Abstract

The rising population and increasing demand for food place added pressure on the agricultural sector to maintain high process efficiency while implementing environmentally friendly methods. In this study, we investigate the effect of pre-hydrolysis of native rye starch and its influence on the yield of ethanol obtained by simultaneous saccharification and fermentation (SSF) from high gravity rye mashes with 25% and 28% w w−1 dry matter content. Fermentation was carried out in a 3-day system at a temperature of 35 ± 1 °C using the dry distillery yeast Ethanol Red (Saccharomyces cerevisiae). The characteristics of the tested raw material and changes in the native rye starch during enzymatic hydrolysis were analyzed using a scanning electron microscope (SEM). The SEM images revealed characteristic changes on the surface of the starch, which was found to have a layered structure, as well as interesting behavior by the yeast during SSF when the glucose concentration in the environment was lowered. Both in the mashes with 25% and 28% w w−1 dry matter, starch pre-hydrolysis did not significantly increase either the initial amounts of sugars available to the yeast or the fermentation efficiency and ethanol yield in comparison to the mashes without this pre-treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Starch is an important, common, and cost-effective renewable biopolymer. It is the main source of carbohydrates in human food and a specific energy store used for plant regeneration. In its natural (native) form, granular starch is present in most cereal seeds and tuber roots (Yazid et al. 2018). Starches of different origin may differ in terms of their granular morphology (size, shape, presence or absence of pores, channels, and cavities), molecular structure (amylose and amylopectin structures), the ratio of amylose to amylopectin, and the content of non-starch components. The differences in morphology and structure of starches from different raw materials affect their properties, such as X-ray diffraction patterns, gelatinization temperature range, gel properties, retrogradation tendencies, granule swelling power and pattern, and others (Chen 2003; Hsieh et al. 2020; Zhang et al. 2016).

Wheat, triticale, barley, and rye starches have bimodal size distributions. The larger (A) granules are a disk shape, whereas the small (B) granules have a spherical shape (Jane et al. 1994; Strąk-Graczyk et al. 2019). Rye starches have A-type granules with average particle sizes of 31 μm, whereas wheat starch has lower levels of A-type granules, with an average particle size of 26 μm. When compared pairwise to the rye starches, wheat starches have higher gelatinization temperatures, higher pasting temperature, higher peak viscosity, and lower end viscosity (Verwimp et al. 2004). The lower gelatinization temperatures and tendency of rye starches to retrograde may be explained by their larger numbers of short amylopectin (AP) chains (degree of polymerization (DP) 6–12) and lower numbers of longer chains (DP 13–24) than those observed for wheat starch. The differences in peak and end viscosities revealed by rapid visco-analysis between rye starches as well as between rye and wheat starches are at least partly attributable to differences in the numbers of AP short chains and the average molecular weight of amylose. The AP average chain lengths and exterior chain lengths are slightly lower for rye starches, while the interior chain lengths are slightly higher than those for wheat starch (Gomand et al. 2011). A study by Zhang et al. (2018) showed that the amylose of the high-amylose jackfruit cultivar (M1) and the amylopectin of the high-amylopectin cultivar (BD) have more compact structures than in other starches. The different properties of starches from various raw materials account for their usefulness in the food industry.

The production of spirit beverages from starchy raw materials has been practiced for centuries. The distillery industry creates its products largely from fermented cereal mashes. Spirit drinks are known and appreciated all over the world due to their taste and aroma values (Poel et al. 2010). Depending on the region, distilleries may use mainly corn, wheat, rice, tapioca, or sweet potato as raw materials (Wadhwa and Bakshi 2016). Usually, local crops and suppliers are chosen, due to cost benefits. For instance, in Great Britain (mainly in Scotland), barley is used for malt whisky production, whereas in North America, corn and rye are used to make whiskey (Rosentrater and Evers 2018). Rye is used in the production of whiskey due to its taste properties. Raw spirit obtained from corn has the poorest volatile profile compared with rye or triticale and others (Biernacka and Wardencki 2012). The spirits industry supplies its products to many other sectors, making it an important player in the economy. The distillery industry strives to achieve the highest possible ethanol yield from the raw material, while taking into account environmental and social considerations. This includes making every effort to improve energy efficiency and reduce waste, in line with European Union legislation (The European Parliament and the Council of the European. Directive (2008/1/EC) 2008).

The type of raw material used to produce ethyl alcohol is a crucial factor. In addition to organoleptic values, parameters such as price, availability, and quality are important. Expensive raw materials requiring long transportation increase the overall costs of distillate production. However, the quality of the raw material affects many more process factors. Such factors include contaminants (e.g., soil) which introduce additional sources of microbial contamination, and too high humidity which deteriorates the storage parameters (encouraging the development of mold and fungi). They may even lead to a reduction in the starch content of the raw material (Szymanowska-Powałowska et al. 2014). For the spirits industry, starch content is the most important indicator of the suitability of a raw material, because all spirit production aims to maximize output per unit. High-starch raw materials are rich sources of sugar for fermentation. Cereal starch consists of two factions, linear amylose (15–30%) and branched amylopectin (70–85%). Amylose has been shown to have a significant role in the initial resistance of native starch granules to swelling and solubility, which is attributed to the formation of complexes with lipids that prevent amylose leaching and, as a consequence, reduce the swelling capacity (Alcázar-Alay and Meireles 2015).

Much of the research (Montesinos and Navarro 2000; Shigechi et al. 2004; Pielech-Przybylska et al. 2017) on spirit production described in the literature focuses on reducing water and energy consumption. Each stage of the process is analyzed, so that the final product maintains its quality and process costs are reduced, while maintaining high efficiency. Biotechnology has contributed significantly to the development of environmentally friendly practices in the food and spirits industries. The introduction of pressureless liberation of starch (PLS) (Pielech-Przybylska et al. 2017) as an alternative to the pressure-thermal method (Kelsall and Lyons 2003), in combination with simultaneous saccharification and fermentation (SSF) and the development of newer enzymes, was an important advance in distillery technology.

Another important step was the development of granular starch hydrolyzing enzymes (GSHE). An advantage of these enzymes is their ability to perform continuous saccharification, including during fermentation. Such enzymes are highly active from the moment they are introduced into the mash and, thanks to synergistic cooperation, generate simple sugars which are fermented on a stable basis (Szymanowska-Powalowska et al. 2012). This prevents the accumulation of glucose in the fermentation medium, high concentrations of which cause osmotic stress, in turn inhibiting the activity of yeast. It is also possible to work with mashes that have higher dry matter contents (> 18% w w−1), thereby saving water. Progress in the field of fermentation technologies has allowed the development of a native starch hydrolysis method which, in combination with SSF technology, simplifies technological operations, lowers energy consumption, reduces the amount of water used (very high gravity mashes, VHG) (Wang et al. 1998), and in turn reduces the amount of wastewater produced. This is possible thanks to the use of specialized enzymes, with high hydrolytic activity at temperatures below the temperature of starch gelatinization (demonstrating the ability to hydrolyze native starch). The hydrolysis of native starch assumes that catalysis of the reaction occurs through adsorption of the enzyme on the surface of the starch grain and penetration within its channels and from there inside the grain (Shariffa et al. 2009). Research on the hydrolysis of native starch is an area of strong research interest, with many new studies published each year. However, there have been only a few pilot plants and industrial applications in the distilling industry.

Raw (native) starch-digesting glucoamylases are capable of directly hydrolyzing raw starch to glucose at low temperatures. This significantly simplifies processing and reduces the cost of producing starch-based products. In one study, raw corn flour and raw cassava flour were used as fermentation substrates to investigate the SSF of raw starch to ethanol by rPoGA15A α-amylase, a novel raw starch-digesting glucoamylase with high enzymatic activity, which was purified from Penicillium oxalicum GXU20. The results of the study showed that raw corn starch was rapidly hydrolyzed after 12 h, and the amount of glucose produced in the mixture increased significantly. A high fermentation efficiency of 95.1% was obtained, and the residual starch (less than 0.2% w v−1) and glucose concentrations (less than 0.1% w v−1) were extremely low after 48 h, indicating that the SSF of raw corn flour to ethanol was very rapid and efficient (Xu et al. 2016).

The most difficult stage in the efficient conversion of granular starch into ethanol is the enzymatic hydrolysis of starch granules. They key factors are the supramolecular structure, crystallinity, and presence of complexing agents (Szymanowska-Powalowska et al. 2012). The effect of heat treatment below the gelatinization temperature on the susceptibility of corn, mung bean, sago, and potato starches towards granular starch hydrolysis (35 °C) has been investigated by Uthumporn et al. (2012). The starches were hydrolyzed in granular state and, after heat treatment (50 °C for 30 min), using granular starch hydrolyzing enzyme for 24 h. The hydrolyzed heat-treated starches showed a significant increase in the percentage of dextrose equivalent compared to the native starches. Scanning electron microscopy micrographs showed the presence of more porous granules and surface erosion in heat-treated starch compared with native starch. X-ray analysis showed no changes, but sharper peaks for all the starches suggested that hydrolysis occurred in the amorphous region. The amylose content and swelling power of the heat-treated starches was markedly altered by hydrolysis. Evidently, the enzyme was able to hydrolyze granular starches and heat treatment before hydrolysis significantly increased the degree of hydrolysis. In turn, Shariffa et al. (2017) studied the hydrolysis of native and annealed tapioca and sweet potato starches at sub-gelatinization temperature, using a mixture of amylolytic enzymes. Scanning electron microscopy micrographs revealed more porous granules and rougher surfaces in the case of the annealed starches compared to their native counterparts. The swelling power and solubility of annealed starches decreased significantly. Annealing was found to affect the pasting properties of the starches appreciably and increased the starch gelatinization temperature. The amylose content in hydrolyzed annealed starches increased, while no significant changes were observed in the X-ray diffraction. This study proved therefore that annealing treatment may be used as a way of increasing the degree of hydrolysis of tapioca and sweet potato starches at sub-gelatinization temperatures, using a raw starch hydrolyzing enzyme.

A producer of native starch hydrolyzing enzyme preparations used in ethanol production recommends the “activation” (i.e., pre-hydrolysis) of starch. A mixture of milled cereal grain and water (or hot plant effluents such as condensates or thin stillage) is heated to a temperature bellow starch gelatinization (for instance to 49–51 °C for rye grains) to improve the hydration of milled grains. It is then treated with acid alpha amylase to activate the starch granules (DuPont 2012). However, Balcerek and Pielech-Przybylska (2013) observed that the activation of triticale starch with acid α-amylase at elevated temperature (not exceeding gelatinization temperature) is not necessary for efficient saccharification and fermentation.

Another method of physically modifying starch is ultrasonication, which leads to effective water diffusivity, the sponge effect, the formation of microscopic channels, and forced heat and mass transfer (Cheng et al. 2014). Starch modifications can improve the hydrolysis efficiency, which can result in an increase in the ethanol yield from the raw material. The suitability of ultrasonication for pre-gelatinization and the physicochemical properties of wheat and tapioca starches were investigated by Abedi et al. (2019). Their results showed that the swelling and solubility of ultrasound-assisted pregelatinized starch increased as a function of the power, temperature, and time of treatment. This increase was probably due to the destruction, disorganization, and reduction of the degree of crystallinity in the starch granules. Pietrzak and Kawa-Rygielska (2014) observed that sonication improved the effectiveness of waste bread starch hydrolysis and fermentation efficiency.

The present study investigates how the pre-hydrolysis of native starch affects the yield of ethanol obtained by SSF from high gravity rye mashes with 25% and 28% w w−1 dry matter (d.m.). The characteristics of the rye native grain and the progress of hydrolysis of the native starch during the SSF process were also examined, using scanning electron microscopy (SEM).

Materials and Methods

Materials

Rye grains from the Dańkowskie Amber cultivar (cv.) (Danko Plant Breeding Ltd., Poland) were used for the mash preparation. The resulting rye middlings after grinding were characterized by the following particle size distributions: < 0.25 mm—49.4%, < 0.6 mm—37.8%, and > 0.6 mm—12.9%. Pre-hydrolysis of the native starch was carried out using the enzyme preparation GC 626 containing the acid α-amylase (EC 3.2.1.1), derived from Trichoderma reesei. The main hydrolysis of native starch was conducted using the enzymatic preparation Stargen 002®, containing a blend of α-amylase (EC 3.2.1.1) from Aspergillus kawachi, expressed in Trichoderma reesei), and glucoamylase (EC 3.2.1.3), from Trichoderma reesei. All the enzyme preparations were purchased from DuPont™ Genencor® Science (USA). According to the manufacturer, the enzymatic activities of the preparations are as follows: GC 626—≥ 10,000 SSU g−1, Stargen™ 002 ≥ 570 GAU g−1. SSU, the soluble starch unit, is the amount of enzyme that will liberate 1 mg of reducing sugars, calculated as glucose minute, from the soluble starch substrate under the conditions of the assay. GAU, one glucoamylase unit, is the amount of enzyme that will liberate 1 g of reducing sugars calculated as glucose per hour from soluble starch substrate under the conditions of the assay.

Mash Preparation

All the mashes were prepared using a modified PLS method, at a temperature below the gelatinization of starch in order to preserve its native form. The standard PLS method proceeds with separate stages of liquefaction and saccharification (Balcerek and Pielech-Przybylska 2009). This method was changed by isolating the pre-hydrolysis (initial dextrinization) stage and then using the SSF method, which involves conducting the saccharification stage simultaneously with the fermentation process. Rye middlings (1 kg of ground rye) were mixed with tap water (in ratios of 2.5 or 2.8 L water per 1 kg of raw material) in a vessel placed in a water bath and equipped with a laboratory stirrer and thermometer, heated to 35 ± 1 °C. The pH of the mixture was adjusted to 4.0 using sulfuric acid solution (25% w w−1) and continually stirred, maintaining a temperature of 35 ± 1 °C. The native starch pre-hydrolysis was then carried out by using a GC 626 preparation (0.3 mL per 1 kg of raw material). The mash was kept for 30 min under these conditions, following which it was digested with a preparation of Stargen 002® (1.2 mL per 1 kg of raw material), while the pH level was monitored (and corrected to 4.0 if necessary). Next, the mash was transferred to a fermentation tank (5 L) and inoculated with yeast. In trials prepared without the pre-hydrolysis, the preparations of GC 626 and Stargen 002 were added simultaneously at 35 °C and at once inoculated with yeast.

Yeast Cream Preparation

Fermentation was carried out using the dry distillery yeast strain Ethanol Red (Saccharomyces cerevisiae). The yeast preparation was hydrated (0.3 g dry yeast per 1 L of mash). The yeast cream was disinfected (incubation of cells suspended in sulfuric acid solution, pH 2.5, 10 min at room temperature to eliminate weaker yeast cells and unintended bacterial cells). The yeast cream was then added to the mash without neutralization. The rye mashes were supplemented with (NH4)2HPO4 solution (0.2 g L−1 mash).

Fermentation Process and Distillation

Alcoholic fermentation of 2.5 L mash samples was performed. The inoculated mashes were carefully mixed prior to fermentation, and then every 24 h. The process was conducted for 3 days at 35 ± 1 °C. Samples were monitored by HPLC analysis every 24 h (control of sugar and ethanol content). After 3 days of fermentation, the ethanol was distilled from the mash using a laboratory kit, which consisted of a round bottom distillation flask placed in a heating mantle, Liebig cooler, thermometer, and receiver. Distillation was continued until all the alcohol had been distilled off, as confirmed by refractometric measurements. The process is illustrated in Fig. 1.

Variants of the fermentation trials were as follows:

-

I

pre-hydrolysis of starch—30 min; 25% w w−1 d.m. content

-

II

pre-hydrolysis of starch—30 min; 28% w w−1 d.m. content

-

III

without pre-hydrolysis of starch—25% w w−1 d.m. content

-

IV

without pre-hydrolysis of starch—28% w w−1 d.m. content

Analytical Procedures

The rye grains were dry-ground using a laboratory disk mill (FidiBus XL, KoMo, Germany). According to the manufacturer, an appropriate mill setting produces particles of less than 1.5 mm. The real particle size distribution was verified by analysis using sieves with specific mesh sizes (0.25 and 0.60 mm). The rye grains were analyzed using methods recommended in the agricultural and food industry for the content of solid substances, total nitrogen (Kjeldahl method, rye protein conversion factor 5.7) (International Standards: ISO 10520 1997), reducing sugars (Miller 1959), and starch, all expressed in grams per kilogram of dry weight (International Standards: ISO 10520 1997). The α-amylase activity of the raw material (rye grain) was measured using Megazyme kits (Megazyme Ltd., Bray, Ireland), according to the manufacturer’s recommendations and in accordance with the ICC Standard Methods (ICC 2019). The activity of α-amylase was measured using the Ceralpha method (K-CERA 02/17, kit). The Ceralpha unit (CU) of α-amylase activity is defined as the amount of the enzyme needed to release 1 μmol of p-nitrophenol from the non-reducing-end blocked p-nitrophenyl maltoheptaoside (BPNPG7) in the presence of excess thermostable β-glucosidase at 40 °C, in 1 min (Megazyme 2017). The amylose content was determined using the colorimetric method developed by Chrastil (1987). Potato amylose (A0512) from Sigma-Aldrich was used as a reference. The content of amylopectin was calculated based on the difference in the content of starch and amylose. Both parameters were expressed in grams per kilogram of starch.

Prior to chemical analysis, samples of the mashes were filtered through sterile gauze to separate the scales from the raw material. Samples were taken after 0 h and 72 h of fermentation to determine the content of reducing sugars and total sugars (after hydrolysis) (both expressed as glucose per liter of mash) and dextrins (expressed as the difference between the contents of total sugars and reducing sugars, using a conversion coefficient into dextrins of 0.9) The degree of starch saccharification (DSS) was calculated as the ratio of the reducing sugars to total sugars (without taking into account the reducing sugars present in the raw material) and expressed as a percentage.

The glucose, maltose, maltotriose, glycerol, and ethanol concentrations in samples taken every 24 h during the fermentation process were determined by high-performance liquid chromatography (HPLC) using an Infinity 1260 liquid chromatography (Agilent Technologies, Santa Clara, CA, USA) with a refractometer detector (RID). The compounds were separated on a Hi-Plex H column (7.7 × 300 mm, 8 μm, Agilent Technologies, USA) at 60 °C using sulfuric acid (0.005 M) as a mobile phase with a flow rate of 0.7 mL min−1 and at an injection volume of 20 μL. The concentration of each compound was determined by measuring the area of the peak in relation to the peak area of the standard solutions (using the external standard method). Prior to analysis, the samples were deproteinized and filtered through a 0.45-μm PES (polyethersulfone) membrane filter (Thermo Fisher Scientific, USA).

To determine the progress of native starch hydrolysis using the SEM technique, fermented mashes after sampling were acidified to pH 1 with sulfuric acid (25% w v−1) to stop the enzymatic reactions and then centrifuged at 4000×g for 10 min at 4 °C (Multifuge 3SR, Germany). The supernatant was separated, and a sample was taken from the top layer of the pellet (white starch layer) for SEM. The SEM samples of the native starch were isolated using the procedure described by Verwimp et al. (2004). Images of the starch granules were created using an electronic jcm-6000 microscope (JEOL, Japan), in accordance with the method described by Uthumporn et al. (2010). Starch granules were applied on aluminum preparation stubs using double-sided adhesive tape and sputtered with a 20–30-nm layer of gold using a jfc-1200 (JEOL) spreader, at an SEM accelerating voltage of 10 kV.

Assessment of the fermentation results was developed by determining the intake of sugars by the yeast and the fermentation efficiency. The intake of sugars was calculated as the ratio of total sugars remaining in the mash after fermentation to their initial content in the mash before fermentation. Alcoholic fermentation efficiency (FE) was calculated based on total sugars in the mash before fermentation in relation to the stoichiometric equation (according to Gay-Lussac) for conversion of glucose to ethanol, which gave us the theoretical efficiency of the process. Next, the ratio of real ethanol to its theoretical yield was compared and expressed as a percentage, according to the following formula:

where E is ethanol concentration in the mash after fermentation (g L−1); TS are total sugars (expressed as glucose) in mash before fermentation (g); and 0.51 is the constant which represents the theoretical yield of ethanol from glucose.

The ethanol yield (EY) was expressed as the amount of absolute ethanol (A100) obtained from 100 kg of raw material, according to the following formula:

where S is starch content in 100 kg of raw material (kg); 1.11—starch conversion coefficient to glucose; RS—reducing sugars (glucose) in 100 kg of raw material (kg); 0.51—as mentioned above; FE—fermentation efficiency (%); 0.789—density of absolute ethanol (kg L−1); and 100—conversion factor per 100 kg of raw material.

All fermentation samples were prepared and analyzed in triplicate. Statistical analysis was performed using Statistica 10.0 software (Tibco Software, Palo Alto, USA). The significance of the effect of the parameters on the variable responses was studied by analysis of variance (ANOVA). The post-hoc test, using the method of least significant difference (LSD) with a significance level of 0.05, was used to compare statistical differences.

Results and Discussion

Specification of Raw Material

The chemical composition of the raw material (rye Dankowskie Amber cv.) used in this study is presented in Table 1. The rye grains had a dry matter content of 901.4 ± 16.8 g kg−1, which means a low moisture content. The contents of starch and reducing sugars were determined as 664.0 ± 13.6 g kg−1 and 18.3 ± 0.2 g kg−1, respectively.

Analysis of the starch from rye used in this study showed that it contained 250.0 ± 0.1 g kg−1 amylose and 410.0 ± 0.1 g kg−1 amylopectin. This qualifies the raw material as having average amylose content (Alcázar-Alay and Meireles 2015). Protein content amounted to 99.4 ± 4.1 g kg−1 dry matter of rye grain. The protein matrix may affect the shape and accessibility of starch granules. Moreover, very high protein content may results in deformation of the starch structure, limiting access to the starch during processing (Agu et al. 2012). During mashing, only 10–15% of the total protein is dissolved (Bringhurst and Brosnan 2014). Amylolytic activity in the rye grain was determined at 0.30 ± 0.08 CU g−1. The activities of the amylolytic enzymes in the raw materials were characterized by a low activity for α amylase, compared to malted cereals which have amylase activities of over 100 CU g−1 (Balcerek et al. 2016).

In distilleries, the milling process is considered crucial for effective mashing and fermentation, especially when pressureless starch liberation methods are used. Protonotariou et al. (2015) studied the effect of jet milling settings on the characteristics of whole wheat flour and on the physical quality and starch enzymatic digestion of whole wheat breads. Their results showed that jet milling promoted a decrease in the flour particle size. An increase in milling pressure (from 4 to 8 bar), decrease in feed rate (from 0.67 to 5.18 kg h−1), and/or recirculation augmented the severity of the process and reduced flour particle size from 84.15 to 17.02 μm. Particles of the aleurone layer and large aggregates of protein matrix embedding groups of cellular components, mainly starch granules, appeared (about 20–180 μm). In our study, sieve analysis of the ground flour showed that 49.4% had a particle size below 0.25 mm, 37.8% was below 0.6 mm, while the rest (12.9%) was above 0.6 mm. Finely ground raw material allows enzymes to more easily penetrate starch granules. In the case of the hydrolysis of native starch from grains, the degree of grinding is an important parameter (Szymanowska-Powalowska et al. 2012). The degree of milling affects the kinetics of the enzyme and the amounts of sugars produced, because small particles provide a larger surface area (Lamsal et al. 2011).

Characteristics of the Simultaneous Hydrolysis and Fermentation of Rye Native Starch-Based Mashes

One of the key factors in the process of native starch hydrolysis is its efficient conversion into ethanol, which consists of a series of consecutive stages. The most difficult stage is the enzymatic hydrolysis of starch granules, of which the effectiveness is closely related to several factors, such as the type of raw material, the structure of its starch, and the presence of complexing factors (Szymanowska-Powalowska et al. 2012; Szymanowska-Powałowska et al. 2014). Native starch hydrolysis proceeds more slowly than gelatinized starch, which has greater substrate availability for starch pre-hydrolysis by enzymes (Das and Kayastha 2018).

The SEM images of the tested rye starch revealed granules with a spherical shape (large and small) and relatively smooth surfaces, with light furrows and shallow depressions (Fig. 2a). There are reports in the literature (Smith et al. 2002; Sujka and Jamroz 2007) that surface changes may increase the area susceptible to amylolysis. Analysis of the process of native rye starch hydrolysis during SSF revealed more about the enzyme activity pattern (Fig. 2b). The images confirmed that enzymatic digestion of the starch proceeded by layers. The amylases used in the study appeared to attach to the granule surface in various places and create holes that narrowed towards the center of the granule. Native starch consists of two glucans: amylose (an amorphous polymer) and highly branched amylopectin, which is responsible for the semicrystalline structure of the granule (Vamadevan and Bertoft 2015). According to other reports, amylose is in the central part of the granule. This hypothesis was suggested by earlier studies of starch structure (Buléon et al. 2014). In our study, with each hour of fermentation, new holes were formed and old ones grow and deepen, showing the structure of the starch (Fig. 3). Eventually, a residue was formed that resembles a honeycomb, consisting of pentagons and hexagons (72 h). In addition to the patches left in the samples, some starch retained its granular shape and was not completely digested. In the literature, there are reports of undigested granular starch residues and pyramid-shaped residues (Islam et al. 1999).

Unusual yeast behavior was observed after 48 h of fermentation. The yeast entered the holes hollowed out by the enzymes in the starch granules, clogging them (Fig. 4). This suggests yeast impatience with the supply of simple sugars. This in line with the assumption that the SSF process minimizes the risk of osmotic stress, due to the low content of fermented sugars. Generally, enzymes “digest” either the entire surface of the granule, or only parts of it (exocorrosion), or hollow out channels from selected points on the surface towards the center of the granule (endocorrosion). In all enzymatic hydrolysis stages, some areas of the granule surface are more easily digested than others. Some barley, wheat, rye or triticale starch granules, and starches from tropical tubers (sweet potatoes, cassava) have specific vulnerable zones. The regions more susceptible to enzyme attack are the less organized amorphous rings, while crystal forms demonstrate greater resistance to enzyme erosion (Oates and Powell 1996).

Table 2 presents the results of chemical analysis of the mashes (total sugars, dextrins, and ethanol) before and after fermentation, respectively, and the degree of starch saccharification (DSS). The studies were carried out in the mashes with a dry matter content of 25 and 28%. Due to the high content of xylans in rye grain, of which hydration may contribute to the much higher viscosity of rye mashes, a higher share of this raw material in distillery mashes requires the use of supportive enzymes catalyzing xylan hydrolysis (Strąk-Graczyk et al. 2019). As can be seen, the initial content of dextrins in the prepared rye mashes was closely correlated with the pre-hydrolysis of starch and the content of dry matter. The mashes without the pre-hydrolysis showed higher dextrin contents (Table 2). Therefore, it can be concluded that the pre-hydrolysis stage affects dextrin content. The more pronounced dextrin reduction in the mash with a lower dry matter content suggests that the higher the solid starch concentration, the more enzyme load should probably be used to ensure successful hydrolysis (Božić et al. 2017).

The DSS of the samples with the pre-hydrolysis stage was below 20%. These values were not high, which is probably due to the low temperature process and the nature of native starch, as well as the dry matter content (the DSS of the samples with 28% d.m. was only 2.7% lower than in the samples with 25% d.m.). No doubt, such DSS values are associated not only with the enzymatic activity of acid alpha-amylase in the mashing environment (probably be due to the high density of the mash) but also with the type of raw material, as shown in a previously published study (Strąk-Graczyk et al. 2019).

Raw material properties such as hardness or mealiness, together with the protein and lipid contents, have a significant impact on starch granules during milling and subsequent hydrolysis, causing damage or displacement on the surface which allows the enzyme easier access to free glucosidic chains (Oates 1997). Hydrolysis of native starch by amylase may also be related to the extent of enzyme adsorption on starch granules (Kim et al. 2008). The enzymatic reaction proceeds according to three main stages: (1) diffusion to the surface, (2) adsorption of the enzyme, and (3) catalysis. The enzyme must cross the interface between the water and the granule surface before it joins (Božić et al. 2017). Starch granules are unevenly degraded enzymatically, probably due to the way in which the amylases are adsorbed on the granule. A specific attack method is combined with water absorption and swelling of the granules and leads to effective starch hydrolysis, layer by layer (Uthumporn et al. 2010) and granule by granule (until the attacked granule is completely hydrolyzed) (Cummings and Englyst 1995; Oates 1997).

Analysis of the fermented mashes showed that the application of starch pre-hydrolysis reduced the content of dextrins that remained in the mashes, in the samples with both 25% and 28% w w−1 dry matter (Table 2). Lower dextrins values have also been reported in the same process for wheat and triticale in other studies (Strąk-Graczyk et al. 2019). This suggests that the raw material influences the results, which may be improved by the action of supportive enzymes (e.g., xylanase and protease). On the other hand, it may be associated with the presence of resistant starch. Hódsági et al. (2012) investigated the in vitro digestibility properties of different native (maize and wheat) and resistant starches (RS2, Hi-maize™260; RS4, Fibersym™70), as well as their stoichiometric mixtures before and after cooking (at 100 °C). The obtained results showed that the two resistant starches show different digestibility in raw and cooked form. After cooking, RS2 caused a linear decrease in the initially and the totally liberated glucose concentration in cooked mixtures. Strong correlations were found between enzymatic digestion of untreated and gelatinized starches. In turn, the results of Arp et al. (2018) revealed that the increasing level (from 10 to 30% w w−1) of maize resistant starch in wheat starch based medium was thought to have the significant influence on the prolongation of fermentation time, from 59 min in the control sample to above 90 min. The authors proved that the dilution of the wheat starch due to its replacement by maize resistant starch with a more compact crystalline structure was, probably, responsible for the longer fermentation times since yeast could be limited access to fermentable substrates.

The observed in our study positive effect of starch pre-hydrolysis on the reduction in dextrin content was not reflected in the final concentration of ethanol. In the samples with both 25% w w−1 d.m. and 28% w w−1 d.m., with starch pre-hydrolysis, no statistically significant effect on the ethanol production was noted (Table 2).

HPLC analysis of mash samples collected every 24 h allowed determination of the contents of sugars (glucose, maltose, and maltotriose) and an increase in ethanol and glycerol during the fermentation process (Fig. 5). The results showed a characteristic rapid decrease in glucose concentration in the first 24 h period in all variants. This was undoubtedly associated with the proliferation of the yeast. In the samples with pre-hydrolyzed starch (25% w w−1 and 28% w w−1 d.m.), the glucose level was close to 0 (lower than 0.13 g L−1). In the variants without pre-hydrolysis, the glucose contents were as follows: in the mash with 25% w w−1 d.m. 0.87 ± 0.1 g L−1 and in the mash with 28% w w−1 d.m. 0.3 ± 0.1 g L−1. During the next phase of the process, the glucose concentration remained below 0.1 g L−1, and after 72 h, it dropped to below 0.01 g L−1 (Fig. 5). The lower glucose concentrations in the mashes with starch pre-hydrolysis may therefore be associated with the longer action of the enzymes on the native starch granules.

Saccharomyces yeast used for ethanol production schematically uses the available fermentable sugars. Having consumed glucose, they utilize maltose, followed by maltotriose (Białas et al. 2014). The changes in the sugar profile have not been exactly described in the literature. In the tested mashes, the maltose and maltotriose concentrations were low in all samples (< 1.5 g L−1). The initial maltose concentrations in the trials with pre-hydrolysis were 0.8 g L−1 (25% w w−1 d.m.) and 0.6 g L−1 (28% w w−1 d.m.). In these variants, in both cases, there was a significant increase in maltose content over 24 h (more than 1.5-fold for 25% w w−1 d.m. and almost 5-fold for 28% w w−1 d.m.). It then remained below 1 g L−1 until the end of the process. During the first 24 h of SSF, maltotriose was not observed in the mashes with pre-hydrolysis (or was at such a low level that it could not be detected). In the mashes with starch pre-hydrolysis, after 48 h of fermentation, the maltotriose concentration in the sample with 25% w w−1 d.m. was determined as 0.3 g L−1, while in the samples with 28% w w−1 d.m., it was 0.6 g L−1. After 72 h of the process, the maltotriose concentration dropped below 0.2 g L−1 mash. In the mashes without pre-hydrolysis, it was below 0.1 g L−1 and had increased slightly after 72 h (lower than 0.3 g L−1). Maltotriose is a fermented sugar. However, the literature reports that not all yeast strains are able to digest it. The metabolism of maltose and maltotriose is closely related. Both of these sugars are glucosides transported by permease (an α-glucoside-HC symporter encoded by AGT1), induced by maltose (Zastrow et al. 2000). Attempts to improve the efficiency of maltose fermentation by yeast have shown that the main factor limiting the fermentation rate is the expression of maltose permease (Kodama et al. 1995). The α-glucoside-HC symporter encoded by AGT1 could be important for the fermentation of mashes containing both maltose and maltotriose, and therefore, genetic modification of strains with this permease may be a way to improve their digestibility (Zastrow et al. 2000).

Glycerol was also found in the fermented mashes. Its concentration after 24 h of fermentation was below 1 g L−1, which indicates the absence of excessive osmotic stress on the yeast during the fermentation process (Hohmann 2002; Wang et al. 2007). The concentration of this metabolite increased until the end of the fermentation period. The final concentration of glycerol in all the samples was below 8 g L−1, with a simultaneous increase in ethanol concentration. The final concentration of glycerol in the mashes with starch pre-hydrolysis ranged from 6.6 ± 0.5 g L−1 (25% w w−1 d.m.) to 6.8 ± 0.5 g L−1 (28% w w−1 d.m.). Without the pre-hydrolysis, the corresponding glycerol concentrations were from 7.2 ± 0.5 to 7.5 ± 0.5 g L−1, respectively. Considering the low sugar concentration after 24 h, the increased glycerol concentration may have been caused by ethanol stress (Szymanowska and Grajek 2009).

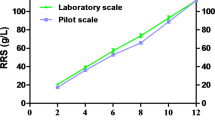

To evaluate the fermentation results, we calculated the degree of sugar utilization, fermentation efficiency (actual yield relative to the theoretical amount), and ethanol yield (fermentation efficiency in relation to theoretical yield based on starch content in 100 kg of raw material). The results are given in Fig. 6. The fermentation of mashes, without starch pre-activation, with higher dry matter content (28% w w−1) resulted in a statistically significant increase in ethanol yield (by approx. 1.6 L A100 from 100 kg of raw material) in comparison to the mashes with lower dry matter content (25% w w−1). However, when pre-hydrolysis of starch was applied, the efficiency of fermentation as well as ethanol yield did not significantly increase for both dry matter contents (Fig. 6). Although no significant effect of native starch pre-hydrolysis on the alcoholic fermentation efficiency of the tested rye mashes was found, all obtained yields can be considered satisfactory similar to the yields obtained in the other studies (Pielech-Przybylska et al. 2017; Wang et al. 2007). Taking into consideration the specificity of the tested raw material (high viscosity mashes, due to the high content of xylans), as indicated by earlier research (Strąk-Graczyk et al. 2019), the impact of the type of raw material on the hydrolysis and fermentation of native starch-based mashes is significant. The results of this study therefore demonstrate the great potential of simultaneous saccharification and fermentation of native rye starch, compared to, for example, the results obtained in other research for triticale (Balcerek and Pielech-Przybylska 2013), in which the pre-hydrolysis parameters were more energy-consuming.

Conclusions

In this study, we investigated the effect of the pre-hydrolysis of native rye starch on the yield of ethanol obtained by SSF from high gravity rye mashes with 25% and 28% w w−1 dry matter content. In accordance with the assumptions of the SSF method, HPLC analysis showed a low concentration of fermenting sugars (glucose, maltose, and maltotriose) during the process (after 24 h), at less than 2 g L−1 mash, which was accompanied by specific yeast behavior observed in the SEM pictures. Despite the low processing temperature, it was possible to achieve satisfactory yields. The fermentation of mashes with dry matter content of 28% w w−1, without starch pre-activation, resulted in a higher ethanol yield (by approx. 1.6 L A100 from 100 kg of raw material) in comparison to the mashes with 25% w w−1 d.m. However, the pre-hydrolysis did not improve the fermentation efficiency and ethanol yield. Further research on the effect of pre-hydrolysis of native starch combined with SSF on the reduction of dextrin contents (e.g., by means of supportive enzymes) could significantly improve the final efficiency of the process.

Change history

23 May 2020

The original version of this article unfortunately contained some mistakes as the last image (Figure 6) does not include statistics (letters) as described in caption.

Abbreviations

- A 100 :

-

absolute alcohol

- AP:

-

amylopectin

- BD:

-

amylopectin of the high-amylopectin cultivar

- CU:

-

Ceralpha unit

- cv:

-

cultivar

- d.m:

-

dry matter

- DP:

-

degree of polymerization

- DSS:

-

degree of starch saccharification

- GSHE:

-

granular starch hydrolyzing enzymes

- HPLC:

-

high-performance liquid chromatography

- LSD:

-

least significant differences

- PES:

-

polyethersulfone

- PLS:

-

pressureless liberation of starch

- SEM:

-

scanning electron microscope

- SSF:

-

simultaneous saccharification and fermentation

- SSU:

-

soluble starch unit

- VHG:

-

very high gravity

- GAU:

-

one glucoamylase unit

References

Abedi, E., Pourmohammadi, K., Jahromi, M., Niakousari, M., & Torri, L. (2019). The effect of ultrasonic probe size for effective ultrasound-assisted pregelatinized starch. Food and Bioprocess Technology, 12(11), 1852–1862. https://doi.org/10.1007/s11947-019-02347-2.

Agu, R. C., Swanston, J. S., Walker, J. W., Pearson, S. Y., Bringhurst, T. A., Brosnan, J. M., & Jack, F. R. (2012). Predicting alcohol yield from UK soft winter wheat for grain distilling: combined influence of hardness and nitrogen measurements. Journal of the Institute of Brewing, 115(3), 183–190. https://doi.org/10.1002/j.2050-0416.2009.tb00367.x.

Alcázar-Alay, S. C., & Meireles, M. A. A. (2015). Physicochemical properties , modifications and applications of starches from different botanical sources. Food Science and Technology, 35(2), 215–236. https://doi.org/10.1590/1678-457X.6749.

Arp, C. G., Correa, M. J., & Ferrero, C. (2018). High-amylose resistant starch as a functional ingredient in breads: a technological and microstructural approach. Food and Bioprocess Technology, 11(12), 2182–2193. https://doi.org/10.1007/s11947-018-2168-4.

Balcerek, M., & Pielech-Przybylska, K. (2009). Effect of supportive enzymes on chemical composition and viscosity of rye mashes obtained by the pressureless liberation of starch method and efficiency of their fermentation. European Food Research and Technology, 229(1), 141–151. https://doi.org/10.1007/s00217-009-1035-y.

Balcerek, M., & Pielech-Przybylska, K. (2013). Effect of simultaneous saccharification and fermentation conditions of native triticale starch on the dynamics and efficiency of process and composition of the distillates obtained. Journal of Chemical Technology and Biotechnology, 88(4), 615–622. https://doi.org/10.1002/jctb.3873.

Balcerek, M., Pielech-Przybylska, K., Strąk, E., Patelski, P., & Dziekońska, U. (2016). Comparison of fermentation results and quality of the agricultural distillates obtained by application of commercial amylolytic preparations and cereal malts. European Food Research and Technology, 242(3), 321–335. https://doi.org/10.1007/s00217-015-2542-7.

Białas, W., Czerniak, A., & Szymanowska-Powałowska, D. (2014). Kinetic modeling of simultaneous saccharification and fermentation of corn starch for ethanol production. Acta Biochimica Polonica, 61(1), 153–162.

Biernacka, P., & Wardencki, W. (2012). Volatile composition of raw spirits of different botanical origin. Journal of the Institute of Brewing, 118(4), 393–400. https://doi.org/10.1002/jib.55.

Božić, N., Lončar, N., Slavić, M. Š., & Vujčić, Z. (2017). Raw starch degrading α-amylases: an unsolved riddle. Amylase, 1, 12–25. https://doi.org/10.1515/amylase-2017-0002.

Bringhurst, T. A., & Brosnan, J. (2014). Scotch whisky: raw material selection and processing. Whisky (Second Edi). Elsevier Ltd. https://doi.org/10.1016/b978-0-12-401735-1.00006-4.

Buléon, A., Cotte, M., Putaux, J., & Susini, J. (2014). Tracking sulfur and phosphorus within single starch granules using synchrotron X-ray micro fluorescence mapping. Biochimica et Biophysica Acta, 1840(1), 113–119. https://doi.org/10.1016/j.bbagen.2013.08.029.

Chen, Z. (2003). Physicochemical properties of sweet potato starches and their application in noodle products. Wageningen University.

Cheng, X., Zhang, M., Adhikari, B., & Islam, M. N. (2014). Effect of power ultrasound and pulsed vacuum treatments on the dehydration kinetics, distribution, and status of water in osmotically dehydrated strawberry: a combined NMR and DSC study. Food and Bioprocess Technology, 7(10), 2782–2792. https://doi.org/10.1007/s11947-014-1355-1.

Chrastil, J. (1987). Improved colorimetric determination of amylose in starches or flours. Carbohydrate Research, 159(1), 154–158. https://doi.org/10.1016/S0008-6215(00)90013-2.

Cummings, J. H., & Englyst, H. N. (1995). Gastrointestinal effects of food carbohydrate. The American Journal of Clinical Nutrition, 61(4), 938S–945S. https://doi.org/10.1093/ajcn/61.4.938S.

Das, R., & Kayastha, A. M. (2018). Enzymatic hydrolysis of native granular starches by a new β -amylase from peanut (Arachis hypogaea). Food Chemistry, 276, 583–590. https://doi.org/10.1016/j.foodchem.2018.10.058.

DuPont TM (2012). Granular starch hydrolyzing enzyme for ethanol production. Retrieved Jan 2, 2020, from https://www.dupont.com/content/dam/dupont/products-and-services/industrial-biotechnology/documents/DuPont-STARGEN002-WB-web-EN.pdf. Accessed 30 Aug 2019.

Gomand, S. V., Verwimp, T., Goesaert, H., & Delcour, J. A. (2011). Structural and physicochemical characterisation of rye starch. Carbohydrate Research, 346(17), 2727–2735. https://doi.org/10.1016/j.carres.2011.09.024.

Hódsági, M., Gelencsér, T., & Salgó, A. (2012). In vitro digestibility of native and resistant starches: correlation to the change of its rheological properties. Food and Bioprocess Technology, 5(3), 1038–1048. https://doi.org/10.1007/s11947-010-0391-8.

Hohmann, S. (2002). Osmotic stress signaling and osmoadaptation in yeasts. Microbiology and Molecular Biology Reviews, 66(2), 300–372. https://doi.org/10.1128/mmbr.66.2.300-372.2002.

Hsieh, C. F., BeMiller, J. N., & Huber, K. C. (2020). Impact of granule hydration on maize and wheat starch chemical reactivity at the granular and molecular levels. Food Hydrocolloids, 100(June 2019), 105374. https://doi.org/10.1016/j.foodhyd.2019.105374.

ICC (2019). Standard methods 303 simple and specific assay for alpha-amylase key data. Retrieved from https://www.icc.or.at/publications/icc-standards/standards-overview/303-simple-and-specific-assay-for-alpha-amylase. Accessed 30 Aug 2019.

International Standards: ISO 10520 (1997). Determination of starch content – Ewers polarimetric method. 1997, 4.

Islam, M., Toledo, R., & Hamdy, M. K. (1999). Stability of virginiamycin and penicillin during alcohol fermentation, 17, 369–376.

Jane, J.-L., Kasemsuwan, T., Leas, S., Zobel, H., & Robyt, J. F. (1994). Anthology of starch granule morphology by scanning electron microscopy. Starch-Stärke, 46(4), 121–129.

Kelsall, D. R., & Lyons, P. T. (2003). Grain dry milling and cooking procedures: extracting sugars in preparation for fermentation. In P. K. A. Jacques, P. T. P. Lyons, & D. R. Kelsall (Eds.), The alcohol textbook. 4th Edition A reference for the beverage, fuel and industrial alcohol industries (pp. 9–21). Nicholasville: Bath: Alltech Inc..

Kim, J. C., Kong, B. W., Kim, M. J., & Lee, S. H. (2008). Amylolytic hydrolysis of native starch granules affected by granule surface area. Journal of Food Science, 73(9), 621–624. https://doi.org/10.1111/j.1750-3841.2008.00944.x.

Kodama, Y., Fukui, N., Ashikari, T., Shibano, Y., Morioka-Fujimoto, K., Hiraki, Y., & Nakatani, K. (1995). Improvement of maltose fermentation efficiency: constitutive expression of MAL genes in brewing yeasts. Journal of the American Society of Brewing Chemists, 53(1), 24–29. https://doi.org/10.1094/ASBCJ-53-0024.

Lamsal, B. P., Wang, H., & Johnson, L. A. (2011). Effect of corn preparation methods on dry-grind ethanol production by granular starch hydrolysis and partitioning of spent beer solids. Bioresource Technology, 102(12), 6680–6686. https://doi.org/10.1016/j.biortech.2011.03.040.

Megazyme. Alpha-amylase assay procedure (Ceralpha method) for the measurement of plants and microbial alpha-amylases (2017).

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(lll), 426–428.

Montesinos, T., & Navarro, J. (2000). Production of alcohol from raw wheat flour by amyloglucosidase and Saccharomyces cerevisiae. Enzyme and Microbial Technology, 27(6), 362–370. https://doi.org/10.1016/S0141-0229(00)00211-8.

Oates, C. G. (1997). Towards an understanding of starch granule structure and hydrolysis. Trends in Food Science & Technology, 8, 54–58.

Oates, C. G., & Powell, A. D. (1996). Bioavailability of carbohydrate material stored in tropical fruit seeds. Food Chemistry, 56(4), 405–414. https://doi.org/10.1016/0308-8146(95)00209-X.

Pielech-Przybylska, K., Balcerek, M., Nowak, A., Wojtczak, M., Czyżowska, A., Dziekonska-Kubczak, U., & Patelski, P. (2017). The effect of different starch liberation and saccharification methods on the microbial contaminations of distillery mashes, fermentation efficiency, and spirits quality. Molecules, 22(10), 1–20. https://doi.org/10.3390/molecules22101647.

Pietrzak, W., & Kawa-Rygielska, J. (2014). Ethanol fermentation of waste bread using granular starch hydrolyzing enzyme: effect of raw material pretreatment. Fuel, 134, 250–256. https://doi.org/10.1016/j.fuel.2014.05.081.

Poel, P., Gosepa, S., Kroes, W., Kruis, G., Berkhout, B., & de Wit, W. (2010). The contribution of the spirits industry to the EU economy. The European Spirits Companies Liaison Group in coordination with the European Spirits Organisation. Retrieved from https://spirits.eu/v1/files/56/december-2010-thecontribution-of-spirits-industry-to-the-eu-economy-summary.pdf. Accessed 25 Sept 2019.

Protonotariou, S., Mandala, I., & Rosell, C. M. (2015). Jet milling effect on functionality, quality and in vitro digestibility of whole wheat flour and bread. Food Bioprocess Technologu, 8(6), 1319–1329. https://doi.org/10.1007/s11947-015-1494-z.

Rosentrater, K. A., & Evers, A. D. (2018). Malting, brewing, fermentation, and distilling. In Kent’s technology of cereals (pp. 729–784). https://doi.org/10.1016/b978-0-08-100529-3.00012-8.

Shariffa, Y. N., Karim, A. A., Fazilah, A., & Zaidul, I. S. M. (2009). Enzymatic hydrolysis of granular native and mildly heat-treated tapioca and sweet potato starches at sub-gelatinization temperature. Food Hydrocolloids, 23(2), 434–440. https://doi.org/10.1016/j.foodhyd.2008.03.009.

Shariffa, Y. N., Uthumporn, U., Karim, A. A., & Zaibunnisa, A. H. (2017). Hydrolysis of native and annealed tapioca and sweet potato starches at subgelatinization temperature using a mixture of amylolytic enzymes. International Food Research Journal, 24(5), 1925–1933.

Shigechi, H., Fujita, Y., Koh, J., Ueda, M., Fukuda, H., & Kondo, A. (2004). Energy-saving direct ethanol production from low-temperature-cooked corn starch using a cell-surface engineered yeast strain co-displaying glucoamylase and α-amylase. Biochemical Engineering Journal, 18, 149–153. https://doi.org/10.1016/j.bej.2003.08.003.

Smith, A. M., Denyer, K., & Martin, C. (2002). The synthesis of the starch granule. Annual Review of Plant Physiology and Plant Molecular Biology, 48(1), 67–87. https://doi.org/10.1146/annurev.arplant.48.1.67.

Strąk-Graczyk, E., Balcerek, M., Przybylsk, K., & Żyżelewicz, D. (2019). Simultaneous saccharification and fermentation of native rye, wheat and triticale starch. Journal of the Science of Food and Agriculture, 99(11), 4904–4912. https://doi.org/10.1002/jsfa.9718.

Sujka, M., & Jamroz, J. (2007). Starch granule porosity and its changes by means of amylolysis. International Agrophysics, 21(1), 107–113.

Szymanowska-Powalowska, D., Lewandowicz, G., Blaszczak, W., & Szwengiel, A. (2012). Structural changes of corn starch during fuel ethanol production from corn flour. Biotechnologia, 93(3), 333–341.

Szymanowska-Powałowska, D., Lewandowicz, G., Kubiak, P., & Błaszczak, W. (2014). Stability of the process of simultaneous saccharification and fermentation of corn flour. The effect of structural changes of starch by stillage recycling and scaling up of the process. Fuel, 119, 328–334. https://doi.org/10.1016/j.fuel.2013.11.034.

Szymanowska, D., & Grajek, W. (2009). Fed-batch simultaneous saccharification and ethanol fermentation of native corn starch. Acta Scientiarum Polonorum. Technologia Alimentaria, 8(4), 5–16.

The European Parliament and the Council of the European. Directive (2008/1/EC) of 15 January 2008 concerning integrated pollution prevention and control., Official Journal of the European Union § (2008).

Uthumporn, U., Shariffa, Y. N., & Karim, A. A. (2012). Hydrolysis of native and heat-treated starches at sub-gelatinization temperature using granular starch hydrolyzing enzyme. Applied Biochemistry and Biotechnology, 166(5), 1167–1182. https://doi.org/10.1007/s12010-011-9502-x.

Uthumporn, U., Zaidul, I. S. M., & Karim, A. A. (2010). Hydrolysis of granular starch at sub-gelatinization temperature using a mixture of amylolytic enzymes. Food and Bioproducts Processing, 88(1), 47–54. https://doi.org/10.1016/j.fbp.2009.10.001.

Vamadevan, V., & Bertoft, E. (2015). Structure-function relationships of starch components. Starch/Staerke, 67, 55–68. https://doi.org/10.1002/star.201400188.

Verwimp, T., Vandeputte, G. E., Marrant, K., & Delcour, J. A. (2004). Isolation and characterisation of rye starch. Journal of Cereal Science, 39(1), 85–90. https://doi.org/10.1016/S0733-5210(03)00068-7.

Wadhwa, M., & Bakshi, M. P. S. (2016). Application of waste-derived proteins in the animal feed industry. In Protein byproducts: transformation from environmental burden into value-added products (pp. 161–192). Elsevier Inc.. https://doi.org/10.1016/B978-0-12-802391-4.00010-0.

Wang, P., Singh, V., Xue, H., Johnston, D. B., Rausch, K. D., & Tumbleson, M. E. (2007). Comparison of raw starch hydrolyzing enzyme with conventional liquefaction and saccharification enzymes in dry-grind corn processing. Cereal Chemistry, 84(1), 10–14. https://doi.org/10.1094/CCHEM-84-1-0010.

Wang, S., Thomas, K. C., Ingledew, W. M., Sosulski, K., & Sosulski, F. W. (1998). Production of fuel ethanol from rye and triticale by very-high-gravity (VHG) fermentation. Applied Biochemistry and Biotechnology - Part A Enzyme Engineering and Biotechnology, 69(3), 157–175. https://doi.org/10.1007/BF02788811.

Xu, Q. S., Yan, Y. S., & Feng, J. X. (2016). Efficient hydrolysis of raw starch and ethanol fermentation: a novel raw starch-digesting glucoamylase from Penicillium oxalicum. Biotechnology for Biofuels, 9(1), 1–18. https://doi.org/10.1186/s13068-016-0636-5.

Yazid, N. M. S., Abdullah, N., Muhammad, N., & Matias-Peralta, H. M. (2018). Application of starch and starch-based products in food industry. Journal of Science and Technology, 10(2), 144–174. https://doi.org/10.30880/jst.2018.10.02.023.

Zastrow, C. R., Mattos, M. A., Hollatz, C., & Stambuk, B. U. (2000). Maltotriose metabolism by Saccharomyces cerevisiae. Biotechnology Letters, 22, 455–459. https://doi.org/10.1023/A:1005691031880.

Zhang, Y., Zhang, Y., Xu, F., Li, S., & Tan, L. (2018). Structural characterization of starches from Chinese jackfruit seeds (Artocarpus heterophyllus Lam). Food hydrocolloids (Vol. 80). Elsevier B.V. https://doi.org/10.1016/j.foodhyd.2018.02.015.

Zhang, Y., Zhu, K., He, S., Tan, L., & Kong, X. (2016). Characterizations of high purity starches isolated from five different jackfruit cultivars. Food hydrocolloids (Vol. 52). Elsevier Ltd. https://doi.org/10.1016/j.foodhyd.2015.07.037.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: Figure 6 has been corrected.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Strąk-Graczyk, E., Balcerek, M. Effect of Pre-hydrolysis on Simultaneous Saccharification and Fermentation of Native Rye Starch. Food Bioprocess Technol 13, 923–936 (2020). https://doi.org/10.1007/s11947-020-02434-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-020-02434-9