Abstract

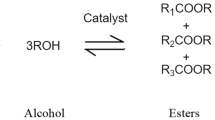

Due to the biological risks of using the conventional lubricants, the vegetable oils have been considered nowadays. Besides, to improve the tribological properties of the vegetable oils in various applications like metal forming processes, nanoparticles have been used as additives. This research evaluated the lubrication performance of the Al2O3 and TiO2 nanoparticles dispersed in rapeseed oil during the parallel tubular channel angular pressing (PTCAP) process. The experimental PTCAP tests have been fulfilled under three lubrication conditions and the comparison between the PTCAP processed tubes has been performed in terms of the maximum forming force, surface roughness, and microhardness. The experimental results indicate that adding the mentioned nanoparticles has caused at least a 50% reduction in the maximum deformation load. Moreover, a remarkable decrement in the surface roughness of the formed tubes has been obtained.

摘要

由于使用传统润滑剂存在生物风险, 植物油已成为人们关注的焦点。此外, 为了提高植物油在 金属成型工艺等各种应用中的摩擦性能, 纳米颗粒被用作添加剂。本文研究了平行通道转角挤压 (PTCAP) 过程中分散在菜籽油中的 Al2O3 和 TiO2 纳米颗粒的润滑性能。在三种润滑条件下进行了 PTCAP 实验, 并在最大成形力、表面粗糙度和显微硬度方面对 PTCAP 加工通道进行了比较。实验结 果表明, 加入上述纳米颗粒可使最大变形力至少降低 50%. 此外, 成型通道的表面粗糙度明显降低

Similar content being viewed by others

References

JAHADI R, SEDIGHI M, JAHED H. ECAP effect on the micro-structure and mechanical properties of AM30 magnesium alloy [J]. Mater Sci EngA, 2014, 593: 178–184.

WANG Bing-feng, SUN Jie-ying, ZOU Jin-dian, VINCENT S, LI Juan. Mechanical responses, texture and microstructural evolution of high purity aluminum deformed by equal channel angular pressing [J]. Journal of Central South University, 2015, 22(10): 3698–3704.

MARAMI G, SAMAN S M, ALI M, S. Enhanced mechanical properties of pure aluminium: Experimental investigation of effects of different parameters [J]. Journal of Cental South University, 2018, 25: 561–569.

RAHMATABADI D, HASHEMI R. Experimental evaluation of forming limit diagram and mechanical properties of nano/ultra-fine grained aluminum strips fabricated by accumulative roll bonding [J]. Int J Mater Res, 2017, 108(12): 1036–1044.

RAHMATABADI D, TAYYEBI M, HASHEMI R. Fracture toughness investigation of A11050/Cu/MgAZ31ZB multi-layered composite produced by accumulative roll bonding process [J]. Mater Sci Eng A, 2018, 734: 427–436.

ZHILYAEV A P, LANGDON T G Using high-pressure torsion for metal processing: Fundamentals and applications [J]. Prog Mater Sci, 2008, 53: 893–979.

LEE H, KYUNG S, HO K, AN G, AHN B, KAWASAKI M, LANGDON T G. Evolution in hardness and texture of a ZK60A magnesium alloy processed by high-pressure torsion [J]. Mater Sci Eng A, 2015, 630: 90–98.

FARAJI G, MASHHADI M M, KIM H S. Deformation behavior in tubular channel angular pressing (TCAP) using triangular and semicircular channels [J]. Mater Trans, 2012, 53(1): 8–12.

MESBAH M, FARAJI G, BUSHROA A R. Characterization of nanostructured pure aluminum tubes produced by tubular channel angular pressing (TCAP) [J]. Mater Sci Eng A, 2014, 590: 289–294.

HOSSEINI S H, ABRINIA K, FARAJI G Applicability of a modified backward extrusion process on commercially pure aluminum [J]. J Mater, 2015, 65: 521–528.

FARAJI G, KIM H S. Review of principles and methods of severe plastic deformation for producing ultrafine-grained tubes [J]. Mater Sci Technol, 2017, 33(8): 905–923.

JAVIDIKIA M, HASHEMI R. Analysis and simulation of parallel tubular channel angular pressing of Al 5083 tube [J]. Trans Indian Inst Met, 2017, 70: 2547–2553.

TAVAKKOLI V, AFRASIAB M, FARAJI G, MASHHADI M M. Severe mechanical anisotropy of high-strength ultra fine grained Cu-Zn tubes processed by parallel tubular channel angular pressing (PTCAP) [J]. Mater Sci Eng A, 2015, 625: 50–55.

JAVIDIKIA M, HASHEMI R. Mechanical anisotropy in ultra-fine grained aluminium tubes processed by parallel-tubular-channel angular pressing [J]. Mater Sci Technol, 2017, 33(18): 2265–2273.

FARAJI G, MASHHADI M M, BUSHROA A R, BABAEI A. TEM analysis and determination of dislocation densities in nanostructured copper tube produced via parallel tubular channel angular pressing process [J]. Mater Sci Eng A, 2013, 563: 193–198.

YANG T S. Investigation of the strain distribution with lubrication during the deep drawing process [J]. Tribiology Int, 2010, 43 (5, 6): 1104–1112.

LAZZAROTTO L, DUBAR L, DUBOIS A, RAVASSARD P. A selection methodology for lubricating oils in cold metal forming processes [J]. Wear, 1998, 215: 1–9.

RAO K P, XIE C L. A comparative study on the performance of boric acid with several conventional lubricants in metal forming processes [J]. Tribiology Int, 2006, 39: 663–668.

KIM H, ALTAN T, YAN Q. Evaluation of stamping lubricants in forming advanced high strength steels (AHSS) using deep drawing and ironing tests [J]. J Mater Process Technol, 2009, 209: 4122–4133.

TOMALA A, HERNANDEZ S, RIPOLL M R, BADISCH E, PRAKASH B. Tribological performance of some solid lubricants for hot forming through laboratory simulative tests [J]. Tribiology Int, 2014, 74: 164–173.

KRISHNA P V, RAO D N. Performance evaluation of solid lubricants in terms of machining parameters in turning [J]. Int J Mach Tools Manuf, 2008, 48: 1131–1137.

ALIMIRZALOO V, SHEYDAYIGURCHINQALEH S. Investigation of the effect of CuO and AL2O3 nanolubricants on the surface roughness in the forging process of aluminum alloy [J]. J Eng Tribol, 2017, 231(12): 1595–1604.

PENG D, CHEN C. Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant [J]. Ind Lubr Tribol, 2010, 62(2): 111–120.

HERNANDEZ BATTEZ A, GONZALEZ R, VIESCA J L, FERNANDEZ J E, MACHADO A, CHOU R, RIBA J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants [J]. Wear, 2008, 265: 422–428.

KHALILPOURAZARY S, MESHKAT S S. Investigation of the effects of alumina nanoparticles on spur gear surface roughness and hob tool wear in hobbing process [J]. Int J Adv Manuf Technol, 2014, 71: 1599–1610.

ZHU Z, SUN J, NIU T, LIU N. Experimental research on tribological performance of water-based rolling [J]. J Nanoeng Nanosyst, 2014, 229(3): 104–109.

WANG B, SUN J, WU Y Lubricating performances of nano organic-molybdenum as additives in water-based liquid during cold rolling [J]. Adv Mater Res, 2011, 337: 550–555.

XIE H M, JIANG B, HE J J, XIA X S, JIANG Z T, DAI J H, PAN F S. Effect of SiO2 nanoparticles as lubricating oil additives on the cold-rolling of AZ31 magnesium alloy sheet [J]. Mater Res Innov, 2015, 8917: 127–132.

BAO Y, SUN J, KONG L. Effects of nano-SiO2 as water-based lubricant additive on surface qualities of strips after hot rolling [J]. Tribiology Int, 2017, 114: 257–263.

ABE Y, YAMASHITA T, ABE Y, YAMASHITA T. Forward extrusion aluminium alloy billet using Engineering of ceramic particles fine ceramic particles costing models for kai capacity in industry trade-off and operational efficiency [J]. Procedia Manuf, 2018, 15: 240–248.

ZAREH-DESARI B, ABASZADEH-YAKHFORVAZANI M, KHALILPOURAZARY S. The effect of nanoparticle additives on lubrication performance in deep drawing process: Evaluation of forming load, friction coefficient and surface quality [J]. Int J Precis Eng Manuf, 2015, 16(5): 929–936.

GULZAR M, MAS JUKI H H, KALAM M A, VARMAN M, ZULKIFLI N W M, MUFTI R A, ZAHID R, YUNUS R. Dispersion stability and tribological characteristics of TiO2/SiO2 nanocomposite-enriched biobased lubricant [J]. Tribol Trans, 2017, 60(4): 670–680.

SYAHRULLAIL S, ZUBIL B M, AZWADI C S N, RIDZUAN M J M. International journal of mechanical sciences experimental evaluation of palm oil as lubricant in cold forward extrusion process [J]. Int J Mech Sci, 2011, 53(7): 549–555.

ZAREH-DESARI B, DAVOODI B. Assessing the lubrication performance of vegetable oil-based nanolubricants for environmentally conscious metal forming processes [J]. J Clean Prod, 2016, 135: 1198–1209.

DIABB J, RODRIGUEZ C A, MAMIDIN, SANDOVAL J A, TAHA-TIJERINA J. Study of lubrication and wear in single point incremental sheet forming (SPIF) process using vegetable oil nanolubricants [J]. Wear, 2017, 376-377: 777–785.

NI J, FENG G, MENG Z, HONG T, CHEN Y, ZHENG X. Reinforced lubrication of vegetable oils with graphene additive in tapping ADC 12 aluminum alloy [J]. Int J Adv Manuf Technol, 2017, 94 (11): 1031–1040.

ZHANG Y, LI C, JIA D, ZHANG D, ZHANG X. Experimental evaluation of M0S2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil [J]. J Clean Prod, 2015, 87: 930–940.

INGOLE S, CHARANPAHARI A, KAKADE A, UMARE S S, BHATT D V, MENGHANI J. Tribological behavior of nano TiO2 as an additive in base oil [J]. Wear, 2013, 301 (1,2): 776–785.

BAHRAMIAN A, RAEISSI K, HAKIMIZAD A. An investigation of the characteristics of Al2O3/TiO2 PEO nanocomposite coating [J]. Appl Surf Sci, 2015, 351: 13–26.

ALI M K A, XIANJUN H, MAI L, QINGPING C, FIIFI R, BICHENG C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives [J]. Tribiology Int, 2016, 103: 540–554.

SYAHRULLAIL S, KAMITANI S, SHAKIRIN A. Performance of vegetable oil as lubricant in extreme pressure condition [J]. ProcediaEng, 2013, 68: 172–177.

AHMADPOUR M, SIAVASHI M, DORANEHGARD M H. Numerical simulation of two-phase flow in fractured porous media using streamline simulation and IMPES methods and comparing results with a commercial software [J]. Journal of Central South University, 2016, 23: 2630–2637.

LI Zhi-hui, ZHANG Yong-jie, ZHANG Yu-zhu. Effect of content of Al2O3 and MgO on crystallization of blast furnace slag during fiber formation [J]. Journal Central South University, 2018, 25: 2373–2379.

MAO C, HUANG Y, ZHOU X. The tribological properties of nanofluid used in minimum quantity lubrication grinding [J]. Int J Adv Manuf Technol, 2014, 71: 1221–1228.

GAO Tie-jun, LV Yang-jie, LIU Qing, WANG Zhong-jin. Effect of aluminum particle on properties of viscous medium during warm viscous pressure bulging [J]. Journal of Central South University, 2018, 25(9): 2085–2092.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kasaeian-Naeini, M., Hashemi, R. & Hosseini, A. Lubrication performance of rapeseed oil-based nano-lubricants in parallel tubular channel angular pressing process. J. Cent. South Univ. 26, 1042–1049 (2019). https://doi.org/10.1007/s11771-019-4069-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4069-8

Key words

- parallel tubular channel angular pressing

- nano lubricant

- nano-particle additives

- vegetable oil

- aluminum alloy