Abstract

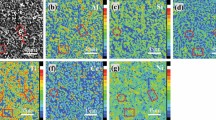

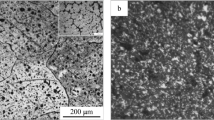

Semisolid metal processing is a promising technique for obtaining complex low-porosity shapes. However, a number of researchers also use thixoforming for composites. This paper evaluates the thixoforming process in an aluminum matrix composite made by the stir casting process. The A380 aluminum alloy was reinforced with 4 different concentrations of NbC (0 wt.%, 5 wt.%, 10 wt.%, and 15 wt.%) by means of the stir casting method at 750°C. To obtain a non-dendritic feedstock, Al-5Ti-1B was added to the molten metal to achieve chemical grain refinement. Isothermal holding for 90 s was applied at the mushy stage of 60% solid fraction at 562°C, determined by differential scanning calorimetry analysis. Optical micrographs, scanning electron microscopy, and x-ray diffraction were used to characterize the material. After performing the thixoforming, an increase in hardness was observed under all conditions. The results show a globular-based morphology with fragmentation of the β-Fe intermetallic phase. The distribution of the NbC particles was improved after the thixoforming process. Thus, the stir casting technique, in conjunction with thixoforming processing of the composite material, A380 + NbC, is an efficient technological route for the manufacture of parts with good characteristics and properties.

Similar content being viewed by others

Data Availability

The raw data and data required to reproduce these findings are available for download from Ref. 48.

References

S. Arunkumar, M. Subramani Sundaram, K.M. Suketh Kanna, and S. Vigneshwara, Mater. Today Proc. 33, 484 (2020).

M.T. Sijo and K.R. Jayadevan, Procedia Technol. 24, 379 (2016).

S. Kumar, R. Kumar, K.K. Goyal, and N. Sharma, Mater. Today Proc. 63, 400 (2022).

U.R. Kanth, P.S. Rao, and M.G. Krishna, J. Mater. Res. Technol. 8, 737 (2019).

A.K. Singh, S. Soni, and R.S. Rana, Adv. Eng. Mater. 22, 2000322 (2020).

T.S. Kumar, G. Suganya Priyadharshini, S. Shalini, K. Krishna Kumar, and R. Subramanian, Trans. Indian Inst. Met. 72, 1593 (2019).

W.D. Callister and D.G. Rethwisch, Materials Science and Engineering: An Introduction, 10th edn. (Wiley: WileyPLUS Products, Hoboken, 2018).

L.M.P. Ferreira, M.H. Robert, E. Bayraktar, and D. Zaimova, Adv. Mater. Res. 939, 68 (2014).

X.J. Wang, X.S. Hu, Y.Q. Wang, K.B. Nie, K. Wu, and M.Y. Zheng, Mater. Sci. Eng. A 559, 139 (2013).

H.Y. Atay, D. Aišman, H. Jirková, M. Behulova, and B. Mašek, Met. Mater. Int. 26, 1420 (2020).

M.S. Salleh, M.Z. Omar, J. Syarif, and M.N. Mohammed, ISRN Mater. Sci. 2013, 679820 (2013).

M.K. Surappa, J. Mater. Process. Technol. 63, 325 (1997).

S.D. Kumar, J. Ghose, A. Mandal, S. Deepak Kumar, J. Ghose, and A. Mandal, in Sustainable Engineering Products and Manufacturing Technologies (Academic Press, London, 2019), pp 25–43.

X.H.X.-H. Chen, G. Liu, P. Chen, L. Liu, S. Rao, and Y. Hu, Int. J. Cast Met. Res. 34, 21 (2021).

L. Wang, T. Chen, and P. Pu, Mater. Sci. Eng. A 830, 142307 (2022).

H.M. Enginsoy, F. Gatamorta, E. Bayraktar, M.H. Robert, and I. Miskioglu, Compos. Part B Eng. 162, 397 (2019).

A. Zulfia, A. Fahmi, and A.H.A.H. Wicaksono, Mater. Today Proc. 17, 1658 (2019).

B.E. Arendarchuck, Avaliação Da Tixoconformação e Desgaste Abrasivo Do Compósito A380/NbC Obtido Pelo Método Stir Casting, 144 f. Master's Thesis (Mechanical Engineering Master Degree) (Federal University of Technology – Paraná, Graduate Program in Mechanical Engineering, Ponta Grossa, PR, 2022).

J. Singh, N. Alba-Baena, R. Trehan, and V.S. Sharma, J. Mater. Eng. Perform. 31, 4887 (2022).

A. Shikika, M. Sethurajan, F. Muvundja, M.C. Mugumaoderha, and S. Gaydardzhiev, Hydrometallurgy 198, 105496 (2020).

B.C. Pai, G. Ramani, R.M. Pillai, and K.G. Satyanarayana, J. Mater. Sci. 30, 1903 (1995).

J. Qi Gan, Y. Jian Huang, C. Wen, and J. Du, Trans. Nonferrous Met. Soc. China 30, 2879 (2020).

J.H. Flynn, Thermochim. Acta 217, 129 (1993).

ASTM International. Standard Test Methods for Determining Average Grain Size, ASTM E112-13 (West Conshohocken, PA, 2013).

A.V. Rodrigues Dantas, G.L. Brollo, D.V. Tamayo, and E.J. Zoqui, Mater. Res. 24, 20200313 (2021).

A. Gregolin, C.A. Facchini, and E.J. Zoqui, Mater. Res. 23, 20200133 (2020).

A.K. Tuli, P. Singh, S. Das, D.P. Mondal, J.P. Shakya, A. Kumar Tuli, P. Singh, S. Das, D.P. Mondal, and J.P. Shakya, Sadhana Acad. Proc. Eng. Sci. 46, 1 (2021).

C. Lin, H. Chen, L. Zeng, S. Wu, and X. Fang, Metals 11, 587 (2021).

N. Zhao, Y. Xu, and Y. Fu, Surf. Coat. Technol. 309, 1105 (2017).

A.E. Karantzalis, A. Lekatou, E. Georgatis, and H. Mavros, J. Mater. Sci. 45, 2165 (2010).

R. Raj and D.G. Thakur, Mater. Sci. Eng. Technol. 49, 1068 (2018).

M.O. Shabani and A. Mazahery, Appl. Math. Model. 36, 5455 (2012).

J. Zhu, W. Jiang, G. Li, F. Guan, Y. Yu, and Z. Fan, J. Mater. Process. Technol. 283, 116699 (2020).

E.J. Zoqui and L.V. Torres, Mater. Res. 13, 305 (2010).

A.A. Abdelsalam, T.S. Mahmoud, A.A. El-Betar, and A.M. El-Assal, Int. J. Curr. Eng. Technol. 5, 3560 (2015).

L.V. Torres, Rev. Eng. e Tecnol. 13, 94 (2021).

H.V. Atkinson, Prog. Mater. Sci. 50, 341 (2005).

S. Gencalp Irizalp and N. Saklakoglu, Eng. Sci. Technol. Int. J. 17, 58 (2014).

M.S. Salleh, M.Z. Omar, K.S. Alhawari, M.N. Mohammed, M.A.M. Ali, and E. Mohamad, Trans Nonferrous Met. Soc. China (Engl. Ed.) 26, 2029 (2016).

Y. Birol and F. Birol, Int. J. Mater. Form. 1, 981 (2008).

M. Sambathkumar, P. Navaneethakrishnan, K. Ponappa, and K.S.K. Sasikumar, Lat. Am. J. Solids Struct. 14, 243 (2017).

N.F.R. Ali, M.S. Salleh, S.S. Al-Zubaidi, and S.H. Yahaya, J. Adv. Manuf. Technol. 15, 27 (2021).

A. Pola, R. Roberti, M. Modigell, and L. Pape, Solid State Phenom. 141–143, 301 (2008).

Z. Wang, K.G. Prashanth, S. Scudino, A.K. Chaubey, D.J. Sordelet, W.W. Zhang, Y.Y. Li, and J. Eckert, J. Alloys Compd. 586, S419 (2014).

X.Z.Z. Zhang, T.J.J. Chen, and Y.H.H. Qin, Mater. Des. 99, 182 (2016).

K. Sekar and P. Vasanthakumar, Mater. Sci. Forum 979, 47 (2020).

H.I. Akbar, E. Surojo, D. Ariawan, G.A. Putra, and R.T. Wibowo, Procedia Struct. Integr. 27, 62 (2020).

B. E. Arendarchuck, Mendeley Data. Database 2. https://doi.org/10.17632/zbk5rpmc3g.2 (2022). Accessed 25 Sep 2022.

Acknowledgements

The authors would like to thank the Graduate Program (DIRPPG) from the Technological Federal University of Paraná (UTFPR). The National Council for Scientific and Technological Development (CNPq)/Araucaria Foundation for aid in promotion and The Centro de Caracterização Multiusuário em Pesquisa e Desenvolvimento de Materiais (C2MMa) for the analyses conducted. Special thanks to CBMM for supplying the NbC powder, José Roberto de Campos for building the stir casting system and State University of Campinas (UNICAMP) for DSC analysis. Likewise, the contribution of the Coordination for the Improvement of Higher Education Personnel—Brazil (CAPES)—Financing Code 001, which provided financial support for this study.

Funding

This study was funded by Coordination for the Improvement of Higher Education Personnel—Brazil (CAPES)—Financing Code 001.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conceptualization: BEA, HDCF, LAL; Writing—original draft preparation: BEA; Writing—review and editing; HDCF, LAL; Supervision: HDCF, LAL; Methodology: BEA, HDCF, LAL. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arendarchuck, B.E., Fals, H.D.C. & Lourençato, L.A. Effect of Thixoforming Process and Microstructural Changes in the A380 Matrix Composite Reinforced with NbC by the Stir Casting Method. JOM 75, 184–194 (2023). https://doi.org/10.1007/s11837-022-05573-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05573-w