Abstract

High-performance commodity polymers are in demand due to low cost, durability, easy productivity, and recycling ability. This article comprises a survey on the performance properties of polytetrafluoroethylene (PTFE) fluoropolymer. It is a well-known choice for coatings, insulation, thermal sealing, lubrication, bearings, and clinical applications. PTFE was engineered in many forms as a function of loading nano and micro fillers for different purposes and the improved properties and performance were addressed by the researchers. Hence, we disclosed the various casting routes of PTFE which is feasible for reliable processing to serve in domestic and industrial applications.

High performance PTFE for domestic and industrial applications

Similar content being viewed by others

References

Gowariker VR, Viswanathan NV, Sreedhar J (1986) Polymer science new age international. Halsted Press, New York. https://doi.org/10.1002/pi.4980200122

Burkarter E, Saul CK, Thomazi F, Cruz NC, Roman LS, Schreiner WH (2007) Superhydrophobic electrosprayed PTFE. Surf Coat Technol 202(1):194–198

Khanna YP (1988) The melting temperature of polytetrafluoroethylene. Mater Sci Lett 7(8):817–818

Suwa T, Seguchi T, Takehisa M, Machi S (1975) Effect of molecular weight on the crystalline structure of polytetrafluoroethylene as-polymerized. J Polym Sci B Polym Phys 13(11):2183–2194

Thomas P (1998) The use of fluoropolymers for non-stick cooking utensils. Surf Coat Int 81(12):604–609

Yuan XD, Yang XJ (2010) A study on friction and wear properties of PTFE coatings under vacuum conditions. Wear 269:291–297

Xia Z, Wedel A, Danz R (2003) Charge storage and its dynamics in porous polytetrafluoroethylene (PTFE) film electrets. IEEE Trans Dielectr Electr Insul 10:102–108

Light DN, Wilcox JR (1995) Process considerations in the fabrication of fluoropolymer printed circuit boards. IEEE Trans Compon Packag Manuf Technol Part A 18:118–126

Su FH, Zhang ZZ, Liu WM (2005) Study on the friction and wear properties of glass fabric composites filled with nano-and micro-particles under different conditions. Mater Sci Eng A 392:359–365

Bureau C, Carlos Garcia-Pagan J, Otal P, Pomier-Layrargues G, Chabbert V, Cortez C, Perreault P, Marie Péron J, Abraldes JG, Bouchard L, Bilbao JI (2004) Improved clinical outcome using polytetrafluoroethylene-coated stents for TIPS: results of a randomized study. Gastroenterology 126(2):469–475

Scarratt LR, Hoatson BS, Wood ES, Hawkett BS, Neto C (2016) Durable superhydrophobic surfaces via spontaneous wrinkling of teflon AF’ ACS. Appl Mater Interfaces 8(10):6743–6750

Wang F, Zhu H, Zhang H, Tang H, Chen J, Guo Y (2015) Effect of surface hydrophilic modification on the wettability surface charge property and separation performance of PTFE membrane. J Water Process Eng 8:11–18

Lai CL, Liou RM, Chen SH, Huang GW, Lee KR (2011) Preparation and characterization of plasma-modified PTFE membrane and its application in direct contact membrane distillation. Desalination 267(2):184–192

Pelagade SM, Singh NL, Rane RS, Mukherjee S, Deshpande UP, Ganesan V, Shripathi T (2012) Investigation of surface free energy for PTFE polymer by bipolar argon plasma treatment. J Surf Eng Mater Adv Tech 2:132–136

Lunkwitz K, Lappan U, Scheler U (2004) Modification of perfluorinated polymers by high-energy irradiation. J Fluor Chem 125:863–873

Zhang J, Li J, Han Y (2004) Superhydrophobic PTFE surfaces by extension. Macromol Rapid Commun 25(11):1105–1108

Hou X, Deem PT, Choy KL (2012) Hydrophobicity study of polytetrafluoroethylene nanocomposite films. Thin Solid Films 520(15):4916–4920

Khedkar J, Negulescu I, Meletis EI (2002) Sliding wear behavior of PTFE composites. Wear 252(5):361–369

Ankita S, Singh AK (2011) Corrosion and wear resistance study of Ni-P and Ni-P-PTFE nanocomposite coatings. Cent Eur J Eng 1(3):234–243

Patil PB, Deore ER (2015) Friction and wear behavior of PTFE and its composites: A review. IJRAT, 3

Bijwe J, Sharma M (2012) Nano and micro PTFE for surface lubrication of carbon fabric reinforced polyethersulphone composites. In: Davim J (ed) Tribology of nanocomposites materials forming machining and tribology. Springer, Berlin Heidelberg, pp 19–39

Li J, Ran Y (2010) Evaluation of the friction and wear properties of PTFE composites filled with glass and carbon fibre. Mater Sci Eng Tech 41:115–118

Rae PJ, Dattelbaum DM (2004) The properties of poly (tetrafluoroethylene) (PTFE) in compression. Polymer 45(22):7615–7625

Li J (2009) Mechanical properties of a polyamide 6-reinforced PTFE composite. Mech Compos Mater 45(3):287–292

Yan Y, Jia Z, Yang Y (2011) Preparation and mechanical properties of PTFE/nano-EG composites reinforced with nanoparticles. Procedia Environ Sci 10:929–935

Shi XB, Wu CL, Rong MZ, Czigany T, Ruan WH, Zhang MQ (2013) Improvement of creep resistance of polytetrafluoroethylene films by nano-inclusions. Chin J Polym Sci 31(3):377–387

Shi YJ, Feng X, Wang HY, Lu XH (2007) Tribological and mechanical properties of PTFE composites filled with the combination of short carbon fibre and carbon nano-fibre. Key Eng Mater 334:689–692

Hemanth R, Sekar M, Suresha B (2014) Effects of fibres and fillers on mechanical properties of thermoplastic composites. Ind J Adv Chem Sci 2:28–35

Hanford WE, Joyce RM (1946) Polytetrafluoroethylene. J Am Chem Soc 68(10):2082–2085

Tuminello WH, Dee GT (1994) Thermodynamics of poly (tetrafluoroethylene) solubility. Macromolecules 27(3):669–676

Tuminello WH (2002) Solubility of poly (tetrafluoroethylene) and its copolymers. In: Fluoropolymers 2. Springer, US, pp 137–143

Price DM, Jarratt M (2002) Thermal conductivity of PTFE and PTFE composites. Thermochim Acta 392:231–236

Joseph T, Uma S, Philip J, Sebastian MT (2011) Electrical and thermal properties of PTFE-Sr2ZnSi2O7 composites. J Mater Sci – Mater Electron 22(8):1000–1009

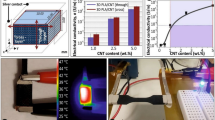

Kappagantula K, Pantoya ML (2012) Experimentally measured thermal transport properties of aluminium–polytetrafluoroethylene nanocomposites with graphene and carbon nanotube additives. Int J Heat Mass Transf 55(4):817–824

Chen YC, Lin HC, Lee YD (2003) The effects of filler content and size on the properties of PTFE/SiO2 composites. J Polym Res 10(4):247–258

Pan C, Kou K, Wu G, Zhang Y, Wang Y (2016) Fabrication and characterization of AlN/PTFE composites with low dielectric constant and high thermal stability for electronic packaging. J Mater Sci-Mater Electron 27(1):286–292

Subodh G, Joseph M, Mohanan P, Sebastian MT (2007) Low dielectric loss polytetrafluoroethylene/TeO2 polymer-ceramic composites. J Am Ceram Soc 90(11):3507–3511

Yuan Y, Zhang SR, Zhou XH, Li EZ (2013) MgTiO3 filled PTFE composites for microwave substrate applications. Mater Chem Phys 141(1):175–179

Xie C, Liang F, Ma M, Chen X, Lu W, Jia Y (2017) Microstructure and dielectric properties of PTFE-based composites filled by micron/submicron-blended CCTO. Crystals 7(5):126

Rajesh S, Nisa VS, Murali KP, Ratheesh R (2009) Microwave dielectric properties of PTFE/rutile nanocomposites. J Alloys Compd 477(1):677–682

Nadal ME, Barnes PY (1999) Near-infrared 45/0 reflectance factor of pressed polytetrafluoroethylene (PTFE) powder. J Res Nat Inst Stand Technol 104(2):185

Tsai BK, Allen DW, Hanssen LM, Wilthan B, Zeng J (2008) A comparison of optical properties between high density and low density sintered PTFE. Proc of SPIE 7065:70650Y–706501

Barnes PY, Hsia JJ (1995) 45°/0° reflectance factors of pressed polytetrafluoroethylene (PTFE) powder. US Dept of Commerce Technology Administration NIST, Washington, DC, pp 101–102

Yang MK, French RH, Tokarsky EW (2008) Optical properties of Teflon® AF amorphous fluoropolymers. J Micro/Nanolithogr MEMS MOEMS 7(3):033010–033010

Ebnesajjad S (2013) Introduction to fluoropolymers: materials technology and applications. Elsevier, New York

Romack TJ, Kipp BJ, De Sirnone JM (1995) Polymerization of tetrafluoroethylene in a hybrid carbon dioxide/aqueous medium. ACS Macromol 28(24):8432–8434

Tervoort T, Visjager J, Graf B, Smith P (2000) Melt-processable poly (tetrafluoroethylene). Macromolecules 33(17):6460–6465

Frick A, Sich D, Heinrich G, Stern C, Schlipf M (2012) Classification of new melt-processable PTFE: comparison of emulsion-and suspension-polymerized materials. Macromol Mater Eng 297(4):329–341

Suzuki S, Whittaker MR, Wentrup-Byrene E, Monteiro MJ, Grondahl L (2008) Adsorption of well-defined fluorine-containing polymers onto poly (tetrafluoroethylene). Langmuir 24(22):13075–13083

Drobny JG (2009) Technology of fluoropolymers, 2nd edn. CRC Press Taylor & Francis Group, LLC

Hambir SS, Jog JP, Nadkarni VM (1994) Strength development in powder processing of poly (tetrafluoroethylene). Polym Eng Sci 34(13):1065–1069

Feng Y, Xiong T, Jiang S, Liu S, Hou H (2016) Mechanical properties and chemical resistance of electrospun polytetrafluoroethylene fibres. RSC Adv 6(29):24250–24256

Tzeng CJ, Yang YK, Lin YH, Tsai CH (2012) A study of optimization of injection molding process parameters for SGF and PTFE reinforced PC composites using neural network and response surface methodology. The Int J Adv Manuf Technol 63(5):691–704

Titterton WE, Frank K (1961) Blow molding of polytetrafluoroethylene. Resistoflex Corp US Patent 298396

Ochoa I, Hatzikiriakos SG (2005) Paste extrusion of polytetrafluoroethylene (PTFE): surface tension and viscosity effects. Powder Technol 153(2):108–118

Ochoa I, Hatzikiriakos SG, Mitsoulis E (2006) Paste extrusion of polytetrafluoroethylene: temperature blending and processing aid effects. Powder Technol 21(5):497–503

Kanazawa T, Matsuda Y, Tasaka S (2010) Fabrication of a porous structure of poly (tetrafluoroethylene) from a mixture with fumaric acid. Polym J 42(6):509–513

Kricheldorf HR, Nuyken O Swift G (2004) Handbook of polymer synthesis from Dekker M 2nd Ed ISBN 9780824754730

Llorens J (ed) (2015) Fabric structures in architecture. Woodhead publishing series in textiles. Elsevier

Rao M, Hooke CJ, Kukureka SN, Liao P, Chen YK (1998) The effect of PTFE on the friction and wear behavior of polymers in rolling-sliding contact. Polym Eng Sci 38(12):1946–1958

Dearn KD, Hoskins TJ, Petrov DG, Reynolds SC, Banks R (2013) Applications of dry film lubricants for polymer gears. Wear 298:99–108

Mashkov YK, Egorova VA, Chemisenko OV, Maliy OV (2016) Polymer nanocomposites development and research for petrochemical and oil and gas production equipment. Procedia Eng 152:545–550

Wenpeng H, Hui Z (2015) Application of PTFE heat exchanger in low-temperature waste heat of big coal-fired power plants. Appl Mech Mater 789-790:503–507

McCook NL, Burris DL, Dickrell PL, Sawyer WG (2005) Cryogenic friction behavior of PTFE based solid lubricant composites. Tribol Lett 20(2):109–113

Storgards E, Simola H, Sjöberg AM, Wirtanen G (1999) Hygiene of gasket materials used in food processing equipment part 2: aged materials. Food Bioprod Process 77(2):146–155

Barish JA, Goddard JM (2013) Anti-fouling surface modified stainless steel for food processing. Food Bioprod Process 91(4):352–361

Ebnesajjad S, Khaladkar PR (2004) Fluoropolymer applications in the chemical processing industries: the definitive user’s guide and databook. William Andrew Inc., New York

O’Brien M, Baxendale IR, Ley SV (2010) Flow ozonolysis using a semipermeable Teflon AF-2400 membrane to effect gas−liquid contact. Org Lett 12(7):1596–1598

Aptel P, Cuny J, Jozefowicz J, Morel G, Neel J (1972) Liquid transport through membranes prepared by grafting of polar monomers onto poly (tetrafluoroethylene) films. I. Some fractionations of liquid mixtures by pervaporation. J Appl Polym Sci 16(5):1061–1076

Teo AJ, Mishra A, Park I, Kim YJ, Park WT, Yoon YJ (2016) Polymeric biomaterials for medical implants and devices. ACS Biomater Sci Eng 2(4):454–472

Catanese JIII, Cooke D, Maas C, Pruitt L (1999) Mechanical properties of medical grade expanded polytetrafluoroethylene: the effects of internodal distance density and displacement rate. J Biomed Mater Res Part A 48(2):187–192

Greene JF, Preger Y, Stahl SS, Root TW (2015) PTFE-membrane flow reactor for aerobic oxidation reactions and its application to alcohol oxidation. Org Process Res Dev 19(7):858–864

Wegener M, Wirges W, Tiersch B (2007) Porous polytetrafluoroethylene (PTFE) electret films: porosity and time-dependent charging behavior of the free surface. J Porous Mater 14(1):111–118

Rodriguez-Lopez J, Alpuche-Aviles MA, Bard AJ (2008) Selective insulation with poly (tetrafluoroethylene) of substrate electrodes for electrochemical background reduction in scanning electrochemical microscopy. Anal Chem 80(5):1813–1818

Pan C, Kou K, Jia Q, Zhang Y, Wu G, Ji T (2017) Improved thermal conductivity and dielectric properties of hBN/PTFE composites via surface treatment by silane coupling agent. Compos Part B 111:83–90

James NK, Jacob KS, Murali KP, Ratheesh R (2010) Ba (Mg 1/3 Ta 2/3) O3 filled PTFE composites for microwave substrate applications. Mater Chem Phys 122(2):507–551

Yuan Y, Cui YR, Wu KT, Huang QQ, Zhang SR (2014) TiO2 and SiO2 filled PTFE composites for microwave substrate applications. J Polymer Res 21(2):366

Li Z, Liu J, Yuan Y, Li E, Wang F (2017) Effects of surface fluoride-functionalizing of glass fibre on the properties of PTFE/glass fibre microwave composites. RSC Adv 7(37):22810–22817

Menini R, Farzaneh M (2009) PTFE-coated anodized aluminum alloy 6061 with icephobic properties. In: Proceedings of the 13th International Workshop on Atmospheric Icing of Structures IWAIS, Andermatt Suisse

Jafari R, Momen G, Farzaneh M (2016) Durability enhancement of icephobic fluoropolymer film. J Coat Technol Res 13(3):405–412

Vigo F, Bottino A, Munari S, Capannelli G (1977) Preparation of asymmetric PTFE membranes and their application in water purification by hyperfiltration. J Appl Polym Sci 21(12):3269–3290

Feng S, Zhong Z, Zhang F, Wang Y, Xing W (2016) Amphiphobic polytetrafluoroethylene membranes for efficient organic aerosol removal. ACS Appl Mater Interfaces 8(13):8773–8781

Yamajo S, Kikkawa F (2004) Development and application of PTFE compound bearings. In: Dynamic positioning conference dynamic positioning society september

Hoashi J, Fumoto S, Oshita K (1987) Novel polytetrafluoroethylene fine powder. United States Patent, Patent No 4714748

Shimizu T, Hosokawa K, Kokumai M, Ono M (1993) Modified polytetrafluoroethylene fine powder and process for preparing the same. United States Patent- Patent Number: 5176958

Yan L Chao M, Xiao J, Gao L, Wiebner S (2015) Study on preparation of BaSO4-containing polytetrafluoroethylene granular powder. Adv Polym Tech 36(4). https://doi.org/10.1002/adv.21623

Nishioka A, Matsumae K, Watanabe M, Tajima M, Owaki M (1959) Effects of gamma radiation on some physical properties of polytetrafluoroethylene resin. J Appl Polym Sci 2(4):114–119

Ariawan AB, Ebnesajjad S, Hatzikiriakos SG (2001) Preforming behavior of polytetrafluoroethylene paste. Powder Technol 121(2):249–258

Ariawan AB, Ebnesajjad S, Hatzikiriakos SG (2002) Properties of polytetrafluoroethylene (PTFE) paste extrudates. Polym Eng Sci 42(6):1247–1259

Huang R, Hsu PS, Kuo CY, Chung Chen S, Lai JY, Lee LJ (2007) Paste extrusion control and its influence on pore size properties of PTFE membranes. Adv Polym Technol 26(3):163–172

Rahl FJ, Evanco MA, Fredericks RJ, Reimschuessel AC (1972) Studies of the morphology of emulsion-grade polytetrafluoroethylene. J Polym Sic Part A-2: Polym Phys 10(7):1337–1349

Lancaster JK (1972) Polymer-based bearing materials: the role of fillers and fibre reinforcement. Tribology 5(6):249–255

Bijwe J, Neje S, Indumathi J, Fahim M (2002) Friction and wear performance evaluation of carbon fibre reinforced PTFE composite. J Reinf Plast Compos 21(13):1221–1240

Tevrüz T (1998) Tribological behaviors of carbon filled polytetrafluoroethylene (PTFE) dry journal bearings. Wear 221(1):61–68

Zhang Z, Aglan H, Faughnan P, Bryan C (1998) Fracture and fatigue analysis of 15% chopped glass fibre reinforced PTFE.J. Reinf Plast Compos 17(8):752–771

Cheng XH, Xue YJ, Xie CY (2002) Friction and wear of rare-earth modified glass-fibre filled PTFE composites in dry reciprocating sliding motion with impact loads. Wear 253(7):869–877

Cheng X, Xue Y, Xie C (2003) Tribological investigation of PTFE composite filled with lead and rare earths-modified glass fibre. Mater Lett 57(16):2553–2557

Wang Y, Yan F (2007) A study on the tribological behavior of transfer films of PTFE/bronze composites. Wear 262(7):876–882

Unal H, Kurtulus E, Mimaroglu A, Aydin M (2010) Tribological performance of PTFE bronze filled composites under a wide range of application conditions. J Reinf Plast Compos 29(14):2184–2191

Khoddamzadeh A, Liu R, Wu X (2009) Novel polytetrafluoroethylene (PTFE) composites with newly developed Tribaloy alloy additive for sliding bearings. Wear 266(7):646–657

Lontz JF, Kumnick MC (1963) Wear studies on moldings of polytetrafluoroethylene resin considerations of crystallinity and graphite content. ASLE trans 6(4):276–285

Scott D, Mills GH (1973) Scanning electron microscopical study of fibre reinforced polymeric cage materials for rolling bearings. Polymer 14(4):130–132

Aderikha VN, Krasnov AP, Shapovalov VA, Golub AS (2014) Peculiarities of tribological behavior of low-filled composites based on polytetrafluoroethylene (PTFE) and molybdenum disulphide. Wear 320:135–142

Babuska TF, Pitenis AA, Jones MR, Nation BL, Sawyer WG, Argibay N (2016) Temperature-dependent friction and wear behavior of PTFE and MoS2. Tribol Lett 63(2):1–7

Zaporojtchenko V, Podschun R, Schürmann U, Kulkarni A, Faupel F (2006) Physico-chemical and antimicrobial properties of co-sputtered Ag–Au/PTFE nanocomposite coatings. Nanotechnology 17(19):4904

Bolvari A, Glenn S, Janssen R, Ellis C (1997) Wear and friction of aramid fibre and polytetrafluoroethylene filled composites. Wear 203:697–702

Wang J, Musameh M (2003) Carbon nanotube/Teflon composite electrochemical sensors and biosensors. Anal Chem 75(9):2075–2079

Shi Y, Feng X, Wang H, Lu X (2008) The effect of surface modification on the friction and wear behavior of carbon nanofibre-filled PTFE composites. Wear 264(11):934–939

McCook NL, Boesl B, Burris DL, Sawyer WG (2006) Epoxy ZnO and PTFE nanocomposite: friction and wear optimization. Tribol Lett 22(3):253–257

Prakash J, Tripathi A, Pivin JC, Tripathi J, Chawla AK, Chandra R, Kim SS, Asokan K, Avasthi DK (2011) Study on the synthesis of magnetic nanocomposite (Ni-Teflon) by swift heavy ion beam mixing. Adv Mater Lett 2(1):71–75

Rahachou AV, Rogachev AA, Yarmolenko MA, Xiao-Hong J, Bo LZ (2012) Molecular structure and optical properties of PTFE-based nanocomposite polymer–metal coatings. Appl Surf Sci 258(6):1976–1980

Vail JR, Burris DL, Sawyer WG (2009) Multifunctionality of single-walled carbon nanotube–polytetrafluoroethylene nanocomposites. Wear 267(1):619–624

Beckford S, Mathurin L, Chen J, Fleming RA, Zou M (2016) The effects of polydopamine coated cu nanoparticles on the tribological properties of polydopamine/PTFE coatings. Tribol Int 103:87–94

Tian ZQ, Wang XL, Zhang HM, Yi BL, Jiang SP (2006) Microwave-assisted synthesis of PTFE/C nanocomposite for polymer electrolyte fuel cells. Electrochem Commun 8(7):1158–1162

Baronin GS, Buznik VM, Zavrazhin DO, Kobzev DE (2013) Polytetrafluoroethylene-based nanocomposites with increased operational rates. Machines Technologies Materials ISSN 1313–0226

Burris DL, Sawyer WG (2005) Tribological sensitivity of PTFE/alumina nanocomposites to a range of traditional surface finishes. Tribol Trans 48(2):147–153

Antonioli D, Sparnacci K, Laus M, Boarino L, Righetti MC (2013) Preparation and properties of PTFE/PAI nanocomposites. Polym Compos 34(9):1451–1459

Antonioli D, Laus M, Sparnacci K, Deregibus S, Kapeliouchko V, Poggio T, Zuccheri G, Passeri R, Boarino L (2012) Preparation and thermal characterization of PTFE/PES nanocomposites. Macromol Symp 311:70–76

Van-Rooyen LJ, Bissett H, Khoathane MC, Karger-Kocsis J (2016) In: Preparation of PTFE/graphene nanocomposites by compression molding and free sintering: a guideline. J Appl Polym Sci 133(17). https://doi.org/10.1002/app.43369

Burris DL, Zhao S, Duncan R, Lowitz J, Perry SS, Schadler LS, Sawyer WG (2009) A route to wear resistant PTFE via trace loadings of functionalized nanofillers. Wear 267(1):653–660

Polastri F, Ligabue O, Kapeliouchko V, Garrison D, Marchese E (2007) In: PTFE nanocomposites in tubes and W&C. In: International wire & cable symposium proceedings of the 56th IWCS, Inc., IWCS

Subodh G, Pavithran C, Mohanan P, Sebastian MT (2007) PTFE/Sr2Ce2Ti5O16 polymer-ceramic composites for electronic packaging applications. J Eur Ceram Soc 27(8):3039–3044

Basu BJ, Dinesh Kumar V (2011) Fabrication of superhydrophobic nanocomposite coatings using polytetrafluoroethylene and silica nanoparticles. ISRN Nanotechnology 2011:6

Kim DY, Lee JG, Joshi BN, Latthe SS, Al-Deyab SS, Yoon SS (2015) Self-cleaning superhydrophobic films by supersonic-spraying polytetrafluoroethylene–titania nanoparticles. J Mater Chem A 3(7):3975–3983

Clough NE (2009) Innovations in ePTFE fibre technology: new capabilities new applications new opportunities. In: Techtextile North America Symp

Harsányi G (2000) Polymer films in sensor applications: a review of present uses and future possibilities. Sens Rev 20(2):98–105

Younse P, de Alwis T, Backes P, Trebi-Ollennu A (2012) Sample sealing approaches for Mars sample return caching. In: Aerospace Conference, IEEE, pp 1–11

Kim JJ, Jeong JH, Sohn JY (2009) Sound absorption characteristics of PTFE membrane material and their application to a multi-purpose stadium. Build Serv Eng Res Technol 30(3):213–226

Bartee BK, Carr JA (1995) Evaluation of a high-density polytetrafluoroethylene (n-PTFE) membrane as a barrier material to facilitate guided bone regeneration in the rat mandible. J Oral Implantol 21(2):88–95

Roy-Chaudhury P, El-Khatib M, Campos-Naciff B, Wadehra D, Ramani K, Leesar M, Mistry M, Wang Y, Chan JS, Lee T, Munda R (2012) Back to the future: how biology and technology could change the role of PTFE grafts in vascular access management. Seminars in dialysis Blackwell Publishing Ltd 25(5):495–504

Simmons JEL, Knox RT, Moss WO (1998) The development of PTFE (polytetrafluoroethylene)-faced hydrodynamic thrust bearings for hydro generator application in the United Kingdom. Proceedings of the Institution of Mechanical Engineers Part J: J of Eng Tribol 212(5):345–352

Liang Q, Yan X, Gu Y, Zhang K, Liang M, Lu S, Zheng X, Zhang Y (2015) Highly transparent triboelectric nanogenerator for harvesting water-related energy reinforced by antireflection coating. Sci Rep 5:9080

Lakshmanan A, Chakraborty SK (2015) Recycling of polytetrafluoroethylene (PTFE) scrap materials. In: Sintering Techniques of Materials, Intech

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dhanumalayan, E., Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—a review. Adv Compos Hybrid Mater 1, 247–268 (2018). https://doi.org/10.1007/s42114-018-0023-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-018-0023-8