Abstract

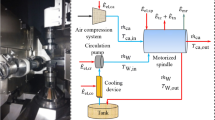

For an air cooling system that is applied in dry machining, the thermodynamic properties of cold compressed air have an important influence on the cooling of the cutting region. In this study, the air cooling system of the dry cutting machine tool is mathematically modeled and analyzed in terms of the exergy and economic aspects of the system design and component selection. With the exergy analysis of system components, the relations between system components parameters and thermodynamic properties of compressed air are obtained. The exergy functions are verified to be acceptable for industrial application by comparing measured values with calculated values of the thermodynamic properties of cold compressed air. A multi-objective optimization process is carried out using GA (genetic algorithm) combined with the Euclidean technique and the TOPSIS (technique for order preference by similarity to ideal solution) decision-making method. Exergetic efficiency and total cost rate of the air cooling system are the objectives, while the thermodynamic properties of cold compressed air supplied to the cutting region are the constraints. The results show that an optimum solution with an exergetic efficiency of 55.1% and total cost rate of 9.37 × 10−4 US$/s is achieved. Furthermore, air compressor, aftercooler, and air refrigerator are the components with the highest exergy destruction rate and capital cost, and have great potential for further improvement.

Similar content being viewed by others

References

Jegatheesan V, Liow JL, Shu L, Kim SH, Visvanathan C (2009) The need for global coordination in sustainable development. J Clean Prod 17(7):637–643. doi:10.1016/j.jclepro.2008.11.016

Jozić S, Bajić D, Celent L (2015) Application of compressed cold air cooling: achieving multiple performance characteristics in end milling process. J Clean Prod 100:325–332. doi:10.1016/j.jclepro.2015.03.095

Klocke F, Eisenblätter G (1997) Dry cutting. CIRP Ann Manuf Technol 46(2):519–526. doi:10.1016/S0007-8506(07)60877-4

Thamke D, Schirsch R, Zielasko W (1998) Wirtschaftlichkeit der trockenbearbeitung. VDI Ber 1375:371–397

Weinert K, Adams FJ, Thamke D (1995) Was kostet die Kühlschmierung? Tech 44(7):19–23

Klocke F, Lung D, Puls H (2013) FEM-modelling of the thermal workpiece deformation in dry turning. Procedia CIRP 8:240–245. doi:10.1016/j.procir.2013.06.096

Sreejith PS, Ngoi BKA (2000) Dry machining: machining of the future. J Mater Process Technol 101(1):287–291. doi:10.1016/S0924-0136(00)00445-3

Weinert K, Inasaki I, Sutherland JW, Wakabayashi T (2004) Dry machining and minimum quantity lubrication. CIRP Ann Manuf Technol 53(2):511–537. doi:10.1016/S0007-8506(07)60027-4

Liew WYH, Hutchings IM, Williams JA (1998) Friction and lubrication effects in the machining of aluminium alloys. Tribol Lett 5(1):117–122. doi:10.1023/A:1019164918708

Cao H, Zhu L, Li X, Chen P, Chen Y (2016) Thermal error compensation of dry hobbing machine tool considering workpiece thermal deformation. Int J Adv Manuf Technol 86(5):1739–1751. doi:10.1007/s00170-015-8314-5

Sukaylo V, Kaldos A, Pieper HJ, Bana V, Sobczyk M (2005) Numerical simulation of thermally induced workpiece deformation in turning when using various cutting fluid applications. J Mater Process Technol 167(2):408–414. doi:10.1016/j.jmatprotec.2005.05.042

Zhu L, Cao H, Zeng D et al (2017) Multi-variable driving thermal energy control model of dry hobbing machine tool. Int J Adv Manuf Technol. doi:10.1007/s00170-017-0086-7

Sun S, Brandt M, Dargusch MS (2010) Machining Ti–6Al–4V alloy with cryogenic compressed air cooling. Int J Mach Tools Manuf 50(11):933–942. doi:10.1016/j.ijmachtools.2010.08.003

Liu NM, Chiang KT, Hung CM (2013) Modeling and analyzing the effects of air-cooled turning on the machinability of Ti–6Al–4V titanium alloy using the cold air gun coolant system. Int J Adv Manuf Technol 67(5):1053–1066. doi:10.1007/s00170-012-4547-8

Rubio EM, Agustina B, Marín M, Bericua A (2015) Cooling systems based on cold compressed air: a review of the applications in machining processes. Procedia Eng 132:413–418. doi:10.1016/j.proeng.2015.12.513

Yalçın B, Özgür AE, Koru M (2009) The effects of various cooling strategies on surface roughness and tool wear during soft materials milling. Mater Des 30(3):896–899. doi:10.1016/j.matdes.2008.05.037

Vittorini D, Cipollone R (2016) Energy saving potential in existing industrial compressors. Energy 102:502–515. doi:10.1016/j.energy.2016.02.115

Azizifar S, Banooni S (2016) Modeling and optimization of industrial multistage compressed air system using actual variable effectiveness in hot regions. Adv Eng Mech Eng 8(5). doi:10.1177/1687814016647231

Zahlan J, Asfour S (2015) A multi-objective approach for determining optimal air compressor location in a manufacturing facility. J Manuf Syst 35:176–190. doi:10.1016/j.jmsy.2015.01.003

Han J, Wang L, Wang H, Cheng N (2012) A new thermal error modeling method for CNC machine tools. Int J Adv Manuf Technol 62(1):205–212. doi:10.1007/s00170-011-3796-2

Ruijun L, Wenhua Y, Zhang HH, Qifan Y (2012) The thermal error optimization models for CNC machine tools. Int J Adv Manuf Technol 63(9):1167–1176. doi:10.1007/s00170-012-3978-6

Wu CW, Tang CH, Chang CF, Shiao YS (2012) Thermal error compensation method for machine center. Int J Adv Manuf Technol 59(5):681–689. doi:10.1007/s00170-011-3533-x

Pusavec F, Krajnik P, Kopac J (2010) Transitioning to sustainable production—part I: application on machining technologies. J Clean Prod 18(2):174–184. doi:10.1016/j.jclepro.2009.08.010

Kotas TJ (1985) The exergy method of thermal plant analysis. Butterworth Publishers, Stoneham, pp 288–292

Keenan JH, Chao, Kaye (1983) Gas tables: international version: thermodynamic properties of air products of combustion and component gases compressible flow functions. Wiley, New York.

Engineers RA (2012) ASHRAE handbook: HVAC systems and equipment. ASHRAE, Atlanta

Min S, Qin H, Wang G, Hu S (2005) Analysis of energy conservation technology of desiccant dryers for compressed air systems. Shanghai Energy Conserv 4:106–110

Engineers RA (2009) ASHRAE handbook: fundamentals. ASHRAE, Atlanta

Shirazi A, Najafi B, Aminyavari M, Rinaldi F, Taylor R (2014) Thermal–economic–environmental analysis and multi-objective optimization of an ice thermal energy storage system for gas turbine cycle inlet air cooling. Energy 69(51):212–226. doi:10.1016/j.energy.2014.02.071

Incropera FP, DeWitt DP, Bergman TL, Lavine AS (2007) Fundamentals of heat and mass transfer, 6th edn. J. Wiley, New York

Colburn AP, De EIDP (1933) Mean temperature difference and heat transfer coefficient in liquid heat exchangers. Indonesia 25:873–877. doi:10.1021/ie50284a010

Winterton RHS (1998) Where did the Dittus and Boelter equation come from? Int J Heat Mass Transf 41(4–5):809–810. doi:10.1016/S0017-9310(97)00177-4

Moran MJ, Shapiro HN (1992) Fundamentals of engineering thermodynamics, 2nd ed. Wiley, New York

Martin H (1977) Heat and mass transfer between impinging gas jets and solid surfaces. Adv Heat Trans 13:1–60. doi:10.1016/S0065-2717(08)70221-1

Roosen P, Uhlenbruck S, Lucas K (2003) Pareto optimization of a combined cycle power system as a decision support tool for trading off investment vs. operating costs. Int J Therm Sci 42(6):553–560. doi:10.1016/S1290-0729(03)00021-8

Wall G (1991) Optimization of refrigeration machinery. Int J Refrig 14(6):336–340. doi:10.1016/0140-7007(91)90029-G

Selbaş R, Kızılkan Ö, Şencan A (2006) Thermoeconomic optimization of subcooled and superheated vapor compression refrigeration cycle. Energy 31(12):2108–2128. doi:10.1016/j.energy.2005.10.015

Konak A, Coit DW, Smith AE (2006) Multi-objective optimization using genetic algorithms: a tutorial. Reliab Eng Syst Saf 91(9):992–1007. doi:10.1016/j.ress.2005.11.018

Najafi H, Najafi B (2010) Multi-objective optimization of a plate and frame heat exchanger via genetic algorithm. Heat Mass Transf 46(6):639–647. doi:10.1007/s00231-010-0612-8

Selleri T, Najafi B, Rinaldi F, Colombo G (2013) Mathematical modeling and multi-objective optimization of a mini-channel heat exchanger via genetic algorithm. J Therm Sci Eng Appl 5(3):1–10. doi:10.1115/1.4023893

Najafi H, Najafi B, Hoseinpoori P (2011) Energy and cost optimization of a plate and fin heat exchanger using genetic algorithm. Appl Therm Eng 31(10):1839–1847. doi:10.1016/j.applthermaleng.2011.02.031

Sayyaadi H, Mehrabipour R (2012) Efficiency enhancement of a gas turbine cycle using an optimized tubular recuperative heat exchanger. Energy 38(1):362–375. doi:10.1016/j.energy.2011.11.048

Yue Z (2011) A method for group decision-making based on determining weights of decision makers using topsis. Appl Therm Eng 35(4):1926–1936. doi:10.1016/j.apm.2010.11.001

Navidbakhsh M, Shirazi A, Sanaye S (2013) Four E analysis and multi-objective optimization of an ice storage system incorporating PCM as the partial cold storage for air-conditioning applications. Appl Therm Eng 58(1–2):30–41. doi:10.1016/j.applthermaleng.2013.04.002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, L., Cao, H., Huang, H. et al. Exergy analysis and multi-objective optimization of air cooling system for dry machining. Int J Adv Manuf Technol 93, 3175–3188 (2017). https://doi.org/10.1007/s00170-017-0731-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0731-1