Abstract

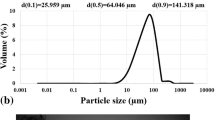

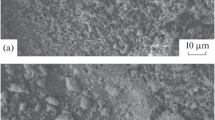

In the present work, Al-2.5Cu-1.5 Mg-1Ni (AA2618) aluminium alloy with the incorporation of Cr3C2 reinforcement at 2, 3, 4 and 5 wt.% was systematically investigated. The composite powders were initially ball-milled and cold-compacted at 400 and 450 MPa. The pressure-less sintering was done at 550 and 600 °C for a holding time of 60 and 90 min under vacuum atmosphere. The experiments are implemented in accordance with Taguchi L8 OA with four process factors and four response characteristics. The results indicate that significant microstructural refinement with the precipitation of new Al-Cr-C compound was noticed up to 4 wt.% of Cr3C2 reinforcement, leading to tensile strength improvement at 28 and 200 °C. However, the strength was decreased at 5 wt.% Cr3C2 reinforcement, which could be attributed to the presence of coarse grain structure and agglomerated large GB precipitate.

Similar content being viewed by others

References

M.K. Sahu, R.K. Sahu, Investigation of mechanical properties and optimization of forming parameters of Al7075-B4C-fly ash hybrid aluminium matrix composite. Arab. J. Sci. Eng. 47, 8161–8176 (2022). https://doi.org/10.1007/s13369-021-06117-1

G. Arumugam et al., Effect of two-step ball milling on microstructure and mechanical properties of Al4032/bimodal-B4C composites. J. Inst. Eng. India Ser. D. (2023). https://doi.org/10.1007/s40033-023-00479-6

R. Arunachalam, K. Pradeep et al., A review on the production of metal matrix composites through stir casting–furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 42, 213–245 (2019). https://doi.org/10.1016/j.jmapro.2019.04.017

P. Bharathi, T.S. Kumar, Mechanical characteristics and wear behaviour of Al/SiC and Al/SiC/B4C hybrid metal matrix composites fabricated through powder metallurgy route. SILICON. (2023). https://doi.org/10.1007/s12633-023-02347-0

A. Mary, A.O. Awotunde et al., Influence of sintering methods on the mechanical properties of aluminium nano-composites reinforced with carbonaceous compounds: a review. J. Mater. Res. Technol. 8, 2432–2449 (2019). https://doi.org/10.1016/j.jmrt.2019.01.026

M.R. Akbarpour, S. Alipour, Microstructure and tribological properties of nanostructured aluminum reinforced with SiC nanoparticles fabricated by powder metallurgy route. Trans. Indian Inst. Met. 71, 745–752 (2018)

M. Benaïssa, M. Catherine, C. Michel, Fatigue behavior of 2618–T851 aluminum alloy under uniaxial and multiaxial loadings. Int. J. Fatigue. (2020). https://doi.org/10.1016/j.ijfatigue.2019.105322

N. Jauković, V. Asanović, Ž Radović, Mechanical properties and recovery of AA 2618 aluminum alloy. High Temp. Mater. Process. 30, 599–602 (2011). https://doi.org/10.1515/htmp.2011.073

G. Arumugam, S. Saravanan et al., Effect of process parameters on microstructure and mechanical properties of Al-11.5%Si-1%Mg/bimodal SiC(m–n) composites. SILICON. 15, 725–737 (2023). https://doi.org/10.1007/s12633-022-02036-4

Y. Balram et al., Wear and corrosion behaviour of multiple pass friction stir processing on aluminium alloy 6061 embedding with B4C particles. Adv. Mater. Process. Technol. (2023). https://doi.org/10.1080/2374068X.2023.2171667

X. Yang, H. Weng, C. Tang, Interfacial bonding mechanism of aluminium and steel composites. Adv. Compos. Lett. 27(2), 255 (2018). https://doi.org/10.1177/096369351802700203

Z. Weiwei, M. Pavlina, F. Yuchi, K. Keiko, N. Naoyuki, K. Akira, Interfacial reaction induced efficient load transfer in few-layer graphene reinforced Al matrix composites for high-performance conductor. Compos. Part B Eng. 167, 93–99 (2019). https://doi.org/10.1016/j.compositesb.2018.12.018

A. Lekatou, A.E. Karantzalis et al., Aluminium reinforced by WC and TiC nanoparticles (ex-situ) and aluminide particles (in-situ): microstructure, wear and corrosion behaviour. Mater. Design. 65, 1121–1135 (2015). https://doi.org/10.1016/j.matdes.2014.08.040

K. Ravi, Desirability-based multi-objective optimization and analysis of WEDM characteristics of aluminium (6082)/tungsten carbide composites. Arab. J. Sci. Eng. 44, 893–909 (2019). https://doi.org/10.1007/s13369-018-3353-5

B. Bir, N. Hemant, Frictional and wear behavior of Cr3C2-NiCr coating on AISI-304 stainless steel. Adv. Mater. Process. Technol. 8, 4007–4017 (2022). https://doi.org/10.1080/2374068X.2022.2036508

S. Wang, S. Zhang, C.H. Zhang, C.L. Wu, J. Chen, S.M. Babar, Effect of Cr3C2 content on 316L stainless steel fabricated by laser melting deposition. Vacuum. 147, 255 (2018). https://doi.org/10.1016/j.vacuum.2017.10.027

J. Yidan, H. Zhenying, H. Wenqiang, L. Xue, Y. Qun, W. Yuanbo, Z. Yang, D. Davoud, In-situ hybrid Cr3C2 and γ′-Ni3(Al, Cr) strengthened Ni matrix composites: microstructure and enhanced properties. Mater. Sci. Eng. A. 820, 921–5093 (2021). https://doi.org/10.1016/j.msea.2021.141524

Z. Jiachen, Y. Zhong, Y. Xigang et al., A low-cost and high-performance casted titanium matrix composite with Cr3C2 additions. Mater. Lett. (2023). https://doi.org/10.1016/j.matlet.2022.133407

M. Yousef, M. Reza, M.J. Mohammad, S. Mohsen, H. Akbar, Mechanical properties and tribological performance of A356/Cr3C2-NiCr surface composite developed by high-velocity oxy-fuel and post friction stir processing treatment. Surf. Interfaces. 28, 1454 (2022). https://doi.org/10.1016/j.surfin.2021.101627

A.M. Pinar, Optimization of process parameters with minimum surface roughness in the pocket machining of AA5083 aluminum alloy via taguchi method. Arab. J. Sci. Eng. 38, 705–714 (2013). https://doi.org/10.1007/s13369-012-0372-5

B. Prosanta, M. Durbadal, K.M. Manas, Failures analysis of in-situ Al–Mg2Si composites using actual microstructure based model. Mater. Sci. Eng. A. (2020). https://doi.org/10.1016/j.msea.2020.140155

N. Yüksel, S. Şahin, Wear behavior–hardness–microstructure relation of Fe–Cr–C and Fe–Cr–C–B based hardfacing alloys. Mater. Des. 58, 491–498 (2014). https://doi.org/10.1016/j.matdes.2014.02.032

Y. Feng, J. Shan et al., Effect of Cr3C2 content on the microstructure and wear resistance of Fe3Al/Cr3C2 composites. Coatings. 12, 1980 (2022). https://doi.org/10.3390/coatings12121980

A. Dolata-Grosz et al. Aluminium matrix cast composite (Amcc) with hybrid reinforcement, 15, 70-78 (2005).

K. Jatinder et al., Comparative study on the mechanical, tribological, morphological and structural properties of vortex casting processed, Al–SiC–Cr hybrid metal matrix composites for high strength wear-resistant applications: fabrication and characterizations. J. Market. Res. 9, 13607–13615 (2020). https://doi.org/10.1016/j.jmrt.2020.10.001

R.R. Mohan, R. Venkatraman et al., Processing of aluminium-silicon alloy with metal carbide as reinforcement through powder-based additive manufacturing: a critical study. Scanning. (2022). https://doi.org/10.1155/2022/5610333

K.M. Shorowordi, T. Laoui, A.S.M.A. Haseeb, J.P. Celis, L. Froyen, Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: a comparative study. J. Mater. Process. Technol. 142, 738–743 (2003). https://doi.org/10.1016/S0924-0136(03)00815-X

U. Erb, G. Palumbo, J.L. McCrea The processing of bulk nanocrystalline metals and alloys by electrodeposition, Woodhead Publishing, 118-151 (2011). https://doi.org/10.1533/9780857091123.1.118.

E. Ghasali, A. Pakseresht, F. Safari-Kooshali, M. Agheli, T. Ebadzadeh, Investigation on microstructure and mechanical behavior of Al–ZrB2 composite prepared by microwave and spark plasma sintering. Mater. Sci. Eng. A. 627, 27–30 (2015)

S.E. Shin, H.J. Choi, J.H. Shin, D.H. Bae, Strengthening behavior of few-layered graphene/aluminum composites. Carbon. 82, 143–151 (2015). https://doi.org/10.1016/j.carbon.2014.10.044

X. Yuming, M. Xiangchen, L. Yulong, M. Dongxin, W. Long, H. Yongxian, Insight into ultra-refined grains of aluminum matrix composites via deformation-driven metallurgy. Compos. Commun. (2021). https://doi.org/10.1016/j.coco.2021.100776

L.K. Pillari, A.K. Shukla, S.V.S.N. Murty et al., Processing and characterization of graphene and multi-wall carbon nanotube-reinforced aluminium alloy AA2219 composites processed by ball milling and vacuum hot pressing. Metallogr. Microstruct. Anal. 6, 289–303 (2017). https://doi.org/10.1007/s13632-017-0365-6

R.M. Penchal, F.R. Ubaid, S. Abdul, M.A.M. Adel, Comparative study of structural and mechanical properties of Al–Cu composites prepared by vacuum and microwave sintering techniques. J. Market. Res. 7, 165–172 (2018). https://doi.org/10.1016/j.jmrt.2017.10.003

R. SK, K. Prabu, G. Rajamurugan, P. Ponnusamy, Comparative analysis of particle size on the mechanical and metallurgical characteristics of Al2O3-reinforced sintered and extruded AA2014 nano-hybrid composite. J. Compos. Mater. 53, 4369–4384 (2019). https://doi.org/10.1177/0021998319856676

V. Bharath, S.S. Ajawan, M. Nagaral et al., Characterization and mechanical properties of 2014 aluminum alloy reinforced with Al2O3p composite produced by two-stage stir casting route. J. Inst. Eng. India Ser. C. 100, 277–282 (2019). https://doi.org/10.1007/s40032-018-0442-x

C.S. Vidyasagar, D.B. Karunakar, Improvement of mechanical properties of 2024 AA by reinforcing yttrium and processing through spark plasma sintering. Arab. J. Sci. Eng. 44, 7859–7873 (2019). https://doi.org/10.1007/s13369-019-03924-5

Wu. Lei, Yu. Zhaoji et al., Microstructure and tensile properties of aluminum powder metallurgy alloy prepared by a novel low-pressure sintering. J. Market. Res. 14, 1419–1429 (2021). https://doi.org/10.1016/j.jmrt.2021.07.074

A. Wąsik, B. Leszczyńska-Madej, M. Madej et al., Effect of heat treatment on microstructure of Al4Cu-SiC composites consolidated by powder metallurgy technique. J. Mater. Eng. Perform. 29, 1841–1848 (2020). https://doi.org/10.1007/s11665-020-04685-1

A. Sakthivel, R. Palaninathan, R. Velmurugan et al., Production and mechanical properties of SiCp particle-reinforced 2618 aluminum alloy composites. J. Mater. Sci. 43, 7047–7056 (2008). https://doi.org/10.1007/s10853-008-3033-z

N. Mathan Kumar, S. Senthil Kumaran, L.A. Kumaraswamidhas, Wear behaviour of Al 2618 alloy reinforced with Si3N4, AlN and ZrB2 in situ composites at elevated temperatures. Alex. Eng. J. 5, 19–36 (2016). https://doi.org/10.1016/j.aej.2016.01.017

L. Ceschini, G. Minak, A. Morri, Forging of the AA2618/20vol.% Al2O3p composite: effects on microstructure and tensile properties. Compos. Sci. Technol. 69, 1783–1789 (2009). https://doi.org/10.1016/j.compscitech.2008.08.027

Acknowledgments

The authors acknowledge the Sophisticated Analytical Instruments Facility, DST-India for providing SEM facilities.

Author information

Authors and Affiliations

Contributions

NVSB was contributed to conception and design of study, acquisition of data, and analysis and/or interpretation of data. VVKPD drafted the manuscript. NVSB and VVKPD revised the manuscript critically for important intellectual content.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Borra, N.V.S., Davuluri, V.V.K.P. Influence of Cr3C2 Addition on Microstructure and Mechanical Properties of AA2618 Composites by Powder Metallurgy. Metallogr. Microstruct. Anal. 12, 788–801 (2023). https://doi.org/10.1007/s13632-023-01003-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-01003-8