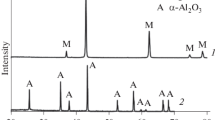

Atechnological approach is proposed making it possible to prepare highly porous ceramic based on Al2O3 using a method of filtration combustion (FC). The method is based on an exothermic oxidation reaction (in an FC regime) of aluminum powder PAP-2 particles mixed with spherulites of commercial alumina (type 1 material) or kaolin fibers (type 2 material). Depending on the volume faction of PAP-2 open porosity for sintered type 1 material is from 38 to 50%, and ultimate strength in bending is from 10 to 50 MPa. Good material thermal shock resistance, evaluated from the relative loss of crack resistance after thermal cycling by a regime of heating to 850°C and cooling in an air stream (18°C), comprises 12 – 15% and is unchanged after five successive thermal cycles. Material of type 2 is an ultra-lightweight heat insulator with density of 0.25 – 0.50 g/cm3. The bearing strength is 0.10 – 0.15 MPa, and thermal conductivity in the range 20 to 1000°C is 0.06 – 0.17 W/(m·K).

Similar content being viewed by others

References

R. V. Zubashchenko, “Heat-resistant high-temperature heat insulation object based on aluminum silicate fiber,” Novye Ogneupory, No. 12, 3 – 5 (2016).

R. V. Zubashchenko, “Lining of a small tunnel kiln with high-alumina objects based on aluminosilicate fiber,” Novye Ogneupory, No. 2, 3 – 5 (2017).

A. Mocciaro, M. B. Lombardi, and A. N. Scian, “Ceramic material porous structure prepared using pore-forming additives,” Refract. Indust. Ceram., 58(1), 65 – 68 (2017).

A. V. Belyakov, Zaw Ye Maw Oo, N. A. Popova, et al., “Strengthening binders for porous permeable ceramic with electromelted corundum filler,” Refract. Indust. Ceram., 58(1), 89 – 93 (2017).

I. Ya. Guzman (editor) Ceramic Chemical technology: Higher School Textbook [in Russian], RIF Stroimatewrialy, Moscow (2003).

S. M. Barinov, V. A. Demin, A. V. Ivanov, D. A. Ivanov, A. Yu. Omarov, A. D. Shlyapin, and S. D. Shlyapin, RF Patent. 2522487, MPK C 04 B 35/111, 35/626. Method for preparing structural aluminum oxide ceramic, No. 2012146829/03, Claim 11.02.12, Publ. 07.20.14, Bull. No. 20.

V. S. Vladimirov, A. P. Galagan, M. A. Ilyukhin, et al., “New refractories and heat insulation materials and the manufacturing technology,” Novye Ogneupory, No. 1 (April), 81 – 88 (2002).

A. A. Vasin, V. P. Tarasovskii, A. Yu. Omarov, and V. V. Rybalchenko, “Study of cermet synthesis from powders prepared by chemical dispersion of Al–Mg (20 wt.%)-alloy,” Refract. Indust. Ceram., 56(3), 310 – 314 (2015).

D. A. Ivanov, A. I. Sitnikov, and G. E. Val’yano, “Evaluation of the thermal resistance of structural ceramics in testing notched prismatic samples,” Glass and Ceramics, 58(5/6), 169 – 173 (2001).

D. A. Ivanov and A. I. Sitnikov, “Features of ceramic material breakage during thermal loading by local thermal shock method,” Ogneupory Tekhn. Keram., No. 12, 30 – 35 (2004).

Research was carried out within the scope of the main part of a state assignment to higher education establishments No. 11.7568.2017/B4 using equipment of the collective use resource center “Aerospace materials and technology” MAI.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 9, pp. 40 – 43, September, 2017.

Rights and permissions

About this article

Cite this article

Ivanov, D.A., Shlyapin, S.D., Val’yano, G.E. et al. Structure and Physicomechanical Properties of Porous Ceramic Based on Al2O3 Prepared Using a Filtration Combustion Method. Refract Ind Ceram 58, 538–541 (2018). https://doi.org/10.1007/s11148-018-0140-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0140-5