Abstract

The short shelf life of bread can be attributed to changes in its textural and sensory properties, a process termed staling, and large amounts of bread residue and waste are generated daily. Because the main component of bread is starch, the use of bread wastes as a substrate for bacterial cellulose (BC) production can significantly contribute to valorisation and reuse of wastes. This study aimed to investigate the BC production potential of various stale breads, convert these wastes into usable forms for food and other industries, and increase their economic value. Stale breads were hydrolyzed with dilute acid, and BC-producing bacteria from Kombucha tea were isolated and identified as Gluconobacter oxydans MG2021 (GO). BCs were produced from bread hydrolysates with GO and Komagataeibacter hansenii GA2016 (KH), and their properties were examined. The results indicated that stale breads represented a good source for BC production, as high BC yields were obtained using GO (8.81%–25.02%) and all BCs had superior properties such as high crystallinity (75.96%–91.39%), thermal stability, liquid holding capacity, and fine fibers (40.16–85.39 nm). This study demonstrated that bread wastes could be used as a low-cost substrate for large-scale BC production, and the abundance of bread wastes demonstrated their potential as a resource for commercial BC producers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Although 12.5% of the world’s population is malnourished and millions of people are dying of hunger, food waste has reached high levels. At present, food loss and waste represent a major global problem. The Food and Agriculture Organization of the United Nations states that waste generated in the agriculture–food sector should be minimized to achieve and ensure the success of the Sustainable Development Goals. Globally, it is estimated that 1.3 billion tonnes of food with a total value of US$1 trillion are lost or wasted annually. Environmental stress caused by agricultural food wastes and byproducts is especially great [1, 2]. Grains, which are the most commonly consumed substances, also represent the most common source of energy loss, and the largest proportion of this loss originates from industrialized countries. Globally, fruits, vegetables, root and tuberous plants, and grains are the most wasted foods [3].

Bread, the production of which exceeds 100 million tonnes/year worldwide, is a widely wasted food in many countries, particularly in most European countries. The distribution of the global bread market share is as follows: Europe, 53.6%; US, 28.6%; Asia Pacific, 10.9%; and Middle East and African countries, 6.9% [4]. Bread consumption is below the global average in developed countries, whereas it is higher in developing and underdeveloped countries. For example, daily bread consumption is 112 g per adult in Spain, 130 g per adult in Switzerland [5], 87 g per adult in England [6], and 300 g per adult in Iran [7]. According to the Turkey Waste Report Data, 4.9 million pieces of bread/day are wasted, with 3 million (62.1%) of them being wasted in bakeries; 1.4 million (27.7%) in households; and 0.5 million (10.2%) in staff and student cafeterias, restaurants, and hotels. In addition, it was stated that bread waste totaled 1223 tonnes per day, 447,000 tonnes per year, 4.9 million pieces per day, and 1.79 billion pieces per year; 27.7% of the bread wasted each year (123,819 tonnes) was wasted in households [8].

One measure to reduce bread waste is to buy bread as needed (41.5%). Other measures included adding leftover bread to the composition of other food products (24%), storing it in the refrigerator (15.1%) or freezer (14.7%), sharing it with other people (14.3%), and using it as animal feed (14%) [9].

Further research on the conversion of bread waste to other products is required. Bakery wastes are materials that can be used as a substrate for microorganisms. The approximate composition of bread waste is as follows: moisture, 22.3%; starch, 59.8%; total organic nitrogen, 1.56%; protein, 8.9%; and phosphorus, trace amounts [10]. Starch, the main component of bread, is used as a substrate for biotechnological processes, and various studies have assessed the valorisation and reuse of bread wastes, including their use in lactic acid, biohydrogen, aroma compounds, ethanol, and succinic acid production [10,11,12,13,14,15,16,17].

Bread waste can also be used as a substrate for bacterial cellulose (BC) production. BC is produced extracellularly by various bacterial species [18]. Compared to plant cellulose, BC has superior properties [19,20,21], and the use of BC is increasing in various industries (such as food, advanced acoustic diaphragms, biosensors, tissue scaffolds, packaging, protective coatings, antimicrobial materials, and flexible electronics) [22]. However, the high cost of BC production limits the use of the polymer in industry. For the widespread use of BC, cheap and sustainable carbon sources are needed for BC production [23]. Because the amounts of BC in these studies were generally low or the wastes used in BC production were not the only sources of nutrients, alternative sources need to be developed. For this, various bread wastes, which have no economic value as waste, have the potential to be important sources of carbohydrates for BC production, thereby reducing its cost and facilitating its wide use in industry.

To the best of our knowledge, no studies on BC production from bread waste have been reported yet. Therefore, this study aimed to investigate the BC production potential of various stale breads, which do not have significant economic value after becoming stale, as the sole carbon source and to convert these wastes into usable forms in food and other industries, thereby increasing their economic value. Therefore, BC was produced using bacteria isolated from Kombucha tea and Komagataeibacter hansenii GA2016 (KH). Stale breads were hydrolyzed with dilute acid to convert them into soluble sugars, BCs were produced from bread hydrolysates as the sole carbon source, and the properties of the BCs was investigated. Thus, the potential of using large amounts of bread waste as the sole carbon source and a low-cost substrate for large-scale BC production were investigated. This approach aims to minimize the harmful effects of bread waste on the environment.

2 Materials and methods

2.1 Materials

Different types of bread commonly consumed in Turkey (traditional bread [TB], francala bread [FB], corn bread [CB], whole wheat bread [WWB], rye bread [RB], bread with wheat bran [BWB], multigrain bread [MGB]), and crispy Turkish bagels (CTB) were used in this study. TB (Nimet, Istanbul, Turkey), WWB (Nimet, Istanbul, Turkey), BWB (Uno, İstanbul, Turkey), MGB (Uno, İstanbul, Turkey), and CTB (Nimet, Istanbul, Turkey) were obtained from local markets, and FB, CB, and RB were supplied from local bakeries. Breads (1000 g) were sliced, shredded by a chopper, oven-dried at 50 °C, ground, and stored at 4 °C until use. KH, which was isolated and identified by Güzel and Akpınar [24], was provided by Gaziosmanpaşa University Faculty of Engineering and Architecture, Department of Food Engineering Culture Collection (Tokat, Turkey) and used to produce BC from bread wastes. In addition, a BC-producing microorganism was isolated from Kombucha tea. The bacterium was identified and applied to BC production. NaOH, methanol (≥ 99.9%), acetone (≥ 99.9%), diethyl ether (≥ 97.5%), petroleum benzene (≥ 99.9%), hexane (≥ 99.9%), benzene (≥ 99.9%), isopropyl alcohol (≥ 99.9%) acetone (≥ 99.5%), dimethyl sulfoxide (≥ 99.9%), acetic acid (≥ 99.9%) solvents, and other chemicals were obtained from Sigma–Aldrich (St. Louis, MO, USA) and Merck KGaA (Darmstadt, Germany).

2.2 Methods

2.2.1 Proximate composition

The dry matter and ash contents of the breads were determined gravimetrically [25]. The micro-Kjeldahl method [25] was used to analyse the nitrogen content of the breads. The value of 6.25 was used as a protein conversion factor. The Soxhlet extraction method [25] was used to determine the fat content of the breads. The carbohydrate contents of samples were calculated by adding the contents of moisture, ash, protein, and fat of breads and subtracting them from 100.

2.2.2 Isolation and identification of BC-producing bacteria

Traditionally produced Kombucha tea (Gümüşhane, Turkey) was used to isolate BC-producing bacteria. One milligram of Kombucha tea was transferred to Hestrin–Schramm (HS) medium, and cellulose-producing bacteria were pregrown for 18–24 h at 30 °C, cultivated on HS agar plates, and incubated at 30 °C at a constant temperature using a gravity convection incubator (Binder BD 23, Tuttlingen, Germany) [26]. The morphologies of the microorganisms were examined under a light microscope, and gram-negative strains were selected by Gram staining. Colonies with a white cream mucous structure were cultivated more than once on HS agar, and the microorganisms were purified. The isolated cellulose-producing bacteria were stored on HS agar at 4 °C and identified via 16S rRNA analysis by an external laboratory (Atlas Biotechnology, Ankara, Turkey). DNA isolation was conducted using GeneAll Clinic SV mini brand kit according to catalog number 108–101. The PCR reaction was conducted using the WizPure PCR 2X Master brand kit and according to catalog number W1401. PCR cleanup was performed using the Thermo ExoSAP-IT Express PCR Cleanup Reagents brand kit according to catalog number 75001.200.UL. The sequencing reaction was performed on the Applied Biosystems ProFlex thermal cycler. After this process, the sequencing product was purified. Purification was conducted using the gel filtration method with Sephadex. DNA sequencing was performed on the ABI 3130XL device using the capillary electrophoresis method. The resulting sequences were compared with available sequences in the GenBank database using BLAST scanning [27], and the 16S rRNA gene sequences of the closest species were retrieved from the database.

2.2.3 Acid hydrolysis of bread wastes and the production of BC

Ground breads (10 g) were hydrolyzed with dilute acid (100 mL of 0.6 M sulfuric acid) in a shaking water bath (Mipro MSC 30, Miprolab, Ankara, Turkey) at 100 °C for 2 h and filtered with a coarse filter. Then, 100 mL of distilled water was added, the pH was adjusted to 4.5 using calcium carbonate (CaCO3), the mixture was filtered, and the final volumes were made up to 200 mL with distilled water [28].

To investigate the effect of reducing sugar contents of bread hydrolysates on BC production, the reducing sugar levels of hydrolysates were determined. The reducing sugar content of the bread hydrolysates was quantified using the Agilent 1260 Infinity HPLC system (Agilent Technologies, Waldbronn, Germany) device, equipped with an Agilent 1260 Infinity Refractive Index Detector (G1362A RID) and a C18 column (CNW Technologies Athena, 120 Å, 5 μm, 250 mm × 4.6 mm, Tokyo, Japan). ACN/pure water (85%) was used as the mobile phase, the flow rate was set at 1.3 mL/min, and the injection volume was 10 μL. Glucose, D-fructose, and D-maltose standards, which were of an analytical grade, were obtained from Merck.

BC was produced from bread samples using bacteria isolated from Kombucha tea and KH. For this, bacteria were inoculated into HS medium (10 mL) and incubated (30 °C, 48 h) in static conditions. Next, 1-mL samples were transferred to 200 mL of sterilized (121 °C, 15 min) bread hydrolysates and HS medium, and cellulose production was continued at 28 °C–32 °C for 14 days until the formed BCs collapsed to the bottom of the flask. The precipitated BCs were removed from the medium, centrifuged at 4000 × g for 10 min, and boiled in a 4% NaOH solution for 30 min at 100 °C [29]. To remove NaOH from the BCs, BCs were rinsed five times with distilled water (5 min each), incubated in a 2% acetic acid solution for 15 min, and incubated in distilled water until neutralized. The neutralized BCs were dried in an oven (50 °C for 48 h), and the BC production yields were calculated according to the following formula: % Production yield: A/B × 100, where A is the amount of dried BC (g) and B is the amount of dried bread (g).

2.2.4 BC analysis

The solubility and liquid holding capacity of BCs from bread samples in different solvents were determined. In addition, Fourier transformed infrared (FT-IR) analysis, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), and X-ray diffraction (XRD) of BCs were performed.

For solubility, 5 mL each of 1 M NaOH (30 °C and 90 °C), methanol (30 °C and 60 °C), acetone (30 °C and 50 °C), diethyl ether (30 °C), petroleum benzine (30 °C), hexane (30 °C and 60 °C), benzene (30 °C and 80 °C), and isopropyl alcohol (30 °C and 80 °C) were added to 250 mg of BCs and mixed for 2 min, and the solubility of the BCs was assessed [30]. To determine the liquid holding capacity of BCs, BCs (1 g) were mixed with water (40 mL), acetone (40 mL), dimethyl sulfoxide (40 mL), or acetic acid (40 mL; allowed to stand for 2 h; and centrifuged (3500 rpm for 30 min), after which the supernatants were removed and the BCs were weighed. The results were calculated and expressed as the liquid holding capacity (%) [31].

FT-IR analyses (4000–500 cm−1) were performed using a Nicolet 6700 spectrophotometer (Thermo Fisher Scientific, Waltham, MA, USA) after the samples were formed into potassium bromide disks. SEM analyses were performed using a QUANTA 450 Field Emission Gun high-resolution scanning electron microscope (FEI Company, Hillsboro, Oregon, USA). The fiber diameters were calculated as the arithmetic mean of at least 10 BC fiber diameters. The thermal properties of the BCs were investigated using TG/DTA Exstar 7300 (SII Nanotechnology, Shizuoka, Japan) in a nitrogen environment. The crystal index properties of the BCs were assessed, and XRD was performed in a Cu X-ray tube device with an Ni filter set at 2θ = 10°–50° using a Panalytical Empyrean High Performance Diffractometer (Malvern Panalytical Ltd., Malvern, UK). The degree of crystallinity (%) was calculated using the curve-fitting method [32, 33].

2.2.5 Statistical analysis

The results were calculated as the mean ± standard deviation of three replicates. The SPSS statistical program (IBM SPSS Statistics 22, Inc., Chicago, IL, USA) was used to analyse the results, and analysis of variance was performed. The differences between the groups were statistically evaluated using the Duncan multiple comparison test at a 95% confidence level.

3 Results and discussion

3.1 Proximate compositions of the breads

In this study, moisture, ash, fat, protein, and carbohydrate contents were determined for dried breads (TB, FB, CB, WWB, RB, BWB, MGB, and CTB) (Table 1). When the approximate compositions of breads were examined, the moisture content of the bread samples varied between 4.64% and 12.60%. BWB (12.60%) had the highest moisture content, followed by WWB (11.72%), TB (11.41%), and FB (11.26%). Meanwhile, the ash content of the bread samples varied between 1.20% and 2.43%. WWB (2.43%), TB (2.42%), BWB (2.14%), and CB (2.03%) had the highest ash contents, and the differences between them were not significant. The high ash contents in these breads might be attributable to the high bran contents of the breads. It was determined that the protein contents of the bread samples varied between 9.75% and 16.75%, and MGB, BWB, WWB, and TB had the highest contents, respectively, BWB, WWB, and TB were statistically insignificant (P > 0.05), and CB had the lowest content. The total fat contents of the bread samples varied between 0.29% and 14.36%, CYB, CB and MGB had the highest contents, respectively. The fat contents of the other bread samples were less than 1%, RB had the lowest content, and the difference with BWB was statistically insignificant (P > 0.05). The carbohydrate contents of breads were calculated by adding the contents of moisture, ash, protein, and fat of the peels and subtracting them from 100, and it was determined that the breads had a content between 66.41% and 78.69%. RB, CB, and FB had the highest contents, respectively, and MGB had the lowest content.

3.2 Isolation and identification of cellulose-producing bacteria

Traditionally produced Kombucha tea has been used to isolate and identify BC-producing bacteria. Bacteria isolated from Kombucha tea were identified by 16S rRNA analyses, and the sequences were compared with sequences in the GenBank database via BLAST scanning [27]. The gene sequences of the closest species were obtained from the database. The gene sequences have been deposited in GenBank, and the bacterial strain isolated from Kombucha tea was identified as Gluconobacter oxydans MG2021 (GO, GenBank accession no OL361833, Fig. 1). In previous studies, GO was identified as a BC-producing bacterium, and it was used for BC production in different studies [34, 35]. In this study, 3.30 g of dry BC were produced by Gluconobacter oxydans MG2021 in 1 L of HS medium.

Phylogenetic tree of bacteria isolated from Kombucha samples according to 16S rRNA sequences (a) and the BC yields from bread hydrolysates produced by Gluconobacter oxydans MG2021 (GO) (b) TB, traditional bread; FB, francala bread; CB, corn bread; WWB, whole wheat bread; RB, rye bread; BWB, bread with wheat bran; MGB, multigrain bread; CTB, crispy Turkish bagel. a, b, c, d represent significant differences according to Duncan’s test (P < 0.05)

3.3 Acid hydrolysis of bread wastes and the production of BC

In previous studies, it was determined that BC production was mostly conducted in HS medium. In addition, existing studies on the production of BC from food waste were insufficient. It was stated in the review by Hussain et al. [23], wastes were generally used by adding different nutrients, in previous studies. In this study, unlike the studies in the literature, only bread hydrolysates were used and no nutritional substances were added to the hydrolysates. For the experimental studies, the hydrolysates obtained from FB were inoculated with KH and GO, and BC production at the end of fermentation was calculated as 3.96% ± 0.47% for KH and 17.71% ± 1.40% (w/w) for GO. Because the amount of BC produced with KH was low compared to that for GO, BC production from other bread varieties was performed only with GO.

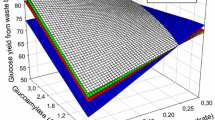

The amounts of BCs produced from hydrolysates of different bread varieties are presented in Fig. 1. The amounts of BCs produced by GO from TB (GO(TB)), FB (GO(FB)), CB (GO(CB)), WWB (GO(WWB)), RB (GO(RB)), BWB (GO(BWB)), MGB (GO(MGB)), and CTB (GO(CTB)) varied between 8.81% and 25.02% (w/w). The highest BC yield was achieved for BWB, followed by FB, MGB, and TB, and the lowest was recorded for WWB (Fig. 1). In this study, 3.30 g of dry BC were produced by GO after 14 days of incubation in 1 L of HS medium at 28 °C–32 °C. In other studies, BC yields were reported as 3.24 g/L from sugar cane juice and pineapple residues with Gluconacetobacter medellinensis [36], 2.67 g/L from discarded waste durian shell with G. xylinus CH001BC [37], 4.81 g/L from banana, 1.95 g/L from mango, 2.37 g/L from whey with Komagataeibacter medellinensis [38], and 1.54%–11.53% (w/w) from various fruit and vegetable wastes with K. hansenii GA2016 [28]. Compared to prior findings, the BC yields from bread wastes were high in this study, demonstrating their BC production potential.

The reducing sugar contents of bread hydrolysates were determined to be 27.91 ± 0.87 g/L (TB), 29.45 ± 0.43 g/L (FB), 21.81 ± 0.77 g/L (CB), 17.37 ± 0.36 g/L (WWB), 23.55 ± 0.53 g/L (RB), 34.98 ± 1.97 g/L (BWB), 26.59 ± 0.39 g/L (MGB), and 18.26 ± 0.24 g/L (CTB). When the effect of reducing sugar contents of bread hydrolysates on BC yield was examined, more BC contents were found to be produced from BWB, FB, TB, and MGB hydrolysates, which have a high reducing sugar content. On the contrary, less BC content was produced from WWB and CTB hydrolysates, which have a lower reducing sugar content.

3.4 BC analysis

3.4.1 Liquid holding capacity and solubility

BC has a complex molecular structure consisting of water molecules bonded through hydrogen bonds. The available surface area and pore size distribution, as well as the presence of hydrophilic additives in the BC, significantly alter liquid holding capacity values. The liquid holding capacity of BCs is crucial, particularly in wound dressings and burn treatment, to maintain wound hydration and enable the absorption of liquid drugs and bioactive compounds onto the dressing material. Liquid holding capacity is a quantitative physical parameter used to evaluate this aspect and depends on the physicochemical and structural characteristics of BCs. BC has a higher water-holding capacity than plant cellulose and commercial microcrystalline cellulose [39]. In addition to the food industry, the use of BCs is increasing in other industries [22]. Therefore, it is important to investigate the ability of BCs to hold water and other liquids. In this study, it was determined that the acetone and acetic acid holding capacities of all BCs were lower than their water and dimethyl sulfoxide holding capacities, in line with previous findings [39, 40]. Specifically, the liquid holding capacity of BCs produced by KH was higher than that of BCs produced by GO, and the acetone holding capacity of the examined BCs was lower than their capacities for other liquids because the hydrogen bonding capacity of acetone is weaker than that of other solvents [39, 41]. Additionally, GO(HS) (664.19) and KH(HS) (609.30) had higher water-holding capacities among the BCs (Table 2).

In previous research, the water-holding capacities of BC were reported to be 90% for BCs produced by Kombucha tea and 70% for commercial crystalline cellulose [39]; 84.4% for BCs produced by Acetobacter xylinum [42]; 118.00% and 313.97% for BCs produced from HS medium and passion fruit peels, respectively, by Komagataeibacter nataicola TISTR 2661 [43]; and between 627.50% and 928.79% for BCs from various fruit and vegetable peels [28]. The current study revealed that the water-holding capacities of BCs from bread hydrolysates were higher than those reported by Goh et al. [39], Gayathry and Gopalaswamy [42], and Moukamnerd [43] but lower than those recorded for fruit and vegetable peels [28].

The solubility of BC depends on various factors, such as its structure, molecular weight, and origin [39]. Although research has been conducted on the solubility and regeneration of BC for more applications in different fields, its further development is impeded by its poor solubility in common solvents. Owing to its high crystallinity, BC has extremely low solubility, which limits its processability. BC is insoluble in most common solvents used in the manufacturing industry, limiting its potential applications in these areas. To date, few solvents have been proven to directly dissolve BC, including lithium chloride/N,N-dimethylacetamide [44], NaOH/urea solution [45, 46], ionic liquids [47], and N-methylmorpholine-N-oxide [48]. However, these solvents pose problems, such as processing costs, health and safety issues due to toxicity, and environmental devastation, and can also adversely change the properties of BC. In this study, all BCs were insoluble in acetone, methanol, diethyl ether, petroleum benzene, hexane, benzene, and isopropyl alcohol, whereas they were partially soluble in cold NaOH (1 M, 30 °C) and soluble in hot NaOH (1 M, 90 °C). Similarly, other studies reported that BCs were soluble in NaOH [28, 45]. The results showed that the solubility of BCs produced from breads was quite low because of their high crystallinity; however, the low solubility of BC provides an advantage in applications where the stability of the material against various gases and liquids is crucial, such as air or water filtration systems.

3.4.2 FT-IR spectrophotometry

The FT-IR spectra of BCs are presented in Fig. 2, and characteristic bands of cellulose (type I) synthesized in different bread hydrolysates nearly appeared at the same wavenumbers, including 3440–3400 cm−1 for hydroxyl groups, 2900–2800 cm−1 for stretching vibrations of methylene, 1640–1620 and 1440–1420 cm−1 for carbonyl groups, and 1068–1040 cm−1 for C–O–C and C-O–H stretching and vibrations [30, 42, 49, 50]. Because two peaks occurred around 1430 and 900 cm−1, we hypothesized that the BC produced by GO mainly consisted of pure cellulose I [39, 51].

FT-IIR spectra of BCs produced by Gluconobacter oxydans MG2021 (GO) and Komagataeibacter hansenii GA2016 (KH) TB, traditional bread; FB, francala bread; CB, corn bread; WWB, whole wheat bread; RB, rye bread; BWB, bread with wheat bran; MGB, multigrain bread; CTB, crispy Turkish bagel; HS, Hestrin–Schramm medium

The band intensities at approximately 3300 cm−1 for GO(CB) and GO(HS) were greater than those of the other BCs. This band is attributed to O–H stretching, indicating an increase in hydrogen interactions [44]. This result is consistent with the SEM images of GO(CB) and GO(HS). In addition, the band around 1430–1420 cm−1 is used to calculate the overall degree of crystallinity of cellulosic materials, whereas the band at 897–893 cm−1 corresponds to the amorphous region in cellulose [18]. Similarly, in the XRD patterns, GO(BWB), GO(MGB), and GO(CTB) had the highest crystallinity, whereas GO(RB) and GO(WWB) had the lowest crystallinity. As expected, the FT-IR spectra of BCs produced from different breads were similar to those of BC produced from HS medium and other media, indicating that the bread variety had little influence on the functional groups of BC products.

3.4.3 Thermal properties

Thermal degradation behavior offers some insights into the structural properties and purity of BCs [52], and the thermal degradation of pure BCs includes two main sites of weight loss caused by dehydration and the subsequent dissociation of glycosyl units [53]. The TG and DTG curves of BCs produced by GO and KH are presented in Fig. 3.

TG and DTG curves and graph of thermal degradation values for BCs produced by Gluconobacter oxydans MG2021 (GO) and Komagataeibacter hansenii GA2016 (KH) TB, traditional bread; FB, francala bread; CB, corn bread; WWB, whole wheat bread; RB, rye bread; BWB, bread with wheat bran; MGB, multigrain bread; CTB, crispy Turkish bagel; HS, Hestrin–Schramm medium

DTGmax is a criterion of thermal stability, and it represents the maximum mass loss rate [54]. This value varied between 280 °C and 338 °C for BCs produced by GO from breads, which exceeded those for BCs in HS medium (280 °C, excluding GO(CTB)). Among BCs, GO(FB) and GO(TB) had the highest values and GO(CTB) and GO(MGB) had the lowest values. The DTGmax of KH(FB) was determined to be at 320 °C (Fig. 3). T50% denotes the time at which BC mass weight loss reaches 50%. This value varied between 333 °C and 529 °C for BCs produced with GO, compared to 338 °C for BC produced by KH. The mass losses of BCs produced by GO were 52%–68% at 650 °C. The value was 59% for GO(HS), whereas the rate was high (81%) for KH(FB). GO(BWB) and GO(CTB) had low mass losses (52% and 60%, respectively) at this temperature (Fig. 3). In other studies, DTGmax was determined to be 330 °C–370 °C for BC from Nata de Coco; 370 °C for BC produced by Acetobacter xylinum [30]; 355 °C, 327 °C, and 368 °C for BCs produced by Komagataeibacter medellinensis from banana, mango, and whey, respectively [38]; and 228 °C–359 °C for BCs from citrus peels [55]. When the mass losses at 650 °C, T50%, and DTGmax were compared in our study, BCs from breads had high thermal stability and BCs produced by GO had higher stability than those produced by KH. In particular, the thermal stability of GO(BWB) was considerably higher than that of the other BCs. Crystallinity affects the thermal properties of biomass [56, 57]. This confirmed that GO(BWB), which had the highest crystallinity, also had the highest thermal stability. Flame-retardant BCs with high thermal stability can be used to make fire-resistant paper, thereby improving the physical properties of the paper [58].

3.4.4 Morphological microstructures

Morphological studies of BCs produced from bread varieties by GO and KH were performed using SEM at × 30,000, × 50,000, and × 100,000 magnifications (Fig. 4). The structures of BC films were formed by the intertwining of cellulose fibrils into a 3D structure, and the pellicle structures of the BC membrane were arranged in rod-shaped nanofibers. The morphological structures of the BCs in this study were similar to those of BCs in other studies [39, 43, 59, 60], and GO(FB), GO(CB), GO(HS), and KH(HS) membranes had more noticeable aggregates with lower porosity.

Scanning electron micrographs and the average BC fiber diameters produced by Gluconobacter oxydans MG2021 (GO) and Komagataeibacter hansenii GA2016 (KH) TB, traditional bread; FB, francala bread; CB, corn bread; WWB, whole wheat bread; RB, rye bread; BWB, bread with wheat bran; MGB, multigrain bread; CTB, crispy Turkish bagel; HS, Hestrin–Schramm medium. 30, × 30,000; 50, × 50,000; 100, × 100,000

It was determined that the mean fiber diameters of BCs produced by GO from bread samples varied between 40.16 nm and 85.39 nm, and the values for KH(FB) and KH(HS) were 64.59 and 77.53 nm, respectively (Fig. 4). Thinner fiber diameters provide some advantages to BCs, such as improved water-holding capacity, thermal stability, and mechanical strength [56]. In this study, BCs produced from breads had thinner fiber diameters than those produced in HS medium by both GO and KH. GO(TB) had the thinnest fiber diameter, and it was substantially lower than those of other BCs. Similarly, in this study, the thermal stability of BCs from bread hydrolysates had higher thermal stability than KH(HS), and GO(TB), which had the thinnest fiber diameter and a higher water-holding capacity than BCs produced from other bread varieties by GO.

3.4.5 XRD

Crystallinity affects the physical, mechanical, chemical, and morphological properties of cellulose, and it is helpful for better understanding the macro-characteristics and performance (such as strength, moisture absorption capacity, and water-holding capacity of the BCs). Cellulose microfibrils are composed of regular (crystalline) and less regular (amorphous) regions, whereas sharp diffraction peaks occur in the crystal part of XRD and scattered peaks occur in the amorphous part of the material [61]. The XRD patterns of BCs produced via bread hydrolysis exhibited three main peaks at 2θ angles of approximately 14.5°, 16.7°, and 22.7°, which indicated that BCs had typical crystalline forms of cellulose I [62], and the higher intensity of 14.5° peaks than that of 16.7° peaks for BCs produced by GO indicated that they mostly contained cellulose Iα [63] (Fig. 5).

X-Ray diffractograms and crystallinity of BCs produced by Gluconobacter oxydans MG2021 (GO) and Komagataeibacter hansenii GA2016 (KH) TB, traditional bread; FB, francala bread; CB, corn bread; WWB, whole wheat bread; RB, rye bread; BWB, bread with wheat bran; MGB, multigrain bread; CTB, crispy Turkish bagel; HS, Hestrin–Schramm medium

The degree of crystallinity (%) was calculated using the curve-fitting method, and these values varied between 75.96% and 91.39% for BCs produced by GO. The highest values were recorded for GO(BWB), GO(MGB), and GO(CTB) (Fig. 5). Many factors such as the cultivation method [64], carbon sources [65], pH [66], agitation speed [67], temperature [68], fermentation time [66], and drying methods [69] affect the crystallinity of BCs. In prior studies, the crystallinities were 85.8% for BCs produced by Gluconacetobacter xylinus, 84.5% for BCs produced from HS medium [70], 74% for BCs produced from pineapple peel wastes [71] and 65%–83% for commercial microcrystalline cellulose [39, 72, 73]. Compared with the literature, the crystallinities of BCs produced from breads were high and the results were compatible with the existing studies.

4 Conclusions

This study aimed to investigate the BC production potential of various stale breads widely produced and consumed in Turkey, convert these wastes into usable forms for food and other industries, and increase their economic value. The results illustrated that stale bread varieties were good sources for BC production. The study also demonstrated that bread hydrolysates provided nutrients for bacterial growth. Meanwhile, bread hydrolysates supported the production of high-yield BCs, and the properties of BCs were similar to those of commercial BCs. High BC yields were obtained using GO (8.81%–25.02%). Among the bread varieties, BC produced from BWB had the highest yield, thermal stability, and acetic acid holding capacity, whereas KH(FB) and GO(TB) had the highest water-holding capacity. All BCs had superior properties such as high crystallinity (75.96%–91.39%), thermal stability, liquid holding capacity, and fine fibers (40.16–85.39 nm). Although BC has superior properties compared to plant cellulose, high costs and low yields hinder the large-scale commercial production of BC. Utilizing stale bread as the sole substrate for BC production is the novelty of the study. This approach is crucial in terms of solving the problem of bread waste management and reducing the cost of producing valuable BC material. In addition, due to the production of BC with superior properties (such as crystallinity, liquid holding capacity, and thermal stability) compared to other bread wastes such as those from BWB, FB, and TB, these bread wastes are suggested as suitable substrates for BC production across different industrial areas (such as food, advanced acoustic diaphragms, biosensors, tissue scaffolds, packaging, protective coatings, antimicrobial materials, and flexible electronics). The high cost of traditional BC production limits the use of the polymer in the industry. For the widespread use of BC, cheap and sustainable carbon sources are needed for BC production. As a result of the study, it was determined that various bread wastes, which have no economic value as waste, have the potential to be important substrate sources for BC production. Reducing the production cost has the potential to enable the wide use of BC in the mentioned industrial areas. This study demonstrated that bread wastes could be used as a low-cost substrate for large-scale BC production, and the availability of large amounts of bread wastes demonstrated their potential as a source for commercial BC producers. Further studies are needed to develop optimized bread hydrolysates to increase the yields and production capacity of BCs, determine the most suitable culture conditions, investigate the effect of the composition of bread hydrolysates on BC production, and calculate the production cost. Addressing these aspects could further enhance the significance and applicability of the research findings and is especially important in ensuring commercial BC production from these wastes.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Food and agriculture organization of the united nations (2022) Technical platform on the measurement and reduction of food loss and waste. https://www.fao.org/food-loss-and-food-waste/en/. Accessed 30 Nov 2022

Plazzotta S, Cottes M, Simeoni P, Manzocco L (2020) Evaluating the environmental and economic impact of fruit and vegetable waste valorisation: the lettuce waste study-case. J Clean Prod 262:121435. https://doi.org/10.1016/j.jclepro.2020.121435

Arora J, Ramawat KG, Mérillon JM (2023) Disposal of agricultural waste and ıts effects on the environment, production of useful metabolites and energy: potential and challenges. In: Ramawat K, Mérillon JM, Arora J (eds) Agricultural waste: environmental impact, useful metabolites and energy production. Sustainable development and biodiversity. Springer, Singapore, pp 3–20 https://doi.org/10.1007/978-981-19-8774-8_1

Narisetty V, Cox R, Willoughby N, Aktas E, Tiwari B, Matharu AS, Salonitis K, Kumar V (2021) Recycling bread waste into chemical building blocks using a circular biorefining approach. Sustain Energy Fuels 5:4842–4849. https://doi.org/10.1039/D1SE00575H

Fogliano V, Morales FJ (2011) Estimation of dietary intake of melanoidins from coffee and bread. Food Funct 2:117–123. https://doi.org/10.1039/c0fo00156b

O’Connor Á (2012) Bread consumption in the UK: what are the main attitudinal factors affecting current intake and its place in a healthy diet? Nutr Bull 37:368–379. https://doi.org/10.1111/j.1467-3010.2012.01989.x

Malakootian M, Dowlatshahi SH, Malakootian M (2005) The quality of the manufactured bread and hygienic conditions of bakeries. Iran J Environ Health Sci Eng 2:72–78

Toprak mahsulleri ofisi genel mudurlugu (2013) Bread waste research in Turkey. https://www.tmo.gov.tr/Upload/Document/Kampanya/ArastirmaKitabi.pdf. Accessed 13 Mar 2022

Türkiye israf raporu (2018) Turkey waste report. https://tuketici.ticaret.gov.tr/data/5e6b33e913b876e4200a0101/Turkiye_Israf_Raporu_2018.pdf. Accessed 25 Mar 2022

Matrawy AA, Khalil AI, Embaby AM (2023) Bioconversion of bread waste by marine psychrotolerant Glutamicibacter soli strain AM6 to a value-added product: cold-adapted, salt-tolerant, and detergent-stable α-amylase (CA-AM21). Biomass Conv Bioref 13:12125–12142. https://doi.org/10.1007/s13399-022-02325-3

Oda Y, Park B, Moon KH, Tonomura K (1997) Recycling of bakery wastes using an amylolytic lactic acid bacterium. Bioresour Technol 60:101–106. https://doi.org/10.1016/S0960-8524(97)00008-4

Daigle P, Gélinas P, Leblanc D, Morin A (1999) Production of aroma compounds by Geotrichum candidum on waste bread crumb. Food Microbiol 16:517–522. https://doi.org/10.1006/fmic.1999.0269

Ebrahimi F, Khanahmadi M, Roodpeyma S, Taherzadeh MJ (2008) Ethanol production from bread residues. Biomass Bioenergy 32:333–337. https://doi.org/10.1016/j.biombioe.2007.10.007

Doi T, Matsumoto H, Abe J, Morita S (2009) Feasibility study on the application of rhizosphere microflora of rice for the biohydrogen production from wasted bread. Int Hydrog Energy 34:1735–1743. https://doi.org/10.1016/j.ijhydene.2008.12.060

Kim JH, Lee JC, Pak D (2011) Feasibility of producing ethanol from food waste. Waste Manag 31:2121–2125. https://doi.org/10.1016/j.wasman.2011.04.011

Yan S, Li J, Chen X, Wu J, Wang P, Ye J, Yao J (2011) Enzymatical hydrolysis of food waste and ethanol production from the hydrolysate. Renew Energy 36:1259–1265. https://doi.org/10.1016/j.renene.2010.08.020

Zhang AY, Sun Z, Leung CCJ, Han W, Lau KY, Li M, Lin CSK (2013) Valorisation of bakery waste for succinic acid production. Green Chem 15:690–695. https://doi.org/10.1039/C2GC36518A

Khan H, Kadam A, Dutt D (2020) Studies on bacterial cellulose produced by a novel strain of Lactobacillus genus. Carbohydr Polym 229:115513. https://doi.org/10.1016/j.carbpol.2019.115513

Ganapathy V, Muthukumaran G, Sudhagar PE, Rashedi A, Norrrahim MNF, Ilyas RA, Goh KL, Jawaid M, Naveen J (2023) Mechanical properties of cellulose-based multiscale composites: a review. Polym Compos 44:734–756. https://doi.org/10.1002/pc.27175

Volova TG, Prudnikova SV, Kiselev EG, Nemtsev IV, Vasiliev AD, Kuzmin AP, Shishatskaya EI (2022) Bacterial cellulose (bc) and bc composites: production and properties. Nanomaterials (Basel) 12:192. https://doi.org/10.3390/nano12020192

Janmohammadi M, Nazemi Z, Salehi AOM, Seyfoori A, John JV, Nourbakhsh MS, Akbari M (2023) Cellulose-based composite scaffolds for bone tissue engineering and localized drug delivery. Bioact Mater 20:137–163. https://doi.org/10.1016/j.bioactmat.2022.05.018

Salari M, Sowti Khiabani M, Rezaei Mokarram R, Ghanbarzadeh B, Samadi Kafil H (2019) Preparation and characterization of cellulose nanocrystals from bacterial cellulose produced in sugar beet molasses and cheese whey media. Int J Biol Macromol 122:280–288. https://doi.org/10.1016/j.ijbiomac.2018.10.136

Hussain Z, Sajjad W, Khan T, Wahid F (2019) Production of bacterial cellulose from industrial wastes: a review. Cellulose 26:2895–2911. https://doi.org/10.1007/s10570-019-02307-1

Güzel M, Akpınar Ö (2017) Komagataeibacter hansenii GA2016 ile bakteriyel selüloz üretimi ve karakterizasyonu. J Food 42:620–633. https://doi.org/10.15237/gida.GD17040

AOAC (2005) Official methods of analysis of the association of analytical chemists international. Official methods: Gaithersburg, MD, USA

Aydın YA, Aksoy ND (2013) Çeşitli gıda atıklarından selüloz üreten asetik asit bakterilerinin izolasyonu ve tanımlanması. J Turk Microbiol Soc 43:26–35. https://doi.org/10.5222/TMCD.2013.026

National library of medicine (2022) Basic local alignment search tool. http://www.ncbi.nlm.nih.gov/blast/. Accessed 5 May 2022

Güzel M, Akpınar Ö (2020) Preparation and characterization of bacterial cellulose produced from fruit and vegetable peels by Komagataeibacter hansenii GA2016. Int J Biol Macromol 162:1597–1604. https://doi.org/10.1016/j.ijbiomac.2020.08.049

Son C, Chung S, Lee J, Kim S (2002) Isolation and cultivation characteristics of Acetobacter xylinum KJ-1 producing bacterial cellulose in shaking cultures. J Microbiol Biotechnol 12:722–728

Halib N, Amin MC, Ahmad I (2012) Physicochemical properties and characterization of nata de coco from local food industries as a source of cellulose. Sains Malays 41:205–211

Technical Association of Pulp and Paper Industry (Tappi) (2011) Tappi useful method UM 256: water retention value (WRV). Tappi Press, Atlanta

Hermans PH, Weidinger A (1948) Quantitative x-ray investigations on the crystallinity of cellulose fibers. A background analysis. J Appl Phys 19:491–506. https://doi.org/10.1063/1.1698162

Fang L, Catchmark JM (2014) Characterization of water-soluble exopolysaccharides from Gluconacetobacter xylinus and their impacts on bacterial cellulose crystallization and ribbon assembly. Cellulose 21:3965–3978. https://doi.org/10.1007/s10570-014-0443-8

Jia S, Ou H, Chen G, Choi D, Cho K, Okabe M, Cha WS (2004) Cellulose production from Gluconobacter oxydans TQ-B2. Biotechnol Bioprocess Eng 9:166–170. https://doi.org/10.1007/BF02942287

Neera N, Ramana KV, Batra HV (2015) Occurrence of cellulose-producing Gluconacetobacter spp. In fruit samples and kombucha tea, and production of the biopolymer. Appl Biochem Biotechnol 176:1162–1173. https://doi.org/10.1007/s12010-015-1637-8

Algar I, Fernandes SCM, Mondragon G, Castro C, Garcia-Astrain C, Gabilondo N, Retegi A, Eceiza A (2015) Pineapple agroindustrial residues for the production of high value bacterial cellulose with different morphologies. J Appl Polym Sci 132:41237. https://doi.org/10.1002/app.41237

Luo MT, Zhao C, Huang C, Chen XF, Huang QL, Qi GX, Tian LL, Xiong L, Li HL, Chen XD (2017) Efficient using durian shell hydrolysate as low-cost substrate for bacterial cellulose production by Gluconacetobacter xylinus. Indian J Microbiol 57:393–399. https://doi.org/10.1007/s12088-017-0681-1

Molina-Ramírez C, Castro C, Zuluaga R, Gañán PF (2018) Physical characterization of bacterial cellulose produced by Komagataeibacter medellinensis using food supply chain waste and agricultural by-products as alternative low-cost feedstocks. J Polym Environ 26:830–837. https://doi.org/10.1007/S10924-017-0993-6

Goh WN, Rosma A, Kaur BJ, Fazilah A, Karim AA, Bhat R (2012) Microstructure and physical properties of microbial cellulose produced during fermentation of black tea broth (kombucha). II. Int Food Res J 19:153–158

Mantanis GI, Young RA, Rowell RM (1995) Swelling of compressed cellulose fiber webs in organic liquids. Cellulose 2:1–22. https://doi.org/10.1007/BF00812768

Robertson AA (1964) Cellulose-liquid interactions. Pulp Pap Mag Can 65:171–178

Gayathry G, Gopalaswamy G (2014) Production and characterisation of microbial cellulosic fibre from Acetobacter xylinum. Ind J Fib Text Res 39:93–96

Moukamnerd C, Ounmuang K, Konboa N, Insomphun C (2020) Bacterial cellulose production by Komagataeibacter nataicola TISTR 2661 by agro-waste as a carbon source. Chiang Mai J Sci 47:16–27

Chen P, Kim H, Kwon S, Yun YS, Jin H (2009) Regenerated bacterial cellulose/multi-walled carbon nanotubes composite fibers prepared by wet-spinning. Curr Appl Phys 9:e96–e99. https://doi.org/10.1016/j.cap.2008.12.038

Laszkiewicz B (1998) Solubility of bacterial cellulose and its structural properties. J Appl Polym Sci 67:1871–1876. https://doi.org/10.1002/(SICI)1097-4628(19980314)67:11%3c1871::AID-APP5%3e3.0.CO;2-I

Phisalaphong M, Suwanmajo T, Sangtherapitikul P (2008) Novel nanoporous membranes from regenerated bacterial cellulose. J Appl Polym Sci 107:292–299. https://doi.org/10.1002/app.27118

Chen P, Cho SY, Jin HJ (2010) Modification and applications of bacterial celluloses in polymer science. Macromol Res 18:309–320. https://doi.org/10.1007/s13233-010-0404-5

Gao Q, Shen X, Lu X (2011) Regenerated bacterial cellulose fibers prepared by the NMMO, H2O process. Carbohydr Polym 83:1253–1256. https://doi.org/10.1016/j.carbpol.2010.09.029

Gao C, Yan T, Du J, He F, Luo H, Wan Y (2014) Introduction of broad spectrum antibacterial properties to bacterial cellulose nanofibers via immobilising ε-polylysine nanocoatings. Food Hydrocoll 36:204–211. https://doi.org/10.1016/j.foodhyd.2013.09.015

Wang SS, Han YH, Ye YX, Shi XX, Xiang P, Chen DL, Li M (2017) Physicochemical characterization of high-quality bacterial cellulose produced by Komagataeibacter sp. strain W1 and identification of the associated genes in bacterial cellulose production. RSC Adv 7:45145–45155. https://doi.org/10.1039/C7RA08391B

Feng X, Ullah N, Wang X, Sun X, Li C, Bai Y, Chen L, Li Z (2015) Characterization of bacterial cellulose by Gluconacetobacter hansenii cgmcc 3917. J Food Sci 80:E2217–E2227. https://doi.org/10.1111/1750-3841.13010

Vazquez A, Foresti ML, Cerrutti P, Galvagno M (2013) Bacterial cellulose from simple and low cost production media by Gluconacetobacter xylinus. J Polym Environ 21:545–554. https://doi.org/10.1007/s10924-012-0541-3

Khattak WA, Khan T, Ul-Islam M, Wahid F, Park JK (2015) Production, characterization and physico-mechanical properties of bacterial cellulose from industrial wastes. J Polym Environ 23:45–53. https://doi.org/10.1007/s10924-014-0663-x

Tan W, Zhang J, Zhao X, Li Q, Dong F, Guo Z (2020) Preparation and physicochemical properties of antioxidant chitosan ascorbate/methylcellulose composite films. Int J Biol Macromol 146:53–61. https://doi.org/10.1016/j.ijbiomac.2019.12.044

Güzel M, Akpınar Ö (2019) Production and characterization of bacterial cellulose from citrus peels. Waste Biomass Valor 10:2165–2175. https://doi.org/10.1007/s12649-018-0241-x

Cheng KC, Catchmark JM, Demirci A (2009) Effect of different additives on bacterial cellulose production by Acetobacter xylinum and analysis of material property. Cellulose 16:1033–1045. https://doi.org/10.1007/s10570-009-9346-5

Cai Z, Kim J (2010) Bacterial cellulose/poly(ethylene glycol) composite: characterization and first evaluation of biocompatibility. Cellulose 17:83–91. https://doi.org/10.1007/s10570-009-9362-5

Basta AH, El-Saied H (2009) Performance of improved bacterial cellulose application in the production of functional paper. J Appl Microbiol 107:2098–2107. https://doi.org/10.1111/j.1365-2672.2009.04467.x

Zhao H, Xia J, Wang J, Yan X, Wang C, Lei T, Xian M, Zhang H (2018) Production of bacterial cellulose using polysaccharide fermentation wastewater as inexpensive nutrient sources. Biotechnol Biotechnol Equip 32:350–356. https://doi.org/10.1080/13102818.2017.1418673

Andriani D, Apriyana AY, Karina M (2020) The optimization of bacterial cellulose production and its applications: a review. Cellulose 27:6747–6766. https://doi.org/10.1007/s10570-020-03273-9

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Pacheco G, Nogueira CR, Meneguin AB, Trovatti E, Silva MCC, Machado RTA, Ribeiro SJL, da Silva Filho EC, Barud HD (2017) Development and characterization of bacterial cellulose produced by cashew tree residues as alternative carbon source. Ind Crops Prod 107:13–19. https://doi.org/10.1016/j.indcrop.2017.05.026

Tokoh C, Takabe K, Fujita M, Saiki H (1998) Cellulose synthesized by Acetobacter xylinum in the presence of acetyl glucomannan. Cellulose 5:249–261. https://doi.org/10.1023/A:1009211927183

Goelzer FDE, Faria-Tischer PCS, Vitorino JC, Sierakowski M-R, Tischer CA (2009) Production and characterization of nanospheres of bacterial cellulose from Acetobacter xylinum from processed rice bark. Mater Sci Eng C 29:546–551. https://doi.org/10.1016/j.msec.2008.10.013

Miyamoto H, Tsuduki M, Ago M, Yamane C, Ueda M, Okajima K (2014) Influence of dyestuffs on the crystallinity of a bacterial cellulose and a regenerated cellulose. Text Res J 84:1147–1158. https://doi.org/10.1177/0040517513517960

Dahman Y (2009) Nanostructured biomaterials and biocomposites from bacterial cellulose nanofibers. J Nanosci Nanotechnol 9:5105–5122. https://doi.org/10.1166/jnn.2009.1466

Czaja W, Romanovicz D, Rm B (2004) Structural investigations of microbial cellulose produced in stationary and agitated culture. Cellulose 11:403–411. https://doi.org/10.1023/B:CELL.0000046412.11983.61

Hirai A, Tsuji M, Horii F (1997) Culture conditions producing structure entities composed of cellulose I and II in bacterial cellulose. Cellulose 4:239–245. https://doi.org/10.1023/A:1018439907396

Hamid NIA, Khairuddin N, Zahan KA, Seng KF, Siddique BM, Muhamad II (2014) Effect of different drying methods on the morphology, crystallinity, swelling ability and tensile properties of Nata de Coco Pa’e N. Sains Malays 43:767–773

He F, Yang H, Zeng L, Hu H, Hu C (2020) Production and characterization of bacterial cellulose obtained by Gluconacetobacter xylinus utilizing the by-products from baijiu production. Bioprocess Biosyst Eng 43:927–936. https://doi.org/10.1007/s00449-020-02289-6

Anwar B, Bundjali B, Sunarya Y, Arcana IM (2021) Properties of bacterial cellulose and its nanocrystalline obtained from pineapple peel waste juice. Fibers Polym 22:1228–1236. https://doi.org/10.1007/s12221-021-0765-8

Leppänen K, Andersson S, Torkkeli M, Knaapila M, Kotelnikova N, Serimaa R (2009) Structure of cellulose and microcrystalline cellulose from various wood species, cotton and flax studied by x-ray scattering. Cellulose 16:999–1015. https://doi.org/10.1007/s10570-009-9298-9

Nada AMA, El-Kady MY, El-Sayed ES, Amine FM (2009) Preparation and characterization of microcrystalline cellulose (MCC). BioResour 4:1359–1371. https://doi.org/10.1016/j.carbpol.2017.12.024

Acknowledgements

I thank the Gümüşhane University Scientific Research Projects Coordination Department for financially supporting this manuscript.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This study was supported by the Gümüşhane University Scientific Research Projects Coordination Department. Project Number: 19.B0433.03.01.

Author information

Authors and Affiliations

Contributions

The author confirms sole responsibility for the following: study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

Corresponding author

Ethics declarations

Research Involving Human Participants and/or Animals

Not applicable.

Informed Consent

Not applicable.

Conflicts of Interest

The author declares that he has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Güzel, M. Valorisation of bread wastes via the bacterial cellulose production. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05662-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05662-7