Abstract

Cold brew is a method of coffee extraction that uses low temperature, preserving the volatile compounds of coffee. Freeze-drying allows the preservation of coffee features and nutritional value. The aim of this study was to evaluate the effects of different cryoprotectants in cold brew extracts as a basis for freeze-dried coffee production. Thus, the Coffea arabica extracts and the soluble coffee were characterized concerning caffeine content, antioxidant capacity, total phenolic compounds, and antimicrobial activity to verify the potential of this method. The extracts did not show antimicrobial activity with a high soluble solid content. It was observed that the cold extraction methods were efficient regarding the caffeine content, antioxidant capacity, and total phenolic compounds. Freeze-dried coffees also did not show antimicrobial activity, and they maintained the water and humidity activity standards. In general, cryoprotectants displayed an unfavorable influence on the extract and freeze-dried coffee in the analyses performed. The coffee extract without cryoprotectants had a higher antioxidant capacity (88.12%) and content of phenolic compounds (7.74 mg AG/mL of the coffee extract). Only for the analyses of soluble solids, the cryoprotectants mannitol and fructose showed promising results (14.03 °Brix, 14.40 °Brix, 11.33 °Brix, respectively). Thus, for the analyses conducted, the cryoprotectants did not lead to significant advantages for this process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The strong characteristic flavor and aroma of Arabica coffee makes it the most common drink in Europe and America. Raw coffee is subjected to the roasting process that results in a new aroma, flavor, and color. Researchers have been evaluating and adding soluble coffee to several different beverages and recipes, such as the incorporation of coffee in the processing of bread (Fonte et al., 2016a; Mussatto et al., 2011; Wu et al., 2022).

The degree of roasting of the coffee beans influences their composition. For example, a high roasting not only decreases the number of bioactive compounds in the coffee beans but also stimulates the conversion of endogenous anti-nutritional compounds in the coffee reducing its nutritional value (Júlio et al., 2019). Depending on the extraction and concentration of coffee, different compositions in the beverage can be achieved, namely concerning polyphenol content, caffeine content, total solids, antioxidant capacity, and volatile profile, which affects the quality of the final drink (Almeida et al., 2022; Ballesteros et al., 2014; Fonte et al., 2016b; Zhang et al., 2017).

New methods of preparation of cold coffee involve lower temperatures rather than rapid exposure to high temperatures (Kyroglou et al., 2021). The temperature significantly influences the aqueous solubility of the compounds and can result in different compositions in hot and cold coffees. In addition, long extraction times in cold coffee can affect the final composition of the extract (Esquivel & Jiménez, 2012). Recent studies have shown that certain extraction conditions can minimize the degradation of volatile compounds during thermal processing (Falé et al., 2009; Rao & Fuller, 2018).

A trend used by the food industry is the development of instant coffee, a term used to justify any form of coffee that does not require special equipment for preparing the drink, requiring only hot water. Worldwide, the instant coffee market is valued at more than 30 billion US dollars and contributes over 40% of the total value of coffee consumed (Cordoba et al., 2019) which corresponds to more than half a million tons of coffee produced each year. Instant coffee can be produced by drying the coffee extract by freeze-drying or spray-drying. Drying processes for commercial instant coffee usually reduce its water content by less than 5% by mass. The remaining composition of the blend is a mixture of carbohydrates, proteins, flavor oils, phosphates, and melanoidins (Gloess et al., 2013; Khan et al., 2021; Shofinita et al., 2024).

The industrial production of instant coffee follows the same principles as ordinary coffee, with roasting, grinding, and extracting roasted beans with either hot or cold water (Cushnie & Lamb, 2011; Sorgi et al., 2021). After being roasted and grounding the coffee starts the extraction; this is a fundamental step for producing soluble coffees, being necessary for high concentrations of solids (from 42 to 45% of weight). The conventional extraction method occurs through a stirring tank, usually made of stainless steel, filled with ground coffee. The mixture is usually grounded with water at a temperature around 180 °C (Khochapong et al., 2021; Olechno et al., 2021). Another form of extraction is by cold method, cold brew (CB), although the solubility of caffeine is lower in water at room temperature or refrigerated. Studies report that the concentrations of this method were like the ones obtained for the extraction methods by mocha and espresso. This fact can be explained by the extensive contact time between chilled water and ground coffee (Duarte et al., 2005). CB preparation techniques have gained popularity in the last few years, both for consumption at home and in coffee shops, being more prevalent in European countries, the United States, and Japan (Brighente et al., 2007). Furthermore, the increase in consumption is related to the fact that these processes being slower and with lower temperatures maintain the flavor, aroma, and bioactive compounds and make the coffee drink sweeter, smoother, and more full-bodied than conventionally (Surkan et al., 2009; Zhang et al., 2014).

After the concentrated coffee extract, the subsequent and final step is drying. The limitation of the spray-drying method is related to the fact that there is a loss of certain low-boiling aromatic compounds that are characteristic of coffee due to being a process that operates at high temperatures. In the case of freeze-drying, the freezing step is the most determinant for the quality of the final product because it can cause changes in the crystal structure, type, size, and stability, and then influencing the water vapor flow during the drying steps, which may have adverse consequences to the lyophilized product. In this sense, cryopreservation often occurs to protect materials from freezing stresses (Fonte et al., 2016a, b; Júlio et al., 2019). This method, on the other hand, avoids the loss of these aromas and the development of unpleasant flavors in the dried product, and even though freeze-drying the aqueous coffee extract requires a longer drying time, the final quality of the product is superior (Duarte et al., 2005). After drying, the solid material is processed to create the commercial product. These are thermal and mechanical processes, such as agglomeration, granulation, and melt extrusion (Gloess et al., 2013). There is little academic literature on these specific applications, due to the lack of standardization by legislation and the secrecy of the instant coffee industry.

Studies related to the preservation of coffee quality are also important because they allow us to study whether the stability and structure of caffeine remain un-changed after processing coffee and subjecting it to extreme temperatures. Castro and co-workers (Castro et al., 2017) in their work incorporated this compound in biopolymer-based oral films and found no changes in its structure after formulation. Recent developments demonstrate novel techniques to enhance the solubility of coffee extracts, such as vacuum freezing (Silva & Schmidt, 2019), or even to improve its organoleptic properties, by generating stable foam based on nanobubbles produced using spray-freeze-drying methodologies (Deotale et al., 2020) or microencapsulation using gelatin and gum arabic to preserve volatile organic compounds (Zanin et al., 2021). However, the impact of cryoprotectants, widely used in the food industry, in preserving Coffee arabica cold brew properties and their influence in the freeze-drying process remains an unexplored field.

The aim of this study is to develop and evaluate a soluble coffee by the freeze-drying method using cold brew method, conducted at room temperature, at low extraction time, in the presence and absence of cryoprotectants (mannitol and fructose). The cold brew and the freeze-dried coffees were fully characterized, to evaluate this methodology’s potential.

Materials and Methods

Materials

The roasted Arabica coffee was commercially available from Café Gema de Minas® (Capelinha, Brazil, at coordinates 17°39ʹ14.5ʺ S; 42°15ʹ32.3ʺ W). Fructose (Lab-synth, Brazil) and mannitol (≥ 98% purity, Sigma-Aldrich, Brazil) were used as cryoprotectants. For antioxidant activity evaluation, 2,2-diphenyl-1-picrylhydrazyl (DPPH, C18H12N5O6, ≥ 99%, Sigma-Aldrich) was used. For caffeine content, Milli-Q water, 10.00% (w/v) aqueous lead acetate solution by Ricca Chemical (Arlington, USA), and methanol (MeOH) CHROMASOLV™ (Honeywell Riedel-de-Haën™, Seelze, Germany) HPLC-grade reagent (purity ≥ 99.9%) were used, and as standard caffeine was used (C8H10N4O2, ≥ 99%, Sigma-Aldrich). For total phenolic content, Milli-Q water, gallic acid (code G7384, Sigma-Aldrich), Folin-Ciocâlteu reagent (code F9252, Sigma-Aldrich), and sodium carbonate (anhydrous, Na2CO3, ≥ 99.5%, Sigma-Aldrich) were used.

Cold Brew Coffee Extraction

The coffee roasted beans were ground in an industrial coffee grinder to prepare the coffee samples (MLVI-5NA, Pinhalense, Espírito Santo do Pinhal, Brazil). An electro-magnetic stirrer with round sieves BT-001 by Bertel (Caieiras, Brazil) was used to provide the particle size used. The ground coffee particle size used was #30 mesh, corresponding to the retention between the #28 mesh and #32 mesh sieve opening. The coffee extraction was performed using an optimized CB method, at 24 °C (Barroso et al., 2022). Two cryoprotectants, fructose (0.5%) and mannitol (0.5%), were added to the extracts. The amount of cryoprotectant was added w/w regarding total solids, in a feasible concentration that does not significantly change the coffee taste. The ground coffee beans and the cryoprotectants were kept in water at a coffee-to-water concentration of 30%, under stirring (20 g force) for 45 min in a biochemical oxygen demand (BOD) incubator CE-300/350-AU by CIENLAB (São Paulo, Brazil) with temperature control set at 24 °C. The same process was performed for the ground coffee beans without the cryoprotectants. The extractions occur in triplicate for each coffee sample. After extraction, the coffee extracts were transferred to falcon tubes (50 mL) and centrifuged at 62,259 g force for 10 min with a benchtop centrifuge from HERMLE (Hermle LaborTechnik GmbH, Wehingen, Germany). The supernatant was vacuum-filtered and stored in amber vials until analyzed.

pH and Soluble Solid Content of Cold Brew

The pH determination of cold brew extract was made by direct reading on the coffee samples. The equipment used was a bench pH meter of Metrohm (São Paulo, Brazil) calibrated with buffer solutions (4.01 and 6.98). The determination of soluble solid content of the cold brew extract was performed according to method 932.12 of the Association of Official Analytical Chemists - AOAC (AOAC, 1998). The analyses used the digital refractometer model RTD-95 from Instrutherm®(São Paulo, Brazil), with the results expressed in °Brix. Previously, the coffee extract samples were filtered with cotton, and the content of soluble solids was determined, with direct reading on the digital refractometer. All measurements were done in triplicate.

Obtaining Freeze-Dried Soluble Coffee

The coffee extracts added with and without cryoprotectants were frozen with the aid of liquid nitrogen (LN, − 196 °C) produced at the Industrial Pharmacy Laboratory of the Faculty of Biological and Health Sciences (UFVJM). After freezing, the samples were transferred to the freeze dryer ModelLS 3000 (Terroni brand), equipped with a control center, vacuum pump, sample extractor, dew point analyzer, and sample closing system, at a shelf temperature from − 40 °C progressing to 10 °C. Lyophilization occurred for 48 h. After 48 h, freeze-dried coffee samples were collected from the trays, packed in polyethylene bags, sealed, wrapped in aluminum foil, and sent to the desiccator at room temperature until subsequent analysis.

Characterization of Cold Brew and Soluble Coffee

Antimicrobial Activity

The method to evaluate the antimicrobial activity of cold brew and the freeze-dried coffee solution was the agar-well diffusion method (Epole et al., 2017). Gram-positive bacteria (Staphylococcus aureus ATCC 25923), Gram-negative bacteria (Escherichia coli ATCC 25922, Proteus mirabilis, Salmonella typhi), and yeast (Candida albicans ATCC 10231) were used as reference strains. Mueller-Hinton Agar culture medium (3 mm layer) was used in this assay. The culture was transferred to a Petri plate (8 cm diameter) and stored at 8 °C. These plates were inoculated with the respective microorganism, each with seven equidistant wells.

For evaluation of the antimicrobial activity, 50 μL of cold brew was used. A 50 μL solution of freeze-dried coffee solution was also prepared by using a mixture of 30% freeze-dried coffee and 70% distilled water. The wells (5 mm diameter) with amoxicillin (1 mg/mL) and amphotericin B (1 mg/mL) were used as positive controls. The microbial plates were incubated at 37 °C for 24 h. All agar-well diffusion tests were performed in three independent experiments.

Caffeine Content

The caffeine content in coffee samples (cold brew and freeze-dried coffee solution) was determined by high-performance liquid chromatography (HPLC) using a previously described method by Jeon and co-workers (Jeon et al., 2017). A total of 1 mL was collected from the cold brew samples, and 300 µL of a 10% solution of basic lead acetate was added and centrifuged at 1800 G force for 5 min in a Sigma 3–15 KL centrifuge by Sigma Zentrifugen GmbH (Osterode am Harz, Germany). The supernatant was collected and filtered with syringe filter PES, pore size 0.45 μm (Berrytec GmbH, Grünwald, Germany). The determination of caffeine content was done in an Agilent Technologies 1260 Infinity II HPLC-UV system (Shimadzu, Barueri, Brazil) equipped with a ZORBAX Eclipse Plus C18 reverse-phase column (4.6 × 100 mm, size 3.5 µm). An isocratic mobile phase of methanol:water (30:70, v/v) at a flow rate of 1 mL.min−1 and the detection of caffeine at a wavelength of 274 nm were set. The identification of caffeine content in samples occurs by comparing their retention time with the 4.5 min observed for the caffeine standard.

The analysis of the concentration of caffeine in the cold brew and freeze-dried coffee followed the same procedure where the solution used for freeze-dried coffee was 30% of dry coffee in 70% distilled water. A standard calibration curve of caffeine dissolved in Milli-Q® water with solutions at 10, 20, 40, 60, 80, and 100 mg/L of caffeine was used. The value absorbance of each solution at the wavelength of 274 nm was measure and repeated in triplicate.

Antioxidant Activity

The antioxidant activity of coffee samples (cold brew and freeze-dried coffee solution) was assessed according to Falé and co-workers (Falé et al., 2009) with some modifications, using the DPPH (2,2-diphenyl-1-picrylhydrazyl) radical scavenging. A total of 24 µL of the coffee extracted sample was added at 976 μL of DPPH solution (0.002% in methanol). The mixture was incubated for 30 min at room temperature (~24 °C) and the reaction between DPPH and coffee extracts occurred. The analysis occurred with the aid of a digital spectrophotometer (BEL Photonics, model UV-M51). The measure of absorbance was done at 515 nm and the antioxidant capacity calculation used the formula

where %AC corresponds to the percentage of antioxidant capacity, ADPPH is the absorption of the DPPH solution, and Aextract is the absorption of coffee sample extract. The essay was performed in triplicate. The analysis of antioxidant capacity in freeze-dried coffee followed the same procedure, but with a 30% freeze-dried coffee solution in 70% distilled water.

Determination of the Total Phenolic Content

The total phenolic content of coffee samples (cold brew and freeze-dried coffee solution) was determined according to the method described by Singleton and Rossi (1965), with some modifications. The samples were prepared by diluting 20 μL of the coffee extract in Milli-Q water (concentration 1:20 v/v). The total phenolic content was obtained by adding 100 μL of Milli-Q water (pH = 7.0), 12.5 μL of the coffee sample, and 12.5 μL of Folin-Ciocalteu reagent, in that order, in each of the wells of the 96-well microplate. The microplates were mixed for 30 s and rested for 5 min. A total of 125 μL of sodium carbonate was added at 1.0 mol.L−1, to a final volume of 250 μL per well. The microplate remained at room temperature, protected from light, for 90 min. The determination of absorbance at a wavelength of 750 nm was made on the microplate reader SpectraMax® using distilled water as the negative control.

The analysis of phenolic compounds in freeze-dried coffee followed the same methodology described with a 30% freeze-dried coffee solution in 70% distilled water. A standard curve was created with gallic acid (GA) at concentrations ranging from 0 to 2000 mg.L−1, and the results were expressed in mg of GA per mL of coffee extract.

Characterization of Instant Coffee

Moisture, Wettability, and Water Activity

The determination of the moisture content of freeze-dried coffees was conducted by the gravimetric method, at a temperature of 105 °C in a conventional oven (Ethik Technology, model 402-5D), until obtaining a constant weight (AOAC, 2006). Water activity measurement was performed only on freeze-dried coffee through a direct reading of the sample on the Aqualab equipment (model 4TE, USA), at a controlled temperature of 25 ± 0.5 °C (Terra et al., 2007).

Freeze-Dried Coffee Particle Morphology

The morphology of the instant coffee microparticles was evaluated by scanning electron microscopy (SEM), available at the Multi-User Advanced Microscopy Laboratory (LAMMA) at UFVJM. The samples were fixed on double-sided adhesive tape, pre-fixed to a metal stub, and coated with gold in a metallizer (Quorum, model Q150 ES) and examined in the TESCAN scanning electron microscope (model VEGA LMH) (Ribeiro et al., 2010).

Solubility

The solubility essay was done according to the method proposed by Cano-Chauca and co-workers (Cano-Chauca et al., 2005) with modifications. For the analysis, 25 mL of deionized water was transferred to a beaker and stirred at 769 g force in an Ultra-Turrax homogenizer. A total of 0.5 g of freeze-dried coffee was added carefully and stirred for 5 min. The solution was transferred to a tube and centrifuged at 831 g force for 5 min (Thermo Scientific centrifuge, model 37 520, Germany). An aliquot of 20 mL of the supernatant was transferred to a Petri plate previously weighed and dried in an oven at 105 °C for 12 h. The estimated solubility percentage was measured by the difference in mass between the dry supernatant and the freeze-dried coffee added initially.

The determination of wettability was done by the method proposed by Pereira de Oliveira and co-workers (Pereira de Oliveira et al., 2022) where 1 g of the freeze-dried coffee sample was spread over 100 mL of deionized water at 20 °C, under no stirring. These properties are measured by assessing the time required for the particles to settle or sink and disappear from the water surface.

Statistical Analysis

All statistical analyses were performed using Stat Soft STATISTICA® 8.0 software. The data were compared to identify significant differences between samples using analysis of variance (ANOVA) followed by the average test Tukey, with significance at the level set at 5% probability.

Results

pH and Soluble Solid Content of Cold Brew

Cryoprotectants were added to maintain the stability and quality of the coffee extracts during processing. The cryoprotectants were added to the extract that pass for indefinite storage at negative temperatures so that when thawed, the material can continue its normal development. The performed temperature at which cryopreservation acts is known as “cryogenic temperature,” that is, the low temperature at which the liquefied gases are at atmospheric pressure, and so the addition of cryoprotectants is essential (Day & Stacey, 2007; Rubinsky, 2003). Table 1 shows the results and standard deviation for pH and soluble solid content from the cold brew and the influence of the cryoprotectants used. No statistical differences were found for pH.

Antimicrobial Activity of Coffee

Cold extraction is a favorable environment for microbiological growth due to the long-brewing time and low temperature used. Additionally, this microbial proliferation is also favored by the low acidity of these beverages, and consequently, pathogens or other deteriorating organisms can develop in them (Kwok et al., 2020). Hence, the antimicrobial activity of cold brew and the freeze-dried coffee solution was measured. Amoxicillin (1 mg/mL) was used as a positive control for S. aureus, P. mirabilis, E. coli, and S. typhi, while amphotericin B (10 μL/mL) was used for C. albicans. None of the coffee extraction samples showed antimicrobial activity.

Caffeine Content, Antioxidant Activity, and Total Phenolic Content

The amount of caffeine obtained by extraction in the coffee drink can be related to several factors such as coffee variety, roasting point, the particle size of the ground bean, coffee/water ratio, method of preparation, water temperature, and time of preparation of the drink (Farah & Donangelo, 2006). The extracts of coffee samples (cold brew and freeze-dried coffee solution) obtained (Table 2) showed no significant difference (p > 0.05) in caffeine content (mg/mL).

Water Activity, Moisture, Solubility, and Wettability of Soluble Coffee

The results from the analysis of water activity, moisture, solubility, and wettability from freeze-dried coffee samples are shown in Table 3. Humidity or moisture content is defined as the total water content, representing the total amount of water contained in the food (total water). This water influences the physical properties of the substance, namely weight, density, viscosity, and conductivity, among others. It is usually determined by weight loss during drying.

Freeze-Dried Coffee Particle Morphology

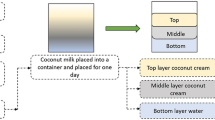

The samples of the analyzed soluble coffees (Fig. 1) have small microstructures to be visible under standard microscopy, so the scanning electron microscope (SEM) was used to examine these samples. Figure 2 demonstrates the amplification of the freeze-dried coffees obtained with the external morphology of the coffees. Most of the particles analyzed had different shapes, which can result from the presence of cryoprotectants. Through the morphological analysis of the particles by SEM, it is possible to see that the addition of the cryoprotectant influenced the structure of freeze-dried coffee, and for each cryoprotectant, the design observed was different.

Another observation noticed is that the soluble coffee exhibited high proportion of smooth surface with some fissures, indicated by destabilization of the coffee during the freezing step.

Discussion

pH and Soluble Solid Content of Cold Brew

Usually, pH alterations work as an indicator of changes in the coffee fruits, such as the undesirable fermentation process that occurs in the pre- and post-harvest period. These alterations result in defective products, in addition to influencing the perceived acidity and overall organoleptic properties, making the pH an essential parameter of analysis in relation to sensory attributes. According to literature, the ideal pH for marketable coffees should be between 4.95 and 5.30, making the coffee’s sensory characteristics more acceptable, palatable to the consumer, without excess bitterness or acidity (Fernandes et al., 2003; Siqueira & Abreu, 2006). Regarding the results in the present study, the EF and EM samples’ pH values were 5.56 ± 0.03 and 5.60 ± 0.02, respectively, which were not distant from the one observed for the EW samples (5.61 ± 0.00), indicating a negligible impact of the cryoprotectants. None of the coffee extracts showed the value within the standards of coffee drinks recommended by Fernandes and co-workers (Fernandes et al., 2003). The difference obtained may be related to the climatological characteristics, the location of the region, and the type of processing to which they were submitted. Rao and Fuller found that cold extraction results in higher pH values compared to those obtained in coffees by hot extraction, resulting in lower total acidity in cold extraction processes (Rao & Fuller, 2018). Cordoba and co-workers (Cordoba et al., 2019) found similar results in their study. The higher pH values can be justified by the degree of coffee roasting. The pH value is proportional to the roasting intensity as there is the degradation of the acids present in green coffee and the degradation of those formed at the beginning of the roasting process (Siqueira & Abreu, 2006; Moura et al., 2013). Furthermore, the sensory profiles of coffee consumption have a positive correlation with soluble solids and the formation of texture; the concentration of caffeine is related to bitterness and astringency (Gloess et al., 2013).

The soluble solids correspond to the mass of ground coffee that is dissolved in the coffee brewing stage. Concerning this analysis, it is desirable for coffee to have a high value of soluble solid content, not only for industrial performance, but also for its contribution to guarantee the quality of the drink. This may suggest that the addition of other substances in roasted coffee can indicate fraud or adulteration in coffee (Pinto et al., 2002). Soluble solids also contribute to the construction of the foam of coffee (proteins, polysaccharides, and melanoidins) (Illy & Viani, 2004). The analysis of soluble solids present in the cold brew extracts was performed in the present study to identify whether cryoprotectants would influence their amount and which of the extracts would have the highest content in these solids. So, the EW sample showed the lowest content of soluble solids (11.33 ± 0.11 °Brix), and consequently a worse coffee texture. On the other hand, the soluble solids represent the content of sugars, glucose, fructose, and sucrose present in the sample, which justifies that fructose (EF) extract had a higher range of soluble solids (14.40 ± 0.10 °Brix).

It was possible to observe that the incorporated cryoprotectants influenced the soluble solid content and influenced the Maillard reaction. The use of cryoprotectants contributed not only to increase the yield of the coffee freeze-drying process, but their addition also increased the quality of the product by increasing the soluble solid content. However, this difference is not that significant compared to the extract without cryoprotectant, so that it is financially unfeasible to use the cryoprotectant.

Regarding the values found for soluble solid content, these are low values when compared to the literature, which presents soluble solid values for Arabica coffee ranging from 24 to 27 °Brix (Moura et al., 2013). This difference may be related to the difference between hot and cold extraction methods since this variation (24–27 °Brix) is for the hot extraction process. Furthermore, the degree of roasting may also have contributed to the low results of this study, because the coffee used was commercial roasting grade and the more the coffee is roasted, the greater is the loss of sugars, due to caramelization.

Antimicrobial Activity of Coffee

Although no coffee extraction samples showed antimicrobial activity, it is known that phenolic compounds, like caffeic acid, an ordinary phenolic compound found in coffee beans, have a large antimicrobial activity against bacteria, viruses, and fungi (Khan et al., 2021). This class of compounds alters the rigidity of the cell wall, which results in the loss of cell integrity. On the other hand, these compounds can disrupt the permeability of the cell membrane in microorganisms by altering various intracellular functions through hydrogen bonding to enzymes. This process can induce irreversible damage to the cell leading to the cessation of its activities, and consequently to cell death (Cushnie & Lamb, 2011). There are few microbiology studies with coffee or its compounds alone. It has been established that high-pressure-assisted extraction enhances the extraction rate of bioactive compounds from coffee beans, such as chlorogenic acid and caffeine (Lin et al., 2022). Sorgi and co-workers studied the antimicrobial effect of caffeic acid stock solution on Streptococcus mutans and obtained an IC50 = 2.938 ± 0.1225 mM, thus revealing antimicrobial activity against S. mutans (Sorgi et al., 2021). Rauha and co-workers (Rauha et al., 2000) also studied the antifungal and antibacterial effects of caffeic acid from Finnish plant extracts. The study showed no antibacterial or antifungal activity for this compound. On the other hand, Khochapong and co-workers’ study showed that coffee pulp extract in concentrations of 150 and 200 mg/mL has an inhibitory effect against E. coli and S. aureus, respectively. These inconsistent results may be due to the different conditions used in the extract preparation method as well as the different origins of Coffea arabica used (Khochapong et al., 2021). Daglia and co-workers (Daglia et al., 1994) investigated the relationship between the inhibitory effect of coffee extract (antimicrobial activity) and some chemical indicators of the degree of roasting. Thus, according to this study, it was possible to confirm that there is an influence of the degree of roasting on the inhibitory effect. And that can justify the absence of antimicrobial activity in the present study. Almeida and co-workers (Almeida et al., 2006) evaluated the antibacterial activity of coffee extracts by the disk diffusion method on E. coli and P. mirabilis, verifying positive antibacterial activity. This difference may be related to the hot extraction method that was used and the coffee/water ratio, which was 20%.

As the coffee extract, the freeze-dried coffee did not show antimicrobial activity for any bacteria and yeast analyzed. Even though there was a halo of inhibition of C. albicans for freeze-dried coffees, the halo of inhibition was smaller than that defined by the legislation to affirm that the analyzed coffee showed antimicrobial activity.

Caffeine Content, Antioxidant Activity, and Total Phenolic Content

In cold brew coffee samples, the caffeine values were slightly higher than in the freeze-dried coffee solution. Cold brew without cryoprotectants (EW) showed the highest caffeine content (4.05 ± 0.03 mg/mL). The soluble coffee without cryoprotectants (LW) showed 3.70 ± 0.04 mg/mL of caffeine content. The present study found higher results than the extracts obtained by Angeloni and co-workers (Angeloni et al., 2019), which found 1.25 mg/mL of caffeine for extraction with a 10% coffee/water ratio and 6 h of extraction at a temperature of 22 °C. And similar results were reported by Fuller and Rao (2017), who found values of approximately 1.2 mg/mL for extraction of 5 h at a temperature of 24 °C.

A loss of approximately 10% in caffeine content was observed after the drying process. Also, the caffeine levels obtained were similar (p > 0.05) for whole freeze-dried coffee, indicating that the addition of cryoprotectants does not affect caffeine levels after the freeze-drying process. Data reported in the literature show that caffeine levels vary according to the species of raw material and that for soluble coffee, the extraction process promotes the enrichment of solids, with a consequent decrease in caffeine content, which confirms our results (Olechno et al., 2021).

The contents of antioxidants as caffeine and chlorogenic acid are essential factors for the healthiness of coffee. The antioxidant content contributes to the bitterness of coffee (Esquivel & Jiménez, 2012; Gloess et al., 2013). Considering the capacity of the coffee samples to perform the oxidation-reduction reaction, analyzing freeze-dried samples through the DPPH stable radical method (Table 2), there was no significant difference (p > 0.05) between samples. However, before drying there were statically significant differences (p < 0.05) between EF—cold brew with fructose sample (58.51 ± 4.05%)—and EW—cold brew without cryoprotectant sample (88.12 ± 2.10%). These values for antioxidant capacity are higher than the results obtained for the samples after freeze-drying (LW—soluble coffee without cryoprotectants 52.23 ± 1.83%; LF—soluble coffee with fructose 52.17 ± 4.12%; LM—soluble coffee with mannitol 49.94 ± 3.72%).

It was observed that in the samples of freeze-dried coffee, the amount of antioxidant capacity decreased in relation to the extract, as a function of the drying process. These results are explained because, during drying processes, there is a loss of bioactive compounds with antioxidant capacity. Indeed, several techniques have been developed to promote real-time quantification throughout the roasting process, such as near-infrared spectroscopy (Catelani et al., 2017). Others have been described as promising pre-treatment methodologies to improve the extraction of antioxidant compounds, such as pulsed electric field (Bilge et al., 2022). A plausible reason for the decrease of antioxidant capacity is the sensitivity of antioxidant compounds to thermal cycles and therefore the reduction in free radical inhibitory activity. Similar effects on the antioxidant activity of coffee have the type of roasting. Usually, low roast grades have the highest antioxidant activity and higher roast grades have the lowest antioxidant activity (Duarte et al., 2005).

According to a study performed by Pinelo and co-workers (Pinelo et al., 2004), who evaluated the interaction between phenols and antioxidant capacity, the variations in the ability to sequestering free radicals can be related to the disposition of polyphenolic compounds subject to polymerization reactions, which results in the formation of oligomers with a larger area for cargo displacement. Thus, when the degree of polymerization exceeds the critical value, there is increased molecular complexity, reducing the availability of hydroxyl groups in the reaction with the stable radical DPPH. That results in a decreased inhibitory capacity of radicals. However, regarding the antioxidant capacity of the cold brew, the samples analyzed, in general, have a high percentage of inhibition. Also, the high rate of inhibition of the coffee samples of cold brew without cryoprotectants (88.12 ± 2.10%) was approximately 8% superior to those values found by Wolska and co-workers (Wolska et al., 2017). Their study evaluated free radicals by the method of DPPH, using a hot extraction by infusion of Coffea arabica, and it was found to have an inhibition of free radicals of approximately 80%.

According to another study that evaluated six brands of commercially roasted coffee, using a cold extraction with a 10% coffee/water ratio, the lowest inhibition of free radical values found were 55% and 60% in the cold brew. Furthermore, in that study, the authors observed the influence of pH and coffee/water ratio on the antioxidant activity (Kamiyama et al., 2015).

Results found in this study were close to those reported by Vignoli and co-workers (Vignoli et al., 2012) for soluble coffee, which obtained values of 48.90% for analysis of antioxidant capacity by DPPH. In addition to the drying process, these low values found for the antioxidant capacity of freeze-dried coffee with fructose may also be related to the fact that fructose is a reducing sugar, which contributed to the oxidation of coffee. In addition to being known for the presence of caffeine and its antioxidant properties, coffee also contains other important phenolic compounds like ferulic acid, caffeic acid, catechins, and anthocyanins, and biologically active compounds like nicotinic acid, trigonelline, quinolinic acid, tannic acid, and pyrogallic acid (Esquivel & Jiménez, 2012; Kyroglou et al., 2021).

The values found for the content of total phenolic compounds in the coffee extracts demonstrated no significant difference, with a value averaged at 7.74 ± 0.72 (mg GA/mL of extract). This method allows quantifying the content of total phenolic compounds acting as a fundamental indicator about the antioxidant capacity. However, the reducing capacity of the Folin-Ciocalteu reagent is related to different electron donor substances, being sensitive not only to the phenolic compounds but also to the presence of proteins, ascorbic acid, and other reducing compounds (Brighente et al., 2007; Falé et al., 2009). According to Panusa and co-workers (Panusa et al., 2013) and Ramalakshmi and co-workers (Ramalakshmi et al., 2009), who evaluated the extraction process of phenolic compounds in coffee, the temperature and extraction method directly influenced such compounds. The part of the plant used also plays a crucial role in the content of these compounds. The solvent used has a significant effect on the extraction efficiency. Panusa and co-workers (Panusa et al., 2013) in their work found that the phenolic content increased about 1.5 times when replacing the solvent from water to ethanol. This shows that ethanol can dissolve a wider range of compounds. In addition, the variety of coffee used in the preparation of the extract also influences the amounts of phenolic compounds extracted. This statement may justify the difference in results obtained by Cruz and co-workers (Cruz et al., 2017) for the extraction of roasted coffee dark by the hot infusion method. The authors obtained 1.00 ± 0.02 mg GA/mL of extract, whereas Cordoba and co-workers (Cordoba et al., 2019) obtained 0.56 ± 0.04 mg GA/mL of extract after 14 h of cold extraction with a 10% coffee/water ratio.

The values found for the content of total phenolic compounds after the lyophilization process showed a significant difference (p < 0.05) between the samples, with the LW—soluble coffee without cryoprotectant sample—having the highest range of phenolic compounds (11.74 mg AG/mL of lyophilized extract).

Considering the value of phenolic compounds in the coffee extract and after drying, the efficiency of lyophilization for all samples was significant, demonstrating that the cryoprotectants and the freeze-drying process did not interfere negatively in the retention of total phenolic compounds, suggesting that the phenolic compounds present in the samples are stable.

Furthermore, after coffee drying, there is high preservation of the phenolics, since the Folin-Ciocalteu reagent is reduced to a high extent by the highly reactive polyphenolic compounds present in the samples. Saénz and co-workers (Saénz et al., 2009) also observed a higher content of phenolic compounds in the dry particles when compared to the initial extract. According to Coelho and co-workers (Coelho et al., 2014) and Pérez-Martínez and co-workers (Pérez-Martínez et al., 2010), this increase may result from the increased concentration of conjugated phenolic compounds during sample preparation and after the drying process relative to the original solution, thus increasing the total phenolic compound content. Moreover, some studies report that solvents with high polarities, such as water, can result in extracts with impurities, such as organic acids and reducing sugars, which may influence the determination of phenolic compounds (Schafranski et al., 2019).

Regarding the effect of reducing sugars, such as fructose, on the concentration of phenolic compounds, we could verify a significant influence; hence, these samples have the lowest values both for the antioxidant capacity (58.51 ± 4.05%) and for the content of phenolic compounds (6.55 ± 0.91 mg AG/mL of extract).

We must keep in mind that phenolic compounds have a diversified chemical structure, with multiple mechanisms of action in the prevention of oxidative reaction (Valenzuela & Nieto, 1996).

Water Activity, Moisture, Solubility, and Wettability of Soluble Coffee

The water activity (aw), or free water, represents the water in the free state and is thus available for biochemical and chemical reactions. All these reactions can compromise the stability and quality of food (Picanço et al., 2018; Terra et al., 2007). For instance, this water favors microbial growth and reactions that can alter the food composition and properties. This activity is determined by a water activity meter, whose value ranges from 0 to 1. Water activity is one of the most important properties for the processing, conservation, and storage of foods. It is also worth mentioning that water activity values below 0.3 lead to little or no microbial growth, because there is no development of microorganisms (Celestino, 2010; Damodaran et al., 2018). According to the Brazilian Health Surveillance Agency (ANVISA), RDC nº 277 in effect, the water activity values must be below 0.3 for soluble coffee; however, all analyzed samples of lyophilized soluble coffee had a water activity near 0.3, thus demonstrating a common tendency to deteriorate and develop microorganisms (ANVISA, 2005).

Coffee without cryoprotectant (LW) showed the lowest water activity (0.15 ± 0.01) and a significant difference (p < 0.05) among the samples with cryoprotectant. This may be related directly to the hygroscopic capacity of the cryoprotectants used. Since the monosaccharide fructose is a reducing sugar, it can absorb moisture which may have favored its high value of water activity to LW. Thus, the cryoprotectant influenced the water activity of freeze-dried coffee; however, the results obtained remained within the standards established by Brazilian regulatory authorities.

Another critical parameter to evaluate the conservation of foods is humidity/moisture, a parameter related to the stability of soluble coffee during storage. The freeze-drying process should result in low residual moisture content because the presence of high residual moisture content can result in the dissolution of the freeze-drying product even after the process following a short storage period (Fonte et al., 2016a, b). Campelo-Felix and co-workers (Campelo-Felix et al., 2017) highlight that knowing the moisture of the powder it is possible to predict its behavior when stored in locations with different values of relative humidity, and thus predict the water absorption and damage to the product.

Since for one good drying process for soluble coffee, the humidity values should not be higher than 5%, only the LF sample showed humidity (11.26 ± 1.12%) higher than 5 g water/100 g dry solid, and therefore does not meet the values recommended by ANVISA (2005).

The LF and LM samples did not present a significant difference in water activity, but regarding humidity, there was a significant difference (p < 0.05). The LM sample had less content (4.78 ± 2.04%) than the LF sample (11.26 ± 1.12%) which is justified since mannitol is not hygroscopic like fructose. This sugar has excellent potential as an ingredient in formulations of products that should not have high humidity (Fernandes et al., 2013).

The soluble coffees obtained showed a significant difference (p < 0.05) between all the samples regarding humidity. However, the LW sample was the only sample that fitted with moisture content less than 3%, a technical specification requirement of diverse soluble coffee for consumption in countries; however, the LM sample is within the maximum range stipulated by legislation (less than 5%). The lower humidity rate is related to a longer useful life and better product’s sensory characteristics. Exposing food to conditions of high moisture content and temperatures results in changes in the food and consequently sensory and microbiological changes (Surkan et al., 2009).

The results obtained with wettability and solubility contributed to verify the good dissolving capacity of lyophilized coffee. The solubility analyzed in all freeze-dried coffees showed a significant difference between the samples (p < 0.05), where the sample that presented the best result was LW (86.03 ± 1.28%). Regarding the samples LF and LM, both showed low solubility (55.03 ± 3.09% and 61.40 ± 3.86% respectively). This is justified by the structure of mannitol, which is a polyol and presents low solubility. Regarding fructose, the low solubility may be related to the fact that the sample shows a collapsed structure after lyophilization (Figs. 1 and 2).

Solubility is associated with the powder’s ability to maintain a homogeneous mixture with water, generating a stable combination, that is, its ability to reconstitute itself in water. Campelo-Felix and co-workers (Campelo-Felix et al., 2017) point out that solubility is one of the critical points considered by the industry and consumers as a factor of product quality. Soluble coffees are expected to have quick and homogeneous resuspension without supernatant particles or sediment.

Although Campelo-Felix and co-workers (Campelo-Felix et al., 2017) and Bhandari and co-workers (Bhandari et al., 1992) indicate that optimal solubility values for powdered foods are in the range of 92–99%, the solubility of the coffees produced in this study was a little lower, indicating just a reasonable solubility. According to Fernandes and co-workers (Fernandes et al., 2013) and Pereira de Oliveira and co-workers (Pereira de Oliveira et al., 2022), solubility is a decisive factor for the quality of powdered products, in line with what Caparino and co-workers (Caparino et al., 2012) reported, indicating that solubility is considered the most reliable criterion for evaluating the behavior of a powder in an aqueous solution.

The wettability analysis relates the time needed to wet, sink, disperse, and solubilize soluble products. For a powder to be considered instantaneous, its wetting time must be less than 60 s (Nakilcioğlu-Taş & Ötleş, 2019).

The results found for LM and LW (1.48 ± 0.57 and 1.25 ± 0.10 min, respectively) were a median reconstitution time. However, they are not good values since there are studies that consider optimal wettability values for powder products with results between 10 and 60 s (Bhandari et al., 1992; Campelo-Felix et al., 2017). In turn, LF shows the worst result, with 3.50 ± 0.08 min for wettability. The reason related to the high wetting time of the LF sample may be related to the cryoprotectant used in this sample, which ended up impairing the water penetration, in addition to the collapsed sample. So, this issue may have contributed to the formation of a barrier and thus have influenced the low wettability due to high surface tension.

Freeze-Dried Coffee Particle Morphology

All the freeze-drying conditions were performed the same way for all the treatments. Regarding the results, it is possible to observe that the samples LW and LM presented a good morphology for soluble coffees. The morphology of the LM sample resembles structures in the form of ice crystals which may have resulted from the interaction of mannitol with compounds in the extract, since it is part of the polyol group and has a compact structure, contributing to the formation of crystals in the system (Rapaille et al., 2003).

It is possible to observe particles with different morphologies, pointed surfaces, and irregular sizes. For example, in the fructose sample, there was a compact structure with defined contorts. While LW presents a porous structure, it does not have a defined atomic structure, corroborated by Bhandari and Hartel (2005), who state that soluble coffee has a porous structure.

The absence of cracks on the surface of the particles produced with fructose (LF) was found, which ensures greater protection of the compounds, and thus an improvement in their stability. However, as shown in the previous analysis, due to their more condensed and compacted structure, these crystals present low solubility since their system prevents diffusion of water during the solubilization process.

Thus, the LW sample presented the highest porosity and rough surface justified by the increased solubility of the model, which confirms that the porosity influences the solubility of dry food (Terroni et al., 2013). These arrangements in the crystalline structure of soluble coffee resulted from the freeze-drying process, in which both the surface morphology and molecular order undergo changes (Levin et al., 2021; Zhang et al., 2014).

In addition, Raman (2015) observed equivalent results, annealing the effects of freezing conditions on 10% coffee samples. In this study, they used microscopy during freeze-drying to evaluate how process parameters help optimize crystal structure. Thus, drying speeds were found to have a high influence on crystal microstructure. The annealing step also influenced the sizes of the ice crystals and had a beneficial effect on the freeze-drying rate of coffee.

Conclusions

Coffee is a complex natural matrix with a wide range of bioactive compounds. In this work, we explored the impact of cryoprotectants in the freeze-drying process of Arabica coffee cold brew, aiming to obtain soluble coffee with desirable properties. The antioxidant properties and phenolic compound concentrations were higher in the Arabica coffee freeze-dried in the absence of cryoprotectants, whereas the evaluated cryoprotectants (fructose and mannitol) increased the content of soluble solids. The caffeine concentration differences between the developed preparations were not significant.

Using fructose as cryoprotectant led to a coffee preparation that does not fulfill the standard requirements, since it presents moisture values above 5%. Freeze-dried soluble coffee prepared in the absence of cryoprotectants displayed better solubility, highest porosity, lowest moisture, and water activity. No significant differences were attained between the two cryoprotectants evaluated.

In summary, the application of fructose or mannitol as cryoprotectants in the preparation of freeze-dried soluble coffee did not present a practical advantage, while freeze-drying Arabica coffee in the absence of cryoprotectant led to a product with desirable features.

Data Availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

(AOAC) AoOAC (1998) Official methods of analysis. 15th edition edn. Association of Official Analytical Chemists, Washington DC, USA.

(AOAC) AoOAC (2006) Official methods of analysis. 18th edition edn. Association of Official Analytical Chemists, Washington DC, USA.

Almeida, A. A. P., Farah, A., Silva, D. A. M., Nunan, E. A., & Glória, M. B. A. (2006). Antibacterial activity of coffee extracts and selected coffee chemical compounds against enterobacteria. Journal of Agricultural and Food Chemistry, 54(23), 8738–8743.

Almeida, F. S., Dias, F. F. G., Sato, A. C. K., & De Moura, B. J. M. L. N. (2022). Scaling up the two-stage countercurrent extraction of oil and protein from green coffee beans: Impact of proteolysis on extractability, protein functionality, and oil recovery. Food and Bioprocess Technology, 15(8), 1794–1809.

Angeloni, G., Guerrini, L., Masella, P., Bellumori, M., Daluiso, S., Parenti, A., & Innocenti, M. (2019). What kind of coffee do you drink? An investigation on effects of eight different extraction methods. Food Research International, 116, 1327–1335.

ANVISA. (2005). Resolução - RDC No 277, de 22 de Setembro de 2005 - "Regulamento técnico para café, cevada, chá, erva-mate e produtos solúveis". In: Brasil MdS- (ed) Resolução - RDC No 277, vol RDC No 277. Ministério da Saúde - Brasil, Brazil. Available in https://bvsms.saude.gov.br/bvs/saudelegis/anvisa/2005/res0277_22_09_2005.html. Accessed 2 Apr 2024.

Ballesteros, L. F., Teixeira, J. A., & Mussatto, S. I. (2014). Selection of the solvent and extraction conditions for maximum recovery of antioxidant phenolic compounds from coffee silverskin. Food and Bioprocess Technology, 7(5), 1322–1332.

Barroso, L. A., Macedo, A. S., Lemos, I. L., de Andrade, N. N., Schmiele, M., da Silveira, J. V. W., Amaral, T. N., & Fonte, P. (2022). Optimization of the brewing parameters on coffee extraction using a central composite rotatable design. JSFA Reports, 2(3), 107–115.

Bhandari, B. R., & Hartel, R. W. (2005). Phase transitions during food powder production and powder stability. In C. Onwulata (Ed.), Encapsulated and powdered foods (pp. 263–293). CRC Press, Boca Raton, USA.

Bhandari, B. R., Dumoulin, E. D., Richard, H. M. J., Noleau, I., & Lebert, A. M. (1992). Flavor encapsulation by spray drying: Application to citral and linalyl acetate. Journal of Food Science, 57(1), 217–221.

Bilge, G., Yurdakul, M., Buzrul, S., & Bulut, O. (2022). Evaluation of the effect of pulsed electric field on coffee Arabica beans. Food and Bioprocess Technology, 15(5), 1073–1081.

Brighente, I. M. C., Dias, M., Verdi, L. G., & Pizzolatti, M. G. (2007). Antioxidant activity and total phenolic content of some Brazilian species. Pharmaceutical Biology, 45(2), 156–161.

Campelo-Felix, P. H., Souza, H. J. B., Figueiredo, Jd. A., Fernandes, RVd. B., Botrel, D. A., de Oliveira, C. R., Yoshida, M. I., & Borges, S. V. (2017). Prebiotic carbohydrates: Effect on reconstitution, storage, release, and antioxidant properties of lime essential oil microparticles. Journal of Agricultural and Food Chemistry, 65(2), 445–453.

Cano-Chauca, M., Stringheta, P. C., Ramos, A. M., & Cal-Vidal, J. (2005). Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innovative Food Science & Emerging Technologies, 6(4), 420–428.

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’ var.) powder. Journal of Food Engineering, 111(1), 135–148.

Castro, P. M., Fonte, P., Oliveira, A., Madureira, A. R., Sarmento, B., & Pintado, M. E. (2017). Optimization of two biopolymer-based oral films for the delivery of bioactive molecules. Materials Science and Engineering: C, 76, 171–180.

Catelani, T. A., Páscoa, R. N. M. J., Santos, J. R., Pezza, L., Pezza, H. R., Lima, J. L. F. C., & Lopes, J. A. (2017). A non-invasive real-time methodology for the quantification of antioxidant properties in coffee during the roasting process based on near-infrared spectroscopy. Food and Bioprocess Technology, 10(4), 630–638.

Celestino, S. M. C. (2010). Princípios de Secagem de Alimentos, 51. Embrapa Cerrados, Planaltina, DF, Brazil (ISSN 1517-5111).

Coelho, C., Ribeiro, M., Cruz, A. C. S., Domingues, M. R. M., Coimbra, M. A., Bunzel, M., & Nunes, F. M. (2014). Nature of phenolic compounds in coffee melanoidins. Journal of Agricultural and Food Chemistry, 62(31), 7843–7853.

Cordoba, N., Pataquiva, L., Osorio, C., Moreno, F. L. M., & Ruiz, R. Y. (2019). Effect of grinding, extraction time and type of coffee on the physicochemical and flavour characteristics of cold brew coffee. Scientific Reports, 9(1).

Cruz, R. G. D., Vieira, T. M. F. D. S., & Lira, S. P. D. (2017). Potential antioxidant of Brazilian coffee from the region of Cerrado. Food Science and Technology, 38(3), 447–453.

Cushnie, T. P. T., & Lamb, A. J. (2011). Recent advances in understanding the antibacterial properties of flavonoids. International Journal of Antimicrobial Agents, 38(2), 99–107.

Daglia, M., Cuzzoni, M. T., & Dacarro, C. (1994). Antibacterial activity of coffee: Relationship between biological activity and chemical markers. Journal of Agricultural and Food Chemistry, 42(10), 2273–2277.

Damodaran, S., Parkin, K. L., & Fennema, O. R. (2018). Química de Alimentos de Fennema (5th ed.). Brazil, Porto Alegre: Artmed.

Day, J. G., & Stacey, G. N. (2007). Cryopreservation and freeze-drying protocols. Methods in Molecular Biology, 368. USA, Totowa, NJ: Humana Press. (ISSN 1064-3745).

Deotale, S. M., Dutta, S., Moses, J. A., & Anandharamakrishnan, C. (2020). Stability of instant coffee foam by nanobubbles using spray-freeze drying technique. Food and Bioprocess Technology, 13(11), 1866–1877.

Duarte, S. M. D. S., Abreu, C. M. P. D., Menezes, H. C. D., Santos, M. H. D., & Gouvêa, C. M. C. P. (2005). Effect of processing and roasting on the antioxidant activity of coffee brews. Ciência e Tecnologia De Alimentos, 25(2), 387–393.

Epole, N., Andrade, J. M., Garcia, C., Reis, C., Teodósio, C., Oliveira, C., Oliveira, C., Roberto, A., & Rijo, P. (2017). Biological Activity Screening of Seven Plectranthus Species Journal Biomedical and Biopharmaceutical Research, 14, 95–108.

Esquivel, P., & Jiménez, V. M. (2012). Functional properties of coffee and coffee by-products. Food Research International, 46(2), 488–495.

Falé, P. L., Borges, C., Madeira, P. J. A., Ascensão, L., Araújo, M. E. M., Florêncio, M. H., & Serralheiro, M. L. M. (2009). Rosmarinic acid, scutellarein 4′-methyl ether 7-O-glucuronide and (16S)-coleon E are the main compounds responsible for the antiacetylcholinesterase and antioxidant activity in herbal tea of Plectranthus barbatus (“falso boldo”). Food Chemistry, 114(3), 798–805.

Farah, A., & Donangelo, C. M. (2006). Phenolic compounds in coffee. Brazilian Journal of Plant Physiology, 18(1), 23–36.

Fernandes, S. M., Pereira, R. G. F. A., Pinto, N. A. V. D., Nery, M. C., & Pádua, F. R. M. D. (2003). Constituintes químicos e teor de extrato aquoso de cafés arábica (Coffea arabica l.) e conilon (Coffea canephora Pierre) torrados. Ciência e Agrotecnologia, 27(5), 1076–1081.

Fernandes, R. V. D. B., Borges, S. V., & Botrel, D. A. (2013). Influence of spray drying operating conditions on microencapsulated rosemary essential oil properties. Food and Science Technology, 33, 171–178.

Fonte, P., Andrade, F., Azevedo, C., Pinto, J., Seabra, V., Van De Weert, M., Reis, S., & Sarmento, B. (2016a). Effect of the freezing step in the stability and bioactivity of protein-loaded PLGA nanoparticles upon lyophilization. Pharmaceutical Research, 33(11), 2777–2793.

Fonte, P., Reis, S., & Sarmento, B. (2016b). Facts and evidences on the lyophilization of polymeric nanoparticles for drug delivery. Journal of Controlled Release, 225, 75–86.

Fuller, M., & Rao, N. Z. (2017). The effect of time, roasting temperature, and grind size on caffeine and chlorogenic acid concentrations in cold brew coffee. Scientific Reports, 7(1).

Gloess, A. N., Schönbächler, B., Klopprogge, B., & D`Ambrosio L, Chatelain K, Bongartz A, Strittmatter A, Rast M & Yeretzian C,. (2013). Comparison of nine common coffee extraction methods: Instrumental and sensory analysis. European Food Research and Technology, 236(4), 607–627.

Illy, A., & Viani, R. (2004). Espresso coffee - The science of quality. Academic Press.

Jeon, J.-S., Kim, H.-T., Jeong, I.-H., Hong, S.-R., Oh, M.-S., Park, K.-H., Shim, J.-H., & Abd El-Aty, A. M. (2017). Determination of chlorogenic acids and caffeine in homemade brewed coffee prepared under various conditions. Journal of Chromatography B, 1064, 115–123.

Júlio, A., Caparica, R., Costa Lima, S. A., Fernandes, A. S., Rosado, C., Prazeres, D. M. F., Reis, S., Santos De Almeida, T., & Fonte, P. (2019). Ionic liquid-polymer nanoparticle hybrid systems as new tools to deliver poorly soluble drugs. Nanomaterials, 9(8), 1148.

Kamiyama, M., Moon, J.-K., Jang, H. W., & Shibamoto, T. (2015). Role of degradation products of chlorogenic acid in the antioxidant activity of roasted coffee. Journal of Agricultural and Food Chemistry, 63(7), 1996–2005.

Khan, F., Bamunuarachchi, N. I., Tabassum, N., & Kim, Y.-M. (2021). Caffeic acid and its derivatives: Antimicrobial drugs toward microbial pathogens. Journal of Agricultural and Food Chemistry, 69(10), 2979–3004.

Khochapong, W., Ketnawa, S., Ogawa, Y., & Punbusayakul, N. (2021). Effect of in vitro digestion on bioactive compounds, antioxidant and antimicrobial activities of coffee (Coffea arabica L.) pulp aqueous extract. Food Chemistry, 348, 129094.

Kwok, R., Lee Wee Ting, K., Schwarz, S., Claassen, L., & Lachenmeier, D. W. (2020). Current challenges of cold brew coffee—Roasting, extraction, flavor profile, contamination, and food safety. Challenges, 11(2), 26.

Kyroglou, S., Thanasouli, K., & Vareltzis, P. (2021). Process characterization and optimization of cold brew coffee: Effect of pressure, temperature, time and solvent volume on yield, caffeine and phenol content. Journal of the Science of Food and Agriculture, 101(11), 4789–4798.

Levin, P., Meunier, V., Kessler, U., & Heinrich, S. (2021). Influence of freezing parameters on the formation of internal porous structure and its impact on freeze-drying kinetics. Processes, 9(8), 1273.

Lin, Y.-H., Huang, H.-W., & Wang, C.-Y. (2022). Effects of high pressure-assisted extraction on yield, antioxidant, antimicrobial, and anti-diabetic properties of chlorogenic acid and caffeine extracted from green coffee beans. Food and Bioprocess Technology, 15(7), 1529–1538.

Moura, S. C. S. R., Germer, S. P. M., Anjos, V. D. A., Mori, E. E. M., Mattoso, L. H. C., Firmino, A., & Nascimento, C. J. F. (2013). Influência dos parâmetros de torração nas características físicas, químicas e sensoriais do Café Arábia puro. Brazilian Journal of Food Technology, 10, 17–25.

Mussatto, S. I., Machado, E. M. S., Martins, S., & Teixeira, J. A. (2011). Production, composition, and application of coffee and its industrial residues. Food and Bioprocess Technology, 4(5), 661–672.

Nakilcioğlu-Taş, E., & Ötleş, S. (2019). Physical characterization of Arabica ground coffee with different roasting degrees. Anais da Academia Brasileira de Ciências, 91(2).

Olechno, E., Puścion-Jakubik, A., Zujko, M. E., & Socha, K. (2021). Influence of various factors on caffeine content in coffee brews. Foods, 10(6), 1208.

Panusa, A., Zuorro, A., Lavecchia, R., Marrosu, G., & Petrucci, R. (2013). Recovery of natural antioxidants from spent coffee grounds. Journal of Agricultural and Food Chemistry, 61(17), 4162–4168.

Pereira de Oliveira, J., Almeida, O. P., Campelo, P. H., Carneiro, G., & de Oliveira Ferreira Rocha L, Santos JHPM & Gomes da Costa JM. (2022). Tailoring the physicochemical properties of freeze-dried buriti oil microparticles by combining inulin and gum Arabic as encapsulation agents. LWT, 161,

Pérez-Martínez, M., Caemmerer, B., De Peña, M. P., Cid, C., & Kroh, L. W. (2010). Influence of brewing method and acidity regulators on the antioxidant capacity of coffee brews. Journal of Agricultural and Food Chemistry, 58(5), 2958–2965.

Picanço, Y., Oliveira, S., Almeida, M., Otani, F., Pereira, E., & Santos, G. (2018). Análise de atividade de água e umidade na qualidade do mel produzido em comunidades da reserva extrativista Tapajós-Arapiuns, Santarem, Pará. Revista Agroecossistemas., 10, 1.

Pinelo, M., Manzocco, L., Nuñez, M. J., & Nicoli, M. C. (2004). Interaction among phenols in food fortification: Negative synergism on antioxidant capacity. Journal of Agricultural and Food Chemistry, 52(5), 1177–1180.

Pinto, N., Fernandes, S., Giranda, R., Pereira, R., & Carvalho, V. (2002). Avaliação de componentes químicos de padrões de bebida para preparo do café expresso. Ciência e Agrotecnologia, 26, 826–829.

Ramalakshmi, K., Rao, L. J. M., Takano-Ishikawa, Y., & Goto, M. (2009). Bioactivities of low-grade green coffee and spent coffee in different in vitro model systems. Food Chemistry, 115(1), 79–85.

Raman, P. (2015). Freeze drying microscopy as a tool to study sublimation kinetics. Loughborough University.

Rao, N. Z., & Fuller, M. (2018). Acidity and antioxidant activity of cold brew coffee. Scientific Reports, 8(1).

Rapaille, A., Goosens, J., & Heume, M. (2003) Sugar alcohols. In: Caballero B (ed) Encyclopedia of food sciences and nutrition (second edition). 5665–5671. Academic Press, Oxford.

Rauha, J.-P., Remes, S., Heinonen, M., Hopia, A., Kähkönen, M., Kujala, T., Pihlaja, K., Vuorela, H., & Vuorela, P. (2000). Antimicrobial effects of Finnish plant extracts containing flavonoids and other phenolic compounds. International Journal of Food Microbiology, 56(1), 3–12.

Ribeiro, P. C., Costa, A. C. F. M., Kiminami, R. H. G. A., Sasaki, J. M., Lira, H. L., Da Costa, A. C. F. M., Kiminami, R. H. G. A., Sasaki, J. M., & Lira, H. L. (2010). Caracterização estrutural e morfológica de nanocristais de TiO2 pelo método pechini. Revista Eletrônica De Materiais e Processos, 3, 58–64.

Rubinsky, B. (2003). Principles of low temperature cell preservation. Heart Failure Reviews, 8(3), 277–284.

Saénz, C., Tapia, S., Chávez, J., & Robert, P. (2009). Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chemistry, 114(2), 616–622.

Schafranski, K., Postigo, M., Vitali, L., Micke, G., Richter, W., & Chaves, E. (2019). Avaliação de compostos bioativos e atividade oxidante de extratos de folhas de amoreira preta (Morus nigra L.) utilizando planejamento experimental. Química Nova, 42, 736–744.

Shofinita, D., Lestari, D., Aliwarga, L., Sumampouw, G. A., Ambarwati, S. A., Gunawan, K. C., & Achmadi, A. B. (2024). Drying methods of coffee extracts and their effects on physicochemical properties: A review. Food and Bioprocess Technology, 17, 47–72.

Silva, A. C. C., & Schmidt, F. C. (2019). Vacuum freezing of coffee extract under different process conditions. Food and Bioprocess Technology, 12(10), 1683–1695.

Singleton, V. L., Rossi, J. A., & J,. (1965). Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. American Journal of Enology and Viticulture, 16(3), 144–158.

Siqueira HHD & Abreu CMPD. (2006). Composição físico-química e qualidade do café submetido a dois tipos de torração e com diferentes formas de processamento. Ciência e Agrotecnologia, 30(1), 112–117.

Sorgi, C. A., Lamarque, D. C. C., & G, Verri MP, Nelson-Filho P, Faccioli LH & Paula-Silva FWG. (2021). Multifaceted effect of caffeic acid against Streptococcus mutans infection: Microbicidal and immunomodulatory agent in macrophages. Archives of Microbiology, 203(6), 2979–2987.

Surkan, S., Albani, O., & Ramallo, L. (2009). Influence of storage conditions on sensory shelf life of yerba mate. Journal of Food Quality, 32(1), 58–72.

Terra, N. N., Freitas, R. JSd., & Cichoski, A. J. (2007). Water activity, pH, moisture and growth of Staphylococcus xylosus during processing and storage of cured, matured and fermented pork shoulder. Food Science and Technology, 27, 756–760.

Terroni, H. C., Jesus, J. D., Artuzo, L. T., Ventura, L. V., Santos, R. F., & Damy-Benedetti, P. D. C. (2013). Liofilização. Revista Científica UNILAGO, 1(1), 271–284.

Valenzuela, A., & Nieto, S. (1996). Synthetic and natural antioxidants: Food quality protectors. Grasas y Aceites, 47(3), 186–196.

Vignoli, J. A., Bassoli, D. G., & Benassi, Md. T. (2012). Atividade Antioxidante de Cafés Torrado e Solúvel: Padronização e Validação de Métodos. Coffee Science, 7, 68–75.

Wolska, J., Janda, K., Jakubczyk, K., Szymkowiak, M., Chlubek, D., & Gutowska, I. (2017). Levels of antioxidant activity and fluoride content in coffee infusions of Arabica, robusta and green coffee beans in according to their brewing methods. Biological Trace Element Research, 179(2), 327–333.

Wu, H., Gu, J., Bk, A., Nawaz, M. A., Barrow, C. J., Dunshea, F. R., & Suleria, H. A. R. (2022). Effect of processing on bioaccessibility and bioavailability of bioactive compounds in coffee beans. Food Bioscience, 46,

Zanin, R. C., Smrke, S., Yeretzian, C., Kurozawa, L. E., & Yamashita, F. (2021). Ultrasound-assisted emulsification of roasted coffee oil in complex coacervates and real-time coffee aroma release by PTR-ToF–MS. Food and Bioprocess Technology, 14(10), 1857–1871.

Zhang, B., Wang, K., Hasjim, J., Li, E., Flanagan, B. M., Gidley, M. J., & Dhital, S. (2014). Freeze-drying changes the structure and digestibility of B-polymorphic starches. Journal of Agricultural and Food Chemistry, 62(7), 1482–1491.

Zhang, C., Jiang, H., Liu, F., & He, Y. (2017). Application of near-infrared hyperspectral imaging with variable selection methods to determine and visualize caffeine content of coffee beans. Food and Bioprocess Technology, 10(1), 213–221.

Funding

Open access funding provided by FCT|FCCN (b-on). This work was financed by Fundação para a Ciência e a Tecnologia (FCT) in the scope of the projects UIDB/04326/2020 (https://doi.org/10.54499/UIDB/04326/2020), UIDP/04326/2020 (https://doi.org/10.54499/UIDP/04326/2020), and LA/P/0101/2020 (https://doi.org/10.54499/LA/P/0101/2020) of the Research Unit Center for Marine Sciences—CCMAR; UIDB/04565/2020 and UIDP/04565/2020 of the Research Unit Institute for Bioengineering and Biosciences—IBB; LA/P/0140/2020 of the Associate Laboratory Institute for Health and Bioeconomy—4HB; and UIDB/04585/2020 (https://doi.org/10.54499/UIDB/04585/2020) of the Research Unit Egas Moniz Center for Interdisciplinary Research (CiiEM). It was also financially supported by FAPEMIG (Research Support Foundation of Minas Gerais State).

Author information

Authors and Affiliations

Contributions

Conceptualization: LAB, ASM, TNA, and PF; methodology: LAB and ILL; validation: MS, JVWS, JMGC, and PB; formal analysis: LAB and ASM; investigation: LAB, ASM, and ILL; resources: PF; data curation: MS and TNA; writing—original draft preparation: LAB and ASM; writing—review and editing: LAB, CV, ASM, and PB; visualization: MS, JVWS, JMGC, TNA, and PF; supervision: TNA and PF; project administration: PF; funding acquisition: TNA and PF. All authors read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Barroso, L.A., Viegas, C., Stančiauskaitė, M. et al. Impact of the Use of Cryoprotectants in the Production of Freeze-Dried Soluble Coffee from Cold Brew Arabica Coffee. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03387-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03387-z