. Clean. Prod. 232, 1121–1133 (2019). https://doi.org/10.1016/j.jclepro.2019.05.271

Pawar, S.S., Bera, T.C., Sangwan, K.S.: Towards energy efficient milling of variable curved geometries. J. Manuf. Process. 94, 497–511 (2023). https://doi.org/10.1016/j.jmapro.2023.03.078

Yusuf, L.A., Popoola, K., Musab, H.: A review of energy consumption and minimisation strategies of machine tools in manufacturing process. Int. J. Sustain. Eng. 14(6), 1826–1842 (2021). https://doi.org/10.1080/19397038.2021.1964633

Li, B., Cao, H., Hon, B., Liu, L., Gao, X.: Exergy-based energy efficiency evaluation model for machine tools considering thermal stability. Int. J. Precis. Eng. Manuf.-Green Technol. 8, 423–434 (2021). https://doi.org/10.1007/s40684-020-00204-8

Deng, Z., Zhang, H., Fu, Y., Wan, L., Liu, W.: Optimization of process parameters for minimum energy consumption based on cutting specific energy consumption. J. Clean. Prod. 166, 1407–1414 (2017). https://doi.org/10.1016/j.jclepro.2017.08.022

Schudeleita, T., Züst, S., Weiss, L., Wegener, K.: The total energy efficiency ındex for machine tools. Energy 102, 682–693 (2016). https://doi.org/10.1016/j.energy.2016.02.126

Lv, Y., Li, C., He, J., Li, W., Li, X., Li, J.: Energy saving design of the machining unit of hobbing machine tool with integrated optimization. Front. Mech. Eng. 17(3), 38 (2022). https://doi.org/10.1007/s11465-022-0694-2

Nagovnak, P., Kienberger, T., Baumann, M., Binderbauer, P., Vouka, T.: Improving the methodology of national energy balances to adapt to the energy transition. Energ. Strat. Rev. 44, 100994 (2022). https://doi.org/10.1016/j.esr.2022.100994

Brillinger, M., Wuwer, M., Smajic, B., Hadi, M.A., Trabesinger, S., Oberegger, B., Jäger, M.: Novel method to predict the energy consumption of machined parts in the design phase to attain sustainability goals. J. Manuf. Process. 101, 1046–1054 (2023). https://doi.org/10.1016/j.jmapro.2023.05.086

Zhaoa, J., Li, L., Li, L., Zhang, Y., Lin, J., Cai, W., Sutherland, J.W.: A Multi-dimension coupling model for energy-efficiency of a machining process. Energy 274, 127244 (2023). https://doi.org/10.1016/j.energy.2023.127244

Petek, J., Glavič, P., Kostevšek, A.: Comprehensive approach to increase energy efficiency based on versatile industrial practices. J. Clean. Prod. 112, 2813–2821 (2016). https://doi.org/10.1016/j.jclepro.2015.10.046

Islam, S., Ponnambalam, S.G., Lam, H.L.: Energy management strategy for industries integrating small scale waste-to-energy and energy storage system under variable electricity pricing. J. Clean. Prod. 127, 352–362 (2016). https://doi.org/10.1016/j.jclepro.2016.04.030

Selim, O.M., Abousabae, M., Hasan, A., Amano, R.S.: Analysis of energy savings and CO2 emission reduction contribution for industrial facilities in USA. J. Energy Res. Technol. 143, 082303 (2021). https://doi.org/10.1115/1.4048983

JRC.: Reference document on best available techniques for energy efficiency. European Commission-Joint Research Center. https://eippcb.jrc.ec.europa.eu/sites/default/files/2019-11/ENE_Adopted_02-2009.pdf. (Accessed 20 April 2020)

Zhao, G., Liu, Z., He, Y., Cao, H., Guo, Y.: Energy consumption in machining: classification, prediction, and reduction strategy. Energy 133, 142–157 (2017). https://doi.org/10.1016/j.energy.2017.05.110

Kaşka, Ö.: Energy and exergy analysis of an organic rankine for power generation from waste heat recovery in steel ındustry. Energy Convers. Manage. 77, 108–117 (2014). https://doi.org/10.1016/j.enconman.2013.09.026

Qin, S., Chang, S.: Modeling thermodynamic and techno-economic analysis of coke production process with waste heat recovery. Energy 141, 435–450 (2017). https://doi.org/10.1016/j.energy.2017.09.105

Saidur, R., Mekhilef, S.: Energy use, energy savings and emission analysis in the Malaysian rubber producing industry. Appl. Energy 87(8), 2746–2758 (2010). https://doi.org/10.1016/j.apenergy.2009.12.018

Camaraza-Medina, Y., Retirado-Mediaceja, Y., Hernandez-Guerrero, A., Luviano-Ortiz, J.L.: Energy efficiency indicators of the steam boiler in a power plant of Cuba. Therm. Sci. Eng. Progress. (2021). https://doi.org/10.1016/j.tsep.2021.100880

Chantasiriwan, S.: Optimum installation of flue gas dryer and additional air heater to increase the efficiency of coal-fired utility boiler. Energy (2021). https://doi.org/10.1016/j.energy.2021.119769

Samukawa, T., Shimomoto, K., Suwa, H.: Estimation of ın-process power consumption in face milling by specific energy consumption models. Int. J. Autom. Technol. 14, 951–958 (2020). https://doi.org/10.20965/ijat.2020.p0951

Nitesh, S., Kuldip, S.S.: A systematic literature review on machine tool energy consumption. J. Clean. Prod. 275, 123125 (2020). https://doi.org/10.1016/j.jclepro.2020.123125

Hasanbeigi, A., Price, L.: A Review of energy use and energy efficiency technologies for the textile ındustry. Renew. Sustain. Energy Rev. 16, 3648–3665 (2012). https://doi.org/10.1016/j.rser.2012.03.029

Demirel, Y.E., Şimşek, E., Öztürk, E., Kitis, M.: Selection of priority energy efficiency practices for industrial steam boilers by PROMETHEE decision model. Energ. Effi. 14, 89 (2021). https://doi.org/10.1007/s12053-021-10007-8

Atmaca, A., Kanoglu, M.: Reducing energy consumption of a raw mill in cement industry. Energy 42, 261–269 (2012). https://doi.org/10.1016/j.energy.2012.03.060

Kaya, D., Eyidogan, M.: Energy conservation opportunity in boiler systems. J. Energy Resour. Technol. 131(3), 032401 (2009). https://doi.org/10.1115/1.3185440

Messerle, V., Ustimenko, A., Lavrichshev, O.: Plasma−fuel systems for clean coal technologies proceedings of the institution of civil engineers. Energy 174(2), 79–83 (2021). https://doi.org/10.1680/jener.19.00053

Gibbs, B.M.: Boiler fuel savings by heat recovery and reduced stanby losses. Heat Rec. Syst. CHP J. 7, 151–157 (1987). https://doi.org/10.1016/0890-4332(87)90079-2

Wang, Y., Cao, L., Li, X., Wang, J., Hu, P., Li, B., Li, Y.: A novel thermodynamic method and insight of heat transfer characteristics on economizer for supercritical thermal power plant. Energy (2020). https://doi.org/10.1016/j.energy.2019.116573

Kislov, V.M., Tsvetkov, M.V., Zaichenkoa, A.Y., Podlesniy, D.N., Salganskya, E.A.: Energy efficiency of the gasification of a dense layer of solid fuels in the filter combustion mode. Russ. J. Phys. Chem. B 15, 819–826 (2021). https://doi.org/10.1134/S1990793121050055

Madejski, P., Zymełka, P.: Calculation methods of steam boiler operation factors under varying operating conditions with the use of computational thermodynamic modeling. Energy (2020). https://doi.org/10.1016/j.energy.2020.117221

Kaya, D., Eyidogan, M.: Energy conservation opportunities in an industrial boiler system. J. Energy Eng. 136(1), 18–20 (2010). https://doi.org/10.1061/(ASCE)0733-9402(2010)136:1(18)

Yılmaz, S., Kumlutas, D., Yücekaya, U.A., Cumbul, A.Y.: Prediction of the equilibrium compositions in the combustion products of a domestic boiler. Energy (2021). https://doi.org/10.1016/j.energy.2021.121123

MacDonald, S., Winner, B., Smith, L., Juillerat, J., Belknap, S.: Bridging the rural efficiency gap: expanding access to energy efficiency upgrades in remote and high energy cost communities. Energ. Effi. 13, 503–521 (2020). https://doi.org/10.1007/s12053-019-09798-8

Shao, Y., Xiao, H., Chen, B., Huang, S., Qin, F.G.Q.: Comparison and analysis of thermal efficiency and exergy efficiency in energy systems by case study. Energy Proced. 153, 161–168 (2018). https://doi.org/10.1016/j.egypro.2018.10.081

Hsieh, J.: Study of energy strategy by evaluating energy-environmental efficiency. Energy Rep. 8, 1397–1409 (2022). https://doi.org/10.1016/j.egyr.2021.12.061

Bühler, F., Nguyen, T.V., Elmegaard, B.: Energy and exergy analyses of the Danish industry sector. Appl. Energy 184, 1447–1459 (2016). https://doi.org/10.1016/j.apenergy.2016.02.072

Costa, V.A.F.: Energy-exergy diagrams for states and energy and exergy balance equations representation. Energy 218, 119506 (2021). https://doi.org/10.1016/j.energy.2020.119506

Su, H., Huang, Q., Wang, Z.: An energy efficiency index formation and analysis of integrated energy system based on exergy efficiency. Front. Energy Res. 9, 723647 (2021). https://doi.org/10.3389/fenrg.2021.723647

Michalakakis, C., Cullen, J.M.: Dynamic exergy analysis from industrial data to exergy flows. J. Ind. Ecol. 26, 12–26 (2022). https://doi.org/10.1111/jiec.13168

Meekers, I., Refalo, P., Rochman, A.: Analysis of process parameters affecting energy consumption in plastic injection moulding. Proced. CIRP. 69, 342–347 (2018). https://doi.org/10.1016/j.procir.2017.11.042

Blume, S., Kurle, D., Herrmann, C., Thiede, S.: Toolbox for ıncreasing resource efficiency in the European metal mechanic sector. Proced. CIRP. 61, 40–45 (2017). https://doi.org/10.1016/j.procir.2016.11.247

Haraldsson, J., Johansson, M.T.: Review of measures for ımproved energy efficiency in production-related processes in the aluminium industry from electrolysis to recycling. Renew. Sustain. Energy Rev. 93, 525–548 (2018). https://doi.org/10.1016/j.rser.2018.05.043

Fılkoskı, R.V., Lazarevska, A.M., Mladenovskab, D., Kıtanovskıc, D.: Steam system optimization of an ındustrial heat and power plant. Therm. Sci. 24, 3649–3662 (2020). https://doi.org/10.2298/TSCI200403284F

Menezes, F.M., Góes, M.F., Kalid, R.A., Tanimoto, H.A., Andrade, J.C.: Economic feasibility of an energy efficiency project for a steam distribution system in a chemical industry. Indep. J. Manag. Prod. 8, 4 (2017). https://doi.org/10.14807/ijmp.v8i4.672

Delpech, B., Milani, M., Montorsi, L., Boscardin, D., Chauhan, A., Almahmoud, S., Axcell, B., Jouhara, H.: Energy efficiency enhancement and waste heat recovery in ındustrial processes by means of the heat pipe technology: case of the ceramic ındustry. Energy 158, 656–665 (2018). https://doi.org/10.1016/j.energy.2018.06.041

Lawrence, A., Thollander, P., Andrei, M., Karlsson, M.: Specific energy consumption/use (SEC) in energy management for ımproving energy efficiency in industry: meaning, usage and differences. Energies 12, 247 (2019). https://doi.org/10.3390/en12020247

Sangi, R., Müller, D.: Application of the second law of thermodynamics to control: a review. Energy 174, 938–953 (2019). https://doi.org/10.1016/j.energy.2019.03.024

Zhu, L.B., Cao, H.J., Huang, H.H., Yang, X.: Exergy analysis and multi-objective optimization of air cooling system for dry machining. Int. J. Adv. Manuf. Technol. 93, 3175–3188 (2017). https://doi.org/10.1007/s00170-017-0731-1

Wu, H., Wang, X., Deng, X., Shen, H., Yao, X.: Review on design research in CNC machine tools based on energy consumption. Sustainability 16, 847 (2024). https://doi.org/10.3390/su16020847

Chen, X., Li, C., Jin, Y., Li, L.: Optimization of cutting parameters with a sustainable consideration of electrical energy and embodied energy of materials. Int. J. Adv. Manif. Technol. 96, 775–788 (2018). https://doi.org/10.1007/s00170-0181647-0

Lee, W., Kim, S.H., Park, J., Min, B.K.: Simulation-based machining condition optimization for machine tool energy consumption reduction. J. Clean. Prod. 150, 352–360 (2017). https://doi.org/10.1016/j.jclepro.2017.02.178

Aravinda, B., Khandelwal, B., Ramakrishnac, P.A., Kumar, S.: Towards the development of a high power density, high efficiency, micro power generator. Appl. Energy 261, 114386 (2020). https://doi.org/10.1016/j.apenergy.2019.114386

Dzikuc, M., Kuryło, P., Dudziak, R., Szufa, S., Dzikuc, M., Godzisz, K.: Selected aspects of combustion optimization of coal in power plants. Energies 13, 2208 (2020). https://doi.org/10.3390/en13092208

Li, G., Niu, P.: Combustion optimization of a coal-fired boiler with double linear fast learning network. Methodol. Appl. 20, 149–156 (2016). https://doi.org/10.1007/s00500-014-1486-3

Figueiredo, A.A.A., Guimaraes, G., Pereira, I.C.: Heat flux in machining processes: a review. Int. J. Adv. Manuf. Technol. 120, 2827–2848 (2022). https://doi.org/10.1007/s00170-022-08720-4

Khan, M.A.A., Hussain, M., Lodhi, S.K., Zazoum, B., Asad, M., Afzal, A.: Green metalworking fluids for sustainable machining operations and other sustainable systems: a review. Metals. 12, 1466 (2022). https://doi.org/10.3390/met12091466

Tiwari, A., Singh, D.K., Mishra, S.: A review on minimum quantity lubrication in machining of different alloys and superalloys using nanofluids. J. Braz. Soc. Mech. Sci. Eng. 46, 112 (2024). https://doi.org/10.1007/s40430-024-04676-6

Pronobis, M., Mroczek, K., Tymoszuk, M., Ciukaj, S., Wejkowski, R., Janda, T., Jagodzinska, K.: Optimisation of coal fineness in pulverised-fuel boilers. Energy 139, 655–666 (2017). https://doi.org/10.1016/j.energy.2017.07.057

Wang, Y., Song, C., Zhang, Z., Hua, W.: Elastic modulus adjustment method of double-stator hts field modulated machine based on entire machine modal analysis. IEEE Access 12, 12808–12817 (2024). https://doi.org/10.1109/ACCESS.2024.3354849

Ahmadi, G.R., Toghraie, D.: Energy and exergy analysis of montazeri steam power plant in Iran. Renew. Sustain. Energy Rev. 56, 454–463 (2016). https://doi.org/10.1016/j.rser.2015.11.074

Yoon, H.S., Kim, E.S., Kim, M.S., Lee, J.S., Lee, G.M., Ahn, S.H.: Towards greener machine tools-A review on energy saving strategies and technologies. Renew. Sustain. Energy Rev. 48, 870–891 (2015). https://doi.org/10.1016/j.rser.2015.03.100

Oh, S.Y., Yun, S., Kim, J.K.: Process integration and design for maximizing energy efficiency of a coalfired power plant integrated with amine-based CO2 capture process. Appl. Energy 216, 311–322 (2018). https://doi.org/10.1016/j.apenergy.2018.02.100

Yi, Z., Hu, X., Zhou, Z.: Experimental study on multi-fuel combustion of lean coal and by-product gas in a 75t/h tangentially-fired boiler. Environ. Progress Sustain. Energy. 41, 13734 (2022). https://doi.org/10.1002/ep.13734

Zima, W.: Simulation of rapid increase in the steam mass flow rate at a supercritical power boiler outlet. Energy 173, 995–1005 (2019). https://doi.org/10.1016/j.energy.2019.02.127

Zhao, H., Jiang, P., Chen, Z., Ezeh, C.I., Hong, Y., Guo, Y., Zheng, C., Džapo, H., Gao, X., Wu, T.: Improvement of fuel sources and energy products flexibility in coal power plants via energy-cyber-physical-systems approach. Appl. Energy 254, 113554 (2019). https://doi.org/10.1016/j.apenergy.2019.113554

Fan, G., Chen, M., Wang, C., Feng, Q., Sun, Y., Xu, J., Du, Y., Che, D.: Numerical study on oxy-fuel combustion characteristics of industrial furnace firing coking dry gas. Energy 286, 129643 (2024). https://doi.org/10.1016/j.energy.2023.129643

Chen, H., Zhang, M., Wu, Y., Xu, G., Liu, W., Liu, W.: Design and performance evaluation of a new waste ıncineration power system integrated with a supercritical CO2 power cycle and a coal-fired power plant. Energy Convers. Manage. 210, 112715 (2020). https://doi.org/10.1016/j.enconman.2020.112715

Zhu, Z., Guo, X., Bai, H., Zhang, Z., Yu, J., Wu, X., Li, Z., Liu, J., Zhang, Q.: Experimental study on NOx reduction performance by ammonia solution injection into the fuel-rich zone in a 75 t/h coal-fired industrial boiler. Fuel 357, 129745 (2024). https://doi.org/10.1016/j.fuel.2023.129745

Li, X., Zeng, L., Zhang, X., Fang, N., Song, M., Chen, Z., Li, Z.: Effects of the fuel-lean coal/air flow damper opening on combustion, energy conversion and emissions in a supercritical down-fired boiler. Fuel 292, 120319 (2021). https://doi.org/10.1016/j.fuel.2021.120319

Chauhan, S.S., Khanam, S.: Energy integration in boiler section of thermal power plant. J. Clean. Prod. 202, 601–615 (2018). https://doi.org/10.1016/j.jclepro.2018.08.161

Yan, T., Sun, J., Qiu, Z., Na, H., Yuan, Y., Che, Z., Du, T., Song, Y.: Energy optimization based on steam system analysis and waste energy recovery for iron and steel industry. Energ. Technol. 10, 2200191 (2022). https://doi.org/10.1002/ente.202200191

Lee, J.Y., Chen, P.Y.: Optimization of heat recovery networks for energy savings in industrial processes. Processes. 11, 321 (2023). https://doi.org/10.3390/pr11020321

Sladewski, L., Wojdan, K., Swirski, K., Janda, T., Nabagło, D., Chachuła, J.: Optimization of combustion process in coal-fired power plant with utilization of acoustic system for in-furnace temperature measurement. Appl. Therm. Eng. 123, 711–720 (2017). https://doi.org/10.1016/j.applthermaleng.2017.05.078

Park, H., Lee, J., Lim, J., Cho, H., Kim, J.: Optimal operating strategy of ash deposit removal system to maximize boiler efficiency using CFD and a thermal transfer efficiency model. J. Ind. Eng. Chem. 110, 301–317 (2022). https://doi.org/10.1016/j.jiec.2022.03.004

Tic, W.J., Guziałowska-Tic, J.: A System of improving energy and ecological efficiency, using the example of fuel oil combustion in power plant boilers. Energies 16, 1107 (2023). https://doi.org/10.3390/en16031107

Tic, W.J., Guziałowska-Tic, J.: The Cost-efficiency analysis of a system for improving fine-coal combustion efficiency of power plant. Energies 14, 4295 (2021). https://doi.org/10.3390/en14144295Boilers

Hanak, D.P., Biliyok, C., Yeung, H., Białecki, R.: Heat integration and exergy analysis for a supercritical high-ash coal-fired power plant integrated with a post-combustion carbon capture process. Fuel 134, 126–139 (2014). https://doi.org/10.1016/j.fuel.2014.05.036

Kurgankina, M.A., Nyashina, G.S., Strizhak, P.A.: Prospects of thermal power plants switching from traditional fuels to coal-water slurries containing petrochemicals. Sci. Total. Environ. 671, 568–577 (2019). https://doi.org/10.1016/j.scitotenv.2019.03.349

Saari, J., Sermyagina, E., Kaikko, J., Haider, M., Hamaguchi, M., Vakkilainen, E.: Evaluation of the energy efficiency improvement potential through back-end heat recovery in the kraft recovery boiler. Energies 14, 1550 (2021). https://doi.org/10.3390/en14061550

Bracco, S., Cravero, C.: Dynamic simulation of a steam generator for ironing machines. Energy Convers. Manag. 84, 13–19 (2014). https://doi.org/10.1016/j.enconman.2014.04.004

Theotokatos, G., Rentizelas, A., Guan, C., Ancic, I.: Waste heat recovery steam systems techno-economic and environmental ınvestigation for ocean-going vessels considering actual operating profiles. J. Clean. Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.121837

Lee, C.M., Choi, Y.H., Ha, J.H., Woo, W.S.: Eco-Friendly technology for recycling of cutting fluids and metal chips: a review. Int. J. Precis. Eng. Manuf.-Green Technol. 4(4), 457–468 (2017). https://doi.org/10.1007/s40684-017-0051-9

Pan, M., Aziz, F., Li, B., Perry, S., Zhang, N., Bulatov, I., Smith, R.: Application of optimal design methodologies in retrofitting natural gas combined cycle power plants with CO2 capture. Appl. Energy 161, 695–706 (2016). https://doi.org/10.1016/j.apenergy.2015.03.035

Kürekçi, N.A., Özcan, M.: A practical method for determination of economic insulation thickness of steel, plastic and copper hot water pipes. J. Therm. Eng. 6, 72–86 (2020). https://doi.org/10.18186/thermal

Wang, C., He, B., Yan, L., Pei, X., Chen, S.: Thermodynamic analysis of a low-pressure economizer based waste heat recovery system for a coal-fired power plant. Energy J. 65, 80–90 (2014). https://doi.org/10.1016/j.energy.2013.11.084

Jungwon Yu, J., Jang, J., Yoo, J., Park, J.H., Kim, S.: A fault ısolation method via classification and regression tree-based variable ranking for drum-type steam boiler in thermal power plant. Energies 11, 1142 (2018). https://doi.org/10.3390/en11051142

Wang, T., Zhang, H., Zhang, Y., Wang, H., Lyu, J., Yue, G.: Efficiency and emissions of gas-fired industrial boiler fueled with hydrogen-enriched nature gas: a case study of 108 t/h steam boiler. Int. J. Hydrogen Energy 47, 28188–28203 (2022). https://doi.org/10.1016/j.ijhydene.2022.06.121

Zhang, Q., Zhao, W., Sun, D., Meng, X., Hooman, K., Yang, X.: Combustion air humidification for NOx emissions reduction in gas boiler: an experimental study. Heat Transf. Eng. 45(1), 55–68 (2024). https://doi.org/10.1080/01457632.2023.2171814

Aliyon, K., Hajinezhad, A., Mehrpooya, M.: Energy assessment of coal-fired steam power plant, carbon capture, and carbon liquefaction process chain as a whole. Energy Convers. Manage. 199, 111994 (2019). https://doi.org/10.1016/j.enconman.2019.111994

Somovaa, E.V., Tugova, A.N., Tumanovskiia, A.G.: Modern coal-fired power units for ultra-supercritical steam conditions (review). Therm. Eng. 70(2), 81–96 (2023). https://doi.org/10.1134/S0040601523020064

Cui, Y., Zou, Y., Wang, X., Zhong, W.: Simulation of gas-solid combustion characteristics in a 1000 MW CFB boiler for supercritical CO2 cycle. Adv. Powder Technol. 34, 104104 (2023). https://doi.org/10.1016/j.apt.2023.104104

Yan, H., Wang, R., Du, S., Hu, B., Xu, Z.: Analysis and perspective on heat pump for industrial steam generation. Adv. Energy Sustain. Res. 2, 2000108 (2021). https://doi.org/10.1002/aesr.202000108

Klute, S., Budt, M., Beek, M., Doetsch, C.: Steam generating heat pumps- Overview, classification, economics, and basic modeling principles. Energy Convers. Manage. 299, 117882 (2024). https://doi.org/10.1016/j.enconman.2023.117882

Gasho, E.G., Kiseleva, A.I.: Analysis of energy-saving measures in industrial steam supply systems. Mater. Sci. Eng. 791, 012042 (2020). https://doi.org/10.1088/1757-899X/791/1/012042

Farrou, I., Androutsopoulos, A., Botzios-Valaskakis, A., Goumas, G., Andreosatos, C., Gavriil, L., Perakis, C.: Energy efficiency in steam using industries in Greece. Int. J. Sustain. Energ. 39(6), 556–582 (2020). https://doi.org/10.1080/14786451.2020.1737066

Zhanga, X., Hongqiang Lia, H., Liu, L., Bai, C., Wang, S., Song, Q., Zeng, J., Liu, X., Zhang, G.: Exergetic and exergoeconomic assessment of a novel CHP system integrating biomass partial gasification with ground source heat pump. Energy Convers. Manage. 156, 666–679 (2018). https://doi.org/10.1016/j.enconman.2017.11.075

Li, J., Laredj, A., Tian, G.: A case study of a CHP system and ıts energy use mapping. Energy Proced. 105, 1526–1531 (2017). https://doi.org/10.1016/j.egypro.2017.03.465

Naseer, M.U., Kallaste, A., Asad, B., Vaimann, T., Rassõlkin, A.: A review on additive manufacturing possibilities for electrical machines. Energies 14, 1940 (2021). https://doi.org/10.3390/en14071940

do Espirito Santo, D.B., Gallo, W.L.R.: Utilizing primary energy savings and exergy destruction to compare centralized thermal plants and cogeneration/trigeneration systems. Energy 120, 785–795 (2017). https://doi.org/10.1016/j.energy.2016.11.130

Jaszczur, M., Michal Dudek, M., Rosen, M.A., Kolenda, Z.: An Analysis of integration of a power plant with a lignite superheated steam drying unit. J. Clean. Prod. 243, 118635 (2020). https://doi.org/10.1016/j.jclepro.2019.118635

Xu, C., Xu, G., Zhao, S., Zhou, L., Yang, Y., Zhang, D.: An Improved configuration of lignite pre-drying using a supplementary steam cycle in a lignite fired supercritical power plant. Appl. Energy 160, 882–891 (2015). https://doi.org/10.1016/j.apenergy.2015.01.083

Usubharatana, P., Phungrassami, H.: Life cycle assessment for enhanced efficiency of small power plants by reducing air ınput temperature. Pol. J. Environ. Stud. 27(4), 1781–1793 (2018). https://doi.org/10.15244/pjoes/78433

Meunier, F.: Co- and tri-generation contribution to climate change control. Appl. Therm. Eng. 22, 703–718 (2002). https://doi.org/10.1016/S1359-4311(02)00032-7

Fan, J., Hong, H., Zhu, L., Jiang, Q., Jin, H.: Thermodynamic and environmental evaluation of biomass and coal co-fuelled gasification chemical looping combustion with CO2 capture for combined cooling, heating and power production. Appl. Energy 195, 861–876 (2017). https://doi.org/10.1016/j.apenergy.2017.03.093

Chicco, G., Mancarella, P.: Assessment of the greenhouse gas emissions from cogeneration and trigeneration systems Part 1: Models and ındicators. Energy 33, 410–417 (2008). https://doi.org/10.1016/j.energy.2007.10.006

Angrisani, G., Canelli, M., Roselli, C., Sasso, M.: Microcogeneration in buildings with low energy demand in load sharing application. Energy Convers. Manage. 100, 78–89 (2015). https://doi.org/10.1016/j.enconman.2015.04.065

Li, B., Cao, H., Liu, H., Zeng, D., Chen, E.: Exergy efficiency optimization model of motorized spindle system for high-speed dry hobbing. Int. J. Adv. Manuf. Technol. 104, 2657–2668 (2019). https://doi.org/10.1007/s00170-019-04134-x

Watanabe, M.D.B., Morais, E.R., Cardoso, T.F., Chagas, M.F., Junqueira, T.L., Carvalho, D.J., Bonomi, A.: Process simulation of renewable electricity from sugarcane straw: Techno-economic assessment of retrofit scenarios in Brazil. J. Clean. Prod. 254, 120081 (2020). https://doi.org/10.1016/j.jclepro.2020.120081

Elwardany, M., Nassib, A.M., Mohamed, H.A., Abdelaal, M.R.: Energy and exergy assessment of 750 MW combined cycle power plant: a case study. Energy Nexus. 12, 100251 (2023). https://doi.org/10.1016/j.nexus.2023.100251

Changchun, L., Wei, H., Zefeng, W., Na, Z.: Proposal and assessment of an engine-based distributed steam and power cogeneration system integrated with an absorption-compression heat pump. J. Therm. Sci. 29(5), 1165–1179 (2020). https://doi.org/10.1007/s11630-020-1302-6

Liu, J., Ren, J., Zhang, Y., Huang, W., Xu, C., Liu, L.: Exergoeconomic evaluation of a cogeneration system driven by a natural gas and biomass co-firing gas turbine combined with a steam rankine cycle, organic rankine cycle, and absorption chiller. Processes 12, 82 (2024). https://doi.org/10.3390/pr12010082

Wang, F., Zhao, J., Zhang, H., Miao, H., Zhao, J., Wang, J., Yuan, J., Yand, J.: Efficiency evaluation of a coal-fired power plant integrated with chilled ammonia process using an absorption refrigerator. Appl. Energy 230, 267–276 (2018). https://doi.org/10.1016/j.apenergy.2018.08.097

Montazerinejad, H., Eicker, U.: Recent development of heat and power generation using renewable fuels: a comprehensive review. Renew. Sustain. Energy Rev. 165, 112578 (2022). https://doi.org/10.1016/j.rser.2022.112578

Bourtsalas, A.C., Wei, J.: Exhaust steam utilization in waste-to-energy strategies: from district heating to desalination. J. Clean. Prod. 428, 139389 (2023). https://doi.org/10.1016/j.jclepro.2023.139389

Sornek, K.: Prototypical biomass fired micro cogeneration systems energy and ecological analysis. Energies 13, 3909 (2020). https://doi.org/10.3390/en13153909

Braimakis, K., Magiri-Skouloudi, D., Grimekis, D., Karellas, S.: Energy-exergy analysis of ultra-supercritical biomass-fuelled steam power plants for industrial CHP, district heating and cooling. Renew. Energy 154, 252–269 (2020). https://doi.org/10.1016/j.renene.2020.02.091

Ciuła, J., Kowalski, S., Generowicz, A., Barbusinski, K., Matuszak, Z., Gaska, K.: Analysis of energy generation efficiency and reliability of a cogeneration unit powered by biogas. Energies 16, 2180 (2023). https://doi.org/10.3390/en16052180

Meftahpour, H., Khoshbakhti-Saray, R., Tavakkol-Aghaei, A., Bahlouli, K.: Comprehensive analysis of energy, exergy, economic, and environmental aspects in implementing the Kalina cycle for waste heat recovery from a gas turbine cycle coupled with a steam generator. Energy 290, 130094 (2024). https://doi.org/10.1016/j.energy.2023.130094

Köse, Ö., Koç, Y., Yağlı, H.: Performance improvement of the bottoming steam Rankine cycle (SRC) and organic Rankine cycle (ORC) systems for a triple combined system using gas turbine (GT) as topping cycle. Energy Convers. Manage. 211, 112745 (2020). https://doi.org/10.1016/j.enconman.2020.112745

Lai, F., Wang, S., Liu, M., Yan, J.: Operation optimization on the large-scale CHP station composed of multiple CHP units and a thermocline heat storage tank. Energy Convers. Manage. 211, 112767 (2020). https://doi.org/10.1016/j.enconman.2020.112767

Herrero Sola, A.V., Mota, C.M.M., Kovaleski, J.L.: A Model for improving energy efficiency in industrial motor system using multicriteria analysis. Energy Policy 39, 3645–3654 (2011). https://doi.org/10.1016/j.enpol.2011.03.070

Garcia, A.G.P., Szklo, A.S., Schaeffer, R., Mcneil, M.A.: Energy-efficiency standards for electric motors in Brazilian industry. Energy Policy 35, 3424–3439 (2007). https://doi.org/10.1016/j.enpol.2006.11.024

Alibeik, M., Dos Santos, E.C.: High-Torque electric machines: state of the art and comparison. Machines 10, 636 (2022). https://doi.org/10.3390/machines10080636

Accordini, D., Cagno, E., Trianni, A.: Identification and characterization of decision-making factors over industrial energy efficiency measures in electric motor systems. Renew. Sustain. Energy Rev. 149, 111354 (2021). https://doi.org/10.1016/j.rser.2021.111354

Cagno, E., Accordini, D., Trianni, A.: A Framework to characterize factors affecting the adoption of energy efficiency measures within electric motors systems. Energy Procedia. 158, 3352–3357 (2019). https://doi.org/10.1016/j.egypro.2019.01.962

Trianni, A., Cagno, E., Accordini, D.: A review of energy efficiency measures within electric motors systems. Energy Proced. 158, 3346–3351 (2019). https://doi.org/10.1016/j.egypro.2019.01.964

Trianni, A., Cagno, E., Accordini, D.: Energy efficiency measures in electric motors systems: a novel classification highlighting specific implications in their adoption. Appl. Energy 252, 113481 (2019). https://doi.org/10.1016/j.apenergy.2019.113481

Zuberi, M.J.S., Tijdink, A., Patel, M.K.: Techno-economic analysis of energy efficiency improvement in electric motor driven systems in Swiss industry. Appl. Energy 205, 85–104 (2017). https://doi.org/10.1016/j.apenergy.2017.07.121

Paramonova, S., Nehler, T., Thollander, P.: Technological change or process innovation-an empirical study of implemented energy efficiency measures from a Swedish industrial voluntary agreements program. Energy Policy 156, 112433 (2021). https://doi.org/10.1016/j.enpol.2021.112433

Manescu, V., Paltanea, G., Gavrila, H., Scutaru, G., Peter, I.: High efficiency electrical motors state of the art and challenges. Rev. Roum. Sci. Tech. Ser. Electrotech. Energ. 62, 14–18 (2017)

Bhadbhade, N., Patel, M.K.: Energy efficiency investment in Swiss industry: analysis of target agreements. Energy Rep. 11, 624–636 (2024). https://doi.org/10.1016/j.egyr.2023.12.021

Gomez, J.R., Sousa, W., Cabello-Eras, J.J., Gutierrez, A.S., Viego, P.R., Quispe, E.C., Leon, G.: Assessment criteria of the feasibility of replacement standard efficiency electric motors with high-efficiency motors. Energy 239, 121877 (2022). https://doi.org/10.1016/j.energy.2021.121877

Tabora, J.M., Tostes, M.E., Matos, E.O., Soares, T.M., Bezerra, U.H.: Voltage harmonic ımpacts on electric motors: a comparison between IE2, IE3 and IE4 ınduction motor classes. Energies 13, 3333 (2020). https://doi.org/10.3390/en13133333

Nehler, T.: Linking energy efficiency measures in industrial compressed air systems with non-energy benefits a—review. Renew. Sustain. Energy Rev. 89, 72–87 (2018). https://doi.org/10.1016/j.rser.2018.02.018

Mousavi, S., Kara, S., Kornfeld, B.: Energy efficiency of compressed air systems. Procedia CIRP 15, 313–318 (2014). https://doi.org/10.1016/j.procir.2014.06.026

Chen, S., Arabkoohsar, A., Zhu, T., Nielsen, M.P.: Development of a micro-compressed air energy storage system model based on experiments. Energy 197, 117152 (2020). https://doi.org/10.1016/j.energy.2020.117152

Rubio, E.M., Agustina, B., Marín, M., Bericua, A.: Cooling systems based on cold compressed air: a review of the applications in machining processes. Proced. Eng. 132, 413–418 (2015). https://doi.org/10.1016/j.proeng.2015.12.513

Heidari, M., Mortazavi, M., Rufer, A.: Design, modeling and experimental validation of a novel finned reciprocating compressor for isothermal compressed air energy storage applications. Energy 140, 1252–1266 (2017). https://doi.org/10.1016/j.energy.2017.09.031

Heidari, M., Wasterlain, S., Barrade, P., Gallaire, F., Rufer, A.: Energetic macroscopic representation of a linear reciprocating compressor model. Int. J. Refrig. 52, 83–92 (2015). https://doi.org/10.1016/j.ijrefrig.2014.12.019

Xiankuia, W., Dahui, Y., Jingliang, Z., Tingyong, F., Xiang, L.: Research on recovery and utilization of waste heat in advanced compressed air energy storage system. Energy Rep. 8, 1436–1445 (2022). https://doi.org/10.1016/j.egyr.2022.02.082

Xu, Y., Zhang, H., Yang, F., Tong, L., Yan, D., Yang, Y., Wang, Y., Wu, Y.: Experimental research on the forward and reverse rotation characteristics of a pneumatic motor for a microscale compressed air energy storage system. Energy Technolgy. 10, 2100724 (2022). https://doi.org/10.1002/ente.202100724

Qing, H., Lijian, W., Qian, Z., Chang, L., Dongmei, D., Wenyi, L.: Thermodynamic analysis and optimization of liquefied air energy storage system. Energy 173, 162–173 (2019). https://doi.org/10.1016/j.energy.2019.02.057

Burian, O., Dancová, P.: Compressed air energy storage (CAES) and liquid air energy storage (LAES) technologies-A comparison review of technology possibilities. Processes. 11, 3061 (2023). https://doi.org/10.3390/pr11113061

Leszczyński, J.S., Gryboś, D., Markowski, J.: Analysis of optimal expansion dynamics in a reciprocating drive for a micro-CAES production system. Appl. Energy 350, 121742 (2023). https://doi.org/10.1016/j.apenergy.2023.121742

Bushehri, M.C., Zolfaghari, S.M., Soltani, M., Nabat, M.H., Nathwani, J.: A comprehensive study of a green hybrid multi-generation compressed air energy storage (CAES) system for sustainable cities: Energy, exergy, economic, exergoeconomic, and advanced exergy analysis. Sustain. Cities Soc. 101, 105078 (2024). https://doi.org/10.1016/j.scs.2023.105078

Arabkoohsar, A., Machado, L., Farzaneh-Gord, M., Koury, R.N.N.: Thermo-economic analysis and sizing of a pv plant equipped with a compressed air energy storage system. Renew. Energy 83, 491–509 (2015). https://doi.org/10.1016/j.renene.2015.05.005

Sarmast, S., Rouindej, K., Fraser, R.A., Dusseault, M.B.: Optimizing near-adiabatic compressed air energy storage (NA-CAES) systems: sizing and design considerations. Appl. Energy 357, 122465 (2024). https://doi.org/10.1016/j.apenergy.2023.122465

Li, C.: A systematic evaluation of adiabatic-compressed air energy storage (A-CAES) based on generating side photovoltaic: a case study on western China. Energy Storage. 5, 439 (2023). https://doi.org/10.1002/est2.439

O’Callaghan, O., Donnellan, P.: Liquid air energy storage systems: a review. Renew. Sustain. Energy Rev. 146, 111113 (2021). https://doi.org/10.1016/j.rser.2021.111113

Chaudhari, S., Abbas, A., Botts, A., Sundaramoorthy, S., Wenning, T.: Load sharing energy savings methodology for systems with multiple centrifugal compressors. J. Clean. Prod. 433, 139630 (2023). https://doi.org/10.1016/j.jclepro.2023.139630

Rabi, A.M., Radulovic, J., Buick, J.M.: Comprehensive review of liquid air energy storage (LAES) technologies. Energies 16, 6216 (2023). https://doi.org/10.3390/en16176216

Piri, A., Aghanajafi, C., Sohani, A.: Enhancing efficiency of a renewable energy assisted system with adiabatic compressed-air energy storage by application of multiple Kalina recovery cycles. J. Energy Storage 61, 106712 (2023). https://doi.org/10.1016/j.est.2023.106712

Shi, X., He, Q., Liu, Y., Zhang, Q., An, X., Du, D.: Design and analysis of a novel liquefied air energy storage system coupled with coal-fired power unit. J. Energy Storage 73, 109204 (2023). https://doi.org/10.1016/j.est.2023.109204

Korkmaz, M.E., Gupta, M.K., Ross, N.S., Sivalingam, V.: Implementation of green cooling/lubrication strategies in metal cutting industries: a state of the art towards sustainable future and challenges. Sustain. Mater. Technol. (2023). https://doi.org/10.1016/j.susmat.2023.e00641

Wu, X., Feng, G., Wen, L.: Simulation and design system of typical tool for steam turbine. Proceedings of the 2015 Joint International Mechanical, Electronic And Information Technology Conference. 10, 1174–1177 (2015) https://doi.org/10.2991/jimet-15.2015.221

Sun, Z., Gao, L., Wang, J., Dai, Y.: Dynamic optimal design of a power generation system utilizing industrial waste heat considering parameter fluctuations of exhaust gas. Energy 44, 1035–1043 (2012). https://doi.org/10.1016/j.energy.2012.04.043

Zhou, J., Ali, M.A., Sharma, K., Almojil, S.F., Alizadeh, A., Almohana, A.I., Alali, A.F., Almoalimi, K.T.: Using machine learning to predict the performance of two cogeneration plants from energy, economic, and environmental perspectives. Int. J. Hydrogen Energy 52, 31–45 (2024). https://doi.org/10.1016/j.ijhydene.2022.12.018

Ghilardi, A., Frate, G.F., Tucci, M., Bravi, M., Leo, R., Ferrari, L.: Benefits of thermal load forecasts in balancing load fluctuations through thermal storage. J. Energy Storage 70, 107929 (2023). https://doi.org/10.1016/j.est.2023.107929

Tabora, J.M., De Lima Tostes, M.E., Bezerra, U.H., de Matos, E.O., Filho, C., Soares, T.M., Rodrigues, C.: Assessing energy efficiency and power quality impacts due to high-efficiency motors operating under nonideal energy supply. IEEE Access 9, 121871–121882 (2021). https://doi.org/10.1109/ACCESS.2021.3109622

Roshandel, E., Mahmoudi, A., Kahourzade, S., Soong, W.L.: Efficiency maps of electrical machines: a tutorial review. IEEE Trans. Indust. Appl. 59, 1263–1272 (2023). https://doi.org/10.1109/TIA.2022.3210077

He, W., Wang, J.: Optimal selection of air expansion machine in compressed air energy storage: a review. Renew. Sustain. Energy Rev. 87, 77–95 (2018). https://doi.org/10.1016/j.rser.2018.01.013

Acknowledgements

Not applicable.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

A. Can: Conceptualization, Methodology, Validation, Formal Analysis, Investigation, Writing, Reviewing, Editing, Visualization, Supervision. N.H-OCAK: Writing—Original draft, Resources, Reviewing, Drawing.

Corresponding author

Ethics declarations

Conflict of ınterests

The authors declared no potential conflicts of interest concerning the research, authorship, and/or publication of this article.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ocak, N.H., Can, A. A review on energy efficiency techniques used in machining for combined generation units. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-024-01789-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-024-01789-z