Abstract

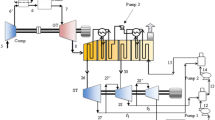

Internal combustion engine-based poly-generation systems have been widely used for energy savings and emissions reductions. To maximize their thermodynamic and environmental performance potentials, the efficient recovery of flue gas and jacket water heat is essential. In a conventional internal combustion engine-based steam and power cogeneration system, the low-temperature (less than 170°C) heat from flue gas and jacket water is usually directly discharged to the environment, which dramatically reduces the thermal and economic performance. In this work, a high-temperature heat pump is employed to recover this part of low-temperature heat for steam generation. The sensible heat of the flue gas and jacket water is cascade utilized in a steam generator and a heat pump. Simulation results show that the process steam yield of the proposed system is almost doubled (increased by 703 kg/h) compared to that of an engine-based cogeneration system without a heat pump. The proposed system can reduce natural gas consumption, CO2 and NOx emissions by approximately 199,069 m3, 372.64 tons and 3.02 tons per year, respectively, with a primary energy ratio and exergy efficiency of 72.52% and 46.28%, respectively. Moreover, the proposed system has a lower payback period with a value of 5.11 years, and the determining factors that affect the payback period are natural gas and electricity prices. The total net present value of the proposed system within its lifespan is 2,441,581 USD, and an extra profit of 785,748 USD can be obtained compared to the reference system. This is a promising approach for replacing gas boilers for process steam production in industrial sectors.

Similar content being viewed by others

Abbreviations

- ABS:

-

Absorber

- ANR :

-

annual net revenue/USD

- AP:

-

ammonia pump

- AUX:

-

auxiliary equipment

- CIF :

-

cash inflow/USD

- COF :

-

cash outflow/USD

- COM:

-

compressor

- CON:

-

condenser

- ch:

-

chemical

- ESR :

-

energy saving ratio/%

- EVA:

-

evaporator

- HACHP:

-

hybrid absorption-compression heat pump

- HEX:

-

heat exchanger

- HRSG:

-

heat recovery steam generator

- ICE:

-

internal combustion engine

- JW:

-

jacket water

- LHV :

-

low calorific value/kJ·kg−1

- MIX:

-

mixer

- NG:

-

natural gas

- NPV :

-

net present value/USD

- O&M:

-

operation and maintenance

- PBP :

-

payback period/a

- PC:

-

partial condenser

- PER :

-

primary energy ratio/%

- ph:

-

physical

- REB:

-

reboiler

- REC:

-

rectifier

- SCR:

-

selective catalytic regeneration

- SP:

-

solution pump

- ST:

-

steam

- TIV :

-

total initial investment/ USD

- TNPV :

-

total net present value/USD

- VAL:

-

valve

- 0:

-

environment

- A :

-

area/m2

- D :

-

destruction

- E :

-

exergy/kW

- M :

-

relative molecular mass

- N :

-

year/a

- Q :

-

thermal energy/kW

- T :

-

temperature/°C

- W :

-

electricity/kW

- Z :

-

cost/USD

- e :

-

specific exergy/kJ·kg−1

- η ex :

-

exergy efficiency/%

- h :

-

specific enthalpy/kJ·kg−1

- i :

-

discount rate

- m :

-

mass flow rate/kg·s−1

- n :

-

equipment lifetime

- s :

-

specific entropy/kJ·(kg·K)−1

- x :

-

mass concentration/%

References

Birol F., World Energy Balances, in, International Energy Agency, International Energy Agency, 2019.

Deymi-Dashtebayaz M., Tayyeban E., Multi objective optimization of using the surplus low pressure steam from natural gas refinery in the thermal desalination process, Journal of Cleaner Production, 2019, 238: 117945.

De Corato U., Cancellara F.A., Measures, technologies, and incentives for cleaning the minimally processed fruits and vegetables supply chain in the Italian food industry, Journal of Cleaner Production, 2019, 237: 117735.

Tumen Ozdil N.F., Tantekin A., Erbay Z., Energy and exergy analyses of a fluidized bed coal combustor steam plant in textile industry, Fuel, 2016, 183: 441–448.

Hasanbeigi A., Harrell G., Schreck B., Monga P., Moving beyond equipment and to systems optimization: techno-economic analysis of energy efficiency potentials in industrial steam systems in China, Journal of Cleaner Production, 2016, 120: 53–63.

Yang M., Dixon R.K., Investing in efficient industrial boiler systems in China and Vietnam, Energy Policy, 2012, 40: 432–437.

Giaccone L., Canova A., Economical comparison of CHP systems for industrial user with large steam demand, Applied Energy, 2009, 86: 904–914.

Jradi M., Riffat S., Tri-generation systems: Energy policies, prime movers, cooling technologies, configurations and operation strategies, Renewable and Sustainable Energy Reviews, 2014, 32: 396–415.

Wang J, Wu J. Investigation of a mixed effect absorption chiller powered by jacket water and exhaust gas waste heat of internal combustion engine. International Journal of Refrigeration. 2015, 50: 193–206.

Liu F.G., Tian Z.Y., Ma Z.X., Jia L.L., Zhang R., Yan A.-B., Experimental research on the property of water source gas engine-driven heat pump system with chilled and hot water in summer, Applied Thermal Engineering, 2020, 165: 114532.

Aly W.I.A., Abdo M., Bedair G., Hassaneen A.E., Thermal performance of a diffusion absorption refrigeration system driven by waste heat from diesel engine exhaust gases, Applied Thermal Engineering, 2017, 114: 621–630.

Chatzopoulou M.A., Markides C.N., Thermodynamic optimisation of a high-electrical efficiency integrated internal combustion engine — Organic Rankine cycle combined heat and power system, Applied Energy, 2018, 226: 1229–1251.

Yang K., Zhu N., Ding Y., Chang C., Wang D., Yuan T., Exergy and exergoeconomic analyses of a combined cooling, heating, and power (CCHP) system based on dual-fuel of biomass and natural gas, Journal of Cleaner Production, 2019, 206: 893–906.

Javan S., Mohamadi V., Ahmadi P., Hanafizadeh P., Fluid selection optimization of a combined cooling, heating and power (CCHP) system for residential applications, Applied Thermal Engineering, 2016, 96: 26–38.

Yan Y., Zhang H., Long Y., Wang Y., Liang Y., Song X., Yu J.J.Q., Multi-objective design optimization of combined cooling, heating and power system for cruise ship application, Journal of Cleaner Production, 2019, 233: 264–279.

Pérez N.P., Machin E.B., Pedroso D.T., Roberts J.J., Antunes J.S., Silveira J.L., Biomass gasification for combined heat and power generation in the Cuban context: Energetic and economic analysis, Applied Thermal Engineering, 2015, 90: 1–12.

Segurado R., Pereira S., Correia D., Costa M., Techno-economic analysis of a trigeneration system based on biomass gasification, Renewable and Sustainable Energy Reviews, 2019, 103: 501–514.

Mohammadkhani F., Yari M., A 0D model for diesel engine simulation and employing a transcritical dual loop Organic Rankine Cycle (ORC) for waste heat recovery from its exhaust and coolant: Thermodynamic and economic analysis, Applied Thermal Engineering, 2019, 150: 329–347.

Song X., Liu L., Zhu T., Zhang T., Wu Z., Comparative analysis on operation strategies of CCHP system with cool thermal storage for a data center, Applied Thermal Engineering, 2016, 108: 680–688.

Yu X., Zhang Y., Kong L., Zhang Y., Thermodynamic analysis and parameter estimation of a high-temperature industrial heat pump using a new binary mixture, Applied Thermal Engineering, 2018, 131: 715–723.

Urbanucci L., Bruno J.C., Testi D., Thermodynamic and economic analysis of the integration of high-temperature heat pumps in trigeneration systems, Applied Energy, 2019, 238: 516–533.

Jensen J.K., Reinholdt L., Markussen W.B., Elmegaard B., Investigation of ammonia/water hybrid absorption/compression heat pumps for heat supply temperatures above 100°C, in: International Sorption Heat Pump Conference, University of Maryland, Washington DC, 2014, 1055: 1–10.

Liu C., Jiang Y., Han W., Kang Q., A high-temperature hybrid absorption-compression heat pump for waste heat recovery, Energy Conversion and Management, 2018, 172: 391–101.

Misra R.D., Sahoo P.K., Gupta A., Thermoeconomic evaluation and optimization of an aqua-ammonia vapour-absorption refrigeration system, International Journal of Refrigeration, 2006, 29: 47–59.

Ahrendts J., Reference states, Energy, 1980, 5: 666–677.

Balli O., Aras H., Hepbasli A., Thermodynamic and thermoeconomic analyses of a trigeneration (TRIGEN) system with a gas-diesel engine: Part I — Methodology, Energy Conversion and Management, 2010, 51: 2252–2259.

Abbasi M., Chahartaghi M., Hashemian S.M., Energy, exergy, and economic evaluations of a CCHP system by using the internal combustion engines and gas turbine as prime movers, Energy Conversion and Management, 2018, 173: 359–374.

Silveira J.L., Tuna C.E., Thermoeconomic analysis method for optimization of combined heat and power systems. Part I, Progress in Energy and Combustion Science, 2003, 29: 479–485.

Aminyavari M., Najafi B., Shirazi A., Rinaldi F., Exergetic, economic and environmental (3E) analyses, and multi-objective optimization of a CO2/NH3 cascade refrigeration system, Applied Thermal Engineering, 2014, 65: 42–50.

Baghernejad A., Yaghoubi M., Exergoeconomic analysis and optimization of an Integrated Solar Combined Cycle System (ISCCS) using genetic algorithm, Energy Conversion and Management, 2011, 52: 2193–2203.

Zare V., Mahmoudi S.M.S., Yari M., Amidpour M., Thermoeconomic analysis and optimization of an ammonia-water power/cooling cogeneration cycle, Energy, 2012, 47: 271–283.

Su B., Han W., Jin H., An innovative solar-powered absorption refrigeration system combined with liquid desiccant dehumidification for cooling and water, Energy Conversion and Management, 2017, 153: 515–525.

Su B., Han W., Chen Y., Wang Z., Qu W., Jin H., Performance optimization of a solar assisted CCHP based on biogas reforming, Energy Conversion and Management, 2018, 171: 604–617.

Su B., Han W., Sui J., Jin H., A two-stage liquid desiccant dehumidification system by the cascade utilization of low-temperature heat for industrial applications, Applied Energy, 2017, 207: 643–653.

Su B., Qu W., Han W., Jin H., Feasibility of a hybrid photovoltaic/thermal and liquid desiccant system for deep dehumidification, Energy Conversion and Management, 2018, 163: 457–467.

Sanaye S., Meybodi M.A., Shokrollahi S., Selecting the prime movers and nominal powers in combined heat and power systems, Applied Thermal Engineering, 2008, 28: 1177–1188.

Jiang R., Han W., Qin F.G.F., Sui J., Yin H., Yang M., Xu Y., Thermodynamic model development, experimental validation and performance analysis of a MW CCHP system integrated with dehumidification system, Energy Conversion and Management, 2018, 158: 176–185.

Hill N., Venfield H., Dun C., James K., Government GHG Conversion Factors for Company Reporting: Methodology Paper for Emission Factors, Department of Environment, Food and Rural Affairs; in, 2013.

Bengtsson S., Andersson K., Fridell E., A comparative life cycle assessment of marine fuels: liquefied natural gas and three other fossil fuels, Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment, 2011, 225: 97–110.

Klein S.A., Alvarado F., Engineering Equation Solver (EES), FChart Software, in, 2011.

Acknowledgements

This work was supported by the National Key Research and Development Program of China (No. 2016YFF0201503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Han, W., Wang, Z. et al. Proposal and Assessment of an Engine-Based Distributed Steam and Power Cogeneration System Integrated with an Absorption-Compression Heat Pump. J. Therm. Sci. 29, 1165–1179 (2020). https://doi.org/10.1007/s11630-020-1302-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-020-1302-6