Abstract

This study investigates the potential for bioethanol production of six types of typical German leftover baked products: bread rolls, pretzel rolls, fine rye bread, white bread, pastry, and cream cakes. The experimental setup consisted of two experiments—one as a control and another with the addition of diammonium phosphate (DAP) to the mash. In terms of monosaccharide concentration at 30% dry matter (DM), white bread mash exhibited the highest level at 251.5 g/L, while cream cakes mash had the lowest at 186 g/L. The highest ethanol production occurred after 96 h of fermentation with rye bread, yielding 78.4 g/L. In contrast, despite having the highest monosaccharide levels, white bread produced only 21.5 g/L of ethanol after 96 h. The addition of DAP accelerated monosaccharide consumption in all baked products, with cream cakes completing the process in just 24 h. Bread rolls, pretzel rolls, pastry, and white bread fermentations finished within 72 h. Ethanol yields significantly increased in three DAP samples, with pretzel rolls yielding the highest ethanol concentration at 98.5 g/L, followed by white bread with 90.6 g/L, and bread rolls with 87.7 g/L. DAP had a substantial impact on all samples, reducing fermentation time and/or increasing ethanol yield. This effect was particularly pronounced with white bread, where it improved conversion efficiency from 17 to 72%, resulting in 90.6 g/L of ethanol. These results demonstrate that waste baked products hold substantial potential for bioethanol production, and this potential can be further enhanced through the addition of DAP.

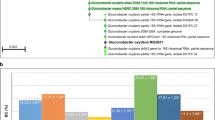

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The rapid depletion of fossil fuels, coupled with the urgent need to reduce the negative environmental impact of burning fossil fuels, has prompted extensive research into sustainable alternatives. One such alternative is employing Saccharomyces cerevisiae, a type of yeast commonly utilized in the production of alcoholic beverages, to produce bioethanol (Lin & Tanaka, 2006). The aim is to create a renewable fuel source that can replace petroleum-derived fossil fuels.

Based on the Alternative Fuel Data Center (RFA, 2022), global ethanol production has experienced a significant increase over time. It is reported that 27 billion gallons were produced globally in 2021. Among them, the USA, as the world’s largest bioethanol producer, contributed 15 billion gallons, marking an almost 90-fold increase since 1980. Notably, from 2000 to 2010, ethanol production underwent a remarkable surge, growing from 1622 million gallons to 13.298 billion gallons (RFA, 2022). Bioethanol is primarily produced from agricultural crops such as corn, wheat, and sugarcane, which are known for their high productivity and ease of processing (Pietrzak & Kawa-Rygielska, 2015). However, the use of these crops as raw materials for fuel production raises concerns about potential impacts on food prices, as they compete with food demands (Pietrzak & Kawa-Rygielska, 2015). The exploration of alternative sources of feedstock, including food waste, has emerged as a popular research area (Han et al., 2019).

Food waste is a significant global concern, as reported by the Food and Agriculture Organization (FAO, 2011). Their research estimates that approximately one-third of edible food produced for human consumption worldwide is either lost or wasted, equivalent to approximately 1.3 billion tonnes per year. To address this challenge, the implementation of smart and efficient waste management strategies is necessary. These strategies play a critical role in promoting a carbon–neutral society and reducing waste generation (FAO, 2011).

According to World Wide Fund For Nature Germany, bakery returns range from 1.5 to 19% (Jaeger, 2018). Present estimates indicate that returns lead to approximately 600,000 tons of baked product losses each year in Germany (Jaeger, 2018). Globally, waste from baked products is estimated to be between 7 and 10% of total production (Kumar et al., 2023). Considering the annual global bread production of around 100 million tons, this waste could potentially amount to 10 million tons per year worldwide (Kumar et al., 2023). Many bakeries therefore try to reuse these returned products. Approaches such as converting leftover baked products into animal feed or using them in biogas plants appear to be effective recycling methods, but they often involve long transportation distances and added expenses. As a result, disposing of the baked products as trash is often a more cost-effective and convenient option than attempting to reuse them. Consequently, repurposing the excess baked products, which share a similar composition to the original raw materials, could provide a viable alternative option for bioethanol production (Pietrzak & Kawa-Rygielska, 2015).

Bread contains significant amounts of starch that can be readily broken down into monosaccharides molecules by amylases through hydrolysis (Pietrzak & Kawa-Rygielska, 2014). The amount of starch and monosaccharides in bread is 500–750 g/kg and 3–50 g/kg, respectively (Pietrzak & Kawa-Rygielska, 2014). Furthermore, bread contains 100–150 g/kg of protein, which plays a vital role in promoting yeast growth and facilitating faster fermentation once it is broken down into peptides and amino acids (Pietrzak & Kawa-Rygielska, 2014). The ethanol yield from bread waste could reach values of about 350–370 g/kg of substrate dry matter depending on the processing conditions (Pietrzak & Kawa-Rygielska, 2015). Thus, the production of ethanol from old baked products is a lucrative opportunity to address the issue of leftover baked products.

So far, literature provides little information on fermentation potentials of different types of baked products in bioethanol production, even though understanding the potential production of the single type helps in preparing the best mixture to achieve the most efficient production. The primary objective of this research investigation was to compare six types of leftover baked products as potential feedstocks for bioethanol production. Additionally, the study aimed to compare the effect of diammonium phosphate (DAP) on ethanol production among the various groups of baked products.

The utilization of diammonium phosphate (DAP) in this study is driven by its recognized ability to enhance various aspects of the fermentation process. A study conducted by Mendes-Ferreira et al. (2010) revealed that the inclusion of DAP accelerates fermentation, improves sugar breakdown, and enhances the production of more intricate aromas by the yeast strain. Additionally, DAP functions as a catalyst for fermentation, widely acknowledged for its efficacy in mitigating the adverse effects of nitrogen deficiency, as discussed by Vilanova et al. in (2015).

Materials and Methods

Leftover Baked Products

The baked products used in this experiment were obtained from Webers Backstube bakery (Friedrichshafen, Germany). These products were categorized into six distinct groups based on their dough and pastry types, namely, bread rolls (Brötchen), pretzel rolls (Laugengebäck), fine rye bread (Mischbrot), white bread (Weißbrot), pastry (Plunder), and cream cakes (Sahne-Cremetorten). The baked products originated as 1-day-old leftovers from the bakery. A detailed list of the various bakery products and their corresponding ingredients is presented in Table 1 and 2. Crude fat and protein were analyzed by Core Facility Hohenheim (CFH).

Mash Preparation

The different groups of bakery products were individually disintegrated to achieve a particle size < 7 mm using a thermal mixer (Vorwerk Deutschland Stiftung & Co. KG, Wuppertal, Germany). Subsequently, they were stored at − 18 °C and thawed to reach a room temperature of 20 °C once required. For each sample, precisely 100 ± 2 g of bread was measured, and the corresponding amount of water was calculated based on the dry matter percentages provided in Table 2 to create a 30% dry matter (DM) water-bread mixture. This mixture was then added to the thermal mixer and stirred at a low speed until homogenized.

Enzymatic Treatment

The enzymatic treatment of the mash involved two consecutive processes. The first process, starch liquefaction, employed α-amylase (EnerZyme® AMYL' (ERBSLÖH Geisenheim GmbH, Geisenheim, Germany)). The second process was saccharification with glucoamylase (“EnerZyme® HT” (ERBSLÖH Geisenheim GmbH, Geisenheim, Germany)). The optimal temperatures for these enzymatic processes were determined from the producer to be 90 °C for starch liquefaction and 65 °C for saccharification. To maintain optimal enzyme activity, the pH of the mash was carefully monitored. The ideal pH value for α-amylase was found to be 6.5, while glucoamylase exhibited optimal activity around pH 4. For the starch liquefaction step, 220 µL of α-amylase per 100 mL of mash was added, and the thermal mixer was set to the optimal temperature of 90 °C. Continuous stirring was maintained for 30 min to facilitate the enzymatic reaction. Subsequently, the pH was measured and adjusted to the optimal range for glucoamylase for starch saccharification. In the saccharification phase, 275 µL of glucoamylase per 100 mL of mash was introduced, and the temperature was lowered to 65 °C. Another 30 min of continuous stirring ensured the completion of the enzymatic reaction. A few drops of the iodine solution were added to a small amount of the mash to confirm the completion of the starch conversion process.

Fermentation

The commercial Saccharomyces cerevisiae yeast strain “Ethanol Red®” (Lesaffre, Marcq-en-Baroeul Cedex, France), was selected for its specialized characteristics developed for the industrial ethanol industry. This strain is known for its High Ethanol Tolerance, enabling it to exhibit superior alcohol yields and maintaining elevated cell viability. Fermentation experiments were conducted in pairs of 100 mL Erlenmeyer flasks, each containing a baked product mash and yeast at a concentration of 0.5 g/L. This concentration aligns with the recommended guidelines from the company, which suggest a minimum of 2–4 lbs per 1000 gallons (250–500 g/m3) of mash. This dosage is intended to achieve an initial viable cell concentration of approximately 18–36 billion viable cells per gallon (5–10 million/mL) in the fermentation vessel. The first flask served as the control, while in the second flask, 300 mg/L of DAP was introduced. DAP was incorporated to serve as a nitrogen source, facilitating yeast growth throughout the fermentation process. Both flasks were then subjected to agitation at 100 rpm on a shaker, maintained at a temperature of 30 °C, and left undisturbed for a duration of 96 h. The experiments were performed in triplicate.

Analytical Methods

Samples were collected at time intervals (0, 24, 48, 72, and 96 h) during fermentation to determine the concentrations of specific substances for evaluating the conversion efficiency from sugar to ethanol. The targeted compounds included glucose, fructose, ethanol, glycerol, acetic acid, and lactic acid. The collected mash samples were centrifuged at 10,000 rpm for 10 min. The resulting supernatant was filtered through 30-mm membrane filters (qpore) with a pore size of 0.45 µm. The filtered liquid was then pipetted into 2-mL vials (neochrom®) and diluted with bi-distilled water (1:5 dilution). The sealed injection vials were placed in the vial sampler (1260 Infinity II, G7129A, Agilent) of the High-Performance Liquid Chromatography (HPLC) (1260 Infinity II, Agilent, Santa Clara, USA) and subjected to analysis using a polar column (Rezex ROA-Organic Acid H + (8%), Phenomenex Inc., Torrance, CA, USA). A volume of 20 µL of the sample was withdrawn for each analysis, and the eluent used was a 0.5mol/l sulfuric acid solution, which was pumped through the column at a flow rate of 0.6 mL/min and a maximum pressure of 100 bar. The optimal temperature during the measurement was 40 °C, detailed parameters are provided in Table 3. The measurement results were evaluated using the Openlab software (Data Acquisition) and further analyzed using Excel.

Statistical Analysis

To assess whether statistically significant differences exist in ethanol concentrations among different baked product groups at various time points, a two-way analysis of variance (ANOVA) was performed using the PROC GLM in SAS program (version 9.4, SAS Institute, Cary, NC, USA). The analysis was conducted in two stages.

First, the ANOVA was carried out within each group, comparing control samples with samples containing DAP (diammonium phosphate) in the same group. This examined the effect of DAP within each baked product group.

Second, a separate ANOVA was performed on samples containing DAP, comparing them across different types of bread. This assessed the influence of bread type on the DAP-treated samples.

Results and Discussion

In comparing the DAP and control samples, the levels of glucose, fructose, glycerol, acetic acid, lactic acid, and ethanol were investigated during fermentation. The levels of glucose and fructose were examined to understand potential differences in sugar consumption. Glycerol, as a reflection of yeast metabolism, and acetic acid, influenced by factors like oxygen exposure and microbial activity, were analyzed for potential variations. The concentration of lactic acid, produced by lactic acid bacteria, was assessed, exploring the role of DAP in its dynamics. Ethanol content was examined, focusing on comparing yields and discussing significant differences between the DAP and control groups. This analysis provides insights into the influence of DAP on ethanol production.

Glucose and Fructose Concentration After Enzymatic Treatment

Figure 1 shows that different baked products exhibit varying glucose concentrations after enzymatic treatment. Among them, white bread displayed the highest glucose concentration at 251.5 g/L. Following closely were pretzel rolls and bread rolls with concentrations of 246.6 g/L and 243.3 g/L, respectively. In comparison, fine rye bread and pastry showed lower concentrations at 199.5 g/L and 176.3 g/L, respectively. Cream cakes had the lowest observed glucose concentration at 120.8 g/L.

In the context of fructose concentration analysis, it was observed that cream cakes exhibited a notable fructose concentration of 66 g/L, while pastry displayed a concentration of 42 g/L. Conversely, the remaining baked products exhibited negligible levels of fructose (Fig. 2).

Based on the findings obtained from this experimental analysis, the monosaccharide content within the dry matter (DM) of each baked product is summarized as follows: White bread exhibited the highest concentration at 83.8%, followed by pretzel rolls at 82%, bread rolls at 81%, pastry at 72.7%, fine rye bread at 66.5%, and cream cakes at 62.2%. Studies have reported that during bread baking and staling, starch undergoes partial gelatinization, depolymerization, and interacts with other components present in flour, such as gluten and lipids. This molecular transformation reduces the starch’s susceptibility to enzymatic hydrolysis and thermo-mechanical treatments (Ribotta & Le Bail, 2007). However, despite differences in composition, baking techniques, and staling properties among the investigated baked products, subjecting them to high liquefaction temperatures, specifically at 90 °C, results in the degradation of all starch in these various baked products. Previous studies have also reported that higher enzymatic liquefaction temperatures can disrupt the crystalline structure of starch (Ebrahimi et al., 2008; Pietrzak & Kawa-Rygielska, 2015; Srichuwong et al., 2005). It is worth noting that Ebrahimi et al. (2008) found no significant impact of staling on saccharification or ethanol production, when the temperature was maintained at 85 °C. The key factor contributing to variations in monosaccharide levels in this study was the quantity of starch and sugar present in the baked products.

Ethanol Production During Fermentation

Ethanol Production in Control Samples

In the control samples (without DAP), the baked products served as the sole nutrient source for the yeast. No additional nutrients were provided to the yeast. Furthermore, the analysis aimed to determine the abundance of vitamins and other compounds essential for yeast growth within each baked product. Ethanol concentration was monitored at specific time intervals (0, 24, 48, 72, and 96 h) during the fermentation process.

As illustrated in Fig. 3, after 96 h the highest ethanol concentration was found in fine rye bread at 78.4 g/L. Pastry and cream cakes followed with a concentration of 72.9 g/L, and 65.8 g/L respectively. Ethanol concentrations in pretzel rolls and bread rolls were almost identical, at 57.5 and 54.3 g/L, respectively. However, with white bread sugar utilization was very inefficient. Even after 96 h, only 21.5 g/L of ethanol was produced, despite having the highest glucose concentration among all the baked products. The limited fermentation observed with white bread can be attributed to its low protein content. It is important to note that the presence of amino acids in the fermentation mash is essential for maintaining the proper physiological conditions and activity of yeast (Buksa et al., 2010; Kłosowski et al., 2010). On another reason could be that in the current investigation, the particle size of bread samples was found to be less than 7 mm. In the case of cream cakes and pastry, these particles exhibited solubility in water, resulting in a creamy structure. Conversely, in the case of white bread, some particles remained undissolved even after the processes of liquefaction and saccharification. This observation aligns with the findings of the previous study that examined the influence of jet milling settings on whole wheat flour characteristics and the physical quality and enzymatic digestion of whole wheat bread. The earlier study demonstrated that jet milling led to a reduction in flour particle size, with variations in milling pressure, feed rate, and recirculation intensifying the process and reducing particle size. Specifically, particles from the aleurone layer and larger aggregates of the protein matrix, encapsulating cellular components, particularly starch granules, exhibited size ranges of approximately 20–180 µm (Protonotariou et al., 2015).

Ethanol Concentration in DAP Samples

In a prior study, Strąk-Graczyk and Balcerek (2020) examined the effect of pre-hydrolysis on the simultaneous saccharification and fermentation of native rye starch. They concluded that pre-hydrolysis had no discernible effect on initial sugar levels, fermentation efficiency, or ethanol yield. In the current study, the decision was made not to employ pre-hydrolysis, opting instead to investigate the influence of DAP on the fermentation process.

Based on the findings presented in Fig. 3, the incorporation of yeast nutrients during the fermentation process resulted in a reduction in fermentation time and an enhancement of glucose conversion efficiency. Specifically, the addition of DAP to the baked products led to faster glucose conversion: cream cakes within 24 h, fine rye bread within 48 h, and bread rolls, pretzel rolls, pastry, and white bread within 72 h. Additionally, the introduction of DAP significantly increased the ethanol yield in three types of bread. Pretzel rolls exhibited the highest ethanol production at 98.5 g/L, followed by white bread with 90.6 g/L, and bread rolls with 87.7 g/L. Fine rye bread recorded 75.9 g/L, while pastry and cream cakes displayed the lowest values at 65.2 g/L and 62.9 g/L, respectively. In the remaining three bread types, ethanol concentrations were close to the control samples but were achieved in a shorter amount of time. These results underscore the impact of DAP on both fermentation speed and ethanol production across a variety of baked product. Shorter fermentation times are beneficial for practical applications, because they reduce the cost of bioethanol production (Han et al., 2020). Previous studies conducted on wheat-rye bread reported the use of complex enzymatic preparations, such as Cremix 2XL and Ceremix 6X MG, which contain proteases and enzymes capable of degrading non-starch polysaccharides, resulting in enhanced bioethanol production and accelerated fermentation. The addition of these complex preparations led to a notable reduction in fermentation time, shortening it to 72 h compared to the control sample’s 93 h. Furthermore, the bioethanol production increased, with ethanol amounts reaching 85.80 and 88.50 g/L, respectively (Kawa-Rygielska et al., 2012).

Conversion Efficiency in Control and DAP Samples

Fine rye bread exhibited a high conversion efficiency in both the control and DAP sample, with values of 78.6% and 76.09%, respectively (Table 4). A significant enhancement in conversion efficiency was observed in pretzel rolls and bread rolls in the DAP samples, showing an increase of 30% compared to the control samples. A marginal decrease of approximately 5% was observed in the DAP samples of pastry and cream cakes. Remarkably, a substantial improvement was noted in white bread in the DAP samples, where the conversion efficiency increased from 17% in the control samples to 72%. These findings underscore the varying effects of DAP on the conversion efficiency of monosaccharides to ethanol across different baked products. The maximum theoretical yield of ethanol from glucose is 0.51 g of ethanol per gram of glucose, assuming complete conversion of glucose to ethanol and no other by-products being produced (Gombert & van Maris, 2015). Therefore, 100 g of glucose could theoretically yield up to 51 g of ethanol.

However, the actual yield of ethanol from glucose is often lower in practice due to various factors such as incomplete conversion, loss of substrate to other metabolic pathways and inhibition of fermentation by the accumulated ethanol (Gombert & van Maris, 2015). The actual yield can vary depending on several factors, including the type of microorganisms used, fermentation conditions, and other variables. Azhar et al. reported a statistically significant impact (p ≤ 0.05) of varying yeast cell number on ethanol yield (Mukhtar et al., 2010). This observation may help explain the relatively low conversion efficiency observed in our experiment, even following the addition of DAP. Consequently, optimizing the yeast cell number becomes essential.

The conversion efficiency in the case of pastry and cream cakes was lower than for the other products in the presence of DAP. One significant factor contributing to this lower efficiency could be the substantial fat content in these baked products. During fermentation, a noticeable foam layer formed above the mash. This foam layer may have a negative effect on fermentation (Deotale et al., 2023). The high fat content was observed to slow down fermentation, leading to a reduced rate of glucose-to-ethanol conversion.

Regarding the condition and aging of the bakery products, the process where starch turns back into its crystalline form, known as retrogradation, usually takes several weeks to occur (Dymchenko et al., 2023). Considering that the baked products used in our study were only one day old, it makes us wonder how the typical characteristics of older baked products might influence the process of making bioethanol. Exploring this further and taking into account how bread changes with time during fermentation could provide valuable information for improving the production of bioethanol using bakery leftovers.

Glycerol Concentration

DAP addition had a marked effect on glycerol production, the concentrations were substantially increased by DAP compared to the control samples. In the control samples the concentrations varied between 5.0 and 7.8 g/L (Fig. 3). Without DAP Pastry registered 7.8 g/L, pretzel rolls contained 7.4 g/L, fine rye bread recorded 7.3 g/L, bread rolls exhibited 6.8 g/L, cream cakes showed 6.5 g/L, and white bread had the lowest concentration at 5 g/L. However, upon the introduction of diammonium phosphate (DAP), glycerol concentrations were substantially higher across all samples: Bread rolls surged to 12.05 g/L, pretzel rolls reached 13 g/L, pastry attained 10.73 g/L, fine rye bread achieved 10 g/L, white bread rose to 12.27 g/L, and cream cakes elevated to 10 g/L. This significant rise in glycerol concentrations in response to DAP supplementation could be the result of a redox factor imbalance due to increased biomass production. When pyruvate from glycolysis is channeled into biomass, NAD+ cannot be regenerated by ethanol synthesis; instead, it is regenerated by reduction of dihydroxyacetone phosphate to glycerol-3-phosphate, resulting in higher glycerol levels (Van Dijken & Scheffers, 1986) (Fig. 4).

Glucose and ethanol concentration in the baked products (g/L) n = 3, mean ± standard deviation (SD). A.1 glucose in bread rolls; A.2 ethanol in bread rolls; B.1 glucose in pretzel rolls; B.2 ethanol in pretzel rolls; C.1 glucose in pastry; C.2 ethanol in pastry; D.1 glucose in fine rye bread; D.2 ethanol in fine rye bread; E.1 glucose in white bread; E.2 ethanol in white bread; F.1 glucose in cream cakes; F.2 ethanol in cream cakes

Table 5 displays the glycerol percentage calculated in relation to the theoretical ethanol production. Notably, the analysis reveals that in the control samples, the percentage of glycerol accounted for approximately 5% of the theoretical ethanol production, while in the DAP-treated samples, this percentage increased to 10%. During the fermentation process, glycerol is produced as a by-product, and prior research, such as (Medina et al., 2010), has demonstrated that its production follows a pattern similar to ethanol production, with lower yields at lower solid loadings. It is noteworthy that glycerol has been associated with osmotic stress, which can lead to a reduction in ethanol production, as shown in previous study (Medina et al., 2010). The encouragement of glycerol overproduction has been suggested as a means to maintain osmotic pressure and shield yeast cells from elevated temperatures, as proposed by (Banuett, 1998).

Acetic Acid and Lactic Acid Concentration

Weak organic acids, namely lactic acid and acetic acid, play a critical role in the production of bioethanol due to their potential to impede the growth of yeast (Graves et al., 2006). Acetic acid serves as an antimicrobial agent in the food and beverage industry, recognized for its capacity to suppress the proliferation of microorganisms (Casey et al., 2010). While S. cerevisiae produces small quantities of acetic acid during alcoholic fermentation, harmful concentrations for yeast can be generated by lactic acid bacteria and/or acetic acid bacteria (Graves et al., 2006). Additionally, acetic acid can serve as an indicator of contaminants or foreign organisms. In our study, most of the time no acetic acid could be detected by HPLC. This indicates that our fermentations were not infected by bacteria, and consequently, no adverse effects attributable to acetic acid were identified.

Likewise, lactic acid was found in minimal quantities in the mash at the onset of fermentation, with no significant change during fermentation. Greater bread content in the mash generally correlated with higher lactic acid levels. Lactic acid is a byproduct of carbohydrate metabolism produced by contaminating lactic acid bacteria (Graves et al., 2006). However, its effect on yeast growth is not as pronounced as the inhibitory effect of acetic acid. Thus, the influence of lactic acid on fermentation is not considered significant (Casey et al., 2010).

Statistical Analysis Results

The observed differences with respect to group (control vs. DAP), fermentation time and the interaction between ethanol yield and fermentation time were statistically analyzed for the different baked products (Table 6). As shown in the tables, the group factor (Control vs. DAP), time, and their interaction have a highly significant effect on bioethanol production in all the baked products, except for bread rolls and cream cakes. In bread rolls, both the group factor and time are highly significant, but the interaction between group and time is not statistically significant. In the case of cream cakes, the group factor does not have a highly significant effect on bioethanol production (p value = 0.0673, Table 6). These results indicate that DAP significantly enhances bioethanol production in all tested baked products except for cream cakes. In the case of cream cakes, DAP speeds up the fermentation process only.

The second test of the two-way ANOVA, focusing only on DAP-treated samples and considering time and baked products as factors, is shown in Table 7. These results indicate that both time and the type of baked product have a significant influence on bioethanol production in the DAP-treated samples.

It is worth noting that challenges linked to incorporating DAP into sustainable alternatives to fossil fuels are primarily tied to the global increase in diammonium phosphate (DAP) prices. The surge can be attributed to several factors. This includes a rise in the cost of oil and energy required for producing and transporting P fertilizers (particularly DAP and monoammonium phosphate), a significant decrease in fertilizer production in the US (a major producer of phosphorus), imbalances in supply and demand, heightened fertilizer demand for biofuel production, and increased excise on phosphate fertilizer exports (Chowdhury et al., 2017). These factors contribute to the complexities associated with using DAP in the pursuit of sustainable alternatives to fossil fuels.

Conclusions

This study significantly contributes to filling a knowledge gap in the field of bioethanol production by examining the untapped potential of six leftover baked products—bread rolls (Brötchen), pretzel rolls (Laugengebäck), fine rye bread (Mischbrot), white bread (Weißbrot), pastry (Plunder), and cream cakes (Sahne-Cremetorten)—for bioethanol production. Notably, these specific baked products had not been previously examined in this context. The study revealed that these baked products exhibit significant potential for bioethanol production due to their simple and rapid production processes, as well as their high starch content. Differences in bioethanol production levels among the baked products were noticed, highlighting the significant role of DAP in speeding up fermentation and increasing ethanol yields. Among the DAP-treated samples, pretzel rolls, bread rolls, and white bread exhibited the most substantial ethanol production increases. DAP impact was particularly effective in white bread, where it significantly improved glucose-to ethanol conversion efficiency. The individual study of these baked products is essential for understanding their unique characteristics, leading to enhanced process optimization and increased economic viability. This research sheds light on the variable bioethanol yield potentials of different leftover baked products as valuable resources for bioethanol production, offering both simplicity and efficiency in the process.

Data Availability

The authors declare that the data supporting the findings of this study are available within the article from the corresponding author, Mervat Almuhammad upon reasonable request.

References

Banuett, F. (1998). Signalling in the yeasts: An informational cascade with links to the filamentous fungi. Microbiology and Molecular Biology Reviews (MMBR), 62(2), 249–274. https://doi.org/10.1128/MMBR.62.2.249-274.1998

Buksa, K., Nowotna, A., Praznik, W., Gambuś, H., Ziobro, R., & Krawontka, J. (2010). The role of pentosans and starch in baking of wholemeal rye bread. Food Research International, 43(8), 2045–2051. https://doi.org/10.1016/j.foodres.2010.06.005

Casey, E., Sedlak, M., Ho, N. W. Y., & Mosier, N. S. (2010). Effect of acetic acid and pH on the cofermentation of glucose and xylose to ethanol by a genetically engineered strain of Saccharomyces cerevisiae. FEMS Yeast Research, 10(4), 385–393. https://doi.org/10.1111/j.1567-1364.2010.00623.x

Chowdhury, R. B., Moore, G. A., Weatherley, A. J., & Arora, M. (2017). Key sustainability challenges for the global phosphorus resource, their implications for global food security, and options for mitigation. Journal of Cleaner Production, 140(2), 945–963. https://doi.org/10.1016/j.jclepro.2016.07.012

Deotale, S. M., Dutta, S., Moses, J. A., et al. (2023). Foaming and defoaming–concepts and their significance in food and allied industries: A review. Discover Chemical Engineering, 3, 9. https://doi.org/10.1007/s43938-023-00025-6

Dymchenko, A., Geršl, M., & Gregor, T. (2023). Trends in bread waste utilisation. Trends in Food Science & Technology, 132, 93–102. https://doi.org/10.1016/j.tifs.2023.01.004

Ebrahimi, F., Khanahmadi, M., Roodpeyma, S., & Taherzadeh, M. (2008). Ethanol production from bread residues. Biomass and Bioenergy, 32(4), 333–337. https://doi.org/10.1016/j.biombioe.2007.10.007

Food and Agriculture Organization (FAO). (2011). Global food losses and food waste: extent, causes and prevention, Save Food! Rome. https://www.fao.org/3/i2697e/i2697e.pdf

Gombert, A. K., & van Maris, A. J. (2015). Improving conversion yield of fermentable sugars into fuel ethanol in 1st generation yeast-based production processes. Current Opinion in Biotechnology, 33, 81–86. https://doi.org/10.1016/j.copbio.2014.12.012

Graves, T., Narendranath, N. V., Dawson, K., & Power, R. (2006). Effect of pH and lactic or acetic acid on ethanol productivity by Saccharomyces cerevisiae in corn mash. Journal of Industrial Microbiology & Biotechnology, 33(6), 469–474. https://doi.org/10.1007/s10295-006-0091-6

Han, W., Liu, Y., Xu, X., Huang, J., He, H., Chen, L., Qiu, S., Tang, J., & Hou, P. (2020). Bioethanol production from waste hamburger by enzymatic hydrolysis and fermentation. Journal of Cleaner Production, 264, https://doi.org/10.1016/j.jclepro.2020.121658

Han, W., Xu, X., Gao, Y., He, H., Chen, L., Tian, X., & Hou, P. (2019). Utilization of waste cake for fermentative ethanol production. The Science of the Total Environment, 673, 378–383. https://doi.org/10.1016/j.scitotenv.2019.04.079

Jaeger, S. (2018). Unser täglich Brot: von überschüssigen Brotkanten und wachsenden Brotbergen. WWF Deutschland. https://www.wwf.de/fileadmin/fm-wwf/Publikationen-PDF/WWF-Studie-Unser-taeglich-Brot_Von-ueberschuessigen-Brotkanten-und-wachsenden-Brotbergen_102018.pdf

Kawa-Rygielska, J., Pietrzak, W., & Czubaszek, A. (2012). Characterization of fermentation of waste wheat-rye bread mashes with the addition of complex enzymatic preparations. Biomass and Bioenergy, 44, 17–22. https://doi.org/10.1016/j.biombioe.2012.04.016

Kłosowski, G., Mikulski, D., Czupryński, B., & Kotarska, K. (2010). Characterization of fermentation of high-gravity maize mashes with the application of pullulanase, proteolytic enzymes, and enzymes degrading non-starch polysaccharides. Journal of Bioscience and Bioengineering, 109(5), 466–471. https://doi.org/10.1016/j.jbiosc.2009.10.024

Kumar, V., Brancoli, P., Narisetty, V., Wallace, S., Charalampopoulos, D., Dubey, B. K., Kumar, G., Bhatnagar, A., Bhatia, S. K., & Taherzadeh, M. J. (2023). Bread waste – A potential feedstock for sustainable circular biorefineries. Bioresource Technology, 369, 128449. https://doi.org/10.1016/j.biortech.2022.128449

Lin, Y., & Tanaka, S. (2006). Ethanol fermentation from biomass resources: Current state and prospects. Applied Microbiology and Biotechnology, 69(6), 627–642. https://doi.org/10.1007/s00253-005-0229-x

Medina, V., Guadalupe, M., Almering, M. J., van Maris, A. J., & Pronk, J. T. (2010). Elimination of glycerol production in anaerobic cultures of a Saccharomyces cerevisiae strain engineered to use acetic acid as an electron acceptor. Applied and Environmental Microbiology, 76(1), 190–195. https://doi.org/10.1128/AEM.01772-09

Mendes-Ferreira, A., Cosme, F., Barbosa, C., Falco, V., Inês, A., & Mendes-Faia, A. (2010). Optimization of honey-must preparation and alcoholic fermentation by Saccharomyces cerevisiae for mead production. International Journal of Food Microbiology, 144(1), 193–198. https://doi.org/10.1016/j.ijfoodmicro.2010.09.016

Mukhtar, K., Asgher, M., Afghan, S., Hussain, K., & Zia-Ul-Hussnain, S. (2010). Comparative study on two commercial strains of Saccharomyces cerevisiae for optimum ethanol production on industrial scale. Journal of Biomedicine & Biotechnology, 2010, 419586. https://doi.org/10.1155/2010/419586

Pietrzak, W., & Kawa-Rygielska, J. (2014). Ethanol fermentation of waste bread using granular starch hydrolyzing enzyme: Effect of raw material pretreatment. Fuel, 134, 250–256. https://doi.org/10.1016/j.fuel.2014.05.081

Pietrzak, W., & Kawa-Rygielska, J. (2015). Simultaneous saccharification and ethanol fermentation of waste wheat–rye bread at very high solids loading: Effect of enzymatic liquefaction conditions. Fuel, 147, 236–242. https://doi.org/10.1016/j.fuel.2015.01.057

Protonotariou, S., Mandala, I., & Rosell, C. M. (2015). Jet milling effect on functionality, quality, and in vitro digestibility of whole wheat flour and bread. Food and Bioprocess Technology, 8(4), 1319–1329. https://doi.org/10.1007/s11947-015-1494-z

RFA. (2022). Entwicklung der Ethanol-Produktion in den USA in den Jahren von 1980 bis 2021 (in Millionen Gallonen). Statista. https://de.statista.com/statistik/daten/studie/274953/umfrage/ethanol-produktion-in-den-usa

Ribotta, P. D., & Le Bail, A. (2007). Thermo-physical assessment of bread during staling. LWT - Food Science and Technology, 40(5), 879–884. https://doi.org/10.1016/j.lwt.2006.03.023

Srichuwong, S., Sunarti, T. C., Mishima, T., Isono, N., & Hisamatsu, M. (2005). Starches from different botanical sources I: Contribution of amylopectin fine structure to thermal properties and enzyme digestibility. Carbohydrate Polymers, 60(4), 529–538. https://doi.org/10.1016/j.carbpol.2005.03.004

Strąk-Graczyk, E., & Balcerek, M. (2020). Effect of Pre-hydrolysis on Simultaneous Saccharification and Fermentation of Native Rye Starch. Food and Bioprocess Technology, 13(6), 923–936. https://doi.org/10.1007/s11947-020-02434-9

Van Dijken, J. P., & Scheffers, W. A. (1986). Redox balances in the metabolism of sugars by yeasts. FEMS Microbiology Reviews, 1(3–4), 199–224. https://doi.org/10.1111/j.1574-6968.1986.tb01194.x

Vilanova, M., Pretorius, I. S., & Henschke, P. A. (2015). Influence of diammonium phosphate addition to fermentation on wine biologicals. In V. Preedy (Ed.), Processing and impact on active components in food (pp. 483–491). Academic Press. https://doi.org/10.1016/B978-0-12-404699-3.00058-5

Funding

Open Access funding enabled and organized by Projekt DEAL. This study was supported by Zentrales Innovationsprogramm Mittelstand (ZIM), grant number KK5246401SK1.

Author information

Authors and Affiliations

Contributions

Conceptualization, investigation, and writing: MA; supervision, review and editing: RK; project administration, funding acquisition, and editing: DE. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Consent for Publication

All authors have given their consent for publication.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Ralf Kölling and Daniel Einfalt are co-authors

On behalf of my co-authors, I now claim that the work is an unpublished original research that is not currently being considered for publication elsewhere, in whole or in part

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Almuhammad, M., Kölling, R. & Einfalt, D. Comparative Assessment of Ethanol Production from Six Typical German Waste Baked Products. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-023-03304-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-023-03304-w