Abstract

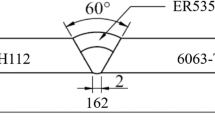

This work aims to establish a suitable numerical simulation model for hybrid laser-electric arc heat source welding of dissimilar Mg alloys between AZ31 and AZ80. Based on the energy conservation law and Fourier’s law of heat conduction, the differential equations of the three-dimensional temperature field for nonlinear transient heat conduction are built. According to the analysis of nonlinear transient heat transfer, the equations representing initial conditions and boundary conditions are obtained. The “double ellipsoidal heat source + 3D Gaussian heat source” combination was chosen to construct the laser-electric arc hybrid heat source. The weld bead morphologies and the distribution of temperature, stress, displacement and plastic strains are numerically simulated. The actual welding experiments were performed by a hybrid laser-electric arc welding machine. The interaction mechanism between laser and electric arc in the hybrid welding of Mg alloys is discussed in detail. The hybrid heat source can promote the absorption of laser energy and electric arc in the molten pool, resulting in more uniform energy distribution in the molten pool and the corresponding improvement of welding parameters. This work can provide theoretical guidance and data supports for the optimization of the hybrid laser-electric arc welding processes for Mg alloys.

摘要

本文为AZ31-AZ80异种镁合金激光-电弧复合热源焊接的热-力耦合过程建立了一个合适的数值 模拟模型。首先,基于能量守恒定律和傅里叶热传导定律,建立了非线性瞬态热传导的三维温度场的 微分方程并根据非线性瞬态热传导的分析,得到了代表初始条件和边界条件的方程。其次,选择了 “双椭球热源+三维高斯热源”的组合形式来构建激光-电弧复合热源,对熔池的形态以及温度、应力、 位移和塑性应变的分布进行了数值模拟。实际的焊接实验是在激光-电弧复合焊接机上完成的。最后, 详细讨论了激光和电弧在镁合金的复合热源焊接中的相互作用机制。复合热源可以促进激光能量和电 弧在熔池中的吸收,使能量在熔池中的分布更加均匀,焊接参数得到相应的改善。该工作可以为镁合 金的激光-电弧混合焊接工艺的优化提供理论指导和数据支持。

Similar content being viewed by others

References

TAN J, RAMAKRISHNA S. Applications of magnesium and its alloys: A review [J]. Applied Sciences, 2021, 11(15): 6861. DOI: https://doi.org/10.3390/app11156861.

SINGH K, SINGH G, SINGH H. Review on friction stir welding of magnesium alloys [J]. Journal of Magnesium and Alloys, 2018, 6(4): 399–416. DOI: https://doi.org/10.1016/j.jma.2018.06.001.

ARUL KUMAR M, BEYERLEIN I J, MCCABE R J, et al. Grain neighbour effects on twin transmission in hexagonal close-packed materials [J]. Nature Communications, 2016, 7: 13826. DOI: https://doi.org/10.1038/ncomms13826.

KARUNAKARAN R, ORTGIES S, TAMAYOL A, et al. Additive manufacturing of magnesium alloys [J]. Bioactive Materials, 2020, 5(1): 44–54. DOI: https://doi.org/10.1016/j.bioactmat.2019.12.004.

HAN Shan-ling, LI Zhi-yong, WANG Zhi-yong, et al. Review on joining processes of magnesium alloy sheets [J]. The International Journal of Advanced Manufacturing Technology, 2022, 118(9–10): 2787–2803. DOI: https://doi.org/10.1007/s00170-021-07981-9.

HAO Kang-da, WANG He-kang, GAO Ming, et al. Laser welding of AZ31B magnesium alloy with beam oscillation [J]. Journal of Materials Research and Technology, 2019, 8(3): 3044–3053. DOI: https://doi.org/10.1016/j.jmrt.2019.04.024.

HUANG Wen-hao, CHEN Shu-jun, XIAO Jun, et al. Laser wire-feed metal additive manufacturing of the Al alloy [J]. Optics & Laser Technology, 2021, 134: 106627. DOI: https://doi.org/10.1016/j.optlastec.2020.106627.

HE Yu-chun, WANG Ling-xiao, WU Ting-ni, et al. Facile fabrication of hierarchical textures for substrate-independent and durable superhydrophobic surfaces [J]. Nanoscale, 2022, 14(26): 9392–9400. DOI: https://doi.org/10.1039/d2nr02157a.

WU Ting-ni, WU Zhi-peng, HE Yu-chun, et al. Femtosecond laser textured porous nanowire structured glass for enhanced thermal imaging [J]. Chinese Optics Letters, 2022, 20(3): 033801. DOI: https://doi.org/10.3788/col202220.033801.

YIN Kai, WANG Ling-xiao, DENG Qin-wen, et al. Femtosecond laser thermal accumulation-triggered micro/nanostructures with patternable and controllable wettability towards liquid manipulating [J]. Nano-Micro Letters, 2022, 14(1): 1–13. DOI: https://doi.org/10.1007/s40820-022-00840-6.

PATTERSON T, HOCHANADEL J, SUTTON S, et al. A review of high energy density beam processes for welding and additive manufacturing applications [J]. Welding in the World, 2021, 65(7): 1235–1306. DOI: https://doi.org/10.1007/s40194-021-01116-0.

WĘGLOWSKI M S, BŁACHA S, PHILLIPS A. Electron beam welding-Techniques and trends — Review [J]. Vacuum, 2016, 130: 72–92. DOI: https://doi.org/10.1016/j.vacuum.2016.05.004.

SOLTANI H M, TAYEBI M. Comparative study of AISI 304L to AISI 316L stainless steels joints by TIG and Nd: YAG laser welding [J]. Journal of Alloys and Compounds, 2018, 767: 112–121. DOI: https://doi.org/10.1016/j.jallcom.2018.06.302.

ACHERJEE B. Laser arc hybrid welding [M]//Advances in Laser Materials Processing. Amsterdam: Elsevier, 2018: 203–234. DOI: https://doi.org/10.1016/b978-0-08-101252-9.00009-1.

ZHANG Xiao-bin, CAO Zhan-yi, ZHAO Peng-fei. Investigation on solidification cracks in pulsed laser spot welding of an AZ31 magnesium alloy [J]. Optics & Laser Technology, 2020, 126: 106132. DOI: https://doi.org/10.1016/j.optlastec.2020.106132.

ZHOU Wei, APRILIA A, MARK C K. Mechanisms of cracking in laser welding of magnesium alloy AZ91D [J]. Metals, 2021, 11(7): 1127. DOI: https://doi.org/10.3390/met11071127.

ZHANG Xiao-bin, CAO Zhan-yi. Effects of pulse shaping on Nd: YAG laser spot welds in an AZ31 magnesium alloy [J]. Optics and Lasers in Engineering, 2019, 119: 1–8. DOI: https://doi.org/10.1016/j.optlaseng.2019.02.002.

COOKE K O, ALHAZAA A, ATIEH A. Dissimilar welding and joining of magnesium alloys: Principles and application [M]. IntechOpen, 2019. DOI: https://doi.org/10.5772/intechopen.85111.

MA Zheng-xiong, CHENG Pei-xin, NING Jie, et al. Innovations in monitoring, control and design of laser and laser-arc hybrid welding processes [J]. Metals, 2021, 11(12): 1910. DOI: https://doi.org/10.3390/met11121910.

KIK T. Computational Techniques in Numerical simulations of arc and laser welding processes [J]. Materials (Basel, Switzerland), 2020, 13(3): 608. DOI: https://doi.org/10.3390/ma13030608.

MENG Xiang-meng, QIN Guo-liang, SU Yu-hu, et al. Numerical simulation of large spot laser + MIG arc brazing-fusion welding of Al alloy to galvanized steel [J]. Journal of Materials Processing Technology, 2015, 222: 307–314. DOI: https://doi.org/10.1016/j.jmatprotec.2015.03.020.

IVEKOVIĆ A, MONTERO-SISTIAGA M L, VLEUGELS J, et al. Crack mitigation in Laser Powder Bed Fusion processed Hastelloy X using a combined numerical-experimental approach [J]. Journal of Alloys and Compounds, 2021, 864: 158803. DOI: https://doi.org/10.1016/j.jallcom.2021.158803.

ZHANG Chen, GAO Ming, ZENG Xiao-yan. Influences of synergy effect between laser and arc on laser-arc hybrid welding of aluminum alloys [J]. Optics & Laser Technology, 2019, 120: 105766. DOI: https://doi.org/10.1016/j.optlastec.2019.105766.

SHUCK G. Double-sided arc welding of AZ31B magnesium alloy sheet [D]. Waterloo, Ontario, Canada: University of Waterloo, 2013.

HAROONI M, CARLSON B, KOVACEVIC R. Effect of process parameters on the weld quality in laser welding of AZ31B magnesium alloy in lap joint configuration [C]//International Congress on Applications of Lasers & Electro-Optics. Miami, Florida, USA: Laser Institute of America, 2013: 509–519. DOI: https://doi.org/10.2351/1.5062923.

BRASZCZYŃSKA-MALIK K N, MRÓZ M. Gas-tungsten arc welding of AZ91 magnesium alloy [J]. Journal of Alloys and Compounds, 2011, 509(41): 9951–9958. DOI: https://doi.org/10.1016/j.jallcom.2011.07.105.

GAO Ming, TANG Hai-guo, CHEN Xiao-feng, et al. High power fiber laser arc hybrid welding of AZ31B magnesium alloy [J]. Materials & Design, 2012, 42: 46–54. DOI: https://doi.org/10.1016/j.matdes.2012.05.034.

REN Da-xin, LIU Li-ming, LI Yong-fei. Investigation on overlap joining of AZ61 magnesium alloy: Laser welding, adhesive bonding, and laser weld bonding [J]. The International Journal of Advanced Manufacturing Technology, 2012, 61(1–4): 195–204. DOI: https://doi.org/10.1007/s00170-011-3683-x.

ISHAK M, YAMASAKI K, MAEKAWA K. Lap fillet welding of thin sheet AZ31 magnesium alloy with pulsed Nd: YAG laser [J]. Journal of Solid Mechanics and Materials Engineering, 2009, 3(9): 1045–1056. DOI: https://doi.org/10.1299/jmmp.3.1045.

CASALINO G, GUGLIELMI P, LORUSSO V D, et al. Laser offset welding of AZ31B magnesium alloy to 316 stainless steel [J]. Journal of Materials Processing Technology, 2017, 242: 49–59. DOI: https://doi.org/10.1016/j.jmatprotec.2016.11.020.

DONG Hong-gang, LIAO Chuan-qing, YANG Li-qun. Microstructure and mechanical properties of AZ31B magnesium alloy gas metal arc weld [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1336–1341. DOI: https://doi.org/10.1016/S1003-6326(11)61323-X.

SCINTILLA L D, TRICARICO L. Optimization of AZ31 magnesium alloy laser beam welding parameters based on process efficiency calculation by finite element method and joint mechanical properties [J]. Optical Engineering, 2013, 52: 105101. DOI: https://doi.org/10.1117/1.OE.52.10.105101.

ZHANG Jun-wei, HU Xiao-dong, ZHANG Dan. Study on CO2 laser welding of AZ31 magnesium alloy sheet produced by strip casting process [J]. Advanced Materials Research, 2011, 228–229: 1012–1016. DOI: https://doi.org/10.4028/www.scientific.net/amr.228-229.1012.

GUO Jing, ZHOU Yong, LIU Chang-meng, et al. Wire arc additive manufacturing of AZ31 magnesium alloy: Grain refinement by adjusting pulse frequency [J]. Materials (Basel, Switzerland), 2016, 9(10): 823. DOI: https://doi.org/10.3390/ma9100823.

ZHAO Yan-qiu, ZHAN Xiao-hong, CHEN Shuai, et al. Study on the shear performance and fracture mechanism of T-joints for 2219 aluminum alloy by dual laser-beam bilateral synchronous welding [J]. Journal of Alloys and Compounds, 2020, 847: 156511. DOI: https://doi.org/10.1016/j.jallcom.2020.156511.

FLINT T F, SCOTTI L, BASOALTO H C, et al. A thermal fluid dynamics framework applied to multi-component substrates experiencing fusion and vaporisation state transitions [J]. Communications Physics, 2020, 3: 196. DOI: https://doi.org/10.1038/s42005-020-00462-7.

YAN Zhao-rui, LIU Wei-wei, TANG Zi-jue, et al. Review on thermal analysis in laser-based additive manufacturing [J]. Optics & Laser Technology, 2018, 106: 427–441. DOI: https://doi.org/10.1016/j.optlastec.2018.04.034.

NASIRI M B, ENZINGER N. Powerful analytical solution to heat flow problem in welding [J]. International Journal of Thermal Sciences, 2019, 135: 601–612. DOI: https://doi.org/10.1016/j.ijthermalsci.2018.08.003.

MOSLEMI N, GOHARI S, ABDI B, et al. A novel systematic numerical approach on determination of heat source parameters in welding process [J]. Journal of Materials Research and Technology, 2022, 18: 4427–4444. DOI: https://doi.org/10.1016/j.jmrt.2022.04.039.

FLINT T F, FRANCIS J A, SMITH M C, et al. Extension of the double-ellipsoidal heat source model to narrow-groove and keyhole weld configurations [J]. Journal of Materials Processing Technology, 2017, 246: 123–135. DOI: https://doi.org/10.1016/j.jmatprotec.2017.02.002.

RAJABI L, GHOREISHI M. Heat source modeling and study on the effect of thickness on residual stress distribution in electron beam welding [J]. Journal of Welding and Joining, 2017, 35(1): 49–54. DOI: https://doi.org/10.5781/jwj.2017.35.1.49.

KIK T. Heat source models in numerical simulations of laser welding [J]. Materials (Basel, Switzerland), 2020, 13(11): 2653. DOI: https://doi.org/10.3390/ma13112653.

Matweb. Material prorerty data [EB/OL]. [2022-03-21]. https://www.matweb.com/index.aspx.

Total Material. The world’s most comprehensive materials database [EB/OL]. [2022-03-21]. https://www.totalmateria.com/page.aspx?ID=Home&LN=CN.

Matmatch. Find materials [EB/OL]. [2022-03-21]. https://matmatch.com/.

BUNAZIV I, FROSTEVARG J, AKSELSEN O M, et al. Process stability during fiber laser-arc hybrid welding of thick steel plates [J]. Optics and Lasers in Engineering, 2018, 102: 34–44. DOI: https://doi.org/10.1016/j.optlaseng.2017.10.020.

CAMPANA G, FORTUNATO A, ASCARI A, et al. The influence of arc transfer mode in hybrid laser-mig welding [J]. Journal of Materials Processing Technology, 2007, 191(1–3): 111–113. DOI: https://doi.org/10.1016/j.jmatprotec.2007.03.001.

Funding

Project(52004154) supported by the National Natural Science Foundation of China; Project(ZR2020QE002) supported by the Shandong Provincial Natural Science Foundation, China; Project(6142005190208) supported by the National Key Laboratory Foundation of China

Author information

Authors and Affiliations

Corresponding authors

Additional information

Contributors

MA Yu-lin edited the draft of manuscript. ZHU Jian developed the overarching research goals and edited the manuscript. ZHANG Long-mei, REN Zhi-qiang, ZHAO Yang, WANG Wen-yu, WANG Xiao-ming and HUI Xi-dong conducted the literature review and modified the manuscript. WU Yong-ling and ZHENG Hong-yu edited the manuscript.

Conflict of interest

MA Yu-lin, ZHU Jian, ZHANG Long-mei, REN Zhi-qiang, ZHAO Yang, WANG Wen-yu, WANG Xiao-ming, HUI Xi-dong, WU Yong-ling and ZHENG Hong-yu declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ma, Yl., Zhu, J., Zhang, Lm. et al. Numerical simulation and experimental study of hybrid laser-electric arc welding between dissimilar Mg alloys. J. Cent. South Univ. 29, 3476–3488 (2022). https://doi.org/10.1007/s11771-022-5159-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5159-6

Key words

- hybrid laser-electric arc welding

- dissimilar Mg alloys welding

- numerical simulation

- interaction mechanisms

- welding optimizations