Abstract

N-glycosylation of recombinant proteins using bacterial glycosylation system has proven to be a valuable although developing tool ultimately applicable to various industries. When used for enzyme engineering, it offers the possibility of increased stability or immobilization route and thus increasing effectiveness of e.g. biotransformation or other biocatalysis procedures. One such promising enzyme is alcohol dehydrogenase (ADH) for use in redox biotransformation reactions. Given the current possibilities of recombinant enzyme production, including major advances in glycoengineering and glycoprotein production in bacterial organisms, the aim of this work was the production of thermotolerant ADH from Rhodococcus ruber (RrADH) in glycosylated form in Escherichia coli. We have successfully developed a dual plasmid expression system enabling glycosylation of target proteins utilizing a glyco-tag approach. We were able to produce RrADH in soluble form and at the same time we detected a bacterial glycan conjugated to RrADH as well as the activity of the enzyme. The glycan bound to recombinant enzyme can be used for oriented covalent immobilization of the enzyme, which would increase the potential for its practical application in biotransformation of various compounds.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biocatalysts, either by using isolated enzymes or whole unicellular organisms, represents an effective tool in the current synthesis of organic compounds, which is characterized by significant chemo-, regio- and especially stereoselectivity in the production of pure enantiomers. In addition, it brings an environmental safety feature to synthetic chemistry in the pharmaceutical, food or agricultural industries. One such enzyme with biotechnological potential is alcohol dehydrogenase (ADH) from various source species of microorganisms with variable specific properties, including enantioselectivity or thermostability. For example, enzymatic catalysis using ADH1 from Saccharomyces cerevisiae represents a very promising approach to the production of important components of the food or cosmetics industry, such as vegetable hexagonal aromatic alcohols (Utekal et al. 2014; Levarski et al. 2018).

Production of recombinant enzymes for biotechnological purposes, the producer of choice is often Escherichia coli, a Gram-negative bacterium with good growth kinetics, studied genetics and proven routinely used handling techniques (Rosano and Ceccarelli 2014; Packiam et al. 2020). Currently, overexpression of proteins in E. coli offers some possibilities that have only been available for only a short period of time. Such a possibility is glycosylation in prokaryotes, which was considered the prerogative of eukaryotic organisms until 1999 (Szymanski et al. 1999). The topic of bacterial N-glycosylation has been covered in multiple review papers (Nothaft and Szymanski 2013, 2019; Jaffé et al. 2014; Anyaogu and Mortensen 2015). Modern methods of manipulating the glycosylation pathway, its modifications and their subsequent applications offer new ways of manipulating recombinant proteins, including enzymes. Through rational design of the expression vector, efficient overexpression, successful glycosylation of a soluble enzyme in E. coli, and optimized purification, the carbohydrate units of the bound glycan can be used for immobilization by covalent interaction without loss of activity (Hu et al. 2013; Hortigüela et al. 2015). Due to the environmental burden, inefficiency and cost of many industrial synthetic processes, this combination of methods allows the production of immobilized enzymes adapted for specific industrial uses with the potential to significantly alleviate these problems (Eş et al. 2015).

Biotransformation, often referred to as biocatalysis, is a method of using biological systems to catalyze the conversion of a chemical compound (substrate) to another (product). Among them, the exceptional property of enzymes is their selectivity, namely chiral (diastereoselectivity and/or enantioselectivity), site-specific (regioselectivity) and selectivity for specific functional groups of the substrate molecule (chemoselectivity). These properties make it possible to minimize the presence of by-products, including undesired isomers, and thus to facilitate the separation of the target product from the reaction mixture. Last but not least, higher conversion efficiencies and environmental friendliness of biocatalysts add value (Hildebrand and Lütz 2006; Höllrigl et al. 2008; Lee et al. 2013). The growing interest in biocatalysis is also focused on the search for enzymes originating in a number of extremophilic organisms with important properties such as thermostability, tolerance to denaturing compounds, including organic solvents and the like.

ADH originating from the Gram-positive bacterium R. ruber DSM 44541 (RrADH, Uniprot db Q8KLT9 (Q8KLT9_9NOCA)) is one of the medium-chain NAD (P) -dependent zinc-dependent ADHs (EC 1.1.1.1). Zinc atoms (2 Zn/monomer) play an important role both catalytically and structurally in stabilizing the desired tertiary structure, and thus its ability to tolerate elevated temperature or pH (Kosjek et al. 2004; Hamnevik et al. 2014). The size of the RrADH monomer is 38 kDa and in native form functions as a homotetramer (Karabec et al. 2010).

It catalyzes the reversible reduction/oxidation of ketones and secondary alcohols and prefers the spatially larger phenyl-substituted compounds over small aliphatic chains and the S-enantiomers (Kosjek et al. 2004; Hamnevik et al. 2014).

RrADH is characterized by tolerance to high concentrations of acetone and isopropanol. These compounds are actually useful as co-substrates for the cofactor regeneration of NAD (P) H in a substrate-coupled manner. RrADH does not require a cell membrane for protective purposes and itself has a high degree of resistance to these compounds. The enzyme is also stable at high pH (up to 11) and, most importantly, tolerates elevated temperatures up to 60 °C. The temperature optimum was determined to be in the range of 30–50 °C, with half-life at 50 °C being 35 h. When the temperature was raised to 70 °C, no activity was observed using the substrates acetophenone and rac-1-phenylethanol (Stampfer et al. 2003; Kosjek et al. 2004).

The ideal form of enzyme for biotransformation is in the form of a stable, active and, at best, reusable catalytic tool. These properties are achieved by a suitable enzyme immobilization approach. Covalent oriented immobilization through the biorthogonal group, which does not disrupt the integrity of the enzyme itself, has great potential due to its ability to preserve the structure of the catalytically active site. Such a protruding group may be, for example, an oligosaccharide unit of a glycoprotein. It follows that, in general, any glycosylated protein containing oxidizable hydroxyl groups of carbohydrate molecules can be effectively immobilized with the certainty that the conjugation mechanism will not disrupt the function of the protein. The same principle is routinely used in the preparation of commercial horseradish peroxidase (HRP)-conjugated antibodies for immunoblot protein analysis (Singh et al. 2013; Steen Redeker et al. 2013). N-glycosylation pathway from Campylobacter jejuni was used to produce glycosylated scFv antibody fragments in E. coli strain CLM37 and subsequently covalently immobilized them via a linked glycan by reacting the aldehyde = O group of the saccharide with an amine anchored to the matrix to form the oxime. With this approach, authors achieved fourfold higher activity than in the case of ionic immobilization (Hu et al. 2013).

Attempts to immobilize ADH are surprisingly focused mainly on the use of adsorption interactions (Barbosa et al. 2013) while covalent interactions are given relatively little attention. ADH from Lactobacillus brevis was immobilized on Sepabeads® nonionic polymer beads, allowing covalent attachment of -SH, -NHR, -NH2 and -OH groups of the protein to an amino-epoxy functional group on the matrix. With this approach, they obtained a 60-fold in-creased stability (degradation half-life > 1200 h at 30 °C) of the active and selective enzyme compared to the soluble enzyme (Hildebrand and Lütz 2006).

Upon covalent immobilization of ADH1 from S. cerevisiae on Fe3O4 magnetic nanoparticles, the enzyme retained 60% of the free enzyme activity, increasing its stability tenfold. At the same time, however, there were structural changes in the enzyme molecules as the specific activity parameters and Km for the cofactor NADH and the substrate 2-butanone changed, indicating lower affinity compared to free ADH (Liao and Chen 2001). If structural parameters of the enzyme are to be preserved in order to allow immobilization, the use of peptide tags or a biorthogonal functional group, including a glycan tag, conjugated to the enzyme molecule is a promising approach. Glycans as a tool for immobilization could have a greater perspective, as the reaction mechanism is selective for vicinal saccharide diols allowing oxime ligation by attachment to an amine or hydrazine functional group anchored to the target matrix. In other words, this mechanism is friendly to protein structural integrity (Steen Redeker et al. 2013; Ulrich et al. 2014; Meldal and Schoffelen 2016).

In our previous works (Utekal et al. 2014; Levarski et al. 2018) we have demonstrated production and application of recombinant enzymes for biotransformation of aromatic compounds. This work builds on those results, with the aim of optimizing production of glycosylated enzymes capable of oriented immobilization through attached glycans.

Materials and methods

Plasmid isolation

Plasmid DNA was isolated using the QIAprep® Spin Miniprep Kit and CompactPrep® Plasmid Midi Kit (both Qiagen) recommended by the manufacturer.

Agarose gel electrophoresis

A 1% agarose gel in Tris–acetate (TAE) buffer enriched with DNA intercalating agent Stain G (Serva; in the ratio 1–2 µL/100 mL of gel) was used for DNA separation, enabling subsequent visualization of DNA at UV radiation (λ = 254 nm) and photo documentation in a G: Box F3 device (Syngene) using GeneSys software. Samples for separation were prepared by mixing with 6 × DNA Loading Dye staining solution (Thermo Scientific) and electrophoresis was performed at 4—10 V · cm−1 for 45—60 min. The GeneRuler 1 kb Plus DNA Ladder (Thermo Scientific) was used as a molecular size marker.

DNA extraction

Fragments of electrophoretically separated plasmid DNA digested with restriction endonucleases were isolated from a 1% agarose gel using the QIAquick® Gel Extraction Kit (Qiagen) according to the manufacturer's recommended procedure.

Cloning

For the construction of the expression vectors pJexpress401-ScADH-CGH and pJex-press401-RrADH-CGH fragments of plasmids pJexpress401-IFN, pUC57ADH-CGH and pUC57-RrADH were used. Plasmids were digested with restriction endonucleases XbaI/SalI or NdeI/XhoI providing complementary cohesive ends. Fragments isolated from electrophoretically separated digested plasmid DNA were used in a ligation reaction and incubated for 1 h at room temperature. The ligation mixture was then used to transform E. coli cells of strain DH5α or JM109 (Table 2). In these strains, plasmids were successfully generated and stored as glycerol stocks.

Strain transformation

Overnight culture inoculated from a glycerol stock or agar plate grown (for 14—16 h; 37 °C) in LB medium (20 mL) enriched with glucose (1%) and the appropriate antibiotic was inoculated into 50 mL of sterile LB medium (1: 100). After reaching the exponential growth phase (OD600 = 0.5—1.0), culture was chilled on ice (15–20 min), centrifuged (1920 × g; 10 min; 4 °C). The cell pellet was resuspended in pre-chilled MgCl2 solution (20 mL) and the mixture was centrifuged (1920 × g; 10 min; 4 °C). The resulting cell pellet was resuspended in pre-chilled CaCl2 solution (2.5 mL) and the mixture was incubated on ice (1.5 h). 50% (v/v) sterile glycerol (0.8 mL volume) was then added to the mixture and the cell suspension was aliquoted (50—100 µL) and stored at − 80° C.

For transformation, 5—10 µL of ligation mixture (or 1—2 µL of plasmid) was added to 50 µL of chemically competent cells. The mixture was incubated on ice (10 min), then subjected to heat shock (42° C; 45 s) and returned to ice (2 min). Fresh LB medium (0.5 mL) without antibiotic was added to the cell suspension and the mixture was incubated at 37 °C with constant shaking (1 h; 550 rpm). The cells were then plated on an agar LB plate supplemented with the appropriate antibiotic and cultured overnight (37 °C). Grown colonies were further analyzed.

Recombinant strains were stored as glycerol stocks prepared from overnight culture in cryotubes at − 80 °C.

Cell cultivation and protein expression in shake-flasks

Overnight culture inoculated from a glycerol stock or agar LB dish grown (for 14—16 h; 37 °C for expression at 37 °C or 28 °C for expression at lower temperatures; 180—200 rpm) in the appropriate culture medium (LB, Dynamite or ZYM-5052 autoinduction medium, 20 mL) glucose-enriched (1% (w/v)) and the appropriate antibiotic was inoculated into 100 mL of glucose-enriched culture medium (1:100) (0.1% (w/v)) and the relevant antibiotic. After reaching the exponential growth phase (OD600 = 0.5—1.0), expression of the protein of interest was induced by adding arabinose or IPTG (to a final concentration of 0.2% (w/v) arabinose or 1 mM IPTG) depending on the type of inducible promoter. During the expression (20—24 h), the OD600 of culture samples was monitored.

Cell cultivation and protein expression in a laboratory bioreactor

The procedure for culturing in a bioreactor was similar to that in shake-flasks. The overnight culture was grown in the appropriate culture medium in a volume of 100 mL (for 14—16 h; 37 °C when expressed at 37 °C or 28 °C when expressed at lower temperatures; 180—200 rpm) enriched with glucose (1% (w/v)) and the corresponding antibiotic. The overnight culture was used to inoculate 1000 mL of pre-sterilized glucose-enriched culture medium (0.1% (w/v)) and the appropriate antibiotic, with a stable culture temperature and pH adjusted to 7.2 by automatic titration with HCl solutions (3.6% (v/v)) and NH4OH (28–30%) (in a 2 L Sartorius Biostat B + fermenter). The aeration of the culture was set to a minimum value of 30%, depending on which the rotor speed set to min. 200 rpm and at the same time manual control of air supply in the interval 0.6—2 L · per min. After reaching the exponential growth phase (OD600 = 10), expression of the protein of interest was induced by adding arabinose or IPTG (to a final concentration of 0.2% (w/v) arabinose and 1 mM IPTG) depending on the type of inducible promoter. During the expression (20—24 h), the OD600 was monitored, and samples were collected from the culture.

SDS-PAGE analysis

Protein separation was achieved by vertical polyacrylamide gel electrophoresis using sodium dodecyl sulfate under reducing conditions (SDS-PAGE) according to Laemmli (1970) or using a modified method according to Schägger and von Jagow (1987) depending on the mass of the proteins of interest, in an electrophoretic apparatus (SE260, Hoefer). Denaturation of the proteins in the sample was achieved by mixing with sample buffer and subsequent heating (95 °C; 10 min). Depending on the proteins to be determined, a gel with a given concentration was prepared (in this work 10% or 12%). Electrophoresis was performed in electrode buffer at 180 V (~ 90 min). Proteins were separated according to their molecular weight and migrated towards the anode due to the negative charge of bound SDS molecules. Comparison with a marker was used to control molecular weight and protein separation. Proteins in gels were stained by reaction with Coomassie Brilliant Blue G-250 staining mixture.

Western blot analysis

After SDS-PAGE, separated proteins were obtained, which were then transferred from the gel to a polyvinylidene difluoride (PVDF) membrane (Immun-Blot® 0.2 µm, Bio-Rad) activated in isopropanol (ca. 15 s) and washed thoroughly in H2O (at least 2 min with vigorous shaking) and in the transfer solution (at least 5 min). The transfer took place at a voltage of 10 V (at a maximum current of 220 mA; 50 min) in a semi-dry transfer apparatus (Fastblot B43, Biometra GmbH). A sandwich composed of blotting papers (Whatman-GB005 or GB003, GE Healthcare), PVDF membrane and gel was pre-wetted in the transfer solution. Tris and SDS again induced protein migration to the anode. After completion of the transfer, the membrane was incubated in blocking solution with constant shaking (RT; 30 min). After blocking the membrane surface, the membrane could be incubated (overnight; 4 °C) in a solution of primary antibody (mouse anti-His; diluted 1:1000), which is specific for the protein to be determined. At the end of the incubation, the excess antibody was removed by washing the membrane in TBST solution (4 × 30 s + 1 × 10 min). In the next step, the membrane was incubated (RT; 1 h) in a secondary antibody solution (goat anti-mouse; diluted 1: 100,000) specific for the Fc fragment of the primary murine antibody. The excess of secondary antibody was removed in a manner similar to primary by re-washing the membrane in TBST solution. The horseradish peroxidase (HRP) -labelled secondary antibody allowed the immunodetection of proteins by the chemiluminescence method. The PVDF membrane with bound antibodies was incubated in a mixture of H2O2 and luminol + signal enhancer (Clarity Max®, Bio-Rad). By exposing the thus treated membrane in a detection apparatus (ImageQuant® LAS 500; GE Healthcare), a signal of chemiluminescent radiation was detected at the site where the antibodies bound.

Lectine blot analysis

The transfer of proteins to the PVDF membrane was identical to that of WB. After completion of the transfer, the membrane surface was incubated in bovine serum albumin blocking solution (BSA) with constant shaking (RT; 30 min), followed by streptavidin (SA) blocking solution to eliminate endogenous biotinylation (RT; overnight 14—16 h). The last blocking step was incubation in biotin solution to cover potentially free binding sites of bound SA (RT; 30 min). To detect bacterial glycans, the membrane was incubated in a solution of biotinylated lectin SBA, which has an affinity for α-GalNAc molecules found in the bacterial glycan. The solution of polyHRP-labelled streptavidin allowed the detection of glycosylated proteins, due to the interaction with biotin conjugated to lectin SBA, using the chemiluminescence method identical to WB. Between all incubation steps, the membrane was washed in TBST solution (2 × 5 min) to remove excess previous mixtures in which the membrane was present.

Protein purification

Extraction of proteins from periplasm

Chemical permeabilization by sodium deoxycholate

Periplasmic proteins were extracted by the method of Jalalirad (2013) in a solution of 0.1% sodium deoxycholate (DOC) in 200 mM Tris–HCl pH 7.5 (Table 3.2 D). The cell pellet obtained by centrifugation after culturing was incubated in the solution for 60 min at RT, and the mixture was vortexed briefly intermittently every 10 min (a volume of 50 mL of DOC solution was used for a cell pellet from 100 mL of culture). After centrifuging the mixture (7690 × g; 30 min; 4 °C), the obtained supernatant was dialyzed against a solution having the same composition as the equilibration solution for subsequent affinity chromatography.

Osmotic shock

Extraction of periplasmic proteins by osmotic shock was ensured by resuspending the cells in a solution (OS) with the composition: 200 mM TrisHCl pH 7.5, 1 mM EDTA, 20% (w/v) sucrose, 0.5 mg/mL lysozyme. The protocol was adapted from the Jalalirad (2013) similar to chemical permeabilization using DOC. The mixture was statically incubated for 15 min at RT and then pre-cooled H2O in a ratio of 1: 1 with the original solution was added to the mixture (for a cell pellet from a 100 mL culture it was 25 mL OS + 25 mL H2O). The treated cells were centrifuged (7690 × g; 30 min; 4 °C) and the supernatant was dialyzed against a solution identical to the affinity chromatography equilibration solution following dialysis.

Disruption of cells by ultrasound

Homogenization of cell lysates was achieved by ultrasonicating the cells (Sonopuls HD300; Bandelin) with the KE76 probe. The cell pellet obtained from 100 mL of culture was suspended in sonication buffer in a volume of 40 mL in a plastic tube. The tube was placed on ice to eliminate local overheating during procedure. The program was set for 10 cycles of ultrasonic homogenization (15 s, 30% amplitude) followed by cooling with occasional stirring (45 s). The obtained lysate was centrifuged (7690 × g; 30 min; 4 °C), sedimenting insoluble cellular material, and soluble proteins remaining in the supernatant. The insoluble sediment was resuspended in solubilization solution by 2% (w/v) SDS, incubated for 1 h with occasional stirring, and then centrifuged (7690 × g; 30 min; 4 °C). The obtained supernatant was used to analyze the distribution of the protein of interest in the cell in soluble and insoluble fraction by SDS-PAGE, WB and/or LecB.

Affinity chromatography

The ÄKTA-avant 25 FPLC system (GE Healthcare) with 1 mL HisTrap-HP columns (34 μm particle size, GE Healthcare) or HisTrap-FF (particle size 45–165 µm) were used for affinity chromatography (IMAC) purification. The program consisted of the steps: washing the column with water (5—10 column volumes, CV), equilibration with equilibration/washing buffer (50 mM TrisHCl pH 8, 500 mM NaCl, 5—10 CV); sample application; washing with equilibration/washing buffer (volume dependent on stabilization of UV280 value); elution with elution solution (50 mM TrisHCl pH 8, 500 mM NaCl, 500 mM imidazole, max. 5 CV). In the case of a very non-specific interaction, and thus also the number of contaminating proteins present in the eluate, the sample was diluted by equilibration or elution solution so that imidazole is present in a concentration of 40 mM and in the washing step 60 mM. The program was set to automatically collect fractions: flow through (fraction not collected on the column when applying the sample), wash (fraction from column washing) and elution (collection set to capture a fixed volume of 1 mL; max. 5 mL and 5 CV, respectively). The collected fractions were analyzed by SDS-PAGE, optionally WB and/or LecB.

Protein concentration measurement

A modified method by Lowry et al. (1951) was used to determine the protein concentration. For each measurement on the microtiter plate, a calibration curve of standard BSA solutions with concentrations of 0 (blank); 25; 50; 100; 150; 200; 250; 300 µg/mL was prepared. 100 µL of the prepared standards were applied to the wells in duplicates, so the standard solutions were prepared in 10% excess, i. in this case 220 µL. The measured sample was also diluted to a volume of 220 µL, as it was applied in duplicate as standard solutions. Since the protein concentration in the sample was unknown, several dilutions were prepared in the same proportions as the diluted standards from the BSA stock solution. After loading the standards and samples to the plate in a volume of 100 µL, 100 µL of Lowry reagent was added and the mixture was incubated for 10 min (time counted from the last sample). Subsequently 100 µL of Folin-Ciocalteu reagent was added and the mixture was incubated for at least 10 min, ideally outside the direct light source. The absorbance at 750 nm was measured using a microtiter plate spectrophotometer (Tecan Saphire II-Basic), and the absorbance of the blank (0 µg/mL BSA standard) had to be subtracted from all measurements before the evaluation itself. The result was evaluated by binomial regression analysis of the concentration dependence of the c (y) concentration on the absorbance of A750 (x).

Enzymatic activity measurement

Enzyme activity was monitored by spectrometry (Shimadzu UV-1800 spectrophotometer) based on absorbance at 340 nm (A340), in which light is absorbed by NADH molecules resulting from the reduction of the NAD+ input component. The reactions were designed to measure changes in A340 using two different concentrations of the input cofactor NAD+ (1.6 or 4.8 mM) at three different concentrations (100; 200; 300 mM) of two monitored substrates, 2-butanol and isopropanol, over 10 min and 37 °C. The reaction volume was 1 mL and the composition was modified according to Hamnevik et al. (2014). The reaction contained 0.1 M of phosphate buffer pH 7.4, appropriate substrate and NAD+ cofactor diluted in the above concentrations, and enzyme (in our case the eluate dialyzed against the storage solution) in a volume of 200 µL with the addition of 100 µL storage solution (if necessary, a different dilution ratio of the eluate). The remaining reaction volume (up to 1 mL) was water. A plot of the change in absorbance ΔA340 versus time t was constructed. The reaction was initiated by the addition of the enzyme.

Results

Plasmid construction

For pJexpress401-ScADH-CGH (Table 1), pJexpress401-IFN was used as the source of the vector sequence. The source of the desired insert, the entire ScADH-CGH expression cassette, including the proposed glycan binding sites—glyco-tags (GT; 5 repeats of the D-Q-N-A-T motif; Fisher et al. (2011)) and His tag, plasmid pUC57-ScADH-CGH was obtained from Genscript. Both plasmids, pJexpress401-IFN and pUC57-ScADH-CGH, were digested with restriction endonucleases XbaI/SalI and fragments purified by preparative electrophoresis followed by isolation of the vector and insert sections obtained, were used as input reactants for the ligation reaction. After transformation and selection of recombinants, the recombinant plasmid pJexpress401-ScADH-CGH was obtained, verified by digestion of the inserted region with the XbaI/SalI restriction enzymes used in the cloning.

The expression vector pJexpress401-RrADH-CGH (Table 1) was constructed from the newly generated plasmid pJexpress401-ScADH-CGH as the source of the vector and the commercially obtained plasmid pUC57-RrADH (Genscript) as the source of the insert, the gene encoding RrADH (UniProtKB—Q8KLT9). Both of these plasmids were digested with NdeI/XhoI enzymes, and the vector and insert sections thus obtained were ligated. The recombinant plasmid pJexpress401-RrADH-CGH was also verified by digesting the insert with the NdeI/XhoI used for the cloning.

Production of RrADH in shake-flask cultures

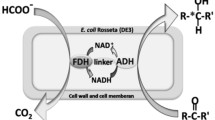

Using plasmids pJexpress401-RrADH-CGH and pACYC(pgl2) (Table 1) the E. coli CLM24 pACYC (pgl2) pJexpress401-RrADH-CGH (GR) expression system was prepared by sequential transformation, providing cytoplasmic protein expression under the control of the T5 promoter, export to the periplasm due to the PelB signal sequence for the Sec translocon and periplasmic N-glycosylation of potentially five glycosylatable GTs located at the C-terminus of RrADH. The E. coli CLM24 system (Table 2) containing only one of the plasmids, CLM24 pJexpress401-RrADH-CGH (CR), served as a negative control of glycosylation.

GR and CR were cultured in 100 mL volumes in Erlenmeyer flasks in two types of medium (LB; D) at three different temperatures (37; 28; 20 °C; Figs. 1 and 2). The obtained biomass was subjected to RrADH solubility analysis and detection of the presence of bacterial glycan using selected SBA lectin.

RrADH solubility analysis

Cell pellets obtained from GR/CR expression at 37/28/20 °C in LB/D medium (GR/CR 37/28/20 LB/D) were treated with DOC. The supernatant (DOC) obtained by centrifugation was purified by affinity chromatography, while the pellet was sonicated. The suspension formed by sonication was centrifuged and the obtained supernatant (SNs) was also purified, and the pellet was solubilized in SDS solution (Psol) in the same volume as in the sonication and centrifuged. The supernatant after this detergent solubilization represented insoluble proteins for comparison with the soluble fraction. An alternative was a procedure without a DOC treatment step in order to obtain the highest possible amount of gRrADH due to the inefficiency of the DOC approach found in the previous section. Individual fractions were analyzed by WB (interaction with anti-His antibody; Figs. 3, 4, and 5). When the same volumes were used for DOC extraction, sonication and solubilization by SDS, the samples loaded on SDS-PAGE in the same volume are comparable in terms of quantitative protein yield. If different volumes were used for each method, the loading on SDS-PAGE was converted to hypothetically identical starting volumes for re-liable comparability of individual samples.

Western blot analysis of RrADH and ScADH solubility produced by CLM24 pACYC(pgl2) pJex-press401-RrADH-CGH (GR), CLM24 pJexpress401-RrADH-CGH (CR), CLM24 pACYC(pgl2) pJex-press401-ScADH-CGH (GS) and CLM24 pJexpress401-ScADH-CGH (CS) at 20°C in Dynamite (D; panels A,B) and Autoinduction (A; panel B) medium. (SNs – soluble fraction after DOC1, Psol – insoluble fraction)

Detection of gRrADH

DOC or SNs obtained from treatment of GR/CR expression cells at 20 °C in D medium (GR/CR 20D) was purified by affinity chromatography on a 1 mL Ni2+ column with. Fractions obtained by chromatography, fraction not captured on the column (flow-through, FT), fraction from column washing (wash, W) and elution (E), were subsequently analyzed by SDS-PAGE, WB (interaction with anti-His antibody) and by LecB (by SBA with affinity for GalNAc) (Fig. 6). The same volume of input sample was used for all purifications and also the method was set to a fixed elution volume so that the samples obtained from the individual purifications were comparable to each other.

RrADH enzymatic activity

To confirm the catalytic properties of RrADH, the activity was monitored for two potential substrates, secondary alcohols isopropanol and 2-butanol at three different concentrations (100; 200; 300 mM) and two different concentrations of the input cofactor NAD+ (1.6 and 4.8 mM) at pH 7.4 and 37 °C. From the graphs of the absorbance values measured at 340 nm for 10 min, the dependence of the slope of the curves on the substrate concentration is evident (Fig. 7). Given the concentration of purified RrADH was 35.9 ± 4.3 µg/mL, Km value was calculated to have an average value of 1160.47 µM (isopropanol) and 514.80 µM (2-butanol) with Vmax values of 3,15 µM/min (isopropanol) and 2,11 µM/min (2-butanol).

Discussion

The use of biocatalysis for the production of industrially valuable compounds, whether as precursors or end products, is not only a topical issue, but is now increasingly necessary given the minimal environmental burden that this approach offers. Along with the other advantages of biocatalysts, in particular the enantioselectivity and overall efficiency of their use, the property of thermostability also comes to the fore, representing an advantageous bonus in the form of a robust and generally more stable enzyme (Elleuche et al. 2014; Sheldon and Brady 2018). One of the ways in which the stability and thus the application potential of the enzyme can be in-creased is undoubtedly its immobilization. There are several approaches to enzymatic immobilization, but with regard to preserving the structural and catalytic character of the molecule and at the same time a stable chemical interaction, covalent immobilization us-ing the so-called biorthogonal group. This can be, for example, a short peptide with the possibility of a specific covalent interaction (e.g. a cysteine tag) or even an oligosaccharide conjugated to a protein in the post- or co-translational process of protein glycosylation (Barbosa et al. 2013; Hu et al. 2013; Zhang et al. 2016). Given the progress made in glycoengineering (Keys and Aebi 2017), including the enrichment of the spectrum of producer organisms for bacterial hosts, the possibility of covalent-oriented immobilization through oxidizable − OH groups of glycans is a minimally promising approach (Hu et al. 2013). The aim of this work is to present a method for in vivo glycosylation of a recombinant enzyme, alcohol dehydrogenase originating from the organism R. ruber, produced in the E. coli two-plasmid expression system. The application potential of this enzyme results not only from the property of thermotolerance, but also from stability to some organic solvents (acetone, isopropanol), which can even be used in practice as a cheap alternative to cofactor regeneration (Kosjek et al. 2004; Karabec et al. 2010). It is also necessary to take into account the spectrum of substrates, which is primarily focused on secondary alcohols resp. ketones, especially with a longer chain or aromatic ring (Hamnevik et al. 2014).

In this work, we focused on the enzyme alcohol dehydrogenase (ADH) and its glycosylation, offering the eventual immobilization of this enzyme precisely through the bound glycan. The model reaction in this case is bioconversion of acetophenone, a ketone with an aromatic ring in the molecule, to the corresponding secondary alcohol 1-phenylethanol, so we opted for ADH from the Gram-positive bacterium R. ruber DSM 44541 (RrADH; Uni-ProtKB—Q8KLT9) with substrate specificity against ketones resp. secondary alcohol, especially with the aromatic ring (Hamnevik et al. 2014). To prepare the expression system allowing glycosyltion of RrADH, we started from the plasmid pJexpress401-IFN (Pandhal et al. 2012), in which the gene encoding human interferon was exchanged for the ADH1 gene from S. cerevisiae (ScADH1) with five terminally oriented D-Q-N-A-T repeats. Subsequently, instead of the gene for ScADH1, a codon-optimized gene encoding RrADH was inserted on the generated plasmid designated pJexpress401-RrADH-CGH. The product in this case is RrADH with N-terminally oriented ssPelB and C-terminal five D-Q-N-A-T glycosylation motifs, so-called glyco-tags (GTs), followed by a His-tag. Based on previous experience with ScADH in our workplace, we assumed that the location of the His-tag at the N-terminus of the protein will interfere with the proper function of the N-catalytic domain, and thus the enzyme itself. Although RrADH differs from ScADH1 in the structural details of the active site determining the spectrum of possible substrates (Karabec et al. 2010), the catalytically active moiety (substrate binding site and binding site for Zn atoms) RrADH is also N-terminally orient-ed (Protein Data Bank in Europe—3jv7). The expression of the product (ssPelB-RrADH-5 × GT-His-tag) is under the control of the T5 promoter recognized by E. coli itself by RNA polymerase. The T5 promoter is flanked on the plasmid by two lac operators, which recognizes the LacI repressor also encoded on the pJexpress401 plasmid and ensure the inducibility of the T5 promoter by IPTG. The gene encoding the neomycin phosphotransferase II enzyme conferring kanamycin resistance plays a role as a selection marker on the plasmid. The origin of replication from pUC determines the high copy number of the plasmid and at the same time the compatibility with the plasmid pACYC (pgl2), which has the p15A origin and allows the creation of a two-plasmid system. Said plasmids were used to transform E. coli strain CLM24 and to create a two-plasmid expression system CLM24 pACYC (pgl2) pJexpress401-RrADH-CGH (abbreviated GR) similarly to AcrA protein. The CLM24 pJexpress401-RrADH-CGH system (abbreviated CR) served as a control for RrADH glycosylation.

We performed parallel cultures of GR and CR expression systems in LB and D medium, again at three different temperatures in a 100 mL volume, similar to AcrA protein. From the measured OD600 values and the constructed growth curves (Figs. 1 and 2), significant differences between individual temperatures can be seen, which suggests that RrADH production in the cell represents a great metabolic load. From the WB detection of RrADH by anti-His antibody (Figs .3 and 4) it is clear that the protein aggregates to a large extent and the largest part of the soluble form (49%) is produced at 20 °C mainly in D medium (Fig. 4). At this temperature, we decided to test expression in ZYM-5052 autoinduction medium (Studier 2005), as in the study by Ding et al. (2017) reported, due to autoinduction, an increased proportion of glycosylated protein production, the domain of human fibronectin type III, in the CLM37 strain using ssOmpA for the Sec translocone at 25 °C. In our case, however, we did not record RrADH production at all in the GR or CR expression system, based on SDS-PAGE and WB detection in the soluble and non-soluble fraction (Fig. 5) and even in the eluate after purification (Fig. 6). We assume that it is the specificity of each protein, the given production strain and the specific conditions that require their biosynthesis and need to be optimized. For comparison with the production of RrADH in D medium at 20 °C (GR20D) we also expressed ScADH1 under the same conditions (GS20D) and based on WB analyzes (Fig. 5) we can evaluate the expression of ScADH1 in this system as much more problematic than in the case of RrADH. The amount of soluble ScADH1 compared to soluble RrADH in this expression system was at the level of 34% evaluated from the densitometric analysis of WB (Fig. 5). This observation is also supported by the result from the online available predictor of protein solubility in the Periscope periplasm (Chang et al. 2016) in which RrADH was evaluated on a solubility scale (with high, medium and low solubility categories) as "medium". ScADH1 was rated "low" by this tool and AcrA was rated "high". In the eluates after IMAC from both DOC extraction and subsequent sonication (SNs), we detected gRrADH from GR20D culture by SBA, while in the sample no signal was present from the CR20D culture. For comparison, samples from both GR/CR 28D and GR/CR 20LB purifications were analyzed and captured minimal to virtually no signal in these eluates, confirming previous findings. The maximum purity of RrADH produced in the GR20D culture, which we managed to achieve so far by one-step purification on a Ni2+ column, was 36% for the DOC extract and 54% for the subsequently sonicated cell material. The total protein concentration in the eluates was 142.0 ± 18.5 µg/mL, while the hypothetical RrADH concentration was 35.9 ± 4.3 µg/mL derived from the densitometrically evaluated RrADH ratio.

In the case of RrADH, we recorded double signals captured by anti-His antibody in the eluates after purification of both GR20D and CR20D (Fig. 6). Hypothetically, this could be inefficient hydrolytic cleavage of the signal peptide. As this phenomenon is also present in the control samples, this double signal is almost certainly not due to the presence of glycan. However, detection by SBA confirmed the glycosylation of RrADH (Fig. 6), these fragments being electrophoretically slower than the mentioned double band from the WB analysis. From a comparison and overlap of anti-His and SBA-detected bands, it is also likely that the presence of five GTs together with bound glycan at the C-terminus of RrADH immediately adjacent to the His-tag sterically prevents binding of the anti-His antibody. This hypothesis is partly supported by the weaker interaction of the His-tag with the Ni2+ column (Appendix 3) as well as the literature describing cases where the presence of basic and hydrophobic amino acids immediately after the signal sequence (first 14 amino acids), e.g. at the N-terminus of the protein produced, interfered with cleavage by signal peptidase I or with periplasmic transport alone (Zalucki and Jennings 2017). RrADH contains one Lys (K2) among the first 14 amino acids among the bases. A potential solution could be to mutate the codon for K2 to another acceptable amino acid, especially with an acidic character.

There are several alternative approaches that could contribute to higher yields of active gRrADH. Kämpf et al. (2015) in their study describe various optimization steps in the in vivo production of a glycoconjugate vaccine against Shigella flexneri 2a by binding an O-polysaccharide typical of this species to the detoxified carrier protein exotoxin A (EPA) derived from Pseudomonas aeruginosa. One optimization was the addition of GlcNAc, as a source of monosaccharides for O-polysaccharide construction, directly to the medium. However, bacterial N-glycan contains mainly GalNAc, so the addition of this saccharide to the medium could increase the glycosylation efficiency of our system. Also, the concentration of divalent cations, including Mg2+ and Mn2+, appears to be a key element in the production of glycoproteins in E. coli. The authors report a concentration of 10 mM Mg2+ as optimal for the transfer of O-polysaccharide to EPA protein Kämpf et al. (2015). Gerber et al. (2013) added salts of MnCl2 (10 mM) or MgCl2 (50 mM) to the medium based on the natural concentrations of these cations in the periplasm in the natural environment of microorganisms, which tend to be significantly higher than in conventional culture media. They monitored the kinetic parameters of PglB and at concentrations of 10 mM MnCl2 or 50 mM MgCl2 the strongest binding to the substrate was achieved, while the highest rate of glycosylation reaction took place at a concentration of 50 mM MnCl2. In our cultures, 1.6 mM MgSO4 was present in D medium. Thus, a possible increase in the concentration of Mn2+ and Mg2+ salts could have a beneficial effect on increasing glycoprotein production.

The mode of transport of the protein of interest into the periplasm is also one of the variable components of periplasmic protein expression. The ssPelB used in our case is recognized by the Sec (general secretory pathway) export system with a post-translational mechanism for the transport of nascent unfolded proteins. Preferentially integral membrane proteins are transported co-translationally through the Sec pathway (also referred to as another type, the so-called SRP (signal recognition particle) pathway) due to the co-translation mechanism (Natale et al. 2008). In addition to the preferred ssPelB, there are other signal peptides for Sec, including OmpA, PhoA, or GeneIIIc (Lee et al. 2006; Linton et al. 2012). Another possibility is the use of Tat (Twin-arginine translocation) translocone, which transports completely assembled proteins. There are also several signal sequences for it (Palmer and Berks 2012), with TorA being the most studied. In a study by Kowarik et al. (2006) compared ssPelB-AcrA and ssTorA-AcrA conjugates. The efficiency of glycosylation was comparable between them and CjPglB was able to glycosylate both in the cytoplasm folded proteins transported through the Tat mechanism and nascent Sec-transported proteins. It is also possible to utilize SRP-dependent co-translational transport for the periplasmic protein DsbA (ssDsbA). Fisher et al. (2011) compared ssDsbA, ssTorA, ssPelB and the signal peptide for the Sec pathway native to the MBP protein. Although they noted a different degree of distribution of individual glycosylated forms (mono-, di-, tri-, etc.), this does not change the fact that CjPglB was able to glycosylate proteins trans-ported by co-translational SRP as well as post-translational Sec and Tat mechanisms.

The quality control of the RrADH enzyme was recorded by the reaction kinetics with two potential substrates, secondary alcohols isopropanol and 2-butanol, at two different concentrations of cofactor NAD+ (1.6 and 4.8 mM) (Fig. 7). Given the concentration of purified RrADH was 35.9 ± 4.3 µg/mL, Km value was calculated to have an average value of 1160.47 µM (isopropanol) and 514.80 µM (2-butanol) with Vmax values of 3.15 µM/min (isopropanol) and 2.11 µM/min (2-butanol). Although these values are significantly lower compared to native RrADH produced in E. coli (Km 56,4 mM; Vmax 92.2 µM/min), these results, however, indicate the expected trend of increasing absorbance depending on the reaction time, in addition to the substrate concentration. Given the general stabilizing properties that glycoproteins have compared to their non-glycosylated counterparts, we can assume that gRrADH is also active and stable. We can partly support this assumption by the study of Fonseca-Maldonado et al. (2013), who monitored and compared the effect of glycosylation on the property of thermostability and overall stability of xylanase A (XynA) from Bacillus subtilis produced in Pichia pastoris. Said enzyme in glycosylated form (gXynA) achieved activity for a long time after exposure to 55 °C. After 3 h at 55 °C, gXynA still had 20% of the original activity, while XynA had zero activity after 1.5 h at this temperature.

Although the evaluation of enzyme activity in this way is preliminary, it is sufficient at this stage of the elaboration of the given issue. In the future, it will also be appropriate to confirm the glycan composition by mass spectrometry, also to produce gRrADH on a larger scale and to separate it from RrADH. For this purpose, it is possible to use the affinity of the cisdiols present on the glycan for the matrix with bound molecules of amino-phenylboronic acid or lectin SBA or separation by liquid chromatography using a medium with high resolution. Subsequent comparison of the activities separated by gRrADH and RrADH would undoubtedly be an interesting finding. However, before such an approach of enzyme production resp. their subsequent immobilization via glycan could be used on a larger scale for industrial applications, it would be necessary to further address the issue of enzyme insolubility, as well as the relatively low proportion of glycosylated fraction.

Our study demonstrates the possibility of utilization of bacterial N-glycosylation machinery for the production of glycosylated recombinant enzymes allowing their oriented immobilization at mild conditions. The results, although promising, showed that the key limitation is the periplasmic transport rate resulting in the low amount of produced material. We were able to produce around 35 µg of RrADH from 1 L of bioreactor culture and further strain and/or pathway engineering is required to achieve potential industrial feasibility and higher yields.

Abbreviations

- RrADH:

-

ADH from Rhodococcus ruber

- ADH:

-

Alcohol dehydrogenase

- HRP:

-

Horseradish peroxidase

- TAE:

-

Tris acetate

- PVDF:

-

Polyvinylidene difluoride

- RT:

-

Room temperature

- DOC:

-

Sodium deoxycholate

- IMAC:

-

Immobilized Metal Affinity Chromatography

- CV:

-

Column volume

- BSA:

-

Bovine serum albumin

- ScADH:

-

ADH from Saccharomyces cerevisae

- IPTG:

-

Isopropyl ß-D-1-thiogalactopyranoside

- EPA:

-

Detoxified carrier protein exotoxin A

References

Anyaogu DC, Mortensen UH (2015) Manipulating the glycosylation pathway in bacterial and lower eukaryotes for production of therapeutic proteins. Curr Opin Biotechnol 36:122–128. https://doi.org/10.1016/j.copbio.2015.08.012

Barbosa O, Torres R, Ortiz C, Berenguer-Murcia Á, Rodrigues RC, Fernandez-Lafuente R (2013) Heterofunctional supports in enzyme immobilization: from traditional immobilization protocols to opportunities in tuning enzyme properties. Biomacromol 14:2433–2462. https://doi.org/10.1021/bm400762h

Chang CC, Li C, Webb GI, Tey B, Song J, Ramanan RN (2016) Periscope: quantitative prediction of soluble protein expression in the periplasm of Escherichia coli. Sci Rep 6:21844. https://doi.org/10.1038/srep21844

Ding N, Yang C, Sun S, Han L, Ruan Y, Guo L, Hu X, Zhang J (2017) Increased glycosylation efficiency of recombinant proteins in Escherichia coli by auto-induction. Biochem Biophys Res Commun 485:138–143. https://doi.org/10.1016/j.bbrc.2017.02.037

Elleuche S, Schröder C, Sahm K, Antranikian G (2014) Extremozymes-biocatalysts with unique properties from extremophilic microorganisms. Curr Opin Biotechnol 29:116–123. https://doi.org/10.1016/j.copbio.2014.04.003

Eş I, Vieira JDG, Amaral AC (2015) Principles, techniques, and applications of biocatalyst immobilization for industrial application. Appl Microbiol Biotechnol 99:2065–2082. https://doi.org/10.1007/s00253-015-6390-y

Feldman MF, Wacker M, Hernandez M, Hitchen PG, Marolda CL, Kowarik M, Morris HR, Dell A, Valvano MA, Aebi M (2005) Engineering N-linked protein glycosylation with diverse O antigen lipopolysaccharide structures in Escherichia coli. Proc Natl Acad Sci U S A 102:3016–3021. https://doi.org/10.1073/pnas.0500044102

Fisher AC, Haitjema CH, Guarino C, Celik E, Endicott CE, Reading CA, Merritt JH, Ptak AC, Zhang S, DeLisa MP (2011) Production of secretory and extracellular N-linked glycoproteins in Escherichia coli. Appl Environ Microbiol 77:871–881. https://doi.org/10.1128/AEM.01901-10

Fonseca-Maldonado R, Vieira DS, Alponti JS, Bonneil E, Thibault P, Ward RJ (2013) Engineering the pattern of protein glycosylation modulates the thermostability of a GH11 xylanase. J Biol Chem 288:25522–25534. https://doi.org/10.1074/jbc.M113.485953

Gerber S, Lizak C, Michaud G, Bucher M, Darbre T, Aebi M, Reymond JL, Locher KP (2013) Mechanism of bacterial oligosaccharyltransferase: in vitro quantification of sequon binding and catalysis. J Biol Chem 288:8849–8861. https://doi.org/10.1074/jbc.M112.445940

Hamnevik E, Blikstad C, Norrehed S, Widersten M (2014) Kinetic characterization of Rhodococcus ruber DSM 44541 alcohol dehydrogenase A. J Mol Catal B Enzym 99:68–78. https://doi.org/10.1016/j.molcatb.2013.10.023

Hildebrand F, Lütz S (2006) Immobilisation of alcohol dehydrogenase from Lactobacillus brevis and its application in a plug-flow reactor. Tetrahedron: Asymmetry 17:3219–3225. https://doi.org/10.1016/j.tetasy.2006.11.013

Höllrigl V, Hollmann F, Kleeb AC, Buehler K, Schmid A (2008) TADH, the thermostable alcohol dehydrogenase from Thermus sp. ATN1: a versatile new biocatalyst for organic synthesis. Appl Microbiol Biotechnol 81:263–273. https://doi.org/10.1007/s00253-008-1606-z

Hortigüela MJ, Aumailley L, Srivastava A, Cunningham C, Anandakumar S, Robin S, Pandit A, Hu X, Wall JG (2015) Engineering recombinant antibodies for polymer biofunctionalization. Polym Adv Technol 26:1394–1401. https://doi.org/10.1002/pat.3619

Hu X, Hortiguela MJ, Robin S, Lin H, Li Y, Moran AP, Wang W, Wall JG (2013) Covalent and oriented immobilization of scFv antibody fragments via an engineered glycan moiety. Biomacromol 14:153–159. https://doi.org/10.1021/bm301518p

Jaffé SRP, Strutton B, Levarski Z, Pandhal J, Wright PC (2014) Escherichia coli as a glycoprotein production host: recent developments and challenges. Curr Opin Biotechnol 30:205–210. https://doi.org/10.1016/j.copbio.2014.07.006

Jalalirad R (2013) Selective and efficient extraction of recombinant proteins from the periplasm of Escherichia coli using low concentrations of chemicals. J Ind Microbiol Biotechnol 40:1117–1129. https://doi.org/10.1007/s10295-013-1307-1

Kämpf MM, Braun M, Sirena D, Ihssen J, Thöny-Meyer L, Ren Q (2015) In vivo production of a novel glycoconjugate vaccine against Shigella flexneri 2a in recombinant Escherichia coli: identification of stimulating factors for in vivo glycosylation. Microb Cell Fact 14:12. https://doi.org/10.1186/s12934-015-0195-7

Karabec M, Łyskowski A, Tauber KC, Steinkellner G, Kroutil W, Grogan G, Gruber K (2010) Structural insights into substrate specificity and solvent tolerance in alcohol dehydrogenase ADH-‘A’ from Rhodococcus ruber DSM 44541. Chem Commun 46:6314–6316. https://doi.org/10.1039/C0CC00929F

Keys TG, Aebi M (2017) Engineering protein glycosylation in prokaryotes. Curr Opin Syst Biol 5:23–31. https://doi.org/10.1016/j.coisb.2017.05.016

Kosjek B, Stampfer W, Pogorevc M, Goessler W, Faber K, Kroutil W (2004) Purification and characterization of a chemotolerant alcohol dehydrogenase applicable to coupled redox reactions. Biotechnol Bioeng 86:55–62. https://doi.org/10.1002/bit.20004

Kowarik M, Young NM, Numao S, Schulz BL, Hug I, Callewaert N, Mills DC, Watson DC, Hernandez M, Kelly JF, Wacker M, Aebi M (2006) Definition of the bacterial N-glycosylation site consensus sequence. EMBO J 25:1957–1966. https://doi.org/10.1038/sj.emboj.7601087

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680a0

Lee PA, Tullman-Ercek D, Georgiou G (2006) The bacterial twin-arginine translocation pathway. Annu Rev Microbiol 60:373–395. https://doi.org/10.1146/annurev.micro.60.080805.142212

Lee WH, Kim MD, Jin YS, Seo JH (2013) Engineering of NADPH regenerators in Escherichia coli for enhanced biotransformation. Appl Microbiol Biotechnol 97:2761–2772. https://doi.org/10.1007/s00253-013-4750-z

Levarski Z, Frano M, Birova S, Struharnanska E, Blasko J, Kubinec R, Kois P, Turna J, Stuchlik S (2018) Small scale biotransformation of food additive trans-2-hexenal to trans-2-hexenol by recombinant alcohol dehydrogenase and formate dehydrogenase produced in Escherichia coli. J Food Nutr Res 57:201–207

Liao M-H, Chen D-H (2001) Immobilization of yeast alcohol dehydrogenase on magnetic nanoparticles for improving its stability. Biotech Lett 23:1723–1727. https://doi.org/10.1023/A:1012485221802

Linton E, Walsh MK, Sims RC, Miller CD (2012) Translocation of green fluorescent protein by comparative analysis with multiple signal peptides. Biotechnol J 7:667–676. https://doi.org/10.1002/biot.201100158

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275. https://doi.org/10.1016/S0021-9258(19)52451-6

Meldal M, Schoffelen S (2016) Recent advances in covalent, site-specific protein immobilization. F1000Res 5. https://doi.org/10.12688/f1000research.9002.1

Natale P, Brüser T, Driessen AJ (2008) Sec- and Tat-mediated protein secretion across the bacterial cytoplasmic membrane–distinct translocases and mechanisms. Biochim Biophys Acta 1778:1735–1756. https://doi.org/10.1016/j.bbamem.2007.07.015

Nothaft H, Szymanski CM (2013) Bacterial protein N-glycosylation: new perspectives and applications. J Biol Chem 288:6912–6920. https://doi.org/10.1074/jbc.R112.417857

Nothaft H, Szymanski CM (2019) New discoveries in bacterial N-glycosylation to expand the synthetic biology toolbox. Curr Opin Chem Biol 53:16–24. https://doi.org/10.1016/j.cbpa.2019.05.032

Packiam KAR, Ramanan RN, Ooi CW, Krishnaswamy L, Tey BT (2020) Stepwise optimization of recombinant protein production in Escherichia coli utilizing computational and experimental approaches. Appl Microbiol Biotechnol 104:3253–3266. https://doi.org/10.1007/s00253-020-10454-w

Palmer T, Berks BC (2012) The twin-arginine translocation (Tat) protein export pathway. Nat Rev Microbiol 10:483–496. https://doi.org/10.1038/nrmicro2814

Pandhal J, Desai P, Walpole C, Doroudi L, Malyshev D, Wright PC (2012) Systematic metabolic engineering for improvement of glycosylation efficiency in Escherichia coli. Biochem Biophys Res Commun 419:472–476. https://doi.org/10.1016/j.bbrc.2012.02.020

Rosano GL, Ceccarelli EA (2014) Recombinant protein expression in Escherichia coli: advances and challenges. Front Microbiol 5:172. https://doi.org/10.3389/fmicb.2014.00172

Schägger H, von Jagow G (1987) Tricine-sodium dodecyl sulfate-polyacrylamide gel electrophoresis for the separation of proteins in the range from 1 to 100 kDa. Anal Biochem 166:368–379. https://doi.org/10.1016/0003-2697(87)90587-2

Schwarz F, Huang W, Li C, Schulz BL, Lizak C, Palumbo A, Numao S, Neri D, Aebi M, Wang LX (2010) A combined method for producing homogeneous glycoproteins with eukaryotic N-glycosylation. Nat Chem Biol 6:264–266. https://doi.org/10.1038/nchembio.314

Sheldon RA, Brady D (2018) The limits to biocatalysis: pushing the envelope. Chem Commun 54:6088–6104. https://doi.org/10.1039/C8CC02463D

Singh RK, Tiwari MK, Singh R, Lee JK (2013) From protein engineering to immobilization: promising strategies for the upgrade of industrial enzymes. Int J Mol Sci 14:1232–1277. https://doi.org/10.3390/ijms14011232

Stampfer W, Kosjek B, Kroutil W, Faber K (2003) On the organic solvent and thermostability of the biocatalytic redox system of Rhodococcus ruber DSM 44541. Biotechnol Bioeng 81:865–869. https://doi.org/10.1002/bit.10540

Steen Redeker E, Ta DT, Cortens D, Billen B, Guedens W, Adriaensens P (2013) Protein Engineering For Directed Immobilization. Bioconjug Chem 24:1761–1777. https://doi.org/10.1021/bc4002823

Studier FW (2005) Protein production by auto-induction in high-density shaking cultures. Protein Expr Purif 41:207–234. https://doi.org/10.1016/j.pep.2005.01.016

Szymanski CM, Yao R, Ewing CP, Trust TJ, Guerry P (1999) Evidence for a system of general protein glycosylation in Campylobacter jejuni. Mol Microbiol 32:1022–1030. https://doi.org/10.1046/j.1365-2958.1999.01415.x

Ulrich S, Boturyn D, Marra A, Renaudet O, Dumy P (2014) Oxime ligation: a chemoselective click-type reaction for accessing multifunctional biomolecular constructs. Chemistry 20:34–41. https://doi.org/10.1002/chem.201302426

Utekal P, Tóth C, Illésová A, Koiš P, Bocánová L, Turňa J, Drahovská H, Stuchlík S (2014) Expression of soluble Saccharomyces cerevisiae alcohol dehydrogenase in Escherichia coli applicable to oxido-reduction bioconversions. Biologia 69:722–726. https://doi.org/10.2478/s11756-014-0376-6

Zalucki YM, Jennings MP (2017) Signal peptidase I processed secretory signal sequences: Selection for and against specific amino acids at the second position of mature protein. Biochem Biophys Res Commun 483:972–977. https://doi.org/10.1016/j.bbrc.2017.01.044

Zhang L, Vilà N, Klein T, Kohring G-W, Mazurenko I, Walcarius A, Etienne M (2016) Immobilization of Cysteine-Tagged Proteins on Electrode Surfaces by Thiol-Ene Click Chemistry. ACS Appl Mater Interfaces 8:17591–17598. https://doi.org/10.1021/acsami.6b02364

Acknowledgements

We are thankful to Dr. Stephen R.P. Jaffe from the Department of Chemical and Biological Engineering, Faculty of Engineering, The University of Sheffield, UK (currently Lonza, Cambridge, UK) for providing valuable advice and experience with analysis of bacterial glycoproteins.

Funding

Open access funding provided by The Ministry of Education, Science, Research and Sport of the Slovak Republic in cooperation with Centre for Scientific and Technical Information of the Slovak Republic This research was funded by Scientific Grant Agency of Ministry of Education, Science, Research and Sport of the Slovak Republic grant (VEGA 1/0710/18), Slovak Research and Development Agency grants APVV17-0333 and APVV-21–0215.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Authors ZL, ES, JT and SS have a financial interest in ReKoMBe, s.r.o.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Levarski, Z., Bírová, S., Hriňová, K. et al. Production of N-glycosylated alcohol dehydrogenase in Escherichia coli. Biologia (2024). https://doi.org/10.1007/s11756-024-01707-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11756-024-01707-4