Abstract

In the present study, the olive mill wastewater (OMW) phenolics were extracted with soy lecithin using the cloud point extraction method, and this enriched lecithin (OMW-L) was converted into spray-dried powders using maltodextrin (MD) and whey protein concentrate to be utilized as a dry food ingredient in a cake premix. The inlet temperature of 170 °C and a 3 mL/min feed flow rate yielded the highest powder yield (70.88 ± 2.12%) with a moisture content of 3.78 ± 0.03% when the mass ratio of lecithin to MD was 1:3 (w:w). The hydroxytyrosol and tyrosol contents of the powder were 42.60 ± 4.51 mg/100 g and 15.48 ± 2.50 mg/100 g, respectively. Vanillic acid, caffeic acid, 3-hydroxybenzoic acid, catechin, and rutin were also identified in the powders. The spray-dried OMW-L powder with a higher loading of polyphenols was then used in a cake premix, replacing 1% and 3% of wheat flour. This substitution significantly reduced the K value of the cake batter, as determined by rheological analyses. The addition of spray-dried OMW-L powder to the cake samples, particularly at higher concentrations (3%), influenced both crust and crumb color, causing changes in L*, a*, and b* values. The hardness values of the cake samples did not alter when blank or OMW-enriched lecithin powders were added; rather, the hardness value was influenced by the powder content. Overall, this research offers a different perspective on the use of OMW phenolics in food applications, especially in ready-to-use blends, and demonstrates the effects of the obtained spray-dried lecithin powders on batter rheology and cake characteristics.

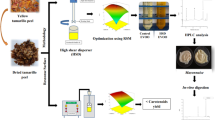

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Modern olive oil production methods such as two-phase and three-phase centrifuge systems generate a significant amount of olive mill wastewater (OMW) in a very short season. For example, it was reported that 0.2–0.3 m3 and 0.3–1.2 m3 tons of OMW were produced for each ton of processed olives by two-phase and three-phase decanters, respectively [1]. This by-product of olive oil extraction is rich in phenolics such as tyrosol, hydroxytyrosol, and oleuropein associated with significant antioxidant properties and could be considered a source of a usable series of products that can be used in nutraceutical and cosmetic applications. Due to the hydrophilic nature of olive oil by-products and the polarity of phenols, most of them are solubilized in the olive oil residues rather than in the oil. The cloud point extraction (CPE) method has distinct advantages over conventional solvent extraction methods, such as low solvent consumption, low cost, a greener procedure, ease of instrumentation, and high extraction efficiency [2]. The CPE method relies on the use of an aqueous solution of amphiphilic surfactants as extraction solvents and the separation of the surfactant-rich phase enriched with the targeted compounds by reducing the solubility of the surfactant by heating the solution to (or above) a critical temperature [3]. The previous studies regarding bioactive components extracted with surfactants by the CPE method was summarized in Table 1. Among surfactants, the use of lecithin (E322) in the CPE method has been suggested to recover bioactive components from various sources, including wine sludge waste [4], olive mill wastewater [5], overripe banana peel [6], and the waste streams of clingstone peach canneries [7]. Since lecithin is an authorized food additive in the European Union, the surfactant rich phase of CPE method applied to recover bioactive compounds could be directly utilized in different food formulations. In our previous study [5], for the first time, the lecithin was enriched with OMW phenolics by applying the CPE method, and this enriched lecithin was exploited in the formulation of vegan salad dressing that yielded higher oxidative stability. Athanasiadis et al. produced enriched lecithin by OMW phenolics in a similar way, and this enriched lecithin was utilized to fortify the olive oil with an extended shelf life [6].

Ready-to-use powder blends have recently become prominent in the baking industry due to their convenience in producing a wide range of formulations quickly and easily at a reasonable cost. Therefore, in this study, we aimed to convert the lecithin enriched with OMW phenolics using the CPE method into water dispersible powders by spray-drying to enhance its utilization as an ingredient in different food products, such as in a powder cake premix. Powders containing OMW phenolics, including commercial products, have been developed through previous research. For example, Fernandez-Bolanos et al. [8] developed a patented technique for two refined forms of hydroxytyrosol (Hytolive 1 and Hytolive 2) from olive oil by-products. Petrotos et al. [9] proposed a technique for creating two OMW extracts: MEDOLIVA, a phenolic extract, and an encapsulated OMW extract with maltodextrin. Similarly, Tornberg and Galanakis and Galanakis et al. have created a product derived from OMW (PHENOLIVE AB), which contains 4% polyphenols as an antioxidant food ingredient [10, 11]. Those powder products contain only OMW phenolics with a food grade biopolymer such as maltodextrin, whereas in our study, the resultant powder would also contain lecithin and OMW together as an output of the CPE method.

Lecithin has already been employed in various bakery products for its ability to provide the necessary aeration and maintain gas bubble stability [12]. Therefore, this study aims to investigate the production of OMW-lecithin powders by employing two different carrier agents and to utilize this powder as a dry food ingredient in a cake premix by evaluating the quality characteristics of the cake samples.

Material and methods

Materials

Polat Machinery Ind. harvested the Gemlik (synonym Trilye) cultivar olives (Olea europaea L.) located in Bozdogan/Aydin, Turkey in the 2021–2022 season for olive oil production, utilizing a two-phase decantation system and then separated the emerged OMW pomace through the following stages: coarse filtering, horizontal decanter, and vertical centrifugation. It was transported to the laboratory and stored at 4 °C until use. OMW was centrifuged at 4230 rpm for 30 min at 4 °C, and then the supernatant was used for the experiments. Soy lecithin (E 322) was supplied from Alfasol (Istanbul, Turkey). Wheat flour, egg white powder, powdered sugar, shortening, and baking powder were purchased from a local market (Istanbul, Turkey). Skimmed milk powder, whey protein concentrate (Noir WPC 70) was donated from Calli Gida (Istanbul, Turkey), and Glucidex DE-19 was purchased from Roquette (Lestrem, France). Folin–Ciocalteu reagent, Na2CO3, methanol, and phenolic standards were purchased from Sigma–Aldrich Ltd (Steinheim, Germany).

Preparation of lecithin enriched with OMW by the CPE method

The optimum CPE conditions determined in our previous study [5] were used to produce enriched lecithin. OMW was mixed with lecithin (15%, w/v) on a magnetic stirrer for 30 min and homogenized for 10 min with an ultrasonic device (Hielscher, UP400S, Germany) with an amplitude of 30%, and the cycle was 0.5. Following that, 10% NaCl (w/v) was added, and the pH value (4.5) of the mixture was adjusted by using NaOH or HCl. The solution was then placed in a temperature-controlled water bath (65 °C) for 20 min. The phase separation was carried out at 5000 rpm for 30 min at 4 °C. The aqueous phase was separated from the bottom by using a syringe, and the micellar phase (OMW enriched lecithin) was used for spray drying. The polyphenol recovery of this enriched lecithin (OMW-L) was 40.15% ± 4.14% [5].

Spray drying

In order to convert OMW-enriched lecithin (OMW-L) into powders by spray drying, the lecithin was dispersed in water on a magnetic stirrer (100 rpm, for 1 h at 25 °C), homogenized by Ultra-Turrax (IKA T-18, Germany) at 5000 rpm for 30 min, and sonicated (0.5 cycles, 60% amplitude) for 5 min with an ultrasonic processor (UP400S, Hielscher, Germany). Afterward, each of the polymers, maltodextrin (MD) and whey protein concentrate (WPC), were dissolved in this lecithin dispersion as the feed of the spray drier (B-290, BUCHI, Switzerland). The final solid content of the spray drier feed was set to 20% (w/v) [21, 22], and the mass ratio of lecithin to polymer ranged from 1:1 to 1:3 (w/w). The final solid content of the spray drier feed was set to 20% (w/v), and the mass ratio of lecithin to polymer ranged from 1:1 to 1:3 (w/w). The inlet temperature and the feed flow rate ranged between 170–190 °C and 3–6 mL/min., with a nozzle diameter of 0.7 mm and 95% of the aspirator rate. The outlet temperatures were recorded between 102 and 110 °C for the conditions conducted. The powders were stored in sealed vessels at 4 °C until the analysis.

The mean particle size (z-average) and zeta potential analysis of lecithin dispersions were determined by dynamic light scattering (DLS) (Nano ZS, Malvern, Worcestershire, UK). The samples were diluted 100-fold with water to avoid multiple scattering effects. The refractive index was 1.44 and 1.33 for lecithin and water, respectively. The results were reported as the average and standard deviation of measurements made from three freshly prepared samples, with three readings made per sample [21].

The yield, moisture content, water activity, and color analysis of the powders

Following the subtraction of moisture content of the spray-dried powders (2.3), the yield was calculated as the mass the ratio of the weight of powder collected to the mass of total solids in the feed [22]. The moisture content of powders and cake samples (2.4) was determined using an infrared moisture analyzer (Rad-Wag, MA 50-R, Poland). 3 g of samples were weighted on the 90 mm surface diameter of the sample collector and then measured. Based on the wet mass of the samples and its mass at the end of the analysis, the moisture analyzer program automatically calculated the water content (dry mass content) of the product.

The water activity of powders and cake samples was measured using AWSprint TH500 (Novasina, Switzerland at 25 °C. The water activity measured by the instrument was noted after stabilization of the reading. The color parameters of powders and cake samples were recorded using a chromameter (CR-400, Konica Minolta, Tokyo, Japan). Five cake samples were used for color analysis. The color of the cake crust was measured first, followed by the color measurement of the cake crumb after cutting. The parameters were expressed as L*, a*, and b*. L* represents the blackness and lightness, a* represents the greenness (−) and redness (+),b* represents the blueness (−) and yellowness (+).

Encapsulation efficiency and loading capacity of OMW phenolics

100 mg of spray-dried powders were dispersed in 5 mL of water, vortexed for 1 min, and sonicated for 20 min. Then 5 mL of methanol was added and mixed for 10 min, and centrifuged at 2500×g for 15 min at 4 °C, and the supernatant was filtered through a 0.45 μm membrane filter were analyzed to calculate the total phenolic content (TPC) and analysis of individual phenolics by HPLC. To determine the amount of TPC retained on the surface of the powders, 100 mg of spray-dried powders were mixed with 10 mL of methanol, and the dispersion was agitated in a vortex for 1 min, centrifuged and the supernatant was filtered and analyzed as previously. The encapsulation efficiency (EE%, Eq. 1) and loading capacity (LC, mg/100 g, Eq. 2) were calculated as follows:

TPC was determined according to the Folin–Ciocalteu (FC) method described by Singleton and Rossi [23]. The results were expressed as mg of Tyrosol equivalent (TyE), and Hydroxytyrosol equivalent (HyTE) per 100 g of powder. Individual phenolics of OMW-L powders were analyzed by HPLC according to our previous study [24], and the results were given as mg of individual phenolics per 100 g of powder.

Scanning electron microscopy (SEM) and confocal laser scanning microscopy (CLSM)

The morphology of spray-dried powders was observed by SEM (Carl Zeiss EVO 10, Köln, Germany) operated at a high vacuum with a voltage of 7 and 10 kV. The samples were mounted onto separate, adhesive-coated aluminum pin stubs. The stubs were sputter-coated with a thin layer of gold in a Leica vacuum coating unit at 40 mA for 100 s × 3 times by using an argon gas purge. OMW phenolics distribution in the spray-dried powders was evaluated using the ZEISS LSM 800 confocal imaging system (ZenSoftware, 2012 SP1, Carl Zeiss, Germany). In order to visualize the natural fluorescence of phenolic compounds, samples were excited at 488 nm, and fluorescence was detected in the green channel signal at λem = 500/550 nm [24]. All images were taken and processed using Zen, version 3.4, blue edition (Carl Zeiss).

FTIR analysis

The FTIR spectrum of OMW-L MD and L-MD powders was performed with the ATR-FTIR spectrophotometer (Attenuated Total Reflectance-Fourier Transform Infrared Spectroscopy, a Bruker Tensor 27 spectrometer, Bremen-Germany) equipped with OPUS software (Version 7.2) and an ATR accessory included with a diamond ATR cell. Each spectrum was an average of 32 scans, with a spectral resolution of 4 cm−1 from 400 to 4000 cm−1 on the dried samples.

Cake preparation

The cake formulation of Pehlivanoglu et al. [25] was applied with minor modifications as follows: wheat flour (22%), powdered sugar (22%), skimmed milk powder (22%), water (22%), shortening (9%), egg white powder (2%) and baking powder (1%). Spray-dried lecithin powders with and without OMW were added to the cake formulation at 1% and 3% by replacing wheat flour. After powdered sugar, shortening, skimmed milk powder, egg white powder, and 40% of the water were mixed for 6 min at speed 4 with the mixer (Kitchen Aid, Model 5 K SM 150), flour, baking powder, and 60% of water were added separately to the cake batter and homogenized for 6 min at speed 4. Finally, 110 g of the batter was measured into a baking tray and baked for 30 min in a convection oven preheated to 180 °C. The cakes were removed and allowed to cool at room temperature for 2 h before being analyzed. Each sample was prepared in three batches for analysis.

Rheological properties of cake batters

The effect of spray dried lecithin powder with and without OMW on the rheological properties of cake batters were assessed using a rheometer equipped with parallel plate configuration (diameter 50 mm, gap 0.5 mm) (Anton Paar MCR 302, Austria. The steady shear measurements were carried out in the shear rate range of 0.1–200 s−1 at a constant temperature of 25 °C, and three parallel experiments were carried out for each sample. The rheological analysis data were fitted to the Ostwald de Waele model, and model parameters were calculated according to the following equation (Eq. 3):

where σ is the shear stress (Pa), K is the consistency coefficient (Pa.sn), ɣ is the shear rate (s−1) and n is the flow behavior index [26].

The frequency sweep test was performed at 25 °C and a 1–10 Hz frequency level. The parallel plate configuration was used with a 0.5 mm gap. The storage (G′) and loss modulus (G′′) were recorded to evaluate the viscoelastic properties of the samples.

Texture analysis

The hardness value was determined using a texture analyzer (TA.XT2 Plus, UK) equipped with a 5 kg load cell and a 36 mm diameter cylindrical compression probe. Each cake sample was cut into 2 × 2 × 2 cm cube shaped slices, and the slices were subjected to texture analysis with the following settings; pretest speed 5.0 mm/s; test speed 2 mm/s; posttest speed 5.0 mm/s; 30% compression; trigger type auto force 5 g [25].

Sensory analysis

Sensory analysis of the cake samples was performed using a hedonic scale for taste, flavor, smell, color, texture, pore structure, and overall acceptability. Ten untrained panelists (6 women, 4 men), who were briefed on the samples, performed the sensory evaluation and rated the samples from 1 (extremely bad) to 5 (excellent). Two slices of each sample were served and tagged with three-digit codes in order to conduct the sensory analysis. Before evaluating the next set of samples, the panelists washed their palates with spring water.

Statistical analysis

The data were statistically evaluated using the analysis of variance (ANOVA) and Tukey’s test at a 95% confidence level (p ≤ 0.05) with SPSS Statistics Software (IBM version 20, USA). Results were expressed as the mean ± standard deviation values of three replicates.

Results

Characterization of spray-dried OMW-L powders

The spray-dried powders containing a higher amount of OMW-L were desired; therefore, the first trial was to mix lecithin (L) with polymers (MD, WPC) at a mass ratio of 1:1 (w:w), but it yielded a rapid phase separation of the spray-drier feed suspension (Fig. 1). At the lower mass ratio of lecithin to polymers (1:2 -1:4, w:w), the feed did not show separation (overnight), and spray-drying experiments were carried out (Table 2). The inlet temperature and the feed flow rate ranged between 170–190 °C and 3–6 mL/min., and the spray-drying yield of powders ranged from 33.81 to 70.88% when MD was used as a carrier agent. When the mass ratio of L to MD was 1:2 at an inlet temperature of 170 °C and a 6 mL/min feed rate was applied (trial 1), the powder yield was the lowest (33.81 ± 0.88%), accompanied by the highest moisture content (8.32 ± 0.04%). At the same drying conditions, lowering the mass ratio of lecithin in the feed (L: MD, 1:3), powder yield was increased to 50.10 ± 1.02% (trial 2) but still contained high moisture content (7.62 ± 0.03%). More lecithin concentration in the feed could increase the stickiness of feed in the drying chamber and reduced the powder yield; additionally, higher inclusion of lecithin was expected to increase the viscosity of the feed, and therefore a lower evaporation rate would be anticipated. Although it had a lower lecithin content, the flow rate of 6 mL/min may not provide enough residence time for particles to dry out efficiently in trial 2. When the feed flow rate was slowed down (3 mL/min) at the same inlet temperature, comparably higher powder yield (66.91 ± 1.54%) and lower moisture content (2.58 ± 0.02%) were obtained (trial 3). In trial 4, in the same drying conditions, the mass ratio of MD was increased, and powder yields of 70.88 ± 2.12% and 3.78 ± 0.035% of moisture content were achieved. For the same feed composition in trials 3 and 4, higher flow rates and higher inlet temperatures were applied in trials 5 and 6, but powder yield was reduced (Table 2). To consider the spray-drying process successful, a production yield higher than 50% was reported to be necessary [27]. The lower moisture content (< 5%) and water activity values of powders (0.08–0.14) were within a safe range for the inhibition of microbial growth and enzymatic and non-enzymatic degradations [28].

In the experiments conducted with WPC as carrier material (trials 7–12), lower powder yields were obtained, ranging from 26.40 to 57.10%. Similarly, increasing the inlet temperature and/or reducing the feed flow rate enhanced the yield, but increasing the WPC mass ratio in the feed suspension reduced the powder yield. All powders showed agglomerates rather than discrete particles, and a higher degree of agglomerates of small particles was observed when WPC was used as the carrier (Fig. 2). The surface morphologies of MD powders of L and OMW-L were not different (Fig. 2A and B) . The dents and wrinkles on the surface of spray-dried particles have also been reported in previous studies where carbohydrate excipients were used [29]. When the MD ratio was higher, the occurrence of smaller-sized particles was more abundant; the higher amount of lecithin in the mixture would increase the viscosity and interfere with the formation of the particles during the atomization stage. Although the proteins as carrier matrices were known for their surface-active properties and spray-dried particles with protein generally produced smooth surfaces [30], in our samples, extensive aggregates were observed in spray dried lecithin-WPC particles that could be related to the properties of feed dispersion. When lecithin was dispersed and homogenized in water, the vesicles, composed of an aqueous core surrounded by a phospholipid bilayer membrane, were produced. Prior to the addition of carriers (MD or WPC), the particle size of the vesicles obtained by the dispersion of lecithin was around 200 nm, with a zeta potential of -44.52 mV (Table 3). After the addition of polymers, the size and surface potential of vesicles differed depending on the carrier agent. When the lecithin dispersion was mixed with MD, the size was slightly reduced ( ̴ 20 nm) with almost no change in surface potential value. However, there was a substantial increase in size (from 200 to 1044 nm) and a reduction in zeta potential values (from − 44.52 to − 23.13 mV) when it was mixed with WPC. MD is a hydrophilic, nonionic, and non-adsorbing polysaccharide; therefore, no change in surface potential values was to be expected. When these lecithin structures were immersed in a solution containing low-molecular-weight compounds with an appreciative potential to reduce water activity, such as salts or sugars, water would migrate from the core to the outside of the vesicles to decrease the concentration gradient. Such an osmotic driving force may explain the size reduction observed [22]. On the other hand, the zeta potential values of WPC, an ionic and adsorbing polymer, ranged from + 12 mV to − 19.17 mV when the pH was increased from 2 to 10 (data was not shown). Therefore, its association with the surface of anionic lecithin vesicles would cause the flocculation of the vesicles, yielding a larger size, and higher shear stress during the atomization process of spray-drying can force those flocculated structures to come close together. It could also explain the reason for the lower powder yield when WPC used as a carrier agent for the spray-drying of lecithin.

The color of powders produced in trials 3–4 and 11–12 (resulting in the highest yield and lowest moisture content) was further analyzed, and the results were given in Table 4. The negative a* value of blank lecithin powders (with no OMW) indicates the greenness altered to the positive values in OMW-L powders, and a* values were higher in powders produced with MD. The yellowness value (b*) was reduced in MD powders of OMW-L, but not changed in WPC powders. The lightness (L*) of powders was similar in all formulations, ranging from 89.40 to 92.13.

Trials 3 and 4 (OMW-L:MD and OMW-L1MD3) were used in the following part of the study since the powder yield was comparably higher and the spray-dried particles were less aggregated and more discrete. The change of L to OMW-L did not change the yield, moisture content, and aw values of powders.

The total amount of phenolics (LC) was 213.84 ± 7.33 and 168.19 ± 1.67 mg HyTE/100 g in OMW-L1MD2 and L1MD3 powders, respectively, which also corresponded to 223.84 ± 3.29 and 317.41 ± 14.39 mg TyE/100 g powder (Table 5), higher in powders with a lower mass ratio of MD. The EE% of OMW phenolics was slightly higher in powders with a higher mass ratio of OMW-L. The surfaces of OMW-L1MD2 and L1MD3 powders had 25.67 and 28.05% (TyE) of total phenolics, respectively, which corresponded to 44.29 and 50.49% (HyTE) (Table 5). Gonzales-Ortega et al. [31] and Saroglu et al. [24] showed that both pure oleuropein, freeze-dried olive leaf extract, and OMW phenolics-loaded powders exhibited fluorescence properties and reported that CLSM can be used to determine the distribution of the phenolic fractions with fluorescent properties in the carrier matrix. When spray-dried MD powder of OMW-L was evaluated under CLSM, the occurrence of green signals indicated the OMW phenolics present on the surface (Fig. 3).

In our previous study related to lecithin enrichment with OMW phenolics, we determined the content of individual phenolics in OMW [5]. As expected in a similar manner, in the MD powder of OMW-L, hydroxytyrosol was the main phenolic compound identified with a value of 42.60 ± 4.51 mg/100 g followed by tyrosol at a concentration of 15.48 ± 2.50 mg/100 g. Additionally, vanillic acid, caffeic acid, catechin, 3-hydroxybenzoic acid, and rutin were identified in the powder sample (Table 5).

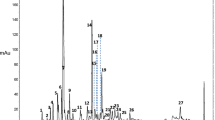

FTIR analysis of spray-dried OMW-L MD and L-MD powders

Figure 4 shows the FTIR spectrums in the range of 600–4000 cm−1 for OMW-L MD and LMD. The broad absorption band at 3324 cm−1 is attributed to O–H stretching vibrations due to hydroxyl groups. The absorption bands at 2923 cm−1 and 2850 cm−1 are associated with the asymmetric and symmetric C–H stretching vibrations of methylene (–CH2) groups, respectively [32]. These bands are typical of the aliphatic chains present in the fatty acid components of lecithin. The prominent peak at 1743 cm−1 was assigned to C=O stretching vibrations of ester carbonyl groups, a characteristic of the phospholipid structure of lecithin, confirming the presence of ester linkages [33]. The region between 1500 cm−1 and 800 cm−1 is recognized as the carbohydrate fingerprint region [34]. In this region, peaks were observed at 1155 cm−1 (C–O stretch and C–O–H bending), 1017 cm−1 (angular deformation of =CH and =CH2 bonds), 850 cm−1 (deformation of CH2 and C1-H), and 701 cm−1 (structural state of the pyranose ring), which are attributed to maltodextrin [32]. In the study by Zhang et al., 2020 [35] where lecithin was utilized as a core to produce polyphenol-loaded liposomes, both bare and polyphenol-loaded liposomes exhibited peaks at 1743 cm−1 and 1223 cm−1, with variations in their intensities. In our study, the peak at 1223 cm−1 probably overlapped with the characteristic peaks of maltodextrin, as this region falls within the fingerprint area of carbohydrates. However, the change in intensity of the peak at 1743 cm−1 in our study could indicate the binding of polyphenols.

Rheological properties of cake batters

In order to observe the effect of spray-dried MD powders of OMW-L in a cake formulation, OMW-L1MD2 was chosen because it had a higher loading of polyphenols. The MD powders of L without (L-MD) and with OMW (OMW-L MD) were used at 1% and 3% as a substitute for wheat flour in the cake formulation (Fig. 5).

Steady shear rheological properties of cake batter samples are presented in Fig. 6. The obtained data were modeled according to the Ostwald de Waele model (with R2 = 0.9977–0.9995), from which the consistency coefficient (K) and flow behavior index (n) were calculated and given in Table 6. All samples showed n < 1 (ranging from 0.66 to 0.73), strongly indicating a shear-thinning flow behavior of the batters. A decreasing increase in the shear stress value was observed as the shear rate increased. Several researchers showed similar behavior for various types of cake batters [36,37,38]. The K value of the dough is a crucial factor affecting the final product’s quality as it determines the retention of air bubbles during the mixing process [36]. If the density of the dough is too low, pores tend to rise to the surface, causing air bubbles to be lost during baking. As can be seen in Table 6, the presence of OMW in lecithin powders reduced the K value from 4.36 to 3.31 and 2.44 to 2.06 when the powder was added at a concentration of 1% and 3% (w:w), respectively. These results clearly show the effect of OMW on structural properties. The cake batters produced with a higher addition of L and /or OMW-L powders showed a dramatic decrease in the K value; for powder of blank L, it was reduced from 4.36 ± 0.51 to 2.44 ± 0.44 when the concentration of powder was increased from 1 to 3%. The decrease was from 3.31 ± 0.19 to 2.06 ± 0.17 when the addition of OMW-L powder was increased to 3%. When Lakshminarayan et al. [39] investigated the effects of fat replacement by maltodextrin on cake batter viscosity, the incorporation of maltodextrin into the structure caused a decrease in the viscosity of cake batters. Kim et al. [40] also reported that the viscosity of cake batter was significantly reduced by maltodextrin. Hedayati and Tehrani [41] found that by replacing eggs with lecithin in the cake formulation, viscosity and consistency index decreased, and this effect became more prominent with an increase in lecithin content.

Figure 7 illustrates the viscoelastic properties of cake batter samples. The G′ value of the batter samples was consistently higher than the G″ value across all frequencies. This finding indicates that the solid nature of all the samples is more prevalent than the liquid nature, meaning that the samples have elastic properties. Previous studies in the literature have found similar outcomes, indicating that samples of cake batter display elastic properties [42, 43].

The G′ and G″ values of the samples exhibited a reduction with an increase in both the powder surfactant percentage and OMW percentage. However, there was no alteration in the elastic properties of the samples. The drop in G′ and G″ values of the samples with increasing powder surfactant content can be attributed to a reduction in the amount of flour in the formulation. The substitution of gluten and starch with a higher quantity of maltodextrin, along with a reduction in the amount of flour, could account for the observed decrease in G′ and G″ values [43, 44]. The findings of the frequency sweep test concluded that an increase in the percentage of powder surfactant and the amount of OMW in the surfactants led to a drop in the G′ and G″ values of the samples. However, it did not have an impact on the viscoelastic solid behavior. These findings suggested that powder surfactant containing OMW could be effectively used in a cake batter formulation without encountering any negative effects.

Water activity, moisture content, color parameters and texture analysis of cake samples

The moisture content and water activity of the cake samples ranged from 19.27 to 22.64% and 0.65 to 0.73, respectively. When MD powder of OMW-L was added at a concentration of 3%, the moisture content and water activity of the cake samples were significantly lower than those of the cake sample containing the same concentration of MD powder of L (without OMW), indicating that the increase in the proportion of OMW could have led to higher integration of hydrophilic components such as hydroxytyrosol into the structure [45].

OMW is a dark colored matrix due to its high concentration of polyphenols; therefore, the impact of OMW integration on cake color is a crucial aspect of evaluating consumer acceptance. The addition of spray-dried OMW-L powders in the cake samples, especially at higher concentrations, significantly affected both the crust and the crumb color of the samples compared to the lecithin powders without OMW. The lightness of crumb values decreased from 74.85 to 67.77 when blank lecithin powder was replaced with OMW-L powder at a lower addition rate (1%). Higher addition to the cake formulation (3%) reduced the lightness value to 68.71 in the cake containing blank lecithin powder and to 58.52 in the formulation having OMW-L powder. Comparably, the a* value was drastically higher in samples having OMW-L powder in their formulations, depending on the addition rate. At a lower addition of powders (1%), the negative a value (− 1.19) was increased to 1.64 when blank lecithin powder was changed with OMW-L powder in the formulation. At a higher addition of powders (3%), the a* value was elevated from 0.39 to 4.43. The addition of powders to the b* values was not significant among samples, except for the cake produced with OMW-L powders at higher concentrations, where a significant reduction was observed from 25.64 to 21.49. The a* values for the crumb of the cake were all positive except for the sample with the addition of 1% LMD powder, indicating the presence of a red hue in the crumb [46].

One of the most useful analytical techniques for product development is texture analysis, which could be used to measure the impact of different flour mixtures and additives on the physical characteristics of cakes’ crumb. There was no difference between the additions of blank or OMW-enriched lecithin powders on the hardness values of cake samples; rather, the hardness value was affected by the concentration of the lecithin powders (Table 7). The higher concentration of lecithin powder added reduced the hardness of the cake samples. Previously, Hedayati and Tehrani [41] stated that the hardness of the cake decreased with a higher ratio of lecithin in the formulations. Increased pore quantity and uniform distribution of small pores in the samples containing a higher concentration of lecithin powders (3%) might result in a less dense cell structure of the cake crumb and hence decreased hardness. In addition to lecithin, MD was the other ingredient in our powder, and the change in the hardness value could also be attributed to its presence. Lakshminarayan et al. [39] reported that the addition of up to 15% MD had a beneficial effect on the texture of cakes with 60% less fat, but the use of a higher addition of MD as a fat substitute adversely affected the overall quality of the cake samples. Psimouli and Oreopoulou [47] also incorporated MD into the cake formulation as a fat replacer and reported the elevated hardness of the end product at a higher addition of MD (35%). In our study, the spray-dried powders were used as a substitute for flour, not as a substitute for fat, and at concentrations of 1% and 3%, they demonstrated a positive impact on hardness values.

The pore structure of the cake samples

The uniform size and distribution of pores in bakery products, including cakes and bread, are indicative of positive product quality. In this study, the distribution and size of the pores in the produced cake samples were imaged using an optic microscope (Fig. 8). The cake containing a lower concentration of lecithin powder (1%) exhibited larger air pores, while those with a higher concentration of powders demonstrated smaller pores. The rheological analysis also revealed that a higher addition of lecithin powders (3%) in cake batters resulted in a lower density of batters. This lower density, as mentioned above, caused the air bubbles to rise to the surface more easily while the product was baking, resulting in the formation of smaller air bubbles and a homogeneous distribution. The implications of this observation could also extend to the hardness of the final product.

Sensory analysis of the cake samples

Sensory analysis of the cake samples was conducted 24 h after baking by 10 panelists. The sensory analysis results for the cake samples are presented in Table 8. It was determined that the addition of microencapsulated powder or enriched lecithin to the formulation had no sensory impact on taste, aroma, smell, texture, pore structure, or overall acceptability parameters. Panelists noted an effect only on color, with color appreciation scores decreasing when using 3% MD powder of OMW-L. Overall acceptability ratings ranged from 4.40 to 3.60 on a scale of 5, with the 3% OMW-L powder receiving a score of 3.60, but there was no statistically significant difference compared to the others.

Conclusion

This study evaluated the conversion of lecithin enriched with OMW phenolics into water-dispersible powders by spray-drying for potential incorporation as an ingredient in different food products, such as a powder cake premix. OMW phenolics were first extracted by the CPE method using lecithin, then converted into spray-dried powders by employing MD or WPC as carriers. The operating conditions of the spray dryer and carrier material significantly influenced powder characteristics. With a mass ratio of L: MD (1:3, w: w), 170 °C inlet temperature, and a 3 mL/min feed flow rate, it yields the highest powder yield (70.88 ± 2.12%) with a moisture content of 3.78 ± 0.03%. In addition to hydroxytyrosol and tyrosol, the main phenolics of OMW, vanillic acid, caffeic acid, 3-hydroxybenzoic acid, catechin, and rutin were also identified in MD powders of OMW-L. The spray-dried lecithin powders with a higher loading of OMW-polyphenols were incorporated into powder cake premix formulations, substituting 1% and 3% of wheat flour. Rheological analyses revealed a significant decrease in the cake batter’s K value, indicating alterations in batter consistency. Compared to the cake samples produced with blank lecithin powders, the enrichment of lecithin with OMW exhibited a significant influence on the moisture content and water activity of the cakes. Notably, the addition of OMW-L powders at a concentration of 3% induced noticeable changes in crust and crumb color. The differences in hardness value could be attributed to the higher lecithin content of the product. As a result, the addition of spray-dried OMW-L powder at a concentration of 3% to the powder cake premix positively affected the final product properties. The results of this study promise innovative and sustainable approaches to utilizing OMW phenolics in various food products.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

F. Sciubba, L. Chronopoulou, D. Pizzichini, V. Lionetti, C. Fontana, R. Aromolo, S. Socciarelli, L. Gambelli, B. Bartolacci, E. Finotti, A. Benedetti, A. Miccheli, U. Neri, C. Palocci, D. Bellincampi, Biology (Basel) 9, 1 (2020)

R. Halko, I. Hagarová, V. Andruch, J. Chromatogr. A 1701, 464053 (2023)

A.S. Yazdi, TrAC - Trends Anal. Chem. 30, 918 (2011)

A. Alibade, G. Batra, E. Bozinou, C. Salakidou, S. Lalas, Chem. Pap. 74, 4517 (2020)

A. Karadag, S. Kayacan Cakmakoglu, R. Metin Yildirim, S. Karasu, E. Avci, H. Ozer, O. Sagdic, J. Food Process. Preserv. (2022). https://doi.org/10.1111/jfpp.16645

V. Athanasiadis, A. Voulgaris, K. Katsoulis, S.I. Lalas, I.G. Roussis, O. Gortzi, Foods 12, 497 (2023)

I. Giovanoudis, V. Athanasiadis, T. Chatzimitakos, D. Kalompatsios, E. Bozinou, O. Gortzi, G. Nanos, S. Lalas, Biomass 3, 291 (2023)

J. Fernández-Bolaños, G. Rodríguez, R. Rodríguez, R. Guillén, A. Jiménez, Grasas Aceites 7, 95 (2006)

K.B. Petrotos, F.K. Karkanta, P.E. Gkoutsidis, I. Giavasis, K.N. Papatheodorou, A.C. Ntontos, World Acad. Sci. Eng. Technol. 64, 867 (2012)

C.M. Galanakis, E. Tornberg, V. Gekas, J. Food Eng. 99, 190 (2010)

N. Solomakou, A.M. Goula, Rev. Environ. Sci. Biotechnol. 20, 839 (2021)

S.P. Cauvain, Baking Problems Solved, 2nd edn. (Woodhead Publishing, Sawston, 2017)

O. Gortzi, S. Lalas, A. Chatzilazarou, E. Katsoyannos, S. Papaconstandinou, E. Dourtoglou, JAOCS: J. Am. Oil Chem. Soc. 85, 133 (2008)

A. Chatzilazarou, E. Katsoyannos, O. Gortzi, S. Lalas, Y. Paraskevopoulos, E. Dourtoglou, J. Tsaknis, J. Air Waste Manage. Assoc. 60, 454 (2010)

E. Katsoyannos, O. Gortzi, A. Chatzilazarou, V. Athanasiadis, J. Tsaknis, S. Lalas, J. Sep. Sci. 35, 2665 (2012)

C. Sun, W. Liu, P. Zhao, Sep. Sci. Technol. (Philadelphia) 49, 2921 (2014)

A. El-Abbassi, H. Kiai, J. Raiti, A. Hafidi, J. Environ. Chem. Eng. 2, 1480 (2014)

H. Kiai, J. Raiti, A. El-Abbassi, A. Hafidi, J. Environ. Chem. Eng. 6, 1569 (2018)

A.C. Leite, A.M. Ferreira, E.S. Morais, I. Khan, M.G. Freire, J.A.P. Coutinho, ACS Sustain. Chem. Eng. 6, 590 (2018)

M. Mohammadzadeh, M. Honarvar, A.R. Zarei, M.M.A. Boojar, H. Bakhoda, J. Food Sci. Technol. 55, 1215 (2018)

O. Saroglu, B. Atalı, R.M. Yıldırım, A. Karadag, J. Food Meas. Charact. 16, 4402 (2022)

A. Karadag, B. Özçelik, M. Sramek, M. Gibis, R. Kohlus, J. Weiss, J. Food Sci. (2013). https://doi.org/10.1111/1750-3841.12023

V.L. Singleton, J.A. Rossi, Am. J. Enol. Vitic. 16, 144 (1965)

O. Saroglu, B. Tav, R.M. Yildirim, A. Karadag, Food Funct. 14, 3746 (2023)

H. Pehlivanoglu, G. Ozulku, R.M. Yildirim, M. Demirci, O.S. Toker, O. Sagdic, J. Food Process. Preserv. 42, e13621 (2018)

A. Akcicek, S. Karasu, F. Bozkurt, S. Kayacan, ACS Omega 7, 26316 (2022)

B.R. Bhandari, N. Datta, T. Howes, Drying Technol. 15, 671 (1997)

I. Tontul, A. Topuz, Trends Food Sci. Technol. 63, 91 (2017)

M. Nuzzo, A. Millqvist-Fureby, J. Sloth, B. Bergenstahl, Drying Technol. 33, 757 (2015)

Z. Akbarbaglu, S.H. Peighambardoust, K. Sarabandi, S.M. Jafari, Food Chem 359, 129965 (2021)

R. González-Ortega, M. Faieta, C.D. Di Mattia, L. Valbonetti, P. Pittia, J Food Eng 285, 110089 (2020)

K. Sarabandi, S.M. Jafari, A.S. Mahoonak, A. Mohammadi, Int. J. Biol. Macromol. 140, 59 (2019)

J.M. Whittinghill, J. Norton, A. Proctor, JAOCS: J. Am. Oil Chem. Soc. 76, 1393 (1999)

E. Sritham, S. Gunasekaran, Food Hydrocoll 70, 371 (2017)

Y. Zhang, C. Pu, W. Tang, S. Wang, Q. Sun, J. Food Eng. 282, 110008 (2020)

E. Turabi, G. Sumnu, S. Sahin, Food Hydrocoll. 22, 305 (2008)

V. Psimouli, V. Oreopoulou, J. Sci. Food Agric. 92, 99 (2012)

A.K.S. Chesterton, D.A.P. De Abreu, G.D. Moggridge, P.A. Sadd, D.I. Wilson, Food Bioprod. Process. 91, 192 (2013)

S.M. Lakshminarayan, V. Rathinam, L. KrishnaRau, J. Sci. Food Agric. 86, 706 (2006)

H.Y.L. Kim, H.W. Yeom, H.S. Lim, S.T. Lim, Cereal. Chem. 78, 267 (2001)

S. Hedayati, M.M. Tehrani, Food Sci. Nutr. 6, 1154 (2018)

Z. Saghafi, M.H. Naeli, M. Bahmaei, M. Tabibiazar, A. Zargaraan, J. Food Meas. Charact. 13, 3040 (2019)

N. Hesso, C. Garnier, C. Loisel, S. Chevallier, B. Bouchet, A. Le-Bail, Food Struct. 5, 31 (2015)

T. Sanz, A. Salvador, G. Vélez, J. Muñoz, S.M. Fiszman, Food Hydrocoll. 19, 869 (2005)

T.J. Silva, P. Ramírez-Carrasco, P. Romero-Hasler, E. Soto-Bustamante, D. Barrera-Arellano, P. Robert, B. Giménez, Food Chem. 379, 132182 (2022)

K.B. Jeddou, F. Bouaziz, S. Zouari-Ellouzi, F. Chaari, S. Ellouz-Chaabouni, R. Ellouz-Ghorbel, O. Nouri-Ellouz, Food Chem. 217, 668 (2017)

V. Psimouli, V. Oreopoulou, J. Food Sci. 78, C1495 (2013)

Acknowledgements

This study was supported by the project of TAGEM-20/AR-GE/06 of General Directorate of Agricultural Research and Policies-Republic of Turkiye Ministry of Agriculture and Forestry.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Ayse Karadag: conceptualization, methodology, writing—original draft preparation, writing-review and editing. Selma Kayacan Cakmakoglu: data curation, formal analysis and investigation, validation. Hatice Bekiroglu: data curation, formal analysis and investigation, validation. Salih Karasu: conceptualization, methodology, writing—original draft preparation. Hayrettin Ozer: data curation, formal analysis and investigation, validation. Osman Sagdic: conceptualization, methodology, writing-review and editing. Rusen Metin Yildirim: conceptualization, methodology, writing—original draft preparation, writing-review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Karadag, A., Cakmakoglu, S.K., Bekiroglu, H. et al. Innovative utilization of olive mill wastewater phenolics extracted by lecithin: spray-dried powders in cake formulations. Food Measure (2024). https://doi.org/10.1007/s11694-024-02780-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11694-024-02780-8