Abstract

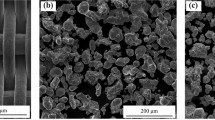

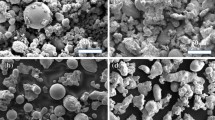

A device that automatically feeds powder and wire mesh was developed to produce a stainless-steel powder/wire mesh composite porous strip (PWMCS). The PWMCS was cut into three same-sized samples, whereby one sample comprised the original strip with no further processing, one sample was rolled for 15 passes, and the last sample was rolled twice for 15 passes and re-sintered; thus, the three samples displayed different porosities. X-ray diffraction, optical microscopy, and scanning electron microscopy were used to investigate the microstructure and phase transformation of the samples. Tensile experiments were also conducted. The results revealed that with the added rolling deformation, more γ-austenite changed to α′-martensite, and both the yield and ultimate tensile strengths increased markedly (361.4 ± 10.5% and 189.5 ± 14.7% increases, respectively). All three samples exhibited ductile fracture, and the dimples varied from large and deep in the initial state to shallow appearance in the final state.

Similar content being viewed by others

References

R.T. Dec, A. Zavaliangos, and J.C. Cunningham, Powder Technol. 130, 265. (2003).

X. Luo, and Y. Liu, JOM 68, 3078. (2016).

Y. Zhao, D. Chen, D.K. Li, J.G. Peng, and B. Yan, Metals 8, 91. (2018).

A. Mazor, L. Orefice, A. Michrafy, A. de Ryck, and J.G. Khinast, Powder Technol. 337, 3. (2018).

G.M. Derkacheva, G.Y. Kalutskii, and R.V. Minakova, Powder Metall. Met. Ceram. 39, 202. (2000).

G.A. Vinogradov, Powder Metall. Met. Ceram. 41, 517. (2002).

I. Oh, N. Naoyuki, N. Nomura, N. Masahashi, and S. Hanada, Scr. Mater. 49, 1197. (2003).

S. Chikosha, T.C. Shabalala, and H.K. Chikwanda, Powder Technol. 264, 310. (2014).

H. Xu, N. Zou, and Q. Li, JOM 69, 1236. (2017).

K.A. Gogaev, V.A. Nazarenko, V.A. Voropaev, Y.N. Podrezov, D.G. Verbilo, O.S. Koryak, and I.Y. Okun, Powder Metall. Met. Ceram. 48, 652. (2009).

R. Floriano, D.R. Leiva, S. Deledda, B.C. Hauback, and W. Botta, Int. J. Hydrogen Energy 38, 16193. (2013).

M. Sakai, Y. Kondo, S. Minoura, T. Sakamoto, and T. Hirasawa, J. Power Sources 185, 559. (2008).

M. Abdullah, L. Jamaludin, K. Hussin, M. Bnhussain, and M.I. Ahmad, Int. J. Mol. Sci. 13, 4388. (2012).

S.V. Smirnov, A.V. Nesterenko, V.N. Bykov, and V.G. Mikhailov, Russ. Metall. 2007, 506. (2007).

B. Zhou, W. Yuan, J.Y. Hu, Y. Tang, L.S. Lu, and B.H. Yu, Trans. Nonferrous Met. Soc. China 25, 2003. (2015).

J. Sun, Y. Yang, and W. Di, Mater. Des. 49, 545. (2013).

D.A. Ivanov, S.D. Shlyapin, G.E. Val’Yano, and L.V. Fedorova, Refract. Ind. Ceram. 58, 538. (2018).

A.P. Rubshtein, I.S. Trakhtenberg, E.B. Makarova, E.B. Triphonova, D.G. Bliznets, L.I. Yakovenkova, and A.B. Vladimirov, Mater. Sci. Eng. C 35, 363. (2014).

K. Ren, Q.K. Wang, Y.L. Lian, and Y.G. Wang, J. Alloys Compd. 747, 1073. (2018).

S.H. Deng, R.D. Li, T.C. Yuan, S.Y. Xie, M. Zhang, K.C. Zhou, and P. Cao, Scr. Mater. 143, 25. (2018).

A.M. Okoro, S.S. Lephuthing, S.R. Oke, O.E. Falodun, M.A. Awotunde, and P.A. Olubambi, JOM 71, 567. (2019).

M.R. Akbarpour, and S.M. Javadhesari, JOM 72, 3262. (2020).

N. Yang, Z. Wang, L. Chen, Y. Wang, and Y.B. Zhu, Int. J. Refract. Met. Hard Mater. 28, 198. (2010).

J. Li, B. Wang, H. Ji, J. Zhou, X. Fu, and X. Huang, Int. J. Adv. Manuf. Tech. 94, 2149. (2018).

M.Y. Zhan, Z.H. Chen, H.G. Yan, and W.J. Xia, J. Mater. Process. Technol. 182, 174. (2007).

A. Chaijaruwanich, R.J. Dashwood, P.D. Lee, and H. Nagaumi, Acta Mater. 54, 5185. (2006).

K. Chen, K. Liu, H. Chen, and Y. Yang, Comput. Mater. Sci. 91, 303. (2014).

H. Shang, A. Mohanram, E. Olevsky, and R.K. Bordia, J. Eur. Ceram. Soc. 36, 2937. (2016).

H.S. Kim, J. Mater. Process. Technol. 123, 319. (2002).

X.W. Du, Z. Zhang, Y. Wang, J.L. Wang, W.M. Wang, H. Wang, and Z.Y. Fu, J. Am. Ceram. Soc. 98, 1400. (2015).

D.W. Kim, H.T. Son, and J.H. Lee, J. Alloys Compd. 528, 146. (2012).

A.R. Deshmukh, T. Sundararajan, R.K. Dube, and S. Bhargava, J. Mater. Process. Technol. 84, 56. (1998).

Y.S. Kwon, G. Son, J. Suh, and K.T. Kim, J. Am. Ceram. Soc. 77, 3137. (1994).

H.M. Jang, W.E. Rhine, and H.K. Bowen, J. Am. Ceram. Soc. 72, 954. (1989).

C. Wang, and S.H. Chen, Sci. China: Phys. Mech. Astron. 55, 1051. (2012).

N.C. Ferreri, R. Pokharel, V. Ivescu, D.W. Brown, M. Knezevic, J.S. Park, M.A. Torrez, and G.T. Gray III., Acta Mater. 195, 59. (2020).

K. Mumtaz, S. Takahashi, J. Echigoya, Y. Kamada, L. Zhang, H. Kikuchi, K. Ara, and M. Sato, J. Mater. Sci. 39, 1997. (2004).

M. Yasuoka, P. Wang, K. Zhang, Z. Qiu, K. Kusaka, Y. Pyoun, and R. Murakami, Surf. Coat. Technol. 218, 93. (2013).

Z. Dai, R. Ding, Z. Yang, C. Zhang, and H. Chen, Acta Mater. 152, 288. (2018).

R. Wei, M. Enomoto, R. Hadian, H.S. Zurob, and G.R. Purdy, Acta Mater. 61, 697. (2013).

H. Luo, J. Shi, C. Wang, W. Cao, X. Sun, and H. Dong, Acta Mater. 59, 4002. (2011).

R. Ding, Z. Dai, M. Huang, Z. Yang, C. Zhang, and H. Chen, Acta Mater. 147, 59. (2018).

C. Lopez, A. Kvryan, S. Kasnakjian, A. Coronado, S. Sujittosakul, O. Villalpando, and V.A. Ravi, JOM 67, 61. (2015).

Y. Zou, Y.B. Xu, Z.P. Hu, X.L. Gu, F. Peng, X.D. Tan, S.Q. Chen, D.T. Han, R.D.K. Misra, and G.D. Wang, Mater. Sci. Eng. A 675, 153. (2016).

S.F. Peterson, M.C. Mataya, and D.K. Matlock, JOM 49, 54. (1997).

J. Trzaska, Arch. Metall. Mater. 60, 181. (2015).

Q. Shan, Z. Li, Y. Jiang, R. Zhou, and Y. Sui, J. Mater. Sci. Technol. 29, 720. (2013).

K.W. Andrews, J. Iron Steel Res. Int. 203, 721. (1965).

X. Rong, S. Liu, Y. Li, B. Hu, M. Enomoto, H. Guo, and C. Shang, Mater. Sci. Eng. A 760, 47. (2019).

S.D. de Souza, P.S. Moreira, and G.L. de Faria, Mater. Res.-Ibero-am. J. Mater. 23 (2020).

T.S. Wang, M. Zhang, Y.H. Wang, J. Yang, and F.C. Zhang, Scr. Mater. 68, 162. (2013).

M. Zhang, T.S. Wang, Y.H. Wang, J. Yang, and F.C. Zhang, Mater. Sci. Eng. A 568, 123. (2013).

J. Erneman, L. Nylöf, J. Nilsson, and H. Andrén, Mater. Sci. Technol. 20, 1245. (2004).

A.W. Wilson, J.D. Madison, and G. Spanos, Scr. Mater. 45, 1335. (2001).

I.G. Shaaban, Y.B. Shaheen, E.L. Elsayed, O.A. Kamal, and P.A. Adesina, Constr. Build. Mater. 171, 802. (2018).

A.B. Kale, A. Bag, J.H. Hwang, E.G. Castle, M.J. Reece, and S.H. Choi, Mater. Sci. Eng. A 707, 362. (2017).

F. Wakai, K. Katsura, S. Kanchika, Y. Shinoda, T. Akatsu, and K. Shinagawa, Acta Mater. 109, 292. (2016).

M. Zhang, H. Chen, Y. Wang, S. Wang, R. Li, S. Li, and Y.D. Wang, J. Mater. Sci. Technol. 35, 1779. (2019).

E. Ishimaru, H. Hamasaki, and F. Yoshida, J. Mater. Process. Technol. 223, 34. (2015).

A. Kundu, and D.P. Field, Mater. Sci. Eng. A 667, 435. (2016).

B. Babu, and L.E. Lindgren, Int. J. Plast. 50, 94. (2013).

M.B. Karimi, H. Arabi, A. Khosravani, and J. Samei, J. Mater. Process. Technol. 203, 349. (2008).

P. Dastur, A. Zarei-Hanzaki, R. Rahimi, M. Moallemi, V. Klemm, B.C. De Cooman, and J. Mola, Metall. Mater. Trans. A 50, 4550. (2019).

D.G. Rodrigues, G. Maria, N. Viana, and D.B. Santos, Mater. Charact. 150, 138. (2019).

H. Matsumoto, S. Watanabe, and S. Hanada, Mater. Sci. Eng. A 448, 39. (2007).

S.M. Na, and A.B. Flatau, Scr. Mater. 66, 307. (2012).

H.K. Cho, and R.E. Rowlands, Compos. Sci. Technol. 67, 2877. (2007).

H. Li, M.W. Fu, J. Lu, and H. Yang, Int. J. Plast. 27, 147. (2011).

Y. Liu, L. Kang, and H.B. Ge, J. Constr. Steel. Res. 158, 381. (2019).

M. Behzadinasab, and J.T. Foster, Int. J. Fract. 224, 261. (2020).

S. Zhang, Y. Lu, Z. Shen, C. Zhou, and Y. Lou, Int. J. Damage Mech. 29, 1199. (2019).

A. Shiga, T. Yamashita, Y. Neishi, and O. Umezawa, Mater. Trans. 62, 505. (2021).

S.K. Paul, S. Sivaprasad, S. Dhar, and S. Tarafder, Theor. Appl. Fract. Mec. 54, 63. (2010).

A. Pequegnat, C.J. Hang, M. Mayer, Y. Zhou, J.T. Moon, and J. Persic, J. Mater. Sci.: Mater. Electron. 20, 1144. (2009).

A. Misra, X. Zhang, D. Hammon, and R.G. Hoagland, Acta Mater. 53, 221. (2005).

T. Hama, R. Namakawa, Y. Maeda, and Y. Maeda, Mater. Trans. 62, 1124. (2021).

X. Li, L.L. Wei, L.Q. Chen, Y. Zhao, and R. Misra, Mater. Charact. 144, 575. (2018).

D.J. Dunstan, and A.J. Bushby, Int. J. Plast. 53, 56. (2014).

N. Hansen, Scr. Mater. 51, 801. (2004).

J.E. Jin, Y.S. Jung, and Y.K. Lee, Mater. Sci. Eng. A 449–451, 786. (2007).

D.A. Hughes, and N. Hansen, Acta Mater. 148, 374. (2018).

H.L. Chang, C.T. Kuo, and M.S. Liang, Microelectron. Eng. 88, 1623. (2011).

K.O. Pedersen, I. Westermann, T. Furu, T.B. Rvik, and O.S. Hopperstad, Mater. Des. 70, 31. (2015).

Y.C. Bai, Y.Q. Yang, Z.F. Xiao, M.K. Zhang, and D. Wang, Mater. Des. 140, 257. (2018).

X. Chen, G.S. Huang, S.S. Liu, T.Z. Han, B. Jiang, A.T. Tang, Y.T. Zhu, and F.S. Pan, Trans. Nonferrous Met. Soc. China 29, 437. (2019).

Y.P. Zheng, W.D. Zeng, D. Li, H.Y. Ma, P.H. Zhang, and X. Ma, J. Alloys Compd. 799, 267. (2019).

Acknowledgement

The authors acknowledge financial support from the Science and Technology Program of Guangzhou, China (No. 201604016015).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, S., Zhou, Z. Evolution of Microstructure and Mechanical Properties of a Stainless-Steel Powder/Wire Mesh Composite Porous Strip for Powder Densification. JOM 74, 2357–2368 (2022). https://doi.org/10.1007/s11837-022-05227-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05227-x