Abstract

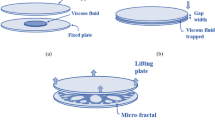

Bio-mimicking is the process of mimicking the various patterns, models, and systems of nature to take inspiration and solve human problems. The fractal-like patterns are seen in the leaves, tree branches, veins and arteries of the human body, etc. Imitation of these structures is a complex process. This can be achieved using lifting plate Hele-Shaw cell (LPHSC). In LPHSC, non-Newtonian fluid is placed between the two flat plates separated by a minimal distance. The lower plate is kept fixed, and the upper plate is lifted precisely. This leads to the formation of Saffman-Taylor instability or uncontrolled viscous fingering. When a low viscous fluid interacts with high viscous fluid, it tries to displace high viscous fluid, resulting in fractal-like structures. This paper investigates fractal formation in Hele-Shaw cell on different polygonal surfaces such as triangular, square, pentagonal, and hexagonal plates. The authors studied the effect of the sides and corners of the polygons and controlled the instabilities using a gap between plates and the lifting velocity of the upper plate. The entire process of fractal formation is simulated in ANSYS software, and experimental and simulated results hold good agreement. This proposed method will be used to fabricate microstructures.

Similar content being viewed by others

References

Pence, D.: Reduced pumping power and wall temperature in microchannel heat sinks with fractal-like branching channel networks. Microscale. Thermophys. Eng. 6, 319–330 (2003). https://doi.org/10.1080/10893950290098359

Bahadorimehr, A.R., Damghanian, M., Burhanuddin, Y.M.: A static micromixer inspired from fractal-like natural flow systems. Adv. Mater. Res. 254, 25–28 (2011). https://doi.org/10.4028/www.scientific.net/amr.254.25

Gervais, L., Delamarche, E.: Toward one-step point-of-care immunodiagnostics using capillary-driven microfluidics and PDMS substrates. Lab Chip 9, 3330 (2009). https://doi.org/10.1039/b906523g

Wu, W., Hansen, C.J., Aragón, A.M., et al.: Direct-write assembly of biomimetic microvascular networks for efficient Fluid Transport. Soft Matter 6, 739–742 (2010). https://doi.org/10.1039/b918436h

Gandhi, P., Deshmukh, S., Ramtekkar, R., Bhole, K., Baraki, A.: “On-axis” linear focused spot scanning microstereolithography system: optomechatronic Design, analysis and development. J. Adv. Manufact. Syst. 12, 43–68 (2013). https://doi.org/10.1142/s0219686713500030

Bhole, K.S., Kale, B.: Techniques to minimise stair-stepping effect in micro-stereolithography process: a review. Adv. Mater. Process. Technol. 30, 1–20 (2021). https://doi.org/10.1080/2374068x.2021.1970997

Bhole, K., Gandhi, P., Kundu, T.: On the evolution of cured voxel in bulk photopolymerization upon focused gaussian laser exposure. J. Appl. Phys. 116(4), 043105 (2014). https://doi.org/10.1063/1.4891109

Gandhi, P., Bhole, K.: Characterization of “bulk lithography” process for fabrication of three-dimensional microstructures. J. Micro Nano-Manufact. 1(4), 5461 (2013). https://doi.org/10.1115/1.4025461

Gandhi, P., Bhole, K.: 3D microfabrication using bulk lithography. In: ASME International Mechanical Engineering Congress and Exposition. Denver, Colorado, USA Nov. 54976, pp. 393–399 (2011)

Gandhi, P., Kamble, S., Bhole, K.: Novel fabrication and characterisation of diaphragm micromirror using bulk lithography, In: ASME International Mechanical Engineering Congress and Exposition, Houston, Texas, USA Nov. pp. 549–554 (2012). https://doi.org/10.1115/IMECE2012-87745

Gandhi, P., Chaudhari N., Bhole K.: Fabrication of textured 3D microstructures using Bulk lithography. In: ASME International Manufacturing Science and Engineering Conference, MSEC Notre Dame, USA June 4–8, pp. 959–964(2012). https://doi.org/10.1115/MSEC2012-7357

Bhole, K.S., Gandhi, P.S., Kundu, T.: Characterization of cured width under wide range of gaussian laser exposure for bulk lithography. Procedia Materials Science. 5, 2487–2492 (2014). https://doi.org/10.1016/j.mspro.2014.07.500

Bhole, K., Ekshinge, S., Gandhi, P.: Fabrication of continuously varying thickness micro-cantilever using bulk lithography process. In: International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, (Vol. 45806, p. V001T01A009, (2014) https://doi.org/10.1115/MSEC2014-4041.

Shewale, J. J, Bhole, K.S.: 3D polymer microneedle array: Fabrication and analysis. International Conference on Nascent Technologies in the Engineering Field (ICNTE) (pp. 1–6). IEEE, (2015) https://doi.org/10.1109/ICNTE.2015.7029915.

Raju, R., Manikandan, N., Palanisamy, D., Arulkirubakaran, D., Binoj, J.S., Thejasree, P., Ahilan, C.: A review of challenges and opportunities in additive manufacturing. In: Palani, I.A., Sathiya, P., Palanisamy, D. (eds.) Recent Advances in Materials and Modern Manufacturing. Lecture Notes in Mechanical Engineering Springer, Singapore (2022)

Varma, M.M.M.K., Baghel, P.K., Raju, R.: Additive manufacturing of thermosetting resins In-Situ Carbon Fibers: a review. In: Palani, I.A., Sathiya, P., Palanisamy, D. (eds.) Recent Advances in Materials and Modern Manufacturing. Lecture Notes in Mechanical Engineering Springer, Singapore (2022)

Thirugnanasambantham, K.G., Francis, A., Ramesh, R., Aravind, M., Reddy, M.K.: Investigation of erosion mechanisms on IN-718 based turbine blades under water jet conditions. Int. J. Interact Design Manufact. (2022). https://doi.org/10.1007/s12008

Saffman, P.G.: Viscous fingering in Hele-Shaw cells. J. Fluid Mech. 173, 73–94 (1986). https://doi.org/10.1017/S0022112086001088

Taylor, G., Saffman, P.G.: A note on the motion of bubbles in a Hele-Shaw cell and porous medium. Quarterly J. Mech. Appl. Math. 12(3), 265–279 (1959). https://doi.org/10.1093/qjmam/12.3.265

Choudhury, M.D., Tarafdar, S.: Fingering instability in non-Newtonian fluids during squeeze flow in a Hele-Shaw cell. Indian J. Phys. 89(5), 471–477 (2015). https://doi.org/10.1007/s12648-014-0606-3

Pouplard, A., Tsai. P. A.: Manipulating viscous fingering of complex fluids. Bull. Am. Phys. Soc. 66 (17) (2021).

Chen, C., Huang, C., Wang, L., et al.: Controlling radial fingering patterns in miscible confined flows. Phys. Rev. E 82, 056308 (2010). https://doi.org/10.1103/PhysRevE.82.056308

Kale, B. S.; Bhole, K. Parametric Analysis for forming meso fractals from nanoparticle seeded resin in Hele Shaw cell. In IOP Conference Series: Materials Science and Engineering (Vol. 577, No. 1, p. 012154). IOP Publishing, November 2019. Doi: https://doi.org/10.1088/1757-899X/577/1/012154

Shuwang, Li., Lowengrub, J., Fontana, J., Muhoray, P.P.: Control of viscous fingering patterns in a radial Hele-Shaw Cell. Phys. Rev. E. 102(17), 174501 (2009). https://doi.org/10.1103/PhysRevLett.102.174501

Dias, E.O., Parisio, F., Miranda, J.A.: Suppression of viscous fluid fingering: A piecewise-constant injection process. Phys. Rev. E. 82(6), 067301 (2010). https://doi.org/10.1103/PhysRevE.82.067301

Kale, B.S., Bhole, K.: Controlling the instabilities in the radial Hele-Shaw cell. Int. J. Theoret Appl. Multiscale Mech. 3(3), 245–260 (2020). https://doi.org/10.1504/IJTAMM.2020.112780

Bhole, K.S., Kale, B.: Sublimation technique for minimisation of stiction induced during fabrication of closely spaced microstructures. Adv. Mater. Process. Technol. (2022). https://doi.org/10.1080/2374068X.2022.2036445

Kale, B.S., Bhole, K., Sharma, C.: Effect of anisotropies in formation of viscous fingering in lifting plate Hele-Shaw cell. Adv. Mater. Process. Technol. (2021). https://doi.org/10.1080/2374068X.2021.2013679

Devkare, S.S., Bhole, K.S., Kale, B.S., Sharma, C.: Control of viscous fingering of Bingham plastic fluid in lifting plate Hele-Shaw cell. Mater. Today: Proc. 28, 1920–1926 (2020). https://doi.org/10.1016/j.matpr.2020.05.314

Islam, T.U., Gandhi, P.S.: Viscous fingering in multiport Hele shaw cell for controlled shaping of fluids. Sci. Rep. 7(1), 1–9 (2017). https://doi.org/10.1038/s41598-017-16830-3

Kabiraj, S.K., Tarafdar, S.: Finger velocities in the lifting Hele Shaw cell. Phys. A: Statist. Mech. Appl. 328, 3–4 (2003). https://doi.org/10.1016/S0378-4371(03)00523-5

Holloway, K.E., De Bruyn, J.R.: Viscous fingering with a single fluid. Can. J. Phys. 83(5), 551–564 (2005). https://doi.org/10.1139/p05-024

Lindner, A., Bonn, D., Amar, M.B., Meunier, J., Kellay, H.: Controlling viscous fingering. Euro Phys. News. 30(3), 77 (1999)

Bonn, D., Kellay, H., Braunlich, M., Amar, M.B., Meunier, J.: Viscous Fingering in complex fluids. Physica A 220, 1–2 (1995). https://doi.org/10.1016/0378-4371(95)00114-M

Lindner, A., Bonn, D., Poire, E.C., Amar, M.B., Meunier, J.: Viscous fingering in non-newtonian fluids. J. Fluid Mech. 469, 237 (2002). https://doi.org/10.1017/S0022112002001714

Al Housseiny, T., Tsai, P., Stone, H.: Control of interfacial instabilities using flow geometry. Nat. Phys. 8, 747–750 (2012). https://doi.org/10.1038/nphys2396

Al, H.T., Stone, H.: Controlling viscous fingering in tapered Hele-Shaw cells. Phys. Fluids 25(9), 092102 (2013). https://doi.org/10.1063/1.4819317

González, D., Asuaje, M.: Simulation of viscous fingering phenomenon using CFD tools. In: ASME International Mechanical Engineering Congress and Exposition (Vol. 46545, p. V007T09A001). American Society of Mechanical Engineers. November 2014. https://doi.org/10.1115/IMECE2014-36896

Kale, B.S., Bhole, K., Devkare, S.S., Sharma, C.: Simulation of viscous fingers developed in lifting plate Hele-Shaw cell in volume of fluid model. Int. J. Adv. Sci. Technol. 29(3), 1486–14874 (2020)

Acknowledgements

The authors acknowledge support for this work by the Science and Engineering Research Board (SERB), Government of India through Project Grant CRG/2021/000747.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kale, B.S., Bhole, K.S., Dhongadi, H. et al. Effect of polygonal surfaces on development of viscous fingering in lifting plate Hele-Shaw cell. Int J Interact Des Manuf (2022). https://doi.org/10.1007/s12008-022-01030-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-022-01030-9