Abstract

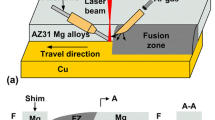

This paper presents the research on weldability of magnesium alloy AZ61 sheets by overlap laser welding, adhesive bonding, and laser seam weld bonding processes. Microstructures and mechanical properties of the joints are investigated. In overlap laser welding, the joint fractures at the interface between the sheets and maximum shear strength can reach 85% of that of the base metal. Off-center moment during tensile shear test can lead to the strength loss, while the weld edge can also influence the strength as a cracking source. Adhesive bonded joint can offer high tensile shear failure force but low peel strength. Laser weld bonded joint offers higher tensile shear failure force than either laser welded joint or adhesive bonded joint does, and the improved failure load is due to combined contribution of the weld seam and the adhesive. The weld seam can block the adhesive crack propagation, and the adhesive improves the stress distribution, so they can offer a synergistic effect.

Similar content being viewed by others

References

Kulekci M (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39:851–865

Luo A, Nyberg A, Sadayappan K, Shi W (2008) Magnesium front and research and development: a Canada-China-USA collaboration. The Minerals, Metals & Materials Society: Magnesium Technology: 3–10

Padmanaban G, Balasubramanian V (2010) An experimental investigation on friction stir welding of AZ31B magnesium alloy. Int J Adv Manuf Technol 49:111–121

Yamamoto M, Gerlich A, North T, Shinozaki K (2007) Cracking in the stir zones of Mg-alloy friction stir spot welds. J Mater Sci 42:7657–7666

Chi C, Chao C, Liu T, Wang C (2006) A study of weldability and fracture modes in electron beam weldments of AZ series magnesium alloys. Mater Sci Eng A 435–436:672–680

Hao X, Song G (2009) Spectral analysis of the plasma in low-power laser/arc hybrid welding of magnesium alloy. IEEE Trans Plasma Sci 37:76–82

Zhang Z, Zhang F (2009) Spectral analysis of welding plasma of magnesium alloy using flux coated. Mater Trans 50:1909–1914

Mahendra G, Balasubramanian V, Senthilvelan T (2009) Developing diffusion bonding windows for joining AZ31B agnesium and copper alloys. Int J Adv Manuf Technol 42:689–695

Qi X, Song G (2010) Interfacial structure of the joints between magnesium alloy and mild steel with nickel as interlayer by hybrid laser-TIG welding. Mater Des 31:605–609

Quan Y, Chen Z, Gong X, Yu Z (2008) CO2 laser beam welding of dissimilar magnesium-based alloys. Mater Sci Eng A 496:45–51

Abderrazak K, Salem WB, Mhiri H, Bournot P, Autric M (2009) Nd:YAG laser welding of AZ91 magnesium alloy for aerospace industries. Metall Mater Trans B 48:54–61

Bretz T, Lazarz A, Hill J, Blanchard J (2004) Adhesive bonding and corrosion protection of a die cast magnesium automotive door. Magnesium Technology: 113–119.

Messler R (2002) Weld-bonding: the best or worst of two processes. Ind Robot 29:138–148

Darwish M, Ghanya A (2000) Critical assessment of weld-bonded technologies. J Mater Process Technol 105:221–229

Darwish M (2003) Weld bonding strengthens and balances the stresses in spot-welded dissimilar thickness joints. J Mater Process Technol 134:352–362

Messler R, Bell J, Craigue O (2003) Laser beam weld bonding of AA5754 for automobile structures. Weld J 82:151–159

Chi C, Chao C (2007) Characterization on electron beam welds and parameters for AZ31B-F extrusive plates. J Mater Process Technol 182:369–373

Cao X, Xiao M, Jahazi M, Immarigeon JP (2005) Continuous wave ND:YAG laser welding of sand-cast ZE41A-T5 magnesium alloys. Mater Manuf Process 20:987–1004

Chang B, Shi Y, Lu L (2001) Studies on the stress distribution and fatigue behavior of weld-bonded lap shear joints. J Mater Process Technol 108:307–313

Santos I, Zhang W, Goncalves V, Bay N, Martins P (2004) Weld bonding of stainless steel. Int J Mach Tool Manuf 44:1431–1439

Acknowledgments

The authors gratefully acknowledge the sponsorship from the National Natural Science Funds of China for Distinguished Young Scholar (51025520).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, D., Liu, L. & Li, Y. Investigation on overlap joining of AZ61 magnesium alloy: laser welding, adhesive bonding, and laser weld bonding. Int J Adv Manuf Technol 61, 195–204 (2012). https://doi.org/10.1007/s00170-011-3683-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3683-x