Abstract

A novel adsorbent was prepared from multi-wall carbon nanotubes (MWCNTs) and Citrus sinensis juice extract-modified MWCNTs (OJMW) and characterized using scanning electron microscopy (SEM), Fourier transform infrared spectra (FTIR), X-ray diffractometer (XRD), BET and thermogravimetric analysis. The results showed that the nanotubes exhibited good surface area, pore size, functional groups, and robust stability at elevated temperatures (308 and 313 K). The adsorbent was applied in water for the sequestration of Cr(VI). The adsorption of Cr(VI) on MWCNTs and OJMW was influenced by factors of adsorption. Optimum removal of Cr(VI) was attained at 180 min contact time, 0.05 g adsorbent dose, and solution pH 2 for MWCNTs and OJMW. The kinetic behaviour of the Cr(VI) adsorption onto MWCNTs and OJMW was governed by the pseudo-first-order and pseudo-second-order kinetic model, respectively. The equilibrium data obtained for the uptake of Cr(VI) onto MWCNTs and OJMW fitted satisfactorily with Freundlich and Langmuir isotherm models, respectively. Meanwhile, MWCNTs and OJMW exhibited monolayer adsorption capacities (qmax) of 44.72 and 12.26 g g−1, respectively, at 298 K. The adsorption process was spontaneous and feasible. The direction of energy flow in the uptake of Cr(VI) onto OJMW and MWCNTs followed endothermic and exothermic adsorption processes, respectively. The adsorption–desorption experiments showed that OJMW had good regenerative abilities.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is necessary for life on Earth to exist. Water covers 70% of the earth’s surface, yet only 3% of it is pure, and only 0.01% of it is safe for human use (Knorr and Augustin 2023). Africa, where 35% of the population lacks access to potable water supplies, is at a critical threshold to find alternative means to generate portable water for her ever increasing population as most available water sources have been heavily polluted by industrial and mining activities (Scanlon et al. 2016). The increase in water pollution is caused by significant advances in industrial technologies over the last century. Water pollutants are often introduced into the water source via natural disasters or anthropogenic activities (Ogidi and Akpan 2022). Meanwhile, human activities are responsible for a large fraction of pollutants in the water bodies. Among these pollutants, an increase in heavy metal ions especially hexavalent chromium (Cr(VI)) have demonstrated the urgent need for pollution control. Effluent from industries such as metal plating, leather tanning, weathering of chromium-containing rocks, textile dyeing, cement, and fertilizers has been reported to constantly release extremely toxic and non-biodegradable metal ions into the environment (Mishra and Bharagava 2016). This has over time accumulated and now poses a grave danger to the environment.

Chromium is a transition metal (heavy metal) with varied oxidation states. Trivalent (Cr(III)) and hexavalent (Cr(VI)) forms of chromium are the most stable oxidation states of chromium (Dalal and Reddy 2019). The Cr(III) exists as mononuclear Cr(OH)2+ and Cr(OH)4− and also poly-nuclear Cr2(OH)24+ and Cr3(OH)45+ (Ali et al. 2016; Fukai 1967). These species are less toxic due to their poor mobility and often precipitate out of the aqueous solution. On the contrary, the hexavalent chromium exists in aqueous solution as oxyanion species (HCr2O7−, HCrO4−, Cr2O72−, CrO42−). These species are extremely toxic, highly mobile and are very soluble in aqueous solution (Sun et al. 2022). Inhaling or ingesting Cr(VI) may cause nasal ulcers, vomiting, haemorrhage, skin cancer, kidney damage, inflammatory bowel disease, lung cancer, and, in extreme cases, death (Costa 1997; DesMarias and Costa 2019). Plants exposed to Cr(VI) on the other hand may suffer membrane damage, reduced growth, delayed fruiting or blooming, photosynthetic impairment, and an overall decrease in crop output and plant death (Kumar et al. 2019; Srivastava et al. 2021). Contact with Cr(VI) causes mortality in fish and seaweeds in the aquatic ecosystems (Kumar et al. 2022; Trivedi et al. 2021). For these reasons, Cr(VI) toxicity should be investigated and managed. The World Health Organization (WHO) has established a standard guideline for chromium levels in water. Chromium concentrations between 0.05 and 0.1 mg dm−3 are safe for drinking water and above this permissible limit is not suitable for domestic purposes. Recent findings indicated an increase in the level of chromium in water bodies, which could be largely attributed to human factors. Hence, to keep this toxicity in check, the US Environmental Protection Agency (USEPA) regulations for environmental quality standards stipulated that industrial wastewater should be pre-treated before discharge into the environment (Santé et al. 2004; Baral and Engelken 2002). Excess chromium in the environment is considered pollution and necessitates appropriate environmental cleanup techniques.

To address this environmental concern, physicochemical techniques such as solvent extraction, biosorption, evaporation, ion exchange, precipitation, electro-dialysis, flotation, membrane separation, and adsorption have been developed (Aksu et al. 1996; Huang et al. 1982; Ibrahim et al. 2010; Kongsricharoern and Polprasert 1996; Pagilla and Canter 1999; Seaman et al. 1999; Tiravanti et al. 1997; Zhou et al. 1993). Among these techniques, adsorption is widely used in wastewater treatment and has demonstrated unmeasurable efficiency in terms of availability, durability, cost-effectiveness, operation processes, ability to perform on low analyte concentrations, ecofriendliness, adsorbent reuse, and ability to meet Environmental Protection Agency standards. Meanwhile, adsorbents, such as CoFe-LDH/g-C3N4 (Ou et al. 2020), kaolin (Belachew and Hinsene 2020), hydrogel (Vilela et al. 2019), biochar (Jiang et al. 2017) activated carbon (Rai et al. 2016), banana peels (Ali et al. 2016), groundnut shell (Bayuo et al. 2019), redox polymer (Vetriselvi and Santhi 2015), Ti-XAD7 (Sharifi et al. 2019), carbon nanotubes (Dehghani et al. 2015), fruit peel (Dinh et al. 2019), red mud (Ma et al. 2014), MOF (Wang et al. 2021), biomass (Ravindranath et al. 2011), and graphene oxide (Mondal and Chakraborty 2020; Rout and Jena 2021, 2022, 2023), have been utilized to explore the removal of Cr(VI) from industrial wastewater via the batch adsorption techniques. Although activated carbon has been widely used in Cr(VI) remediation, its high production cost and poor regeneration have limited its usage in Cr(VI) adsorption techniques.

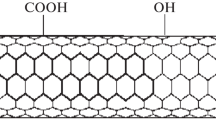

Due to the pronounced physicochemical properties (large surface area, robust mechanical and chemical properties) of multi-walled carbon nanotubes (MWCNTs), extensive investigation on the effectiveness of MWCNTs for environmental remediated has been assessed (Arnawtee et al. 2022; Lee et al. 2022). Limitations to the application of MWCNTs have been circumvented via acid treatment techniques that incorporate oxygen functionalities to the surface of MWCNTs (Hadavifar et al. 2014). However, to significantly impact the performance of acid-functionalized MWCNTs (f-MWCNTs), surface modification of f-MWCNTs becomes imperative. Oranges are citrus fruits with a glandular skin called zest, an inner white skin, and cells with one end linked to the inner skin; they are consumed by humans and most animals (Peterson et al. 2006). Orange juice extract has strong antioxidant properties and can function as an active reducing agent for Cr(VI). As a result, using juice derived from ruined oranges as modifiers may increase the value of oranges.

The synergistic effect of MWCNTs and orange juice is anticipated to enhance the overall efficiency of Cr(VI) adsorption, presenting a sustainable and cost-effective alternative to activated carbon. In this study, we report the fabrication of nanoparticles using MWCNTs and orange juice for the sequestration of Cr(VI) from wastewater. To validate the effectiveness of the nanoparticles, the antioxidant and adsorption potential of the adsorbent were assessed. The implication of adsorbent dose, solution temperature, solution pH, contact time, adsorption kinetics, thermodynamics and regeneration potential was used to optimize the capacity of the nanoparticles for the remediation of Cr(VI).

Material and chemicals

Reagents used in the study include sodium hydroxide (99.99%), 1.5-Diphenylcarbazide (98%), potassium dichromate (99.99%), nitric acid (98.98%), hydrochloric acid (99.9%), sulphuric acid (98%), sodium chloride (> 95%), acetone, and ethanol (99.5%). The reagents were purchased from Sigma-Aldrich and used without further purification. Multi-walled carbon nanotubes with a purity of 95% (having an average length of 17 nm and external mean diameter of 39 nm) were purchased from the same vendor. Spoilt Citrus sinensis fruit was picked from the dry waste bin at the Ahia-Eke community market, Umuahia, Abia State, Nigeria (5°30′43.0"N and 7°31′48.0"E).

Preparation of Citrus sinensis juice

The exocarp and Citrus sinensis albedo of the discarded Citrus sinensis fruits were manually peeled. About 500 g of the Citrus sinensis endocarp (orange flesh) was then extracted using a Kenwood accent centrifugal juicer (Bash product UUID 154011AAAA7). The juice was filtered again to remove a trace amount of pulp. Thereafter, the juice was concentrated using a rotary evaporator. The concentrate was stored for further use.

Preparation of Citrus sinensis juice-modified MWCNTs

Under constant stirring, 6.0 M HCl (50 cm3) was in contact with 1 g MWCNTs for 3 h. The mixture was washed and dried, and the procedure was repeated using 6.0 M HNO3 (50 cm3). The purified MWCNTs were dried and calcined at 300 °C for 30 min. A mixture of concentrated nitric and sulfuric acids in a 3:1 (v/v) ratio (50 cm3) was used to introduce oxygen functionalities to the surfaces of the purified MWCNTs (0.3 g). The mixture was stirred for 6 h in a round-bottom flask. Thereafter, the mixture was neutralized using 3 M NaOH, vacuum filtered, and washed continuously to the pH of the deionized employed. The product obtained was sequentially washed with ethanol and acetone, then oven-dried for 24 h at 120 °C. About 0.25 g of Citrus sinensis juice concentrate was redissolved in a 100-cm3 beaker containing 20 cm3 of double-distilled water at 40 °C. Following that, 2.5 g of the functionalized MWCNTs were contacted with the 25-cm3 Citrus sinensis juice extract for 6 h at 50 °C with constant stirring. The mixture was then vacuum oven-dried, and the black product obtained was labelled OJMW and kept for further application (see Scheme 1).

Antioxidant assay

The modified method of Vindhya and Kavitha (2023) was used to validate the inhibitory characteristics of OJMW and MWCNTs. Briefly, 0.5 cm3 of DPPH (0.3 mM) solution was contacted with various concentrations (25, 50, 100, 200, and 400 g/mL) of OJMW and MWCNTs. DPPH is a radical source. The reaction mixture was then incubated for 30 min at room temperature in a dark atmosphere. The % change in absorption wavelength at 517 nm was utilized to track radical concentration (Matussin et al. 2020; Vindhya and Kavitha 2023). On the other hand, the modified method of Chew and Lim (2018) was used to determine the ferric-reducing antioxidant potential (FRAP) of OJMW and MWCNTs (Chew and Lim 2018). To estimate the free radical concentration, the percentage inhibition (% I) of the DPPH and the percentage of FRAP in gallic acid equivalents are calculated using Eqs. (1) and (2), respectively.

Characterization

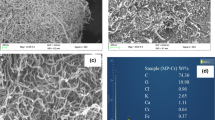

OJMW and MWCNTs were sputter coated with platinum before the acquisition of the micrograph using field emission scanning electron microscopy (FESEM) (ZEISS ultra plus, USA). The crystalline structures of OJMW and MWCNTs were observed by making use of an X-ray diffractometer (XRD Bruker D8 Advance powder X-ray diffraction). The functional groups of these adsorbents (OJMW and MWCNTs) were analysed using Fourier transform infrared (FTIR) spectroscopy (Nicolet-870 spectrophotometer, USA). The Brunauer–Emmett–Teller (BET) and Barrett–Joyner–Halenda (BJH) technique was adopted in the measurement of the specific surface area and pore volume of OJMW and MWCNTs with N2 adsorption (Micromeritics Instruments Corp., Ltd., USA). The PerkinElmer simultaneous thermal analyser (STA6000 instrument, USA) was used to assess the thermal behaviour of MWPJ and MWCNTs.

Adsorption and regeneration experiments

The uptake capacities of the OJMW and MWCNTs were assessed by the adsorption of Cr(VI). About 2.835 g of K2Cr2O7 were dissolved in 1 dm3 of deionized water to prepare the stock solution (1000 mg dm−3). A working solution (100 mg dm−3) was prepared from the stock via dilution and adjusted to initial pH 2 using 0.3 M HCl or 0.1 M NaOH. Then, 0.05 g of OJMW and MWCNTs was suspended in a 25 cm3 solution containing Cr(VI) (100 mg dm−3) and agitated in a thermostated shaking water bath (150 rpm) at room temperature. The residual Cr(VI) concentration was acquired at λ = 540 nm using UV–visible spectrophotometry (Analyst 600, PerkinElmer Company, USA). Essential factors of adsorption such as adsorbent dose, solution pH, contact time, initial concentration, solution temperature and regeneration tendency were also investigated. Adsorption–desorption studies were performed to regenerate the OJMW and MWCNTs after adsorbing Cr(VI) for further recycling process. Initially, the loaded adsorbent (Cr-OJMW and Cr-MWCNTs) was desorbed using 0.5 M NaOH under continuous shaking for 3 h at 25 °C. Subsequently, OJMW and MWCNTs were washed with diluted HCl solution to regenerate the active adsorption sites to recover the adsorption capacity of OJMW and MWCNTs in the next adsorption cycle. After that, acid-washed OJMW and MWCNTs were rinsed with distilled water to neutralize the surface, and the above two steps were repeated three times for the OJMW and MWCNTs regeneration. The removal capacities and the adsorption efficiency of OJMW and MWCNTs are estimated using Eqs. (3) and (4) (Alwan and Alshamsi 2022; Amaku et al. 2021):

where Ci is the initial Cr(VI) concentration (mg dm−3), Ceq is the equilibrium concentration of Cr(VI) (mg dm−3), m is the adsorbent mass (g), and V is the volume of Cr(VI) solution (dm3).

Kinetics and isotherm models

To establish the efficacy of Cr(VI) adsorption onto OJMW and MWCNTs, experimental data obtained from contact time and initial concentration experiment were fitted into nonlinear kinetic and isotherm equations, respectively. Pseudo-first-order, pseudo-second-order, intraparticle diffusion, and Elovich kinetics models were employed (see Table 1). On the other, Freundlich and Langmuir were used for isotherm study (see Table 2).

pH point of zero charge (pHPZC)

Using the solid addition method, the effect of pH on the surface charge was investigated. (Belachew and Hinsene 2020; Zubrik et al. 2017). In eleven Erlenmeyer flasks, 0.1 g of OJMW or MWCNTs were contacted for 48 h with a pH 2–12 pre-adjusted NaCl (50 cm3 of 0.1 mol dm3) solution. Finally, the pHPZC of OJMW and MWCNTs was calculated using a plot of the mixture’s final pH versus its initial pH.

Data analysis

Data acquired from contact time and initial Cr(VI) concentration experiment were fitted into kinetics and isotherm models utilizing the nls nonlinear regression procedure in the R statistical computing environment and Origin 2016 suite. The sum of squared residuals (SSR) and the correlation coefficient (R2) were used to determine the models’ ability to reflect the experimental data (Team 2018). Microsoft Excel and Origin 2016 were also employed to process the acquired data.

Results and discussion

The surface morphologies of OJMW, MWCNTs and the juice extract concentrate are assessed using SEM and shown in Fig. 1. Mixed layers of irregular shapes were observed on the SEM image obtained for the juice extract concentrate (see Fig. 1e). The SEM micrograph acquired for OJMW and MWCNTs revealed an interwoven cylindrical tube. Similar surface morphology was observed for Cr-OJMW. However, the SEM micrograph obtained for Cr-OJMW exhibited smooth textural characteristics, suggesting the incorporation of Cr to the surface of the adsorbent. The EDX spectrum of spent OJMW (OJMW-Cr) revealed the presence of Cr, among other elements, as evidence of adsorption of Cr onto OJMW (see Fig. 1d).

To establish the effect of Citrus sinensis juice extract on the surface of MWCNTs and the binding of Cr(VI) onto OJMW and MWCNTs, FTIR spectra of the nanotubes before and after Cr(VI) adsorption were detailed and compared, as shown in Fig. 2. The FTIR spectra of Citrus sinensis juice extract concentrate were also obtained and compared with the adsorbents. A comparison of the spectra showed several new peaks on the spectrum of OJMW, suggesting a successful modification step. A broad band at 3305 cm−1 is assigned to surface –OH groups (Rasana and Jayanarayanan 2022). Meanwhile, peaks at 2909, 1645, 1405 and 621 cm−1 were assigned to the vibration –C–H, –C=O, –C–N and –C=C– bands, respectively (Alam et al. 2016; Omer et al. 2018). The spectra revealed a shift in bands and the formation of new peaks after the modification step. Similar observations were made for the spectrum acquired for spent adsorbents (see Fig. 2). Peaks at the wavelength ranges of 500–600 cm−1 (X) in the spectra indicate the incorporation of Cr onto the surface of the adsorbents.

Thermal analysis

Prior to the specific surface area analysis of the adsorbents, the decomposition process of the pristine and spent adsorbents (OJMW and MWCNTs) was assessed via the thermogravimetric analysis under the N2 atmosphere. The weight loss (%) of OJMW, MWCNTs, OJMW-Cr, and MWCNTs-Cr as a function of temperature and their corresponding derivative mass-loss curves are shown in Fig. 3. The adsorbent demonstrated weight loss (2.2% (MWCNTs), 12.3% (OJMW), 3.5% (MWCNTs-Cr), and 16.8% (OJMW-Cr)) at temperatures < 150 C. The initial weight loss is attributed to the loss of water. The thermogram of MWCNTs and MWCNTs-Cr showed endothermic degradation peaks in their respective derivative mass-loss curves. Peaks at 350 and 750 °C were attributed to the emission of volatile organic compounds and the combustion of graphite. Meanwhile, the implication of chromium adsorption can be observed from the characteristic’s multiple peaks displayed in the derivative mass-loss curve of MWCNTs-Cr. On the other hand, the TGA scan for OJMW and OJMW-Cr exhibited two and four degradation peaks. The first two peaks were due to the release of water and emissions of volatile organic compounds. The third peak (350–450) of OJMW-Cr was ascribed to the decomposition of the organic constituent of the Citrus sinensis juice. Finally, the last peak was associated with the degradation characteristic chromium affixed onto the adsorbent. Multiple peaks of the derivative mass-loss curves of the spent adsorbents showed that the water treatment agent successfully sequestered chromium from the aqueous solution.

The crystalline structure of MWCNTs was assessed using powder XRD. The implication of Citrus sinensis juice extract on the crystallinity of the MWCNTs was evaluated. Diffraction peaks with 2θ values of 26.75° and 51.42° for MWCNTs, 27.44° and 52.31° for OJMW were obtained and indexed to the (003) and (006) reflections of graphite (ICDD No. 01-074-2379) (see Fig. 4). There were no observable changes in the characteristic peaks of MWCNTs and OJMW studies, and this simply suggests that the surface modification of MWCNTs using Citrus sinensis juice extract has no significant effect on the crystalline structure of the MWCNTs.

The effectiveness of an adsorbent is a function of its surface area, pore diameter and pore volume. Therefore, the nitrogen adsorption–desorption experiment was performed to determine the surface characteristics of MWCNTs and OJMW (see Fig. 5). With reference to IUPAC isotherms classification, the BET curves acquired for MWCNTs and OJMW conformed to type III and had a hysteresis loop of H3 type within the relative pressure of 0.8 < P/P0 < 1 indicating capillary condensation, suggesting the ascendancy of a mesoporous structure and a weak adsorbent–adsorbate interaction. Meanwhile, 47.21 and 21.66 m2 g−1 surface areas were estimated for MWCNTs and OJMW, respectively (see Table 3).

Antioxidants study

Antioxidants are chemical components that are utilized to halt oxidation reactions by preventing the creation of free radicals. Antioxidants are known to shield organic matter from nascent oxygen, which is damaging to biomolecules like amino acids, enzymes, fats and proteins, and can result in cell death (Mates 2000; 純二 and 寺尾 2023). Ferric-reducing antioxidant power and DPPH assay were used to assess the antioxidant activity of Citrus sinensis juice extract-modified multi-walled carbon nanotubes (OJMW). Figures 6 and 7 show that OJMW sustained some degree of antioxidant characteristics. Furthermore, antioxidant performance increased in a dose-dependent pattern as the concentration of OJMW increased. The Citrus sinensis juice extract used as a modifier contains phytochemicals that have functional groups which have the capacity to donate electrons or protons resulting in the reduction in natural free radicals. Speaking of the reductive potential of OJMW, the interaction of OJMW with oxyanions of chromium may result in the reduction in hexavalent chromium to its trivalent state.

Effect of solution pH

Solution pH is essentially a major factor in the batch adsorption process. Solution pH affects the adsorbent’s surface chemistry, solubility, and ionization (metal ionization). Figure 8 indicates that the capacity of the adsorbents to sequester Cr(VI) is pH-dependent. A decrease in the uptake capacity of Cr(VI) by OJMW and MWCNTs was noticed with increased solution pH. About 35 and 19 mg g−1 were estimated at pH 2 for OJMW and MWCNTs, respectively. The adsorbent to adsorbate ratio was higher at pH 1, but in other to sustain the integrity of the surfaces OJMW and MWCNTs, pH 2 was selected for further study. The pHPZC of OJMW and MWCNTs was determined as 4.57 for OJMW and 4.91 for MWCNTs (see Fig. 9). The results suggest that at a solution pH greater than the pHPZC of the adsorbents, the surface of OJMW and MWCNTs will be negatively charged. Hence, the effectiveness of OJMW and MWCNTs at lower solution pH (solution pH < pHPZC of the adsorbents) may be ascribed to electrostatic attractions between anionic chromate ion species (Cr2O72− and HCrO4−) and the positively charged adsorbents. On the other hand, there was a decrease in the adsorption capacity of OJMW and MWCNTs at higher solution pH. This could be because the surfaces of the MWCNTs and OJMW were saturated with hydroxyl ions, causing the repulsion of oxyanion of chromium from the surface of the adsorbents (Gupta et al. 2010). This result is in good agreement with the adsorption of hexavalent chromium onto Leucaena leucocephala seed pod-activated carbon (Yusuff 2019).

Effect of contact time

The experimental research of the adsorption of hexavalent chromium from aqueous solutions onto OJMW and MWCNTs for varied time intervals was undertaken to establish the contact time required to attain equilibrium. Figure 10 demonstrates that the uptake capacity of Cr(VI) onto OJMW and MWCNTs increased as the agitation time increased. The removal process was quite fast at the early stage (0–40 min) of the process. The second stage (40–180 min) of the removal process was slow with no observable amount of Cr(VI) removed. A plateau is formed in this stage as shown in Fig. 10, which indicates that the adsorbate-adsorbent interaction is approaching equilibrium. The fast removal of Cr(VI) may be attributed to the availability of sufficient adsorption sites on OJMW and MWCNTs at the early stage of the adsorption process. Meanwhile, as the adsorption process progresses, adsorption sites become limited due to the saturation of active sites on the OJMW and MWCNTs by Cr(VI), and this may be responsible for the plateau observed in the second stage of the removal process. The result acquired is consistent with the previous study (Kong et al. 2020).

By fitting the kinetics data acquired from the contact time experiment into the Lagergren pseudo-first-order, pseudo-second-order, Elovich and intraparticle diffusion kinetic models, the mechanism and rate-determining step of Cr(VI) adsorption onto OJMW and MWCNTs were investigated (see Fig. 11). The equations for these models are shown in Table S2 (see supplementary information). Adsorption is typically accomplished through four processes: adsorbate diffusion onto the adsorbent’s surface from the bulk solution, adsorbate passage through the liquid film attached to the adsorbent’s surface (film diffusion), adsorbate diffusion through the adsorbent’s pores (intraparticle diffusion), and adsorbate interaction with the active sites on the adsorbent (Gupta and Bhattacharyya 2011). To determine the model’s reliance on the experimental data, the model with the lowest sum of squared residuals (SSR) and residual standard error (RSE) was employed. According to these calculations, the pseudo-second-order model (see Table 4) best explained the collected kinetics data for the adsorption of Cr(VI) onto OJMW. The model assumes that adsorption occurs through bimolecular interactions involving electron sharing or exchange between Cr(VI) and OJMW (Das et al. 2018). On the other hand, the uptake of Cr(VI) onto MWCNTs was best described by pseudo-first-order. Given that multiple factors typically govern adsorption kinetics, the intraparticle diffusion model was also used to investigate the rate-limiting step of the adsorption process. A plot of qe versus t0.5 is usually suggestive of multi-step adsorption processes (Wang and Guo 2022). If a linear plot that also passes through the origin is obtained, adsorption is believed to occur solely through intraparticle diffusion. On the contrary, if a linear plot that does not pass through the origin is obtained, it is assumed that the process is controlled by two or more steps (Wu et al. 2009). The Weber-Morris plots yielded linear graphs that did not pass through the origin. As a result, while adsorption occurred via intraparticle diffusion, it was not the only rate-controlling step in the process of the removal of Cr(VI) by OJMW and MWCNTs. The plots also show that Cr(VI) adsorption occurred via the film diffusion of Cr(VI) to the external surface of OJMW and MWCNTs, followed by intraparticle diffusion of Cr(VI) into the pores of OJMW and MWCNTs, and then the interaction of Cr(VI) with active adsorption site of the adsorbents. As a result, a multi-step process is involved.

Effect of adsorbent dose

The masses of MWCNTs or OJMW varied from 0.01 to 0.1 g in the determination of the uptake capacity for Cr(VI). As the mass of the adsorbents increased, the efficiency of the adsorbents was noticed to increase from 42.64 to 90.75% for OJMW and 19.81 to 50.56% for MWCNTs (see Fig. 12). The observed is ascribed to the greater number of active adsorption sites with increased MWCNTs and OJMW dosage. On the contrary, the adsorption potential of OJMW and MWCNTs was noticed to decrease from 88.83 to 22.68 mg g−1 and 41.27 to 12.46 mg g−1, respectively. The increased dosage with a fixed amount of adsorbate as well as the agglomeration of the adsorbents at higher dosages may be responsible for this phenomenon (Zhong et al. 2013). The surface modification of OJMW using Citrus sinensis juice extract as well as the enhanced pore diameter of OJMW (see Table 3) may be responsible for the superior effectiveness of OJMW.

Equilibrium studies

The influence of solution temperature and initial Cr(VI) concentration is assessed and shown in Fig. 13. The curves showed that solution temperature has a significant effect on the sorption characteristics of OJMW and MWCNTs. Meanwhile, as the concentration of Cr(VI) increases from 10 to 100 mg dm-3, the removal potential of OJMW and MWCNTs increases from 4.32 to 32.67 mg g−1 and from 3.94 to 23.67 mg g−1, respectively. The increase in the removal capacity with an increased initial concentration of Cr (VI) could be attributed to the decrease in the mass transfer resistance at the adsorbent–adsorbate interface with an increased concentration gradient (Tyagi and Khandegar 2018). Furthermore, the implications of solution temperature on the removal potential of the adsorbents become pronounced at high temperatures. This phenomenon may be associated with increased pores diameter, generation of new adsorption sites on the surface of the adsorbent or enhanced kinetics of the adsorbate at higher solution temperature (Albatrni et al. 2022).

In other to assess the equilibrium sorbent–sorbate ratio of Cr(VI) adsorption on OJMW and MWCNTs, experimental data obtained from the effect of initial Cr(VI) concentrations were fitted into Langmuir and Freundlich and isotherm models. The Langmuir isotherm was primarily designed to describe the monolayer adsorption process, with the assumption that the sites were comparable and independent. On the other hand, the Freundlich isotherm was used to investigate the heterogeneous nature of adsorbent surfaces, the distribution of active sites, and their corresponding energetics. Table 5 displays parameters that were estimated using the nonlinear equations Langmuir and Freundlich. In the adsorptive removal of Cr(VI) adsorption by OJMW and MWCNTs, the R2 values of the models employed reveal that the uptake of Cr(VI) onto OJMW followed the Langmuir adsorption process. This indicates that the adsorbate was adsorbed on the monolayer surface OJMW, and no interaction occurred between sorbed molecules at the adsorption sites. On the contrary, the uptake of Cr(VI) onto MWCNTs followed Freundlich adsorption, indicating a multi-molecular layered adsorption process. Table 5 shows the estimated n and kF. For values of n within the range of 2 ≤ n ≤ 10 suggesting easy adsorption, a value ≤ 1 n < 2 indicates moderate adsorption, and finally, a value of n < 1 shows hard adsorption (Jia et al. 2014). The estimated value of n in the adsorption of Cr(VI) onto MWCNTs was greater than 1 indicating that the uptake of Cr(VI) onto MWCNTs was an easy process. Furthermore, a comparison of the adsorption potential obtained for OJMW and MWCNTs with other adsorbents that were used for Cr(VI) removal revealed that OJMW is a promising adsorbent for wastewater treatment (see Table 6).

Thermodynamics study

The adsorptive interactions of Cr(VI) with the surface of OJMW and MWCNTs are better understood by assessing adsorption energies at different temperatures. To achieve this, experimental data acquired for the adsorption of Cr(VI) at different initial concentrations and varied solution temperatures were used to deduce the spontaneous nature of the process and the path of energy flow. Thermodynamic parameters such as standard free energy (ΔG°), enthalpy change (ΔH°), and entropy change (ΔS°) were estimated for the adsorptive removal of Cr(VI) onto OJMW and MWCNTs using Eqs. (5) and (6)

where K = 1000 X qm X b (qm and b are Langmuir constants) in dm3 mol−1, and it denotes the equilibrium constant. The thermodynamic parameters calculated for the adsorption of Cr(VI) onto OJMW and MWCNTs are shown in Table 7. It was noticed that in the uptake of Cr(VI) onto OJMW and MWCNTs, the calculated ∆G° values were negative for all the studied temperatures. This suggests spontaneity and the feasibility of the overall process. The adsorption of Cr(VI) onto OJMW and MWCNTs was observed to have positive and negative values of ∆H° indicating endothermic and exothermic adsorption processes, respectively. On the other hand, an increase and decrease in the randomness of Cr(VI) at the surface of MWCNTs and OJMW were observed, respectively. Meanwhile, similar observations were made in the adsorption of Cr(VI) by porous polyacrylonitrile/graphene oxide nanofibers (Feng et al. 2020).

Regeneration study

The reusability of OJMW and MWCNTs up to 5 cycles was assessed, and the results are shown in Fig. 14. The effectiveness of OJMW and MWCNTs was noticed to decrease with increasing regeneration steps and reuse. Factors such as saturation or impaired adsorption sites may be responsible for the declined removal efficiency of the adsorption process with the increased number of cycles. Citrus sinensis juice extract-modified MWCNTs (OJMW) demonstrated good efficiency (> 70%) for Cr(VI) removal after the fourth adsorption–desorption process. Hence, OJMW can be scaled up for a large-scale application in the environmental remediation practice.

Adsorption mechanism

In other to have an in-depth knowledge of the Cr(VI) interaction with OJMW and MWCNTs, SEM micrograph, FTIR spectral and TGA/DTA curves of the pristine and Cr-loaded adsorbents were acquired. These spectroscopic techniques showed the incorporation of the adsorbate to the surfaces of OJMW and MWCNTs. However, the mechanism responsible for the uptake of Cr(VI) on MWCNTs may be pore entrapment or electrostatic interaction between the positively charged surface of MWCNTs and oxyanions of chromium. On the other hand, the main removal mechanism of Cr(VI) by OJMW may involve an electrostatic interaction of Cr(VI) to the surface of OJMW, followed by the reduction of Cr(VI) to Cr(III) and finally the adsorption of Cr(III) to the surface and internal pores of OJMW (see Fig. 15). The FRAP assay also revealed the reductive tendency of OJMW, besides the protonation of OJMW at pH 2, tends to trigger anionic exchange between oxyanions and protons on the oxygen functional groups at the surface of OJMW resulting in the reduction of Cr(VI) to Cr(III). The proposed mechanism was supported by adsorption kinetics data. The adsorption-kinetic for the uptake of Cr(VI) onto OJMW was best described by the pseudo-second-order model (see Table 4), suggesting a bimolecular interaction involving electron sharing or exchange between oxyanions and OJMW. The result is in good agreement with the report of Fu-Xin et al. on the adsorption of Cr(VI) onto biochar-based iron oxide composites (Dong et al. 2021).

Conclusion

Citrus sinensis juice extract-modified multi-walled carbon nanotubes (OJMW) have been successfully synthesized. In this study, the optimum removal of Cr(VI) by MWCNTs and OJMW was achieved within a contact period of 180 min, pH 2 and an adsorbent dosage of 0.05 g. The uptake kinetics revealed that the adsorptive removal of Cr(VI) ion using MWCNTs and OJMW followed pseudo-first-order and pseudo-second-order kinetic models, respectively. On the other hand, the adsorptive removal of Cr(VI) using OJMW and MWCNTs follows Langmuir and Freundlich models, respectively. FRAP and DPPH assay also revealed that OJMW sustained antioxidant characteristics, which further suggests that the adsorption of Cr(VI) ions using OJMW takes place via chemisorption. In addition, based on thermodynamic studies, the adsorption of Cr(VI) onto MWCNTs and OJMW was a spontaneous and feasible process. The adsorption of Cr(VI) onto OJMW and MWCNTs followed endothermic and exothermic adsorption processes, respectively. The effectiveness of the OJMW after several cycles revealed the robust and positive prospect of OJMW in environmental remediation practices.

Data availability

Data will be supplied upon request from the corresponding author.

References

Agarwal G, Bhuptawat HK, Chaudhari S (2006) Biosorption of aqueous chromium (VI) by Tamarindus indica seeds. Biores Technol 97:949–956

Aksu Z, Karabayır G (2008) Comparison of biosorption properties of different kinds of fungi for the removal of Gryfalan Black RL metal-complex dye. Biores Technol 99:7730–7741

Aksu Z, Özer D, Ekiz HI, Kutsal T, Çaglar A (1996) Investigation of biosorption of chromium (VI) on Cladophora crispata in two-staged batch reactor. Environ Technol 17:215–220

Alam RS, Moradi M, Nikmanesh H (2016) Influence of multi-walled carbon nanotubes (MWCNTs) volume percentage on the magnetic and microwave absorbing properties of BaMg0. 5Co0. 5TiFe10O19/MWCNTs nanocomposites. Mater Res Bull 73:261–267

Albatrni H, Qiblawey H, Al-Marri MJ (2022) Walnut shell based adsorbents: a review study on preparation, mechanism, and application. J Water Process Eng 45:102527

Ali A, Saeed K, Mabood F (2016) Removal of chromium (VI) from aqueous medium using chemically modified banana peels as efficient low-cost adsorbent. Alex Eng J 55:2933–2942

Alwan SH, Alshamsi HA (2022) In situ synthesis NiO/F-MWCNTs nanocomposite for adsorption of malachite green dye from polluted water. Carbon Lett 32:1073–1084

Amaku JF, Ngwu CM, Ogundare SA, Akpomie KG, Edozie OI, Conradie J (2021) Thermodynamics, kinetics and isothermal studies of chromium (VI) biosorption onto Detarium senegalense stem bark extract coated shale and the regeneration potentials. Int J Phytorem 23:1486–1496

Arnawtee WH, Jaleh B, Nasrollahzadeh M, Bakhshali-Dehkordi R, Nasri A, Orooji Y (2022) Lignin valorization: Facile synthesis, characterization and catalytic activity of multiwalled carbon nanotubes/kraft lignin/Pd nanocomposite for environmental remediation. Sep Purif Technol 290:120793

Baral A, Engelken RD (2002) Chromium-based regulations and greening in metal finishing industries in the USA. Environ Sci Pol 5:121–133

Bayuo J, Pelig-Ba KB, Abukari MA (2019) Adsorptive removal of chromium (VI) from aqueous solution unto groundnut shell. Appl Water Sci 9:107

Belachew N, Hinsene H (2020) Preparation of cationic surfactant-modified kaolin for enhanced adsorption of hexavalent chromium from aqueous solution. Appl Water Sci 10:38

Boddu VM, Abburi K, Talbott JL, Smith ED (2003) Removal of hexavalent chromium from wastewater using a new composite chitosan biosorbent. Environ Sci Technol 37:4449–4456

Cherdchoo W, Nithettham S, Charoenpanich J (2019) Removal of Cr (VI) from synthetic wastewater by adsorption onto coffee ground and mixed waste tea. Chemosphere 221:758–767

Chew Y-L, Lim Y-Y (2018) Evaluation and comparison of antioxidant activity of leaves, pericarps and pulps of three Garcinia species in Malaysia. Free Radic Antioxid 8:130–134

Costa M (1997) Toxicity and carcinogenicity of Cr (VI) in animal models and humans. Crit Rev Toxicol 27:431–442

Dakiky M, Khamis M, Manassra A, Mer’eb M (2002) Selective adsorption of chromium (VI) in industrial wastewater using low-cost abundantly available adsorbents. Adv Environ Res 6:533–540

Dalal U, Reddy SN (2019) A novel nano zero-valent iron biomaterial for chromium (Cr6+ to Cr3+) reduction. Environ Sci Pollut Res 26:10631–10640

Daneshvar N, Salari D, Aber S (2002) Chromium adsorption and Cr (VI) reduction to trivalent chromium in aqueous solutions by soya cake. J Hazard Mater 94:49–61

Das S, Dash SK, Parida K (2018) Kinetics, isotherm, and thermodynamic study for ultrafast adsorption of azo dye by an efficient sorbent: ternary Mg/(Al+ Fe) layered double hydroxides. ACS Omega 3:2532–2545

Dehghani MH, Taher MM, Bajpai AK, Heibati B, Tyagi I, Asif M, Agarwal S, Gupta VK (2015) Removal of noxious Cr (VI) ions using single-walled carbon nanotubes and multi-walled carbon nanotubes. Chem Eng J 279:344–352

DesMarias TL, Costa M (2019) Mechanisms of chromium-induced toxicity. Current Opin Toxicol 14:1–7

Dinh V-P, Le HM, Nguyen V-D, Dao V-A, Hung NQ, Tuyen LA, Lee S, Yi J, Nguyen TD, Tan L (2019) Insight into the adsorption mechanisms of methylene blue and chromium (III) from aqueous solution onto pomelo fruit peel. RSC Adv 9:25847–25860

Dong F-X, Yan L, Zhou X-H, Huang S-T, Liang J-Y, Zhang W-X, Guo Z-W, Guo P-R, Qian W, Kong L-J (2021) Simultaneous adsorption of Cr (VI) and phenol by biochar-based iron oxide composites in water: Performance, kinetics and mechanism. J Hazard Mater 416:125930

Dupont L, Guillon E (2003) Removal of hexavalent chromium with a lignocellulosic substrate extracted from wheat bran. Environ Sci Technol 37:4235–4241

Feng Z-Q, Yuan X, Wang T (2020) Porous polyacrylonitrile/graphene oxide nanofibers designed for high efficient adsorption of chromium ions (VI) in aqueous solution. Chem Eng J 392:123730

Freundlich H (1906) Over the adsorption in solution. J Phys Chem 57:e470

Fukai R (1967) Valency state of chromium in seawater. Nature 213:901–901

Gupta SS, Bhattacharyya KG (2011) Kinetics of adsorption of metal ions on inorganic materials: a review. Adv Coll Interface Sci 162:39–58

Gupta VK, Rastogi A, Nayak A (2010) Adsorption studies on the removal of hexavalent chromium from aqueous solution using a low-cost fertilizer industry waste material. J Colloid Interface Sci 342:135–141

Hadavifar M, Bahramifar N, Younesi H, Li Q (2014) Adsorption of mercury ions from synthetic and real wastewater aqueous solution by functionalized multi-walled carbon nanotube with both amino and thiolated groups. Chem Eng J 237:217–228

Hu J, Chen C, Zhu X, Wang X (2009) Removal of chromium from aqueous solution by using oxidized multiwalled carbon nanotubes. J Hazard Mater 162:1542–1550

Huang S-D, Fann C-F, Hsieh H-S (1982) Foam separation of chromium(VI) from aqueous solution. J Colloid Interface Sci 89:504–513

Ibrahim MM, Ngah WW, Norliyana M, Daud WW, Rafatullah M, Sulaiman O, Hashim R (2010) A novel agricultural waste adsorbent for the removal of lead (II) ions from aqueous solutions. J Hazard Mater 182:377–385

Jia B-B, Wang J-N, Wu J, Li C-J (2014) “Flower-Like” PA6@ Mg (OH) 2 electrospun nanofibers with Cr (VI)-removal capacity. Chem Eng J 254:98–105

Jiang L, Liu S, Liu Y, Zeng G, Guo Y, Yin Y, Cai X, Zhou L, Tan X, Huang X (2017) Enhanced adsorption of hexavalent chromium by a biochar derived from ramie biomass (Boehmeria nivea (L.) Gaud.) modified with β-cyclodextrin/poly (L-glutamic acid). Environ Sci Pollut Res 24:1–10

Knorr D, Augustin MA (2023) Vanishing water: rescuing the neglected food resource. Food Eng Rev 15:1–16

Kong X, Gao H, Song X, Deng Y, Zhang Y (2020) Adsorption of phenol on porous carbon from Toona sinensis leaves and its mechanism. Chem Phys Lett 739:137046

Kongsricharoern N, Polprasert C (1996) Chromium removal by a bipolar electro-chemical precipitation process. Water Sci Technol 34:109–116

Kumar P, Tokas J, Singal H (2019) Amelioration of chromium VI toxicity in Sorghum (Sorghum bicolor L.) using glycine betaine. Sci Rep 9:16020

Kumar N, Bhushan S, Patole PB, Gite A (2022) Multi-biomarker approach to assess chromium, pH and temperature toxicity in fish. Comp Biochem Physiol C: Toxicol Pharmacol 254:109264

Lalvani S, Hubner A, Wiltowski T (2000) Chromium adsorption by lignin. Energy Sour 22:45–56

Langmuir I (1918) The adsorption of gases on plane surface of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Lee CS, Shuit SH, Lim CC, Ng QH, Hoo PY, Lim S, Teoh YP (2022) Synthesis of magnetic multi-walled carbon nanotubes via facile and solvent-free direct doping method for water remediation. J Water Process Eng 45:102487

Lian G, Wang B, Lee X, Li L, Liu T, Lyu W (2019) Enhanced removal of hexavalent chromium by engineered biochar composite fabricated from phosphogypsum and distillers grains. Sci Total Environ 697:134119

Luther S, Brogfeld N, Kim J, Parsons J (2013) Study of the thermodynamics of chromium (III) and chromium (VI) binding to iron (II/III) oxide or magnetite or ferrite and magnanese (II) iron (III) oxide or jacobsite or manganese ferrite nanoparticles. J Colloid Interface Sci 400:97–103

Lyubchik SI, Lyubchik AI, Galushko OL, Tikhonova LP, Vital J, Fonseca IM, Lyubchik SB (2004) Kinetics and thermodynamics of the Cr (III) adsorption on the activated carbon from co-mingled wastes. Colloids Surf A 242:151–158

Ma M, Lu Y, Chen R, Ma L, Wang Y (2014) Hexavalent chromium removal from water using heat-acid activated red mud. Open J Appl Sci 4:275

Mates J (2000) Effects of antioxidant enzymes in the molecular control of reactive oxygen species toxicology. Toxicology 153:83–104

Matussin S, Harunsani MH, Tan AL, Khan MM (2020) Plant-extract-mediated SnO2 nanoparticles: synthesis and applications. ACS Sustain Chem Eng 8:3040–3054

Mishra S, Bharagava RN (2016) Toxic and genotoxic effects of hexavalent chromium in environment and its bioremediation strategies. J Environ Sci Health C 34:1–32

Mondal NK, Chakraborty S (2020) Adsorption of Cr (VI) from aqueous solution on graphene oxide (GO) prepared from graphite: equilibrium, kinetic and thermodynamic studies. Appl Water Sci 10:1–10

Nnadozie EC, Ajibade PA (2020) Adsorption, kinetic and mechanistic studies of Pb (II) and Cr (VI) ions using APTES functionalized magnetic biochar. Micropor Mesopor Mater 309:110573

Ofomaja A, Naidoo E, Modise S (2009) Removal of copper (II) from aqueous solution by pine and base modified pine cone powder as biosorbent. J Hazard Mater 168:909–917

Ogidi OI, Akpan UM (2022) Aquatic biodiversity loss: Impacts of pollution and anthropogenic activities and strategies for conservation, Biodiversity in Africa: potentials, threats and conservation. Springer: New York, pp 421–448

Oliveira E, Montanher S, Andrade A, Nobrega J, Rollemberg M (2005) Equilibrium studies for the sorption of chromium and nickel from aqueous solutions using raw rice bran. Process Biochem 40:3485–3490

Omer A, Khalifa R, Hu Z, Zhang H, Liu C, Ouyang X (2018) Fabrication of tetraethylenepentamine functionalized alginate beads for adsorptive removal of Cr (VI) from aqueous solutions. Int J Biol Macromol 125:1221–1231

Omorogie MO, Babalola JO, Unuabonah EI, Gong JR (2016) Clean technology approach for the competitive binding of toxic metal ions onto MnO2 nano-bioextractant. Clean Technol Environ Policy 18:171–184

Ou B, Wang J, Wu Y, Zhao S, Wang Z (2020) Efficient removal of Cr (VI) by magnetic and recyclable calcined CoFe-LDH/g-C3N4 via the synergy of adsorption and photocatalysis under visible light. Chem Eng J 380:122600

Pagilla KR, Canter LW (1999) Laboratory studies on remediation of chromium-contaminated soils. J Environ Eng 125:243–248

Park S-H, Shin SS, Park CH, Jeon S, Gwon J, Lee S-Y, Kim S-J, Kim H-J, Lee J-H (2020) Poly (acryloyl hydrazide)-grafted cellulose nanocrystal adsorbents with an excellent Cr (VI) adsorption capacity. J Hazard Mater 394:122512

Peterson JJ, Dwyer JT, Beecher GR, Bhagwat SA, Gebhardt SE, Haytowitz DB, Holden JM (2006) Flavanones in oranges, tangerines (mandarins), tangors, and tangelos: a compilation and review of the data from the analytical literature. J Food Compos Anal 19:S66–S73

Rai M, Shahi G, Meena V, Meena R, Chakraborty S, Singh R, Rai B (2016) Removal of hexavalent chromium Cr (VI) using activated carbon prepared from mango kernel activated with H3 PO4. Resour Efficient Technol 2:S63–S70

Rasana N, Jayanarayanan K (2022) Nano, micro and multiscale filler-reinforced functionalized polypropylene composites: FTIR characterization and mechanical study. Polyolefins J 9:33–43

Ravindranath SP, Henne KL, Thompson DK, Irudayaraj J (2011) Surface-enhanced Raman imaging of intracellular bioreduction of chromate in Shewanella oneidensis. PLoS ONE 6:e16634

Rout DR, Jena HM (2021) Synthesis of novel reduced graphene oxide decorated β-cyclodextrin epichlorohydrin composite and its application for Cr (VI) removal: Batch and fixed-bed studies. Sep Purif Technol 278:119630

Rout DR, Jena HM (2022) Enhanced Cr (VI) adsorption using ZnO decorated graphene composite: Batch and continuous studies. J Taiwan Inst Chem Eng 140:104534

Rout DR, Jena HM (2023) Synthesis of graphene oxide-modified porous chitosan cross-linked polyaniline composite for static and dynamic removal of Cr (VI). Environ Sci Pollut Res 30:22992–23011

Santé Omdl, Organization WH, Programme W--W, Staff WHO, Zdrowia ŚO, WHO (2004): Guidelines for drinking-water quality, 1. World Health Organization

Scanlon T, Uguru OP, Jafry T, Chinsinga B, Mvula P, Chunga J, Zimba LM, Mwape M, Nyundo L, Mwiinga B (2016) The role of social actors in water access in Sub-Saharan Africa: Evidence from Malawi and Zambia. Water Resour Rural Develop 8:25–36

Seaman JC, Bertsch PM, Schwallie L (1999) In situ Cr (VI) reduction within coarse-textured, oxide-coated soil and aquifer systems using Fe (II) solutions. Environ Sci Technol 33:938–944

Sevim AM, Hojiyev R, Gül A, Çelik MS (2011) An investigation of the kinetics and thermodynamics of the adsorption of a cationic cobalt porphyrazine onto sepiolite. Dyes Pigm 88:25–38

Sharifi S, Nabizadeh R, Akbarpour B, Azari A, Ghaffari HR, Nazmara S, Mahmoudi B, Shiri L, Yousefi M (2019) Modeling and optimizing parameters affecting hexavalent chromium adsorption from aqueous solutions using Ti-XAD7 nanocomposite: RSM-CCD approach, kinetic, and isotherm studies. J Environ Health Sci Eng 17:873–888

Srivastava D, Tiwari M, Dutta P, Singh P, Chawda K, Kumari M, Chakrabarty D (2021) Chromium stress in plants: toxicity, tolerance and phytoremediation. Sustainability 13:4629

Sun J, Luo Y, Ye J, Li C, Shi J (2022) Chromium distribution, leachability and speciation in a chrome plating site. Processes 10:142

Team RC (2018) A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. www.R-project.org (Accessed on 11 September 2020)

Tiravanti G, Petruzzelli D, Passino R (1997) Pretreatment of tannery wastewaters by an ion exchange process for Cr(III) removal and recovery. Water Sci Technol 36:197–207

Trivedi S, Kumar V, Singh S, Kumar M (2021) Efficacy evaluation of Rauwolfia serpentina against Chromium (VI) toxicity in fish, Channa punctatus. J Environ Biol 42:659–667

Tyagi U, Khandegar V (2018) Biosorption potential of Vetiveria zizanioides for the removal of chromium (VI) from synthetic wastewater. J Hazardous Toxic Radioact Waste 22:04018014

Vetriselvi V, Santhi RJ (2015) Redox polymer as an adsorbent for the removal of chromium (VI) and lead (II) from the tannery effluents. Water Resour Ind 10:39–52

Vilela PB, Dalalibera A, Duminelli EC, Becegato VA, Paulino AT (2019) Adsorption and removal of chromium (VI) contained in aqueous solutions using a chitosan-based hydrogel. Environ Sci Pollut Res 26:28481–28489

Vindhya P, Kavitha V (2023) Phyto-mediated synthesis of pure and cobalt-doped SnO2 nanoparticles for antimicrobial, antioxidant, and photocatalytic activities. Biomass Convers Bioref. https://doi.org/10.1007/s13399-023-04548-4

Wang J, Guo X (2022) Rethinking of the intraparticle diffusion adsorption kinetics model: Interpretation, solving methods and applications. Chemosphere 309:136732

Wang C, Xiong C, He Y, Yang C, Li X, Zheng J, Wang S (2021) Facile preparation of magnetic Zr-MOF for adsorption of Pb (II) and Cr (VI) from water: Adsorption characteristics and mechanisms. Chem Eng J 415:128923

Weng C-H, Sharma Y, Chu S-H (2008) Adsorption of Cr (VI) from aqueous solutions by spent activated clay. J Hazard Mater 155:65–75

Wu F-C, Tseng R-L, Juang R-S (2009) Initial behavior of intraparticle diffusion model used in the description of adsorption kinetics. Chem Eng J 153:1–8

Yusuff AS (2019) Adsorption of hexavalent chromium from aqueous solution by Leucaena leucocephala seed pod activated carbon: equilibrium, kinetic and thermodynamic studies. Arab J Basic Appl Sci 26:89–102

Zhong Q-Q, Yue Q-Y, Gao B-Y, Li Q, Xu X (2013) A novel amphoteric adsorbent derived from biomass materials: synthesis and adsorption for Cu (II)/Cr (VI) in single and binary systems. Chem Eng J 229:90–98

Zhou X, Korenaga T, Takahashi T, Moriwake T, Shinoda S (1993) A process monitoring/controlling system for the treatment of wastewater containing chromium(VI). Water Res 27:1049–1054

Zubrik A, Matik M, Hredzák S, Lovás M, Danková Z, Kováčová M, Briančin J (2017) Preparation of chemically activated carbon from waste biomass by single-stage and two-stage pyrolysis. J Clean Prod 143:643–653

純二, 寺尾 (2023) Revisiting carotenoids as dietary antioxidants for human health and disease prevention. Food Funct

Funding

Open access funding provided by Walter Sisulu University.

Author information

Authors and Affiliations

Contributions

FJA designed and implemented the study; RT edited, corrected, improved and supervised the manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interest.

Ethics approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amaku, J.F., Taziwa, R. Aqueous removal of Cr(VI) by Citrus sinensis juice-coated multi-walled carbon nanotubes. Chem. Pap. 78, 5415–5431 (2024). https://doi.org/10.1007/s11696-024-03481-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-024-03481-8