Abstract

Scientists are currently working to develop more effective and less harmful methods of delivering drugs to tissue. One method is to use a special type of carrier to help the drug get to the right place in the body. In this study, an organometallic framework nanocarrier with the formula IRMOF-3 [Zn4O(NH2-BDC)3] was successfully prepared, containing magnetic nanoparticles of manganese ferrite (MnFe2O4) and the drug doxorubicin encapsulated in a pH- and temperature-sensitive smart polymer of poly-N-isopropylacrylamide. Doxorubicin, an anticancer drug, was loaded into the pores of a magnetic organometallic framework and modified with the smart polymer poly(N-isopropylacrylamide-co-AA), which has a lower critical solution temperature (LCST) of less than 38 °C. The synthesis of magnetic nanoparticles and magnetic organometallic frameworks encapsulated in smart polymer was investigated using various analytical techniques such as Fourier transform infrared spectrometer, thermal stability analysis, BET, and VSM. The particles in the synthesized nanocarrier are uniform in size, have high magnetic properties, and are thermally stable. The effective surface area is 7.26 m2/g, and the pore volume is 166.394 m. The drug carrier has the ability to load up to 78% of the drug into the solution. The highest drug release was observed when the pH was 5 and the temperature was higher than the LCST. 71% of cancer cells were destroyed by the drug carrier in the culture medium. This nanosystem, designed with more drug retention, reduced side effects and controlled release in different conditions, is suitable as a drug delivery system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The delivery of therapeutic compounds to the target site is a major issue in the treatment of many diseases. Typical drug use is associated with low efficacy or biodistribution, as well as a lack of selectivity. These limitations and weaknesses can be overcome by using drug delivery systems that transport drugs to the target site in a controlled manner, minimizing their impact on healthy tissues. Furthermore, drug delivery systems prevent drug destruction or rapid clearance while increasing drug concentration in the target tissue (Misiak et al. 2020).

The use of nanoparticles as drug carriers in cancer treatment has recently attracted the interest of different scientists. Nanoparticles are more effectively absorbed by cells than micro-molecules. Organic systems such as liposomes and nanomaterials including magnetic nanoparticles and gold nanoparticles are examples of drug delivery systems. Hybrid nanoparticles including inorganic and organic compounds retain the beneficial properties of both organic and inorganic nanoparticles and offer distinct advantages (Horcajada et al. 2010). Organometallic frameworks, also known as coordination polymers, are a type of hybrid material composed of metal ions and polydentate bridging ligands.

Due to the analytical merits of organic frameworks such as large surface area, large pore volume, adjustable pore size, and surface chemistry, they have been considered as a potential candidate for drug delivery systems (Orellana-Tavra et al. 2016). Frey et al. presented the first idea of drug absorption in organometallic frameworks in 2006 (Frey 2006). Frey's study used 1.83 grammes and 0.83 grammes of ibuprofen encapsulated in Cr-MIL-101 and Cr-MIL-100, respectively. The inherent mesoporous nature of MIL-101's aided high loading of the drug (Horcajada et al. 2010).

By incorporating nanomaterials into the organometallic framework, new features can be added to this porous structure. Magnetic nanoparticles incorporated into the MOF structure form a magnetic framework composite that responds to stimuli and can be used in targeted drug delivery, selective separation, and sensors. In medicine, the magnetization of the organometallic framework transports the drug to a specific location in the body through drug encapsulation and resituates it in specific tissue, limiting drug spread and reducing side effects (Taylor-Pashow et al. 2010; Babincova and Babinec 2009).

Magnetic materials, such as MnFe2O4, can be used in hyperthermia (raising the temperature of cancer cells above 45 °C) and as a contrast agent in medical imaging (Babincova and Babinec 2009). Vasseur et al. (2015) made the first attempt to design a medical device by combining magnetically active species with an organometallic framework.

Smart polymers undergo large and reversible physical or chemical changes in response to slight environmental changes such as pH, temperature, dual stimuli, light, and phase changes. pH-sensitive polymers and temperature-sensitive polymers are two of the most important biomedical systems. The pH of the human body varies throughout the digestive tract and specific tissues (such as tumors). Temperature-sensitive polymers with a critical temperature close to physiological temperature offer many capabilities in the medical field; for example, N-isopropylacrylamide is a pH and temperature-sensitive polymer with a critical temperature close to physiological temperature (Coughlan and Corrigan 2006; Bellusci et al. 2018; Imaz et al. 2009; Alidadykhoh et al. 2021; Ghasemi et al. 2007; Peyman et al. 2021; Gholivand et al. 2017; Lalabadi et al. 2022; Aguilar et al. 2007) and has several advantages such as biocompatibility, high sensitivity, and structural stability (Coughlan and Corrigan 2006).

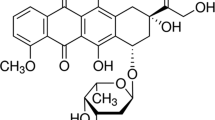

In this study, we developed a drug carrier with potentially multiple targets and high drug loading that reacts to environmental conditions by first synthesizing an organometallic framework (IRMOF-3 [Zn4O(NH2-BDC)3]) with a supermagnetic core (MnFe2O4). The anticancer drug doxorubicin (DOX) was used as a template and the resulting complex was incorporated into the poly-N-isopropylacrylamide smart polymer.

Experimental

Materials

The chemicals include: Manganese(II) Chloride (MnCl2, 97%), Iron Chloride (III) (FeCl3), Ethylene Glycol (C2H4(OH)2)), Sodium acetate (NaCH3COO−), 2-Aminoterephthalic Acid (C8H7NO4), Zinc nitrate (Zn(NO3)2), Polyvinylpyrrolidone (PVP) ((C6H9NO)n) (2.5 g/mol), Dimethylformamide ((CH3)2NC(O)H), Ethanol (C2H6O), Potassium persulfate (K2S2O8), Acrylic acid (CH2CHCOOH), Isopropylacrylamide (C6H11NO)n (113.16 g/mol), Bisacrylamide (C7H10N2O2 154.17 g/mol), and Sodium dodecyl sulfate (CH3(CH2)11OSO3Na), dialysis membrane, Dulbecco's Modified Eagle Medium (DMEM), 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide assay (MTT), and Doxorubicin (C27H29NO11·HCl) were obtained from Sigma Co. All materials were used without further purification.

Characterizations

Spectroscopic measurements were performed using a double-beam spectrophotometer (UV–Vis) model (Perkin Lambda 25) from 400 to 600 nm to determine the content of dissolved doxorubicin. The Fourier infrared spectroscopy (FT-IR) analysis was performed using an infrared spectrometer (Bruker-VERTEX 70) (400–4000 cm−1). Vibration sample magnetometer (VSM) analysis was performed to prove the paramagnetism of manganese ferrite magnetic nanoparticles with the MDK model VSM device of the desert magnetism company. A Belsorp mini ll BET device was used to measure the surface area. Scanning electron microscopy (SEM) images were taken using a TESCAN mira3 device, and Transmission electron microscopy (TEM) images were taken using a Philips CM30 TEM device. A Rigaku ultima iv model XRD machine was used for X-ray diffraction (XRD) imaging. In order to check the thermal stability of the designed polymer nanocarrier, thermal gravimetric analysis (TGA), under nitrogen gas in the temperature range of 20 to 950 °C with a heating rate of 10 °C/min and thermal gravimetry analysis (TGA) model PL-150 (Polymer Laboratories) were used.

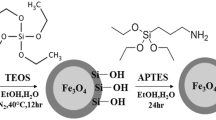

Synthesis of magnetic manganese ferrite nanoparticles

The solvothermal method was used to synthesize the supermagnetic MnFe2O4 nanoparticles. Briefly, 0.416 g of MnCl2, 0.683 g of FeCl3, and 3 g of sodium acetate were dissolved in 30 mL of ethylene glycol and stirred for 1 h at room temperature. The homogeneous solution was transferred to an autoclave and heated for 24 h at 160 °C. Before removing the sample, the autoclave was cooled to room temperature. The obtained mixture was decanted to obtain MnFe2O4 nanoparticles, which were rinsed with ethanol and distilled water several times before drying for 12 h at 60 °C (Sahoo et al. 2014).

Synthesis of magnetic organometallic framework nanoparticles

The composite nanostructure of the organometallic framework@supermagnetic nanoparticles (IRMOF-3 [Zn4O(NH2-BDC)3] was synthesized using solvent solvothermal method. In brief, 0.2 g of PVP was dissolved in a solvent mixture containing 5 mL of pure ethanol and 5 mL of DMF. Then, 0.01 g of the freshly synthesized MnFe2O4 nanoparticles was dispersed in a PVP-containing solution. Thereafter, 66.93 mg of Zn(NO3)2·6H2O and 16.29 mg of NH2-H2BDC were dissolved in 4 mL of DMF, and the resulting solution was slowly added to the MnFe2O4 solution. The solution was then subjected to ultrasonic waves for 10 min before being transferred to a Teflon stainless steel autoclave and placed at 100 °C for 4 h. A brown precipitate was formed which was separated from the solvent by a magnet and dispersed in 20 mL of DMF and heated to 80 °C. The product was dialyzed with distilled water for 12 h and dried at 60 °C for 12 h in an oven (Chowdhuri et al. 2016).

Doxorubicin loading on MnFe2O4@IRMOF-3

To test the loading of the doxorubicin (DOX) drug, 5 mg of supermagnetic MOF was added to the DOX-containing solution. The sample was shaken in the dark for 48 h to allow DOX to penetrate the magnetic MOF. The aliquots of the sample were taken at 2, 4, 8, 24, 30, and 48 h, respectively. The nanocarrier drug solution was centrifuged for 10 min at 15,000 rpm in 2 mL increments. The supernatant absorbance spectra were obtained using UV–Vis spectroscopy to determine the amount of drug remaining in the solution. The following equation (Eq. 1) was used to calculate the drug loading efficiency:

where Wfeed DOX is the weight of doxorubicin in the initial solution and Wfree DOX is the weight of the remaining drug. Beer's equation was used to converts the amount of absorption into the ratio.

Encapsulation of drug-carrying magnetic MOF by smart polymer PNIPAM-co-AA

This was done by dissolving 0.81 mol of isopropylacrylamide and 0.1 mol of methylbisacrylamide in 100 mL of distilled water, the resulting solution was stirred for 30 min, and placed under a nitrogen atmosphere (all reaction was done under nitrogen atmosphere). After that, 1 mg of the loaded nanoparticle was added to the reaction solution and stirred for 30 min. The resultant solution was then treated with 0.09 mol acrylic acid and 0.15 mmol sodium dodecyl sulfate and stirred at 70 °C for 1 h. After that, potassium persulfate was added to the reaction solution, which was then stirred at 70 °C for 9 h. Finally, the resulting solution was centrifuged at 15,000 rpm for 15 min, and the resulting sediment was dry at room temperature for 72 h (Fan et al. 2011).

Doxorubicin drug release from polymeric nanocarrier structure

2 mg of polymer (PNIPAM-co-AA) containing nanoparticles and drug was added to a 5 mL phosphate buffer solution and the resulting solution was shaken at different pH (5, 7.4) and temperatures (7 °C and 45 °C) and (T = 37 °C and 45 °C). 3 mL aliquots were taken every 2 h and centrifuged at 12,000 rpm for 10 min. A spectrophotometer was used to measure the absorbance of the obtained supernatant. The drug release from the polymer-coated nanocarrier was studied at the same temperature and pH as healthy and diseased body tissues in this manner.

LCST investigation of smart polymer

2 mg of (PNIPAM-co-AA) polymer was dissolved in 2 mL buffer solution to determine the lower critical solution temperature (LCST). The UV–Vis spectrums were recorded at the desired temperatures (30, 34, 37, 39, and 43 °C). Due to the turbidity caused by MnFe2O3@MOF nanoparticles, the LCST of colloidal solutions was not observed in this study, so only a smart polymer was used to measure LCST (Yoo et al. 2000).

Investigation of polymer swelling

Polymer swelling is the primary cause of drug release or non-release from the drug carrier's smart polymer structure. Phosphate buffer was used to adjust pH to investigate the effect of environmental conditions on polymer swelling (Zarrintaj et al. 2019; Sponchioni et al. 2019). The pH studies were carried out by adding 0.01 g of dry polymer to different phosphate buffer with pHs of 5.5, 6.5, 7.4, and 8.5. The weight of the polymer was measured after 24 h in the solution and separated using appropriate filter paper. The following equation (Eq. 2) is used to calculate polymer swelling:

where W and W0 represent the weight of the swollen and dried polymers, respectively.

Temperature is another factor that influences polymer swelling, so to investigate the effect of this parameter, 0.01 g of the studied polymer was placed in a phosphate buffer with a specific and constant pH, and the amount of polymer swelling was measured at temperatures of 28, 33, 37, and 40 °C. It should be noted that, in addition to temperature and pH, the ionic strength of the environment can have a significant impact on polymer swelling. As a result, the swelling of the studied polymer in NaCl solution at various concentrations ranging from 0.001 to 0.5 M was investigated.

Study of cytotoxicity

The efficiency of the nanodrug carrier to destroy cancerous cells (cytotoxicity) was investigated as a targeted release of the loaded drug in specific environmental conditions. We examined using the MTT method and Hela cells (Pappinen et al. 2012).

1 mL of DMEM medium was placed in each well of a 96-well plate, and the desired cells were cultured. The resulting medium was incubated at 37 °C in 5% CO2 for 24 h. Each well received a solution mixture of DMEM and loaded pharmaceutical nanoparticles, which was incubated for 4 h at 25 °C. Following that, 600 µL of fresh DMEM medium was added to each well, and the incubation process was continued at 37 °C for 48 h. Finally, 100 L of MTT medium was added to each well, and the incubation period was extended to 4 h. Thereafter, we replaced 500 µL of DMSO with an MTT solution. The optical density was measured at a wavelength of 570 nm using a microplate reader model 550. Equation 3 was used to calculate the number of surviving cells:

Acontrol is the optical density of the control well, which does not contain polymer drug carriers, and Atreated is the optical density in the other wells. We also perform the above procedure for the drug doxorubicin without a drug carrier.

Discussion and conclusion

Investigation of the synthesized MOF nanoparticle

The scanning electron microscopy (SEM) was used to determine the size and shape of these synthesized nanoparticles (Fig. 1). The nanoparticles have a uniform size of 39.25 nm (Vatanpour et al. 2012; Nasrollahi et al. 2018).

The morphology of the nanoparticles can be examined using SEM imaging. As a result, TEM micrographs of (MnFe2O4@MOF) were used to determine the position of supermagnetic MnFe2O4 nanoparticles within the MOF structure (Fig. 2). The nanocomposites have bright and dark areas. The bright area is associated with the light density MOF structure, which allows light to pass through, whereas the high density MnFe2O4 structure blocks most of the light and thus appears darker. This confirms the supermagnetic nanoparticle's position within the MOF (Vatanpour et al. 2012; Nasrollahi et al. 2018).

Examining the VSM analysis of the mentioned supermagnetic nanoparticles is another way to demonstrate their synthesis. The MnFe2O4@MOF nanostructure provided the VSM spectrum (Fig. 3). The magnetic saturation volume of MnFe2O4@MOF nanoparticle is 66.8 emu/g. Figure 3 also shows that the residual magnetism is close to zero, demonstrating the superparamagnetic nature of the MnFe2O4@MOF structure (Kolhatkar et al. 2013).

The crystallographic structure of MOF nanoparticles was determined using XRD spectra. The XRD spectrum has many sharp peaks related to the structure of the synthesized MOF, as shown in Fig. 4, which was confirmed by comparing it to the reference XRD spectra of the cubic (crystalline) structure for the synthesized MOF. The zirconium benzene carboxylate units organize themselves into a crystal lattice with a complex three-dimensional channel system (Vatanpour et al. 2012; Nasrollahi et al. 2018).

Because nanoparticles have a high surface-to-volume ratio, they have a much larger loading and reaction volume than macro- and microstructures. In BET, the nitrogen inert gas absorption technique is used to check and measure the surface-to-volume ratio of nanoparticles. This technique can determine the effective surface area as well as the average pore size and other information about the studied nanoparticle. According to Fig. 5, the adsorbent adsorption on the MOF surface follows the second type of isotherm adsorption mechanism. Furthermore, the effective surface area of the synthesized MOF and MnFe2O4@MOF are 7.26 and 5.87 m2/g, respectively, and the adequate volume of the synthesized MOF is 166.394 and 152.031 m/g. The pores' average sizes are 2.3 and 1.9 nm. Because of the presence of super magnetic nanoparticles inside the structure, as well as the tension they exert on the structure, the value and surface of MOF, as well as the size of the pores, have changed (Lalabadi et al. 2022).

FTIR spectrum of polymeric nanocarriers

The FTIR was used to confirm the presence of functional groups in the polymer and nanocomposite. The broad peaks in the 400–1000 cm−1 range are due to the metal–oxygen bond found in manganese ferrite nanoparticles (Fig. 6A) (Bennet et al. 2016). The spectrum for Fig. 6B is related to the MOF. The peak intensity of the carbonyl group at 1688 cm−1 in the organometallic framework is lower than that of the free carbonyl group of the ligand. In addition, there is a strong peak in the MOF in the region of 1580 cm−1, which indicates the degradation of the –COOH group in the ligand and its reaction with metal ions. The vibrational frequency of the OH group of the carboxylic acid ligand is around 2970 cm−1. This peak is not observed in the MOF due to deprotonation and the formation of the oxygen-metal (Zn) bond (Rostamnia and Xin 2014). The IR spectrum of the magnetic MOF (MnFe2O4@MOF) for Fig. 6C shows not only the characteristic peaks of the magnetic nanoparticle but also the peaks of the MOF.

The spectrum of Fig. 7 is related to the smart polymer. In addition to the peaks related to the functional groups of the polymer, which include NH2 stretching vibration at 3463 cm−1, CH2 stretching vibration at 2928 and 2858 cm−1, and C=O stretching vibration at 1732 cm−1 and the stretching vibration of –CH(CH3)2 in cm−1 is 1546 cm−1. The peaks related to magnetic nanoparticles are observed in the region below 1000 cm−1, which confirms the presence of nanocarriers in the polymer capsule. The 1247 cm−1 peak corresponding to COCH3 doxorubicin absorption bands of doxorubicin (795 cm−1) is observed (Farooqi et al. 2017).

Figure 7 depicts the spectrum of the synthesized smart polymer. The peaks related to the polymer's functional groups, which include NH2 stretching vibration at 3463 cm−1, CH2 stretching vibration at 2928 and 2858 cm−1, C=O stretching vibration at 1732 cm−1, and –CH(CH3)2 stretching vibration at 1546 cm−1. Magnetic nanoparticle peaks are observed in the region below 1000 cm−1, confirming the presence of nanocarriers in the polymer capsule. The peak at 1247 cm−1 corresponds to the COCH3 doxorubicin absorption bands of doxorubicin (795 cm−1) (Farooqi et al. 2017).

DTA-TGA thermal analysis

The thermal stability of the synthesized samples was determined using DTA-TGA analysis. The DTA-TGA curves of polymer-containing nanoparticles (Fig. 8) show several thermal events occurring during heating. Only 5% of the weight of the samples was lost in the first stage and up to 220 °C were lost through moisture. This moisture loss was accomplished in three stages, confirming the sample's porous nature. A second extreme weight loss was observed after 225 °C due to a change in the structure of the samples and the release of various gases, including CO2, CO, H2O, and other gases are released because of the decomposition of polymer and MOF at various temperatures (254, 446, and 521 °C).

Dispersion index of nanocarriers

The size distribution of nanoparticles in a solvent is depicted by the polydispersity index (PDI) (Tochacek and Jancar 2012). A PDI of around 0.7, according to sources and references, indicates a distribution with a minimal range of nanoparticles and their homogeneity and uniformity in the solution. A PDI near 1.0 indicates dispersion and a broad range of nanoparticles in the solvent, both of which are undesirable (Danaei et al. 2018). The numerical value of PDI is obtained using equation (Eq. 4):

where d represents the size of the nanoparticle and σ is the standard deviation. The calculated PDI value for the used drug nanocarriers is approximately 0.7, which indicates the dispersion of acceptable distribution of polymer carriers in solution.where d represents the nanoparticle size and is the standard deviation. The calculated PDI value for the used drug nanocarriers is approximately 0.7, indicating the dispersion of acceptable polymer carrier distribution in solution. The carrier size is in the nanorange, as demonstrated by different devices in “Investigation of the synthesized MOF nanoparticle” section.

Determination of LCST of polymeric nanocarrier

UV–Vis spectroscopy at various temperatures is used to determine the LCST temperature of the polymer nanocarrier. Temperatures ranging from 30 to 43 °C were extracted from the smart polymer solution's UV–Vis spectrum, and the solution percentage was calculated using the Beer-Lambert equation. As illustrated in Fig. 9a. Because of hydrogen bonding between polymer chains and water molecules at temperatures between 30 and 37 °C, below the critical temperature, the polymer has a single-phase structure, resulting in a stable structure. When the temperature rises above 39 to 43 °C, C–O and N–H groups form in the structure of intramolecular bonds, resulting in hydrophobicity and biphasic solution. As a result, the critical temperature was chosen to be in the middle of the phase change, around 38 °C (Liu et al. 2014). The polymer undergoes a reversible change in shape and volume at this temperature (Liu et al. 2014; Klouda and Mikos 2008).

Polymer swelling in different environmental conditions

The effect of three variables, pH, temperature, and ionic strength on the smart polymer's swelling rate was studied. The highest swelling was observed in phosphate buffer and alkaline condition (pH of 8.5) as shown in Fig. 10. In an acidic environment, hydrogen bond is lost due to the protonation of all pairs of free electrons, which causes a decrease in water absorption by the polymer structure and a decrease in swelling (Scott et al. 2019). At conditions higher than the physiological pH, the COONH2 amide groups of acrylamide remains constant, and their combined complex with the functional groups of acrylic acid and acrylamide becomes weaker. So, the hydrogen bond and swelling increases. However, in an acidic environment, since the COONH2 amide group is converted into COONH3+, the electrostatic bond between the acrylamide polymer and acrylic acid is formed, and the ionic charge is changed (0.001–0.5 M NaCl). For this reason, the intensity of the complex between acrylamide and acrylic acid increases and swelling decreases (Scott et al. 2019). The effect of temperature on the swelling of polymer nanocarriers is depicted in Fig. 10. This diagram depicts how temperature affects polymer swelling, which decreases as temperature rises. When the temperature rises, the binding of water molecules to the polymer structure loosens, and because the structure is hydrophobic, hydrogen bonds and intramolecular bonds replace the binding of water molecules to the structure, increasing the strength of the polymer nanocarrier structure and reducing swelling.

The ionic strength does not change significantly under physiological conditions, but if it does, it affects the swelling of the polymer. The osmotic pressure between the polymer and the polar solvent decreases as the electric charge in the layer around the polymer increases, resulting in less water absorption by the polymer carrier. The decrease in water absorption causes the polymer to shrink and contract, as shown in Fig. 10 (Liu et al. 2014; Scott et al. 2019).

Loading and release of doxorubicin from the nanocarrier structure

The UV–Vis spectrum of doxorubicin drug solution was measured in the presence and absence of the designed nanocarrier, and 1% loading was calculated using the equation. It was discovered that 74.2% of the drug is loaded inside the nanocarrier structure, and this value does not change significantly after 24 h (Cao et al. 2010).

The conditions simulated by the phosphate buffer solution were used to investigate the drug release rate from the smart polymer nanocarrier; as environmental conditions change and the swelling of the drug carrier changes, so does the amount of drug released. This is due to the polymer carrier's pores being opened by reducing swelling and shrinking.

Because the PNIPAAm-co-AA polymer structure is temperature sensitive, the amount of drug released after 24 h was measured at temperatures lower and higher than LCST. At temperatures below the LCST, no significant drug release was observed. The polymer pores close due to high swelling at low temperatures. As a result, the drug release is kept to a bare minimum. The drug's release decreases at 37 °C, which is lower than the critical temperature. The drug can be released in small doses. High temperatures cause the polymer to shrink, causing the pores to open and release the drug (Fig. 11A). Due to the very high activity caused by cell proliferation, cancer tissues have a higher temperature than the average temperature of healthy tissue (temperature of 40 °C), so drug release increases with the entry of drug nanocarriers into the cancer tissue. Because of the very low release of the drug from the polymer nanocarrier structure at temperatures lower than LCST, the drug was stored at a temperature of 25 °C (Shieh et al. 2014; Xiong et al. 2011).

The pH of the environment has a significant impact on the structure of the nanopolymer carrier. Pairs of free electrons and hydrogen are attached to oxygen and nitrogen in the structure of this polymer, causing a tendency to form hydrogen bonds. The hydrogen bond changes as the pH changes, as well as the swelling and density of the structure. Contraction occurs as the environment becomes more acidic and the number of inter-structural ionic connections in the polymer increases, resulting in the opening of the polymer pores and, as a result, an increase in drug release (Fig. 11B).

The pH of cancerous tissues ranges between 5 and 5.3; based on the findings, drug release in these acidic tissues should be higher than in healthy tissue (Du et al. 2013). Less drug release in healthy tissues means fewer side effects in such a drug delivery system. The results of this experiment point to alkaline storage conditions for these drug carriers.

Antitumor effect of smart drug nanocarrier

To investigate the anti-tumor effect of polymer nanocarrier, drug nanocarrier, and DOX drug in the absence of carrier. We observed that, the aforementioned compounds were added to the culture medium and incubated at 25 °C for 4 h before being raised to 40 °C. Low drug concentrations and nanocarriers with the drug had no visible anti-tumor effect. However, increasing the concentration of these compounds to 50 g/L results in 71, 99, and 5% viability of incubated cells in contact with smart polymer loaded with DOX, DOX, and the polymer, respectively (Fig. 12). These results show the negligible anti-tumor effect of the polymer alone and the significant effect of the drug loaded in the polymer carrier structure.

Conclusion

Any drug delivery system's goal is to provide the ideal concentration of the drug in the right place of the body at the right time and to retain it for the desired time. The drug's rapid release into the bloodstream raises the risk of damage to healthy cells and tissues. When drug particles are placed in a bed of hydrogel, the explosive release of the drug is reduced, and the duration of the drug's release from its carrier is increased. An organometallic framework nanocarrier containing MnFe2O4 magnetic nanoparticles and loaded with doxorubicin drug modified with PNIPAM-co-AA smart polymer was successfully prepared in this study to investigate drug release.

The porosity of the organometallic framework and the relatively high loading of the drug doxorubicin are advantages of this nanosystem. Another benefit of this system is its magnetic nature, which allows it to be targeted by applying an external magnetic field to guide the magnetic nanoparticles containing medicine to the diseased tissue and improve it without harming the healthy tissue (Nevozhay et al. 2007). In this nanosystem, the shape, size, and efficiency of drug loading were investigated. The nanocarrier is then modified with the smart polymer PNIPAM-co-AA, which allows the drug to be preserved for an extended period, reducing the patient's need for ongoing drug use. At an acidic pH and a temperature of 40 °C (higher than the critical dissolution temperature), the highest drug release rate was observed at 71%

References

Aguilar MR, Elvira C, Gallardo A, Vazquez B, Román JS (2007) Smart polymers and their applications as biomaterials. Top Tissue Eng 3:6

Alidadykhoh M, Pyman H, Roshanfekr H (2021) Application of a new polymer AgCl nanoparticles coated polyethylene terephetalat [PET] as adsorbent for removal and electrochemical determination of methylene blue dye. Chem Methodol 5:96–106

Babincova M, Babinec P (2009) Magnetic drug delivery and targeting: principles and applications. Biomed Pap Med Fac Univ Palacky Olomouc Czech Repub 153:243–250

Bellusci M, Guglielmi P, Masi A, Padella F, Singh G, Yaacoub N, Peddis D, Secci D (2018) Magnetic metal–organic framework composite by fast and facile mechanochemical process. Inorg Chem 57:1806–1814

Bennet J, Tholkappiyan R, Vishista K, Jaya NV, Hamed F (2016) Attestation in self-propagating combustion approach of spinel AFe2O4 (A = Co, Mg and Mn) complexes bearing mixed oxidation states: magnetostructural properties. Appl Surf Sci 383:113–125

Cao MJ, Li LY, Xu WL (2010) Synthesis and properties of biodegradable thermo-and pH-sensitive poly[(N-isopropylacrylamide)-co-(methacrylic acid)] hydrogels. Polym Degrad Stab 95:719–724

Chowdhuri AR, Bhattacharya D, Sahu SK (2016) Magnetic nanoscale metal organic frameworks for potential targeted anticancer drug delivery, imaging and as an MRI contrast agent. Dalt Trans 45:2963–2973

Coughlan DC, Corrigan OI (2006) Drug–polymer interactions and their effect on thermoresponsive poly (N-isopropylacrylamide) drug delivery systems. Int J Pharm 313:163–174

Danaei M, Dehghankhold M, Ataei S, Hasanzadeh Davarani F, Javanmard R, Dokhani A, Khorasani S, Mozafari MR (2018) Impact of particle size and polydispersity index on the clinical applications of lipidic nanocarrier systems. Pharmaceutics 10:57

Du C, Deng D, Shan L, Wan S, Cao J, Tian J, Achilefu S, Gu Y (2013) A pH-sensitive doxorubicin prodrug based on folate-conjugated BSA for tumor-targeted drug delivery. Biomaterials 34:3087–3097

Fan T, Li M, Wu X, Li M, Wu Y (2011) Preparation of thermoresponsive and pH-sensitivity polymer magnetic hydrogel nanospheres as anticancer drug carriers. Colloids Surfaces B Biointerfaces 88:593–600

Farooqi ZH, Khan HU, Shah SM, Siddiq M (2017) Stability of poly (N-isopropylacrylamide-co-acrylic acid) polymer microgels under various conditions of temperature, pH and salt concentration. Arab J Chem 10:329–335

Frey HV (2006) Impact constraints on the age and origin of the lowlands of Mars. Geophys Res Lett 33:8

Ghasemi J, Peyman H, Niazi A (2007) Spectrophotometric determination of acidity constants of 4-(2-pyridylazo) resorcinol in various micellar media solutions. J Chin Chem Soc 54:1093–1097

Gholivand MB, Peyman H, Gholivand K, Roshanfekr H, Taherpour AA, Yaghobi R (2017) Theoretical and instrumental studies of the competitive interaction between aromatic α-aminobisphosphonates with DNA using binding probes. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-016-2371-6

Horcajada P, Chalati T, Serre C, Gillet B, Sebrie C, Baati T, Eubank JF, Heurtaux D, Clayette P, Kreuz C (2010) Porous metal–organic-framework nanoscale carriers as a potential platform for drug delivery and imaging. Nat Mater 9:172–178

Imaz I, Hernando J, Ruiz-Molina D, Maspoch D (2009) Metal–organic spheres as functional systems for guest encapsulation. Angew Chemie Int Ed 48:2325–2329

Klouda L, Mikos AG (2008) Thermoresponsive hydrogels in biomedical applications. Eur J Pharm Biopharm 68:34–45

Kolhatkar AG, Jamison AC, Litvinov D, Willson RC, Lee TR (2013) Tuning the magnetic properties of nanoparticles. Int J Mol Sci 14:15977–16009

Lalabadi MA, Peyman H, Roshanfekr H, Azizi S, Maaza M (2022) Polyethersulfone nanofiltration membrane embedded by magnetically modified MOF (MOF@Fe3O4): fabrication, characterization and performance in dye removal from water using factorial design experiments. Polym Bull 2022:1–21. https://doi.org/10.1007/S00289-021-03988-0

Liu J, Huang Y, Kumar A, Tan A, Jin S, Mozhi A, Liang X-J (2014) pH-sensitive nano-systems for drug delivery in cancer therapy. Biotechnol Adv 32:693–710

Misiak P, Markiewicz KH, Szymczuk D, Wilczewska AZ (2020) Polymeric drug delivery systems bearing cholesterol moieties: a review. Polymers (basel) 12:2620

Nasrollahi N, Vatanpour V, Aber S, Mahmoodi NM (2018) Preparation and characterization of a novel polyethersulfone (PES) ultrafiltration membrane modified with a CuO/ZnO nanocomposite to improve permeability and antifouling properties. Sep Purif Technol 192:369–382

Nevozhay D, Kańska U, Budzyńska R, Boratyński J (2007) Current status of research on conjugates and related drug delivery systems in the treatment of cancer and other diseases. Postepy Hig Med Dosw 61:350–360

Orellana-Tavra C, Marshall RJ, Baxter EF, Lázaro IA, Tao A, Cheetham AK, Forgan RS, Fairen-Jimenez D (2016) Drug delivery and controlled release from biocompatible metal–organic frameworks using mechanical amorphization. J Mater Chem B 4:7697–7707

Pappinen S, Pryazhnikov E, Khiroug L, Ericson MB, Yliperttula M, Urtti A (2012) Organotypic cell cultures and two-photon imaging: tools for in vitro and in vivo assessment of percutaneous drug delivery and skin toxicity. J Control Release 161:656–667

Peyman H, Roshanfekr H, Babakhanian A, Jafari H (2021) PVC membrane electrode modified by Lawson as synthetic derivative ionophore for determination of cadmium in alloy and wastewater. Chem Methodol 5:446–453

Rostamnia S, Xin H (2014) Basic isoreticular metal–organic framework (IRMOF-3) porous nanomaterial as a suitable and green catalyst for selective unsymmetrical Hantzsch coupling reaction. Appl Organomet Chem 28:359–363

Sahoo B, Devi KSP, Dutta S, Maiti TK, Pramanik P, Dhara D (2014) Biocompatible mesoporous silica-coated superparamagnetic manganese ferrite nanoparticles for targeted drug delivery and MR imaging applications. J Colloid Interface Sci 431:31–41

Scott AJ, Duever TA, Penlidis A (2019) The role of pH, ionic strength and monomer concentration on the terpolymerization of 2-acrylamido-2-methylpropane sulfonic acid, acrylamide and acrylic acid. Polymer (guildf) 177:214–230

Shieh J, Chen S-R, Chen G-S, Lo C-W, Chen C-S, Chen B-T, Sun M-K, Huang C-W, Chen W-S (2014) Acrylic acid controlled reusable temperature-sensitive hydrogel phantoms for thermal ablation therapy. Appl Therm Eng 62:322–329

Sponchioni M, Palmiero UC, Moscatelli D (2019) Thermo-responsive polymers: applications of smart materials in drug delivery and tissue engineering. Mater Sci Eng C 102:589–605

Taylor-Pashow KML, Della Rocca J, Huxford RC, Lin W (2010) Hybrid nanomaterials for biomedical applications. Chem Commun 46:5832–5849

Tochacek J, Jancar J (2012) Processing degradation index (PDI)—a quantitative measure of processing stability of polypropylene. Polym Test 31:1115–1120

Vasseur A, Perrin L, Eisenstein O, Marek I (2015) Remote functionalization of hydrocarbons with reversibility enhanced stereocontrol. Chem Sci 6:2770–2776

Vatanpour V, Madaeni SS, Rajabi L, Zinadini S, Derakhshan AA (2012) Boehmite nanoparticles as a new nanofiller for preparation of antifouling mixed matrix membranes. J Memb Sci 401:132–143

Xiong W, Wang W, Wang Y, Zhao Y, Chen H, Xu H, Yang X (2011) Dual temperature/pH-sensitive drug delivery of poly(N-isopropylacrylamide-co-acrylic acid) nanogels conjugated with doxorubicin for potential application in tumor hyperthermia therapy. Colloids Surfaces B Biointerfaces 84:447–453

Yoo MK, Sung YK, Lee YM, Cho CS (2000) Effect of polyelectrolyte on the lower critical solution temperature of poly(N-isopropyl acrylamide) in the poly(NIPAAm-co-acrylic acid) hydrogel. Polymer (guildf) 41:5713–5719

Zarrintaj P, Jouyandeh M, Ganjali MR, Hadavand BS, Mozafari M, Sheiko SS, Vatankhah-Varnoosfaderani M, Gutiérrez TJ, Saeb MR (2019) Thermo-sensitive polymers in medicine: a review. Eur Polym J 117:402–423

Funding

Open access funding provided by University of South Africa.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdollahy, M., Peyman, H., Roshanfekr, H. et al. Synthesis and characterization of a smart polymer-coated core–shell MnFe2O4@ organometallic framework for targeted drug delivery. Chem. Pap. 77, 3897–3909 (2023). https://doi.org/10.1007/s11696-023-02750-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-02750-2