Abstract

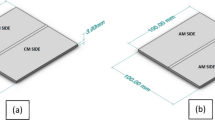

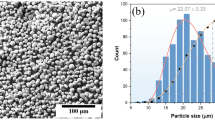

In this study, a three-dimensional (3D) finite element model was established to predict the shape of the molten zone and the temperature fields of multi-layer laser–MIG hybrid welding for Fe36Ni Invar alloy. The multi-layer laser–MIG hybrid welding experiments of 19.05-mm-thick Invar plates were conducted to obtain the well-welded joints. The molten zone shapes were compared to the simulated results to figure out the relation between the energy distribution factor and the welding temperature field. A combined heat source model was proposed to describe the interaction between laser heat source and arc heat source. Besides, the empirical formula of energy distribution factor was given. The metallography detection results showed that the increasing ratio of laser power in hybrid welding could increase the weld penetration depth and the increasing ratio of arc power in hybrid welding could increase the weld width. In addition, it was also found that the laser heat source in hybrid welding heat source contributed equiaxed grains, and weld centerlines had rotation, due to different ratios of energy distribution during the multi-layer laser–MIG hybrid welding.

Similar content being viewed by others

References

Kakehashi Y (1981) Theory of the Invar effect in FeNi alloy. J Phys Soc Jpn 50(7):2236–2245

Zhan X, Liu J, Chen J, Peng Q, Wei Y, Zhao Y (2016) Parameter optimization of multi-pass multi-layer MIG welded joint for invar alloy. The Int J Adv Manuf Tech 87(1–4):601–613

Corbacho JL, Suárez JC, Molleda F (1998) Welding of invar Fe-36Ni alloy for tooling of composite materials. Weld Int 12(12):966–971

Xu PQ, Ren JW, Zhang PL, Gong HY, Yang SL (2013) Analysis of formation and interfacial WC dissolution behavior of WC-Co/invar laser-TIG welded joints. J Mater Eng Perform 22(2):613–623

Xu PQ, Bao CM, Lu FG, Ma CW, He JP, Cui HC, Yang SL (2011) Numerical simulation of laser–tungsten inert arc deep penetration welding between WC–Co cemented carbide and invar alloys. Int J Adv Manuf Tech 53(9–12):1049–1062

Zhan X, Li Y, Ou W, Yu F, Chen J, Wei Y (2016) Comparison between hybrid laser-MIG welding and MIG welding for the invar36 alloy. Opt Laser Technol 85:75–84

Zain-Ul-Abdein M, Nelias D, Jullien JF, Deloison D (2008) Thermo-mechanical analysis of laser beam welding of thin plate with complex boundary conditions. Int J Mater Form 1(1):1063–1066

Wang Q, Chen H, Zhu Z, Qiu P, Cui Y (2016) A characterization of microstructure and mechanical properties of A6N01S-T5 aluminum alloy hybrid fiber laser-MIG welded joint. Int J Adv Manuf Tech 86(5–8):1375–1384

Tani G, Campana G, Fortunato A, Ascari A (2007) The influence of shielding gas in hybrid LASER–MIG welding. Appl Surf Sci 253(19):8050–8053

Ghosal S, Chaki S (2010) Estimation and optimization of depth of penetration in hybrid CO 2 LASER-MIG welding using ANN-optimization hybrid model. Int J Adv Manuf Tech 47(9):1149–1157

Faraji AH, Goodarzi M, Seyedein SH, Barbieri G, Maletta C (2015) Numerical modeling of heat transfer and fluid flow in hybrid laser–TIG welding of aluminum alloy AA6082. Int J Adv Manuf Tech 77(9–12):2067–2082

Campana G, Fortunato A, Ascari A, Tani G, Tomesani L (2007) The influence of arc transfer mode in hybrid laser-MIG welding. J Mater Process Tech 191(1):111–113

Gao Z, Wu Y, Huang J (2009) Analysis of weld pool dynamic during stationary laser–MIG hybrid welding. Int J Adv Manuf Tech 44(9–10):870–879

Hong H, Han Y, Du M, Tong J (2016) Investigation on droplet momentum in VPPA-GMAW hybrid welding of aluminum alloys. Int J Adv Manuf Tech 86(5–8):2301–2308

Guoxiang X, Chuansong W, Guoliang Q, Xuyou W, Shangyang L (2008) Numerical simulation of weld formation in laser plus GMAW hybrid welding. Acta Metall Sin 44(6):641–646

Chen YB, Lei ZL, Li LQ, Wu L (2006) Experimental study on welding characteristics of CO2 laser TIG hybrid welding process. Sci Technol Weld Joi 11(4):403–411

Hu B, Richardson IM (2006) Mechanism and possible solution for transverse solidification cracking in laser welding of high strength aluminium alloys. Mater Sci Eng A 429(1):287–294

Kong F, Ma J, Kovacevic R (2011) Numerical and experimental study of thermally induced residual stress in the hybrid laser-GMA welding process. J Mater Process Tech 211(6):1102–1111

Zhan X, Liu Y, Ou W, Gu C, Wei Y (2015) The numerical and experimental investigation of the multi-layer laser-MIG hybrid welding for Fe36Ni Invar alloy. J Mater Eng Perform 24(12):4948–4957

Bidi L, Mattei S, Cicala E, Andrzejewski H, Le Masson P, Schroeder J (2011) The use of exploratory experimental designs combined with thermal numerical modelling to obtain a predictive tool for hybrid laser/MIG welding and coating processes. Opt Laser Technol 43(3):537–545

Piekarska W, Kubiak M (2011) Three-dimensional model for numerical analysis of thermal phenomena in laser–arc hybrid welding process. Int J Heat Mass Tran 54(23):4966–4974

Xu GX, Wu CS, Qin GL, Wang XY, Lin SY (2011) Adaptive volumetric heat source models for laser beam and laser + pulsed GMAW hybrid welding processes. Int J Adv Manuf Tech 57(1–4):245–255

Le Guen E, Carin M, Fabbro R, Coste F, Le Masson P (2011) 3D heat transfer model of hybrid laser Nd: Yag-MAG welding of S355 steel and experimental validation. Int J Heat Mass Tran 54(7):1313–1322

Leo P, Renna G, Casalino G, Olabi AG (2015) Effect of power distribution on the weld quality during hybrid laser welding of an Al-Mg alloy. Opt Laser Technol 73:118–126

Kim YC, Hirohata M, Murakami M, Inose K (2015) Effects of heat input ratio of laser–arc hybrid welding on welding distortion and residual stress. Weld Int 29(4):245–253

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305

Kou S, Sun DK (1985) Fluid flow and weld penetration in stationary arc welds. Metall Trans A 16(2):203–213

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhan, X., Zhang, C., Liu, Y. et al. The influence of energy distribution factor during laser-MIG hybrid welding of Invar alloy. Int J Adv Manuf Technol 93, 4305–4316 (2017). https://doi.org/10.1007/s00170-017-0844-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0844-6