Abstract

Herein, a superior adsorbent was fabricated via immobilizing Ananas comosus juice extract on nanotubes (MWPJ) for the removal of chromium (VI) from simulated wastewater. The batch adsorption technique was used to establish the influence of solution pH, adsorbent dosage, solution temperature, initial Cr(VI) concentration, and contact time on the adsorption of chromium (VI). To comprehend the surface properties and to confirm chromium (VI) adsorption onto MWPJ and MWCNTs, TGA, SEM, and FTIR analyses were performed for MWPJ and MWCNTs before and after the adsorption process. These spectroscopic techniques revealed the temperature and surface characteristics responsible for the effectiveness of MWPJ. MWPJ and MWCNTs demonstrated optimum removal potential at solution pH 2, 0.05 g adsorbent dosage, and 180 min contact time. The MWPJ and MWCNTs had a maximum adsorption potential of 44.87 and 33.38 mg g−1 at 25 °C respectively. The reaction rate kinetics data for MWPJ and MWCNTs fitted well with Elovich and the pseudo-first-order kinetic model, respectively, while the saturated equilibrium data were best described by Freundlich isotherm. The thermodynamics analysis revealed that the uptake of Cr(VI) onto MWPJ and MWCNTs was a spontaneous and exothermic process. After five adsorption–desorption cycles of MWPJ, about 80% removal efficiency of Cr(VI) ions was sustained. Hence, MWPJ has demonstrated a superior capacity for practical applications in environmental remediation practice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rapid industrialization and urbanization of the modern world have resulted in to increase in environmental pollution, particularly the contamination of water sources by heavy metals [1]. Water pollution has been reported to be one of the major challenges of man. These water pollutants emanate from agricultural and industrial wastewater that is channelled and disposed of into water bodies [2,3,4,5]. Wastewater from industries is known to constitute toxic metals like hexavalent chromium (Cr(VI)) among others [6]. These toxic metal ions in water are harmful to aquatic life and man on consumption [7]. The fact that these industries are on the increase poses a greater threat to surface water as more untreated effluents enhance the amount of toxic metal ions in water [8]. Hexavalent chromium (Cr(VI)), a toxic heavy metal, is among the most prevalent and hazardous pollutants present in water, due to its wide industrial use in various processes such as electroplating, metal finishing, and leather tanning [9, 10]. Cr(VI) contamination in water sources has become a major environmental concern. Meanwhile, exposure to Cr(VI) can lead to severe health issues, including respiratory problems, liver damage, skin irritation, kidney damage, and an increased risk of cancer [11,12,13,14,15].

To solve this problem, several methods such as biodegradation [16], chemical precipitation [17], electrocoagulation [18], membrane filtration [19], photocatalysis [20], ion exchange [21], osmosis [22], and adsorption [23,24,25,26,27] have been used in the removal of hexavalent chromium separation. Among these methods, adsorption is a frequently used method because of its high efficiency, easy operation, and low cost [28]. Various adsorbents such as MOF [29], coffee ground [30], clay [31], nanocomposite [32], activated carbon [33, 34], hydrogel [35, 36], resins, graphene oxide [23,24,25], biochar [37, 38], clay [31], nano cellulose [39], and silica [40] have been used for Cr(VI) adsorption. However, the major challenge of this adsorbent is the high production cost, poor recyclability, low adsorption capacity, and poor removal efficiency at low absorbate concentration.

The use of carbon nanotubes in environmental remediation has gained immense popularity, owing to the unique physicochemical properties exhibited by nanomaterials [41]. Among these, multi-walled carbon nanotubes (MWCNTs) have proven to be exceptionally promising due to their high surface area, tunable pore sizes, and outstanding adsorption capacity [42]. However, high production cost and toxicity tendency are major drawback to the application of MWCNTs. By effectively adsorbing pollutants, MWCNTs offer a potential solution for the efficient removal of Cr(VI) from water sources [43,44,45,46,47]. In addition to nanotechnology, nature has also provided us with numerous bioresources that demonstrate excellent adsorption capabilities. One such resource is Ananas comosus juice (pineapple juice), which has been garnering attention for its multi-functional properties, extending beyond its culinary appeal. Pineapple juice is rich in organic compounds (bromelain), particularly enzymes (serotonin), and organic acids (ferulic acid, caffeic acid, sinapic acid, and p-coumaroylquinic acid), which impart its multi-work nature, showcasing not only culinary characteristics but also unique antioxidants properties [48]. Hence, juice obtained from pineapple can function as modifying agent.

In this research, we propose a novel approach that combines MWCNTs with Ananas comosus juice for Cr(VI) removal from aqueous solutions. The synergistic effect of these two materials is anticipated to enhance the overall efficiency of Cr(VI) adsorption, presenting a sustainable and cost-effective alternative to conventional methods. Hence, we aim to develop an environmentally efficient adsorbent for the remediation of Cr(VI)-contaminated water sources. The study has the potential to contribute significantly to the field of environmental science, providing valuable insights into the development of efficient and sustainable technologies for Cr(VI) sequestration. Additionally, the integration of nanotechnology with natural bioresources opens doors to explore similar applications for the remediation of other toxic pollutants, further broadening its impact on environmental sustainability.

2 Materials and methods

2.1 Materials and reagents

1,5-Diphenycarbazide (98%), nitric acid (98.98%), sulphuric acid (98%), sodium chloride (> 95%), hydrochloric acid (99.9%), potassium dichromate (99.99%), and sodium hydroxide (99.99%) were obtained from Sigma–Aldrich and used without supplementary purification. The same vendor provided multi-walled carbon nanotubes with a purity of 95%, having lengths ranging from 10 to 20 nm (average length 17 nm), and external diameters ranging from 30 to 50 nm (mean diameter 39 nm). Spoilt Ananas comosus fruit was collected from the dry waste bin at the Orie Ugba community market, Umuahia, Abia State, Nigeria (5°53′71″ N and 7°49′97″ E).

2.2 Preparation of Ananas comosus juice

Spoilt Ananas comosus fruit was processed using a stainless-steel pineapple peeler. About 500 g of Ananas comosus flesh was then extracted by making use of a Kenwood accent centrifugal juicer (Bash product UUID 154011AAAA7). To eliminate the pulp, the juice was refiltered. Thereafter, the juice was vacuum oven-dried at 50 °C and the concentrate was stored for future application.

2.3 Purification of MWCNTs

For 3 h, 6.0 M HCl (25 cm3) was in contact with 0.5 g MWCNTs under continual stirring. The mixture was diluted, and washed under vacuum to the pH of the use deionized water. The same purification technique was carried out with HNO3. To remove amorphous carbon, the purified MWCNTs were oven-dried for 12 h at 110 °C before being calcined for 60 min at 300 °C.

2.4 Preparation of Ananas comosus juice–modified MWCNTs

About 1 g of the purified MWCNTs were treated with a mixture of HNO3 and H2SO4 in a 3:1 (v/v) ratio to generate oxygen functionalities on the surface of MWCNTs. At room temperature, the mixture was stirred for 6 h. Following that, the mixture was neutralized with 1 mol dm−3 NaOH. Thereafter, the mixture was washed to neutrality under a vacuum with deionized water. Finally, the black product obtained was then rewashed using acetone and ethanol before being oven-dried at 110 °C overnight. About 0.5 g of Ananas comosus juice concentrate was redissolved in a 100 cm3 beaker containing 20 cm3 of double-distilled water at 40 °C. Thereafter, 2.5 g of the acid-functionalized MWCNTs was contacted with the 25 cm3 Ananas comosus juice extract under continuous stirring for 12 h at 80 °C. Following that, the black product was vacuum oven-dried and stored for future use. The obtained product was labelled as MWPJ.

2.5 Characterization

Fourier transform infrared (FTIR) spectra of pristine and spent adsorbents (MWPJ and MWCNTs) were acquired using Nicolet-870 spectrophotometer, USA. The surface morphology of MWPJ and MWCNTs was assessed by field emission scanning electron microscopy (ZEISS ultra plus, USA). To avoid the charging effect, MWPJ and MWCNTs were sputter-coated with platinum before the acquisition of the micrograph. The crystal structure of MWPJ and MWCNTs was determined using X-ray diffractometry (XRD Bruker D8 Advance powder X-ray diffraction). The specific surface area and pore volume of MWPJ and MWCNTs were obtained using the surface N2 adsorption technique by Brunauer–Emmett–Teller (BET) and Barrett-Joyner-Halenda (BJH) (Micromeritics Instruments Corp., Ltd., USA). The PerkinElmer simultaneous thermal analyzer (STA6000 instrument, USA) was used to investigate the thermal behaviour of MWPJ and MWCNTs.

2.6 Batch adsorption

Batch experiments were used to investigate the removal of Cr(VI) from aqueous solutions. About 0.05 g of MWPJ or MWCNTs was contacted with 25 cm3 (100 mg dm−3) of K2CrO4 solution adjusted to pH 2 using 0.1 M H2SO4 or 0.1 M NaOH in a 100 cm3 stoppered plastic bottle. The resultant mixture was agitated for 3 h in a thermostated shaking water bath (agitation speed of 120 rpm) at a fixed temperature of 25 °C. UV–visible spectrophotometry (Analyst 600, PerkinElmer Company, USA) (λ = 540 nm) was used to estimate the residual concentration of Cr(VI) after the filtration step. Furthermore, the effects of various parameters such as the adsorbent dosage, adsorption kinetics, solution pH, solution temperature, and initial Cr(VI) concentration were explored in this study. Experiments were performed in duplicate. To investigate the reusability of MWPJ and MWCNTs. About 0.2 g of MWPJ or MWCNTs was contacted with 100 cm3 of 100 mg dm−3 of Cr(VI) for 180 min. The chromium-loaded adsorbents were then desorbed using 25 cm3 (0.05 M) of aqueous NaOH solution under constant agitation for 30 min. Thereafter, deionized water was used to wash the desorbed adsorbent to remove residual NaOH solution. The aforementioned procedure was repeated five times to establish the reusability of the MWPJ and MWCNTs. The adsorption capacity (mg g−1) and the adsorption efficiency (% adsorbed) of MWPJ or MWCNTs were estimated by making use of Eqs. (1) and (2) respectively [28, 49].

where Ci is the initial Cr(VI) concentration (mg dm−3), Ceq is the equilibrium concentration of Cr(VI) (mg dm−3), m is the adsorbent mass (g), and V is the volume of Cr(VI) solution (dm3).

2.7 Antioxidant assay

The adapted approach of Chew and Lim (2018) was employed to measure the ferric-reducing antioxidant power (FRAP) of MWPJ or MWCNTs [50]. Briefly, 1 cm3 of MWPJ or MWCNTs (25, 50, 100, 200, and 400 g/mL) was contacted, with 2 cm3 of potassium phosphate buffer (0.1 M, pH 6.6) and 1% (m/v) potassium ferricyanide (2.5 cm3). After 20 min of incubation at 50 °C, the mixtures were treated with 2.5 cm3 of 10% (m/v) trichloroacetic acid. To enhance colour development, 2.5 cm3 of deionized water and 0.5 cm3 of 0.1% (m/v) ferric chloride (0.5 cm3) were added to 2.5 cm3 of the reaction mixtures and incubated at 28 °C for 30 min. Finally, the absorbance readings were acquired at 700 nm. On the other hand, The DPPH assay was used to assess the antioxidant activity of MWPJ or MWCNTs. 0.5 cm3 of DPPH (0.3 mM) solution was typically contacted with varying amounts of MWPJ or MWCNTs (25, 50, 100, 200, and 400 g/mL) [51, 52]. MWPJ or MWCNTs are radical scavengers, and DPPH is a radical generator. The reaction mixture was then incubated for 30 min at room temperature in a dark atmosphere. To measure the free radical concentration, the % change in absorption wavelength at 517 nm was employed. The percentage inhibition (% I) of the DPPH and the percentage of FRAP in gallic acid equivalents were estimated using Eqs. (3) and (4) respectively.

2.8 Determination of point of zero charge (pHpzc) of MWPJ and MWCNTs

The pHpzc of MWPJ or MWCNTs was estimated by making use of the solid addition technique [53, 54]. Briefly, 50 cm3 of 0.1 M NaCl solution was taken in eleven different Erlenmeyer flasks. The pH of the NaCl solution was adjusted from pH 2 to pH 12 by adding 0.1 M NaOH and 0.1 M HCl solutions. The pH-adjusted solution was then contacted with 1 g of MWPJ or MWCNTs in each flask. The suspension of MWPJ or MWCNTs in each flask was agitated for 48 h. The difference in the initial and final pH of the solution was obtained. Finally, the pHPZC of MWPJ and MWCNTs were extrapolated from the plot of the final pH versus the initial pH of the mixture.

2.9 Data analysis

Microsoft Excel and Origin 2016 suite were used to process experimental data. Data retrieved from the contact time and effect of concentration and temperature experiments were fitted into the kinetics and isotherm models using the nls nonlinear regression routine in the R statistical computing environment and Origin 2016 suite. Estimated residuals such as the sum of squared residuals (SSR), residual squared error (RSE), and correlation coefficient (R.2) used to establish model that best describe the adsorption process [55]

3 Results and discussion

3.1 Characterization of MWCNTs and MWJP

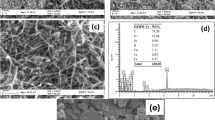

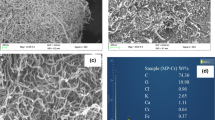

The shape and surface morphology of MWCNTs and MWJP were acquired using SEM analysis. The SEM micrograph obtained for pristine and the Ananas comosus juice extract–modified nanotubes revealed a similar entwined tubular network (see Fig. 1). This indicates that the modification step did not denature the physicochemical characteristics of the nanotubes. On the other hand, the SEM–EDX of the chromium-loaded MWJP showed a trace amount of chromium that was incorporated into the adsorbent surface, indicating the successful adsorption of Cr(VI) onto the surface of MWJP.

The FTIR spectral MWCNTs and MWPJ were acquired before and after the adsorption of Cr(VI). As shown in Fig. 2, characteristic peaks were assigned to the following absorption bands: 3305 (OH), 2909 (C-H), 1645 (C = O), 1405 (C-N), and 621 (C = C) cm−1, respectively [56,57,58]. The viewed peaks were ascribed to the bending and stretching due to phenolic, alkane, alkene, and nitrile. In this study, FTIR analysis validated that the surface modification of MWCNTs using Ananas comosus juice extract resulted in the introduction of new peaks and this could be due to the availability of flavonoids and phenolics content of Ananas comosus juice extract [59]. Furthermore, a decrease in the intensity of peaks and a slight shift in adsorption bands were observed for the spectral acquired for the spent adsorbent. This phenomenon may be attributed to the interaction between adsorbate and the functional groups on the surface of the MWCNTs and MWPJ.

The thermogravimetric analysis curves for MWPJ and MWCNTs are shown in Fig. 3. The mass-loss curves of the as-prepared and spent adsorbents were found to be decreasing continually from 20 to 900 °C. The derivative mass-loss curve for the thermal degradation of MWPJ, MWCNTs, MWPJ-Cr, and MWCNTs-Cr reflects an endothermic process. The derivative mass-loss curves of MWPJ and MWPJ-Cr presented only three and two maximum peaks at temperatures slightly below 100 °C, 200 °C, and 350 °C. The first peak shows the volatilization of physically adsorbed water (17%, MWPJ and MWPJ-Cr). About 23% weight loss was observed for the second peak (< 200 °C) and this could be due to the release of volatile organic compounds that were trapped in the adsorbent. The decrease in thermal stability of MWCNTs after treatment with pineapple juice could be attributed to disruption of the lattice and weaken intermolecular forces of MWCNTs by the pineapple juice resulting to a less thermally stable material (MWPJ). The third peak (< 350 °C, MWPJ) on the derivative mass-loss curves was associated with the degradation of the surface modifier (Ananas comosus juice extract) of the nanotubes. Meanwhile, the disappearance of the peak third on the derivative mass-loss curve of MWPJ-Cr suggests that the Ananas comosus juice extract was used up in the removal of Cr(VI) from the simulated wastewater. On the other hand, about 2.2% and 3.5% weight loss was observed at temperature < 100 °C for MWCNTs and MWCNTs-Cr, respectively. The derivative mass-loss curves for MWCNTs and MWCNTs-Cr showed peaks at temperatures slightly below 100 °C, 350 °C, and 750 °C. These peaks are attributed to water evolved, the emission of volatile organic compounds, and the volatilization of CO2 and CO via the combustion of graphite. Peaks observed at > 800 °C were due to the further decomposition of complexes formed by adsorbed chromium and the surface of the functionalized MWCNTs. The high residual weight of MWCNTs-Cr further justifies the incorporation of the adsorbate into the adsorbents.

The BET nitrogen adsorption–desorption analysis and Barrett-Joyner-Halenda (BJH) concept were used to estimate the pore volume, pore diameter, and surface area of MWCNTs and MWPJ. The BET surface area, pore volume, and pore diameter of MWCNTs were observed to reduce after the modification step (see Table 1). This effect may be a result of the surface coverage of MWCNTs by the Ananas comosus juice extract that leads to pore blockage. Considering the pore diameters of MWCNTs and MWPJ, the adsorbents reported in this study were observed to sustain mesoporous surface characteristics. The BET curves obtained for MWCNTs and MWPJ are consistent with type III IUPAC isotherms classification (see Fig. 4). The curves were also noticed to have a hysteresis loop of H3 type within the relative pressure of 0.8 < P/P0 < 1 suggesting capillary condensation that is anchored on the ascendancy of a mesoporous structure. This observation also suggests a weak adsorbent-adsorbate interaction.

The crystalline structure of MWCNTs was examined utilizing powder XRD. The effect of surface modification of the nanotubes using Ananas comosus juice extract was also evaluated. The XRD patterns of MWCNTs and MWPJ are displayed in Fig. 5. The occurrence of characteristic crystalline peaks of MWCNTs was observed at 2θ values of 29.32° and 49.50° typical for graphite carbon and was ascribed to the crystal planes (002) and (102). On the other hand, the diffraction peaks for MWPJ occurred at the 2 theta values of 30.03° and 50.53°, suggesting that the application of Ananas comosus juice extract as a modifier did not alter the crystallinity of the nanotubes, regardless of the slight shift in the 2θ values of the nanotubes after modification.

Free radicals are produced in biological systems as a result of biomolecules interacting with molecular oxygen [60]. The antioxidant activity of MWPJ was assessed via its ability to scavenge free radicals such as 1,1-diphenyl-2-picrylhydrazyl (DPPH) and ferric-reducing antioxidant power (FRAP) assay [61]. Antioxidants are chemical components that are utilized to halt oxidation reactions by preventing the creation of free radicals. These chemicals tend to protect biomolecules from nascent oxygen. The presence of phenolic chemicals in plant extract functions as an antioxidant. These phenolic compounds contain hydroxyl functional groups that can stabilize a free radical via proton donation. The DPPH scavenging activity and the FRAP of MWPJ were acquired and compared to ascorbic acid as a positive control (see Figs. 6 and 7). Meanwhile, Figs. 6 and 7 showed that MWPJ sustained a moderated antioxidant characteristic. Furthermore, it was also observed that the antioxidant performance of MWPJ increases with a rise in sample concentration in a dose-dependent fashion. Thus, the Ananas comosus juice extract that was used as a modifier may serve as a source of secondary metabolites on the surface of MWPJ; the phytochemical may readily donate electrons or protons resulting in the reduction of free radicals. Hence, the elimination of Cr(VI) from simulated wastewater may be attributed to the reductive potential of MWPJ. Previous reports have had similar results [52, 62].

3.2 Effect of pH

The initial pH of the solution plays a crucial role in the solubility of adsorbate, surface chemistry of adsorbents, and ionization tendency of the adsorbate, all of which influence the adsorption process. Hexavalent chromium mostly exists as oxyanions (Cr2O72− and HCrO4−) and the negatively charged ions bind on the protonated active sites on the surface of adsorbents (MWCNTs and MWPJ) at lower solution pH. As shown in Fig. 8, the pHPZC of MWCNTs and MWPJ were estimated as 4.83 and 4.08, respectively. Hence, at a solution pH less than these values, the surfaces of these adsorbents will be positively charged, enhancing the attraction between the adsorption site of the adsorbents (MWCNTs and MWPJ) and the negatively charged adsorbate. As shown in Fig. 8, the maximum sorbent-to-sorbate ratio of Cr(VI) is reached at pH = 1.0 with uptake capacity of 20.23 mg g−1 and 42.73 mg g−1 for MWCNTs and MWPJ, respectively. To sustain the integrity of the adsorbents, pH 2 with a lesser removal capacity was selected for further study. The effectiveness of Cr(VI) removal by MWCNTs and MWPJ may be ascribed to electrostatic interaction between the protonated surface of the adsorbents and the anionic species of Cr(VI). The adsorption potential of MWCNTs and MWPJ diminishes as the initial solution pH increases. This may be due to the competition/repulsion between oxyanions (Cr2O72− and HCrO4−) and the increased amount of hydroxyl ions in the solution. Similar outcomes have been reported earlier for a variety of adsorbents [63,64,65].

3.3 Effect of contact time

Figure 9 depicts the implication of contact time on the adsorptive removal of Cr(VI) by MWCNTs and MWPJ. A contact time range of 5 to 180 min was employed for the assessment of time-dependent study. The adsorption rate was quite fast within the first 40 min, reaching 27.34 mg g−1 and 44.16 mg g−1 for MWCNTs and MWPJ, respectively. As time increases, the uptake capacity of Cr(VI) removal increases progressively until 60 min, when the adsorption equilibrium is established. Meanwhile, between 60 and 160 min, the continuous and smooth part of the graph revealed monolayer coverage of Cr(VI) onto the surface of MWCNTs and MWPJ. Beyond 160 min, an incremental Cr(VI) removal was observed, indicating the presence of unsaturated adsorption sites; it could also be ascribed to the increased rate of intraparticle diffusion of Cr(VI) into the pores of the MWCNTs and MWPJ with contact time. The findings are in good agreement with the reports of other authors [36, 66].

3.4 Adsorption kinetics

Change in the rate of adsorption over time is frequently influenced by various factors of adsorption. Kinetic parameters are used to assess and predict the behaviour of an adsorption process that is time-dependent. To evaluate the rate of Cr(VI) uptake by the MWPJ and MWCNT, experimental data obtained from the influence of time experiment was fitted into four kinetic models, namely pseudo-first and pseudo-second order, intraparticle diffusion, and the Elovich model (see Fig. 10). These models help to uncover the underlying mechanisms responsible for the adsorption of Cr(VI) onto porous MWPJ and MWCNT. The pseudo-first-order model assumes that the rate of change of solute uptake with respect to time is precisely proportional to the change in saturation concentration and amount of uptake with respect to time [67, 68]. On the other hand, the pseudo-second-order model suggests that the rate-limiting step is chemisorption; this suggests that the removal process goes beyond mere attachment of adsorbate molecules to the surface. In this model, the adsorption rate is linked to the square of the number of unoccupied adsorption sites [69, 70].

The intraparticle diffusion model is rooted in the concept that the rate of adsorption is governed by the diffusion of adsorbate molecules into the pores of the adsorbent. The model assumes that the uptake of adsorbate onto the adsorbent occurs in three steps; the first stage is adsorbate bulk diffusion on the adsorbent surface, followed by intraparticle or pore diffusion, and finally equilibrium adsorption [71]. Meanwhile, the Elovich model characterizes adsorption as a process with two parameters, α and β. The α parameter is associated with the activation energy of adsorption, while β is connected to the bonding energy of the adsorbed molecules [72]. This model is primarily concerned with the rate of adsorption which declines exponentially as the amount of adsorbate increases. Furthermore, the Elovich model demonstrates that the adsorption of Cr(VI) by MWPJ was significant and non-reversible. Meanwhile, as α surpasses β, it suggests that the adsorption process is dominated by strong chemical interactions and that the adsorbed Cr(VI) tends to stay bound to the surfaces MWPJ rather than being easily released (see Table 2). This observation further suggests that chemisorption is the rate-determining step in the adsorptive removal of Cr(VI) from aqueous solutions [73].

According to the Weber and Morris model, a linear plot of qe versus t0.5 indicates a rate controlled by intraparticle diffusion. The magnitude of the intercept obtained is known to provide an estimate of the boundary layer. Hence, the greater the intercept value, the bigger the boundary layer effect. Thus, the driving force and diffusion rate are enhanced with increased initial Cr(VI) concentration [74]. As displayed in Table 2, the non-zero values of the intercept were estimated for the adsorption of Cr(VI) onto MWPJ and MWCNT suggests that intraparticle diffusion was not the primary rate-controlling step for the adsorption process. Hence, it indicates that the uptake of Cr(VI) proceeded through transportation of Cr(VI) to the external surface of the MWPJ and MWCNT by film diffusion, followed by intraparticle diffusion of Cr(VI) to the pores of the MWPJ and MWCNT, and subsequent intraparticle diffusion slows down due to the low Cr(VI) concentration. As a result, a multi-step process is involved. The observation made in this study is consistent with previous report [75,76,77].

3.5 Effect of adsorbent dosage

Another key factor influencing Cr(VI) adsorption is the sorbent dosage. Figure 11 shows the effect of different adsorbent dosages (0.01–0.10 g) on Cr(VI) adsorption. As displayed in Fig. 11, it was observed that there was an increase in percentage adsorption from 40.3 to 89.6% for MWJP and from 19.6 to 38.1% for MWCNTs with the increase of adsorbent dosage from 0.01 to 0.10 g. This could be attributed to the fact that as the mass of adsorbent is increased, the surface area available for adsorption increases, thereby resulting in more active adsorption sites. On the other hand, there was a decrease in the adsorption capacity from 85.2 to 24.1 mg g−1 for MWJP and from 42.6 to 12.5 mg g−1 for MWCNTs as shown in Fig. 11. The phenomenon could be ascribed to the decrease in the concentration of Cr(VI) with increasing adsorbent dosage or the agglomeration of the adsorbent at high dosage [78].

3.6 Effect of initial concentration and solution temperature on Cr(VI) removal

The effect of initial Cr(VI) concentration on the adsorption capacity of MWPJ and MWCNTs was investigated by varying the initial Cr(VI) concentration from 10 to 100 mg dm−3. As displayed in Fig. 12, the adsorption capacity increased from 4.34 to 25.34 mg g−1 for MWCNTs and from 5.85 to 36.09 mg g−1 for MWPJ as the solution temperature increased from 298 to 308 K. The increase in the uptake potential of the adsorbent with increasing concentrations could be attributed to an increase in the concentration gradient of the adsorbate. It was also observed that the solution temperature also influenced the adsorption capacity of MWPJ and MWCNTs. At high solution temperatures, the removal of Cr(VI) by MWPJ and MWCNTs was enhanced, and this may be ascribed to the creation of new adsorption sites at elevated temperatures or increased mobility of the adsorbate due to the decreased viscosity of the solvent or enhanced pore entrapment of the Cr(VI) due to pore expansion [79]. Experimental data acquired from equilibrium studies offered a comprehensive insight into the nature of the interaction between Cr(VI) and MWCNTS as well as MWPJ. This investigation involved the use of Langmuir and Freundlich isotherm models. Table 3 shows the isotherm parameters estimated for the Langmuir and Freundlich models. By examining the nonlinearized plots of the Freundlich and Langmuir models and comparing the values of the correlation coefficient (R2), it was deduced that the Freundlich model provides a better fit for describing the adsorption of Cr(VI) onto MWCNTs and MWPJ. This conclusion is drawn from the fact that the calculated R2 values for the Freundlich model were significantly closer to 1 than the R2 estimated for the Langmuir model. This suggests multilayer adsorption, allowing for the attachment of multiple molecular layers to the surface of the adsorbent. Table 3 displays the calculated n and kF obtained for the adsorption of Cr(VI) onto MWCNTs and MWPJ. Values of n within the range of 2 ≤ n ≤ 10 indicate easy uptake of adsorbate, a value ≤ 1 n < 2 reflects a moderate uptake of adsorbate, and finally, a value of n < 1 shows tough uptake of adsorbate [80]. The estimated value of n in the adsorptive removal of Cr(VI) by MWCNTs and MWPJ was greater than 2 suggesting easy adsorptive removal of Cr(VI) by MWCNTs and MWPJ. Additionally, a comparison of the monolayer adsorption capacity obtained for OJMW and MWCNTs with other adsorbent that were employed for Cr(VI) removal revealed that OJMW is a promising adsorbent for wastewater treatment (see Table 4).

3.7 Thermodynamics study

The adsorptive removal of Cr(VI) by MWPJ and MWCNTs is influenced by solution temperature; hence, it is essential to estimate the energy responsible for the process. Thermodynamic parameters such as standard free energy (ΔG°), enthalpy change (ΔH°), and entropy change (ΔS°) were estimated using Eqs. (5) and (6)

where K is the equilibrium constant obtained from Langmuir isotherm. ΔH° and ΔS° were estimated from the slope and intercept of the plot of ln K versus 1/T. The negative values of ΔG° and ΔH° displayed in Table 5 suggest that the Cr(VI) adsorption onto MWPJ and MWCNTs was spontaneous and exothermic. The positive values of ΔS° estimated for the uptake of Cr(VI) onto MWPJ and MWCNTs suggest that the randomness at the solid-solute interface increased during the adsorption of Cr(VI).

3.8 Adsorbent reusability study

The recyclability of water treatment agents is the most remarkable advantage of adsorbent. Hence, it is imperative to validate the efficiency of an adsorbent after several reuse. Adsorption–desorption experiments of MWPJ and MWCNTs were performed to establish the feasibility of regeneration of the adsorbent. Figure 13 displays the adsorption efficiencies of MWPJ and MWCNTs after five cycles of adsorption–desorption using 0.1 M NaOH as an eluting agent at room temperature. The efficiency of adsorption for MWPJ and MWCNTs after five regenerations had slightly decreased from 95.6 to 81.3% and 42.8 to 38.3%, respectively. The reduction of their removal efficiency after five cycles was less than 15% of the starting value, which shows that MWPJ and MWCNTs may have promising recycling characteristics for Cr(VI) removal.

3.9 Reaction mechanisms

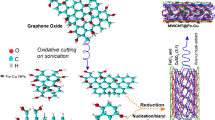

The mechanism of Cr(VI) uptake by MWPJ at solution pH 2 is anticipated and the schematic illustration of the removal mechanism of Cr(VI) is displayed in Fig. 14. There are two basic steps that are essential for the sequestration of Cr(VI) from the aqueous phase. The oxyanions of Cr(VI) and the protonated surface of MWPJ interact via electrostatic interaction at solution pH 2. Thereafter, the Cr(VI) ions are transferred into the inner pores through intraparticle diffusion [94]. The pre-adsorbed adsorbate is then reduced to its trivalent state via the interaction with the functional group on the surface of MWJP. The trivalent chromium is then sequestered by MWPJ via the adsorption process. The shift in bands observed on the FTIR spectral obtained for the spent adsorbents indicates the incorporation of the chromate ions onto the surface of the adsorbents. However, the oxidative nature of Cr(VI) and the reductive characteristics of MWPJ as earlier discussed suggest the possible reduction of Cr(VI) to Cr(III) in the acidic environment (see Fig. 14).

4 Conclusion

The findings of this study showed that Cr(VI) is better absorbed by Ananas comosus juice extract–modified nanotubes than MWCNTs. It further revealed suitable adsorptive conditions such as pH 2.0, 180 min contact time, and 0.05 g adsorbent dosage. The implication of the modification was assessed using FTIR and SEM. The FTIR spectral and TGA/DTA curves were used to investigate the fixation of chromium to the surface of MWPJ and MWCNTs. The uptake kinetics of MWPJ and MWCNTs followed an Elovich and pseudo-first-order kinetic model, respectively. The adsorption isotherm data were best described by the Freundlich isotherm model; MWPJ and MWCNTs demonstrated a monolayer adsorption potential of 44.87 and 33.38 mg g−1 at 25 °C. The adsorbents (MWPJ and MWCNTs) could be regenerated and reused for five consecutive adsorption–desorption cycles with a slight loss of the initial adsorption efficiency for Cr(VI) removal. The thermodynamic study revealed that the Cr(VI) uptake by MWPJ and MWCNTs is a spontaneous and exothermic process. The uptake of Cr(VI) by MWPJ is anchored on electrostatic interactions, reduction, and adsorption. Therefore, MWPJ could be a promising material in the treatment of Cr(VI)-loaded wastewater.

Data availability

Not applicable.

References

Khan SAR, Ponce P, Yu Z, Golpîra H, Mathew M (2022) Environmental technology and wastewater treatment: strategies to achieve environmental sustainability. Chemosphere 286:131532

Garg S, Chowdhury ZZ, Faisal ANM, Rumjit NP, and Thomas P (2022) Impact of industrial wastewater on environment and human health. advanced industrial wastewater treatment and reclamation of water: comparative study of water pollution index during pre-industrial, industrial period and prospect of wastewater treatment for water resource conservation. 197–209

Ahmed M, Mavukkandy MO, Giwa A, Elektorowicz M, Katsou E, Khelifi O, Naddeo V, Hasan SW (2022) Recent developments in hazardous pollutants removal from wastewater and water reuse within a circular economy. NPJ Clean Water 5:12

Egbosiuba TC, Abdulkareem AS, Tijani JO, Ani JI, Krikstolaityte V, Srinivasan M, Veksha A, Lisak G (2021) Taguchi optimization design of diameter-controlled synthesis of multi walled carbon nanotubes for the adsorption of pb (ii) and ni (ii) from chemical industry wastewater. Chemosphere 266:128937

Ani IJ, Egbosiuba TC (2023) Metal oxides and their nanocomposites in wastewater treatment. Adsorption through advanced nanoscale materials. Elsevier, pp 185–203

de Borja OF, Sammaraie H, Campano C, Blanco A, Merayo N, Negro C (2022) Hexavalent chromium removal from industrial wastewater by adsorption and reduction onto cationic cellulose nanocrystals. Nanomaterials 12:4172

Meunier B, Robert A, Crisponi G, Nurchi V, Lachowicz JI, Nairz M, Weiss G, Pai AB, Ward RJ, and Crichton RR (2019) Essential metals in medicine: therapeutic use and toxicity of metal ions in the clinic. 19: Walter de Gruyter GmbH & Co KG

Singh K, Kumari M, Prasad KS (2023) Tannery effluents current practices, environmental consequences human health risks and treatment options. CLEAN-Soil Air Water 51:2200303

Han FX, Banin A, Su Y, Monts DL, Plodinec JM, Kingery WL, Triplett GE (2002) Industrial age anthropogenic inputs of heavy metals into the pedosphere. Naturwissenschaften 89:497–504

Alouache A, Selatnia A, and Halet F (2017) Biosorption of cr (vi) from aqueous solutions by dead biomass of pleurotus mutilus in torus reactor. in frontiers international conference on wastewater treatment and modelling, Springer

Kim J, Haque MN, Lee S, Lee D-H, Rhee J-S (2022) Exposure to environmentally relevant concentrations of polystyrene microplastics increases hexavalent chromium toxicity in aquatic animals. Toxics 10:563

Xing J, Zhu C, Chowdhury I, Tian Y, Du D, Lin Y (2018) Electrically switched ion exchange based on polypyrrole and carbon nanotube nanocomposite for the removal of chromium (vi) from aqueous solution. Ind Eng Chem Res 57:768–774

Lee KP, Ulrich CE, Geil RG, Trochimowicz HJ (1988) Effects of inhaled chromium dioxide dust on rats exposed for two years. Fundam Appl Toxicol 10:125–145

Gad S, Powers W, Dunn B, Hoffman G, Siino K, and Walsh R (1986) Acute toxicity of four chromate salts. in Chromium Symposium

Sharma P, Singh SP, Parakh SK, Tong YW (2022) Health hazards of hexavalent chromium (cr (vi)) and its microbial reduction. Bioengineered 13:4923–4938

Zwiener C, Frimmel F (2003) Short-term tests with a pilot sewage plant and biofilm reactors for the biological degradation of the pharmaceutical compounds clofibric acid, ibuprofen, and diclofenac. Sci Total Environ 309:201–211

Kongsricharoern N, Polprasert C (1996) Chromium removal by a bipolar electro-chemical precipitation process. Water Sci Technol 34:109–116

Pan C, Troyer LD, Catalano JG, Giammar DE (2016) Dynamics of chromium (vi) removal from drinking water by iron electrocoagulation. Environ Sci Technol 50:13502–13510

Hartig C, Ernst M, Jekel M (2001) Membrane filtration of two sulphonamides in tertiary effluents and subsequent adsorption on activated carbon. Water Res 35:3998–4003

Liu W, Ni J, Yin X (2014) Synergy of photocatalysis and adsorption for simultaneous removal of cr (vi) and cr (iii) with tio2 and titanate nanotubes. Water Res 53:12–25

Tiravanti G, Petruzzelli D, Passino R (1997) Pretreatment of tannery wastewaters by an ion exchange process for cr(iii) removal and recovery. Water Sci Technol 36:197–207

Çimen A (2015) Removal of chromium from wastewater by reverse osmosis. Russ J Phys Chem A 89:1238–1243

Malwade K, Lataye D, Mhaisalkar V, Kurwadkar S, Ramirez D (2016) Adsorption of hexavalent chromium onto activated carbon derived from leucaena leucocephala waste sawdust: kinetics, equilibrium and thermodynamics. Int J Environ Sci Technol 13:2107–2116

Weng C-H, Sharma Y, Chu S-H (2008) Adsorption of cr (vi) from aqueous solutions by spent activated clay. J Hazard Mater 155:65–75

Demiral H, Demiral I, Tümsek F, Karabacakoğlu B (2008) Adsorption of chromium (vi) from aqueous solution by activated carbon derived from olive bagasse and applicability of different adsorption models. Chem Eng J 144:188–196

Demirbas E, Kobya M, Senturk E, Ozkan T (2004) Adsorption kinetics for the removal of chromium (vi) from aqueous solutions on the activated carbons prepared from agricultural wastes. Water Sa 30:533–539

Namasivayam C, Yamuna R (1995) Adsorption of chromium (vi) by a low-cost adsorbent: biogas residual slurry. Chemosphere 30:561–578

Amaku JF, Ngwu CM, Ogundare SA, Akpomie KG, Edozie OI, Conradie J (2021) Thermodynamics, kinetics and isothermal studies of chromium (vi) biosorption onto detarium senegalense stem bark extract coated shale and the regeneration potentials. Int J Phytorem 23:1486–1496

Wang C, Xiong C, He Y, Yang C, Li X, Zheng J, Wang S (2021) Facile preparation of magnetic zr-mof for adsorption of pb (ii) and cr (vi) from water: adsorption characteristics and mechanisms. Chem Eng J 415:128923

Cherdchoo W, Nithettham S, Charoenpanich J (2019) Removal of cr (vi) from synthetic wastewater by adsorption onto coffee ground and mixed waste tea. Chemosphere 221:758–767

Foroutan R, Peighambardoust SJ, Mohammadi R, Omidvar M, Sorial GA, Ramavandi B (2020) Influence of chitosan and magnetic iron nanoparticles on chromium adsorption behavior of natural clay: adaptive neuro-fuzzy inference modeling. Int J Biol Macromol 151:355–365

Sharifi S, Nabizadeh R, Akbarpour B, Azari A, Ghaffari HR, Nazmara S, Mahmoudi B, Shiri L, Yousefi M (2019) Modeling and optimizing parameters affecting hexavalent chromium adsorption from aqueous solutions using ti-xad7 nanocomposite: Rsm-ccd approach, kinetic, and isotherm studies. J Environ Health Sci Eng 17:873–888

Yusuff AS (2019) Adsorption of hexavalent chromium from aqueous solution by leucaena leucocephala seed pod activated carbon: equilibrium, kinetic and thermodynamic studies. Arab J Basic App Sci 26:89–102

Valentín-Reyes J, García-Reyes R, García-González A, Soto-Regalado E, Cerino-Córdova F (2019) Adsorption mechanisms of hexavalent chromium from aqueous solutions on modified activated carbons. J Environ Manage 236:815–822

Luo Q, Huang X, Luo Y, Yuan H, Ren T, Li X, Xu D, Guo X, Wu Y (2021) Fluorescent chitosan-based hydrogel incorporating titanate and cellulose nanofibers modified with carbon dots for adsorption and detection of cr (vi). Chem Eng J 407:127050

Pavithra S, Thandapani G, Sugashini S, Sudha P, Alkhamis HH, Alrefaei AF, Almutairi MH (2021) Batch adsorption studies on surface tailored chitosan/orange peel hydrogel composite for the removal of cr (vi) and cu (ii) ions from synthetic wastewater. Chemosphere 271:129415

Shakya A, Agarwal T (2019) Removal of cr (vi) from water using pineapple peel derived biochars: adsorption potential and re-usability assessment. J Mol Liq 293:111497

Dong F-X, Yan L, Zhou X-H, Huang S-T, Liang J-Y, Zhang W-X, Guo Z-W, Guo P-R, Qian W, Kong L-J (2021) Simultaneous adsorption of cr (vi) and phenol by biochar-based iron oxide composites in water: performance, kinetics and mechanism. J Hazard Mater 416:125930

Shahnaz T, Padmanaban V, Narayanasamy S (2020) Surface modification of nanocellulose using polypyrrole for the adsorptive removal of congo red dye and chromium in binary mixture. Int J Biol Macromol 151:322–332

Jang E-H, Pack SP, Kim I, Chung S (2020) A systematic study of hexavalent chromium adsorption and removal from aqueous environments using chemically functionalized amorphous and mesoporous silica nanoparticles. Sci Rep 10:5558

Sajid M, Asif M, Baig N, Kabeer M, Ihsanullah I, Mohammad AW (2022) Carbon nanotubes-based adsorbents: properties, functionalization, interaction mechanisms, and applications in water purification. J Water Process Eng 47:102815

Kim SD, Kim JW, Im JS, Kim YH, Lee YS (2007) A comparative study on properties of multi-walled carbon nanotubes (mwcnts) modified with acids and oxyfluorination. J Fluorine Chem 128:60–64

Rostami MS, Khodaei MM, Rostami S (2022) Polymer-based nanocomposites reinforced with functionalized-mwcnt and their utilizing as sorbent for removal of mb and cd2+ ion from water media: a review. J Organomet Chem 957:122170

Egbosiuba T (2022) Incorporation of zero-valent silver and polyvinyl acetate on the surface matrix of carbon nanotubes for the adsorption of mercury and chromium from industrial wastewater. Niger J Technol 41:158–168

Abdulkareem AS, Kovo AS, Afolabi EA, Tijani JO, and Bankole MT (2021) Adsorption of cr (vi), ni (ii), fe (ii) and cd (ii) ions by kiagnps decorated mwcnts in a batch and fixed bed process

Egbosiuba TC, Egwunyenga MC, Tijani JO, Mustapha S, Abdulkareem AS, Kovo AS, Krikstolaityte V, Veksha A, Wagner M, Lisak G (2022) Activated multi-walled carbon nanotubes decorated with zero valent nickel nanoparticles for arsenic, cadmium and lead adsorption from wastewater in a batch and continuous flow modes. J Hazard Mater 423:126993

Abdulkareem AS, Hamzat WA, Tijani JO, Egbosiuba TC, Mustapha S, Abubakre OK, Okafor BO, Babayemi AK (2023) Isotherm, kinetics, thermodynamics and mechanism of metal ions adsorption from electroplating wastewater using treated and functionalized carbon nanotubes. J Environ Chem Eng 11:109180

Meena L, Sengar AS, Neog R, Sunil C (2021) Pineapple processing waste (ppw): Bioactive compounds, their extraction, and utilisation: a review. J Food Sci Technol 1–13

Alwan SH, Alshamsi HA (2022) In situ synthesis nio/f-mwcnts nanocomposite for adsorption of malachite green dye from polluted water. Carbon Letters 32:1073–1084

Chew Y-L, Lim Y-Y (2018) Evaluation and comparison of antioxidant activity of leaves, pericarps and pulps of three garcinia species in malaysia. Free Radicals and Antioxidants 8:130–134

Matussin S, Harunsani MH, Tan AL, Khan MM (2020) Plant-extract-mediated sno2 nanoparticles: synthesis and applications. ACS Sustain Chem Eng 8:3040–3054

Vindhya P and Kavitha V (2023) Phyto-mediated synthesis of pure and cobalt-doped sno2 nanoparticles for antimicrobial, antioxidant, and photocatalytic activities. Biomass Conversion and Biorefinery 1–18

Belachew N, Hinsene H (2020) Preparation of cationic surfactant-modified kaolin for enhanced adsorption of hexavalent chromium from aqueous solution. Appl Water Sci 10:38

Zubrik A, Matik M, Hredzák S, Lovás M, Danková Z, Kováčová M, Briančin J (2017) Preparation of chemically activated carbon from waste biomass by single-stage and two-stage pyrolysis. J Clean Prod 143:643–653

Team RC (2018) A language and environment for statistical computing. R foundation for statistical computing, vienna, austria. Available online: https://www.R-project.org/Accessed on 11 Sept 2020

Omer A, Khalifa R, Hu Z, Zhang H, Liu C, and Ouyang X-k (2018) Fabrication of tetraethylenepentamine functionalized alginate beads for adsorptive removal of cr (vi) from aqueous solutions. International journal of biological macromolecules

Alam RS, Moradi M, Nikmanesh H (2016) Influence of multi-walled carbon nanotubes (mwcnts) volume percentage on the magnetic and microwave absorbing properties of bamg0. 5co0. 5tife10o19/mwcnts nanocomposites. Mater Res Bull 73:261–267

Rasana N, Jayanarayanan K (2022) Nano, micro and multiscale filler-reinforced functionalized polypropylene composites: Ftir characterization and mechanical study. Polyolefins J 9:33–43

Pipliya S, Kumar S, & Srivastav PP (2023) Effect of dielectric barrier discharge nonthermal plasma treatment on physicochemical, nutritional, and phytochemical quality attributes of pineapple [Ananas comosus (L.)] juice. J Food Sci 88(11):4403–4423

Valgimigli L, Baschieri A, Amorati R (2018) Antioxidant activity of nanomaterials. J Materials Chem B 6:2036–2051

Phaniendra A, Jestadi DB, Periyasamy L (2015) Free radicals: properties, sources, targets, and their implication in various diseases. Indian J Clin Biochem 30:11–26

Villanueva ME, Diez AMdR, González JA, Pérez CJ, Orrego M, Piehl L, Teves S, Copello GJ (2016) Antimicrobial activity of starch hydrogel incorporated with copper nanoparticles. ACS Appl Mater Interfaces 8:16280–16288

Singh S, Anil AG, Naik TSK, Basavaraju U, Khasnabis S, Nath B, Kumar V, Subramanian S, Singh J, Ramamurthy PC (2022) Mechanism and kinetics of cr (vi) adsorption on biochar derived from citrobacter freundii under different pyrolysis temperatures. J Water Process Eng 47:102723

Gan C, Liu Y, Tan X, Wang S, Zeng G, Zheng B, Li T, Jiang Z, Liu W (2015) Effect of porous zinc–biochar nanocomposites on cr (vi) adsorption from aqueous solution. RSC Adv 5:35107–35115

Shakya A, Vithanage M, Agarwal T (2022) Influence of pyrolysis temperature on biochar properties and cr (vi) adsorption from water with groundnut shell biochars: Mechanistic approach. Environ Res 215:114243

Park S-H, Shin SS, Park CH, Jeon S, Gwon J, Lee S-Y, Kim S-J, Kim H-J, Lee J-H (2020) Poly (acryloyl hydrazide)-grafted cellulose nanocrystal adsorbents with an excellent cr (vi) adsorption capacity. J Hazard Mater 394:122512

Sahoo TR, Prelot B (2020) Adsorption processes for the removal of contaminants from wastewater: the perspective role of nanomaterials and nanotechnology. Nanomaterials for the detection and removal of wastewater pollutants. Elsevier, pp 161–222

Islam MA, Hameed BH, Ahmed MJ, Khanday WA, Khan MA, Marrakchi F (2023) Porous carbon–based material from fish scales for the adsorption of tetracycline antibiotics. Biomass Convers Biorefin 13(14):13153–13162

Hazrin HMMN, Lim A, Li C, Chew JJ, Sunarso J (2022) Adsorption of 2, 4-dichlorophenoxyacetic acid onto oil palm trunk-derived activated carbon: isotherm and kinetic studies at acidic, ambient condition. Materials Today: Proceed 64:1557–1562

Hu Q, Pang S, Wang D (2022) In-depth insights into mathematical characteristics, selection criteria and common mistakes of adsorption kinetic models: a critical review. Sep Purif Rev 51:281–299

Zhao Y, Yue Q, Li Q, Xu X, Yang Z, Wang X, Gao B, Yu H (2012) Characterization of red mud granular adsorbent (rmga) and its performance on phosphate removal from aqueous solution. Chem Eng J 193:161–168

Cheng D, Ngo HH, Guo W, Chang SW, Nguyen DD, Zhang X, Varjani S, Liu Y (2020) Feasibility study on a new pomelo peel derived biochar for tetracycline antibiotics removal in swine wastewater. Sci Total Environ 720:137662

Dhiman V, Kondal N (2021) Zno nanoadsorbents: a potent material for removal of heavy metal ions from wastewater. Colloid and Interface Sci Comm 41:100380

Masinga T, Moyo M, Pakade VE (2022) Removal of hexavalent chromium by polyethyleneimine impregnated activated carbon: Intra-particle diffusion, kinetics and isotherms. J Market Res 18:1333–1344

Aslam MMA, Den W, Kuo H-W (2021) Encapsulated chitosan-modified magnetic carbon nanotubes for aqueous-phase crvi uptake. J Water Process Eng 40:101793

Verma B, Goel S, Balomajumder C (2021) Multiwalled cnts for cr (vi) removal from industrial wastewater: an advanced study on adsorption, kinetics, thermodynamics for the comparison between the embedded and non-embedded carboxyl group. The Canadian J Chem Eng 99:281–293

Kunde G, Sehgal B, Ganguli A (2019) Synthesis of mesoporous rebar mwcnt/alumina composite (rmac) nodules for the effective removal of methylene blue and cr (vi) from an aqueous medium. J Hazard Mater 374:140–151

Zhong Q-Q, Yue Q-Y, Gao B-Y, Li Q, Xu X (2013) A novel amphoteric adsorbent derived from biomass materials: synthesis and adsorption for cu (ii)/cr (vi) in single and binary systems. Chem Eng J 229:90–98

Albatrni H, Qiblawey H, Al-Marri MJ (2022) Walnut shell based adsorbents: a review study on preparation, mechanism, and application. J Water Process Eng 45:102527

Jia B-B, Wang J-N, Wu J, Li C-J (2014) “Flower-like” pa6@ mg (oh) 2 electrospun nanofibers with cr (vi)-removal capacity. Chem Eng J 254:98–105

Dupont L, Guillon E (2003) Removal of hexavalent chromium with a lignocellulosic substrate extracted from wheat bran. Environ Sci Technol 37:4235–4241

Hu J, Chen C, Zhu X, Wang X (2009) Removal of chromium from aqueous solution by using oxidized multiwalled carbon nanotubes. J Hazard Mater 162:1542–1550

Yu J, Jiang C, Guan Q, Ning P, Gu J, Chen Q, Zhang J, Miao R (2018) Enhanced removal of cr (vi) from aqueous solution by supported zno nanoparticles on biochar derived from waste water hyacinth. Chemosphere 195:632–640

Qiu J, Wang Z, Li H, Xu L, Peng J, Zhai M, Yang C, Li J, Wei G (2009) Adsorption of cr (vi) using silica-based adsorbent prepared by radiation-induced grafting. J Hazard Mater 166:270–276

Jain M, Garg V, Kadirvelu K (2009) Chromium (vi) removal from aqueous system using helianthus annuus (sunflower) stem waste. J Hazard Mater 162:365–372

Yusuff AS, Gbadamosi AO, Lala MA, Ngochindo JF (2018) Synthesis and characterization of anthill-eggshell composite adsorbent for removal of hexavalent chromium from aqueous solution. Environ Sci Pollut Res 25:19143–19154

Samuel MS, Bhattacharya J, Raj S, Santhanam N, Singh H, Singh NP (2019) Efficient removal of chromium (vi) from aqueous solution using chitosan grafted graphene oxide (cs-go) nanocomposite. Int J Biol Macromol 121:285–292

Ma M, Lu Y, Chen R, Ma L, Wang Y (2014) Hexavalent chromium removal from water using heat-acid activated red mud. Open J App Sci 4:275

Dakiky M, Khamis M, Manassra A, Mer’eb M (2002) Selective adsorption of chromium (vi) in industrial wastewater using low-cost abundantly available adsorbents. Adv Environ Res 6:533–540

Tan L, Li H, Liu M (2018) Characterization of cmc–ldh beads and their application in the removal of cr (vi) from aqueous solution. RSC Adv 8:12870–12878

Namasivayam C, Sureshkumar M (2008) Removal of chromium (vi) from water and wastewater using surfactant modified coconut coir pith as a biosorbent. Biores Technol 99:2218–2225

Sun H, Wu T, Zhang Y, Ng DH, Wang G (2018) Structure-enhanced removal of cr (vi) in aqueous solutions using mos 2 ultrathin nanosheets. New J Chem 42:9006–9015

Aslani H, Ebrahimi Kosari T, Naseri S, Nabizadeh R, Khazaei M (2018) Hexavalent chromium removal from aqueous solution using functionalized chitosan as a novel nano-adsorbent: modeling and optimization, kinetic, isotherm, and thermodynamic studies, and toxicity testing. Environ Sci Pollut Res 25:20154–20168

Wan Z, Cho D-W, Tsang DC, Li M, Sun T, Verpoort F (2019) Concurrent adsorption and micro-electrolysis of cr (vi) by nanoscale zerovalent iron/biochar/ca-alginate composite. Environ Pollut 247:410–420

Acknowledgements

The authors thank the anonymous reviewers for their helpful comments.

Funding

Open access funding provided by Walter Sisulu University.

Author information

Authors and Affiliations

Contributions

The authors contributed equally to this work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amaku, J.F., Taziwa, R. Sequestration of chromium by Ananas comosus extract–coated nanotubes: synthesis, characterization, optimization, thermodynamics, kinetics, and antioxidant activities. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-023-05210-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05210-9