Abstract

Cheese is one of the most popular and extensively consumed dairy products. It comes in a variety of flavors, textures, shapes and is prone to infection and decomposition. Edible coatings as cheese packaging serve various key functions in the preservation and enhancement of cheese quality, including increasing shelf life, retaining texture, boosting sensory qualities, and lowering plastic waste and environmental impact. In recent decades, the development of edible coatings has witnessed tremendous growth, and it is projected to have a significant impact on the quality of cheese products in the next few years. Novel edible materials and processing methods are of great interest due to their intriguing potential as revolutionary cheese packaging systems. This review summarizes recent trends in adding edible coating to increase the quality and the shelf-life of cheese, plus the functional of edible coating and their application on cheese to reduce the plastic waste and environmental impact.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cheese is a popular dairy product that is consumed all around the world, and it is largely recognized as a healthy food, which has contributed to its widening public popularity. The nutritional composition of cheese varies by type, but in general, cheese is high in fat, mineral, and protein content, both of which have been linked to biological activities such as antihypertensive, antioxidant, and anti-inflammatory properties [1]. Cheese consumption is widespread around the world and varies depending on the region and culture. Cheese, also as a nutrient-dense dairy item, is prone to contamination and spoilage [2].

Numerous microorganisms such as (bacteria, yeasts, molds, virus, and parasites) from several sources can contaminate food during production, processing, and storage. The main bacteria correlated with spoilage are (Carnobacterium spp., Lactobacillus spp., Lactococcus spp., Brochothrix thermosphacta, Leuconostoc spp., Stretococcus spp., Weisella spp, Pediococcus spp., and Kurthia zopfii,). The primary cause of contamination in cheese is thought to be raw milk. Furthermore, if dairy workers do not practice proper hygiene, bacteria might be transferred to cheese [3]. Environmental sources, such as air, water, and soil, are major causes of cheese contamination. Moreover, microorganisms could be transferred to cheese during manufacture and storage from food contact surfaces such as equipment, utensils, and packaging materials [4]. The growth of bacteria and other microorganisms” on the cheese surface can cause rapid contamination. Because of the suitable acidity conditions and suitable water activity, the surfaces of cheeses are more susceptible to being contaminated by microorganisms [5].

Cheese packaging, like other areas of the food business, has become an important aspect of cheese production, distribution, and retailing. It is critical to consider elements such as the type of cheese, shelf life requirements, storage circumstances, consumer preferences, and regulatory constraints [6]. Furthermore, establishing effective and successful cheese packaging solutions requires balancing functionality, food safety, branding, and sustainability issues. Nowadays, edible packaging for cheese is a novel concept that involves wrapping or coating cheese products with appetizing components [7]. Edible packaging, as opposed to traditional packaging materials such as plastic or paper, provides a more sustainable and potentially environmentally benign option. As research and development continue, we may expect to see more breakthroughs and the adoption of edible packaging in the cheese sector [8,9,10,11,12,13,14,15].

Nanotechnology in food packaging has demonstrated a significant promise for improving packaging material qualities, where the control of materials properties at nanosized scale will allow explore new functionalities. The use of nanocomposites antimicrobial packaging systems results in strong interfacial contacts between polymer bonds and nanofillers, considerably increasing bionanocomposites properties such as mechanical, barrier, thermal, and antibacterial capabilities [16]. Nanotechnology and edible coatings have shown great potential for improving the packaging of cheese [17], edible coatings combined with nanomaterial have been developed to address this issue and improve the shelf life of cheese by inhibiting bacterial growth and spoilage. Bacteria, such as Gram-positive or Gram-negative bacteria, can grow on the surface of cheese and cause spoilage, which can lead to changes in the texture, flavor, and overall quality of the cheese [18]. These coatings form a barrier between the cheese and its surrounding environment as shown in (Fig. 1), preventing contamination and preserving the cheese’s quality.

Materials like lysozyme, chitosan, and other additives are utilized in the formulation of these coatings to improve their antibacterial qualities and protect the cheese’s quality [19]. Other components that can be used in cheese edible coatings include liquid acid whey protein concentrate, apple pectin, sunflower oil, glycerol, sodium caseinate, plant extracts, and essential oils. These materials contribute to the preservation and quality improvement of cheese [20]. The present review discusses the concept and possibilities of contemporary scientific findings on edible coatings for cheese, including their edible materials, different additives, characteristics, processing techniques, functional properties, and recent application for various types of cheese.

Cheese history, production and consumption

Cheese production dates back to the earliest civilizations, such as Sumer and Egypt, and was well established in classical Rome. Cheese production moved throughout Europe and the Middle East, then to North and South America, and lastly to Oceania, where it evolved into at least 1000 types. Until the mid-nineteenth century, cheese production was a farm-based activity, and much cheese is still manufactured at an artisanal level. However, the major types are now produced in very large, highly mechanized plants using cutting-edge technology. Cheese is the generic term for a variety of fermented milk-based food products made all over the world in a wide range of flavors, textures, and forms. According to Sandine and Elliker [21], there are about 1,000 different types of cheese. Burkhalter [22] identified 510 types, while Harbutt [23] provides images and descriptions of over 750 varieties. Walter and Hargrove [24] characterized roughly 400 varieties and recorded the names of another 400. Cheese output worldwide is ~ 19 × 106 tonnes a year (35% of total milk production) and has increased at an annual rate of 4% on average over the last 30 years. Europe is the greatest producing block, with an annual production of ~ 11 × 106 tonnes [25]. Cheese consumption in most nations has steadily increased over many years; cheese, along with fermented milks, is the primary growth product in the dairy sector.

The history and the purposes of packaging of cheeses

Throughout the years, cheese packaging has evolved to match improvements in materials, technology, and consumer needs, with the ultimate goal of preserving the quality and freshness of cheese while guaranteeing its safe transportation and accessibility. Cheese was frequently preserved and carried in ancient times in simple vessels made of materials such as leaves or woven baskets. Cheese, for example, was extensively preserved in ancient Rome in clay pots or wooden barrels. Cheese manufacturing and distribution were increasingly organized during the Middle Ages, and specialized cheese-making regions arose. Cheese makers began wrapping their cheeses in cloth to allow longer trips and increase sanitation. Cloth was still used for cheese wrapping throughout the nineteenth century, especially for aged and hard cheeses [26]. The discovery of the tin can and the introduction of wax-coated paper revolutionized cheese packaging in the late nineteenth and early twentieth centuries. These materials provided improved spoilage protection, a longer shelf life, and easier distribution over longer distances [27]. With the rise of plastics in the mid-twentieth century, cheese packaging underwent more changes. Because of their flexibility, transparency, and ability to form an airtight seal, plastic films and wraps became widely employed. Cheese packaging now comes in a variety of shapes and sizes to accommodate varied cheese kinds and consumer preferences. Furthermore, in recent years, sustainable packaging has become an increasing concern. Cheese manufacturers and customers are increasingly choosing environmentally friendly materials and packaging designs that reduce waste and environmental impact [28]. Cheese packaging plays several important roles in ensuring the quality, safety, and preservation of the cheese [29]. So, the main purposes of packaging cheeses are summarized as follows:

Extended Shelf Life

Cheese packaging can extend its shelf life by creating an optimal storage environment, reducing spoilage growth, and preventing flavor deterioration. Modified atmospheric packaging (MAP) is one of the technologies that helps preserve the freshness, flavor, and texture of cheese by serving as a barrier against pollutants, moisture, light, and oxygen [30]. MAP inhibits microbial growth and delays spoilage by modifying the air inside the package. Many bacterially-ripened cheeses are packaged in low gas permeability plastic bags or coated with film-forming material. These packaging materials act as a barrier against moisture, oxygen, light, and contaminants, preserving the cheese’s freshness, flavor, and texture [31, 32].

[Cheese packaging plays a role in addressing sustainability concerns. Manufacturers are increasingly exploring eco-friendly packaging options, such as recyclable materials, biodegradable films, or reduced packaging waste [33, 34]. Moreover, packaging design and branding play a significant role in differentiating cheese products on the market. Unique and visually appealing packaging can help attract consumer attention, create brand recognition, and convey the product’s quality. Packaging can contribute to the overall brand image and influence consumer purchasing decisions [35]. Packaging is essential for cheese, providing essential information like type, brand, origin, nutritional content, ingredients, allergen warnings, and storage instructions. It ensures compliance with regulations, protects cheese during transportation, and provides convenience through features like easy-open seals or user-friendly formats [36].

The main factors for selecting cheese packaging materials

When picking the perfect choice for cheese packaging materials, several factors come into play. By understanding preservation techniques, shelf life, and sustainability concerns, Packaging solutions that help extend shelf life, such as vacuum sealing or active packaging with antimicrobial agents, can be beneficial in reducing waste and ensuring your product remains fresh for consumers. Cheese should be stored at the appropriate temperature to prevent spoilage and maintain its quality. Insulated packaging materials or those that can withstand refrigeration or freezing were crucial for temperature-sensitive cheese [37]. Packaging materials that help regulate humidity are essential to prevent cheese from drying out or becoming too moist. Different cheese types require varying levels of airflow. While some cheeses benefit from limited airflow (e.g., soft cheeses), others may need a more breathable packaging material (e.g., blue cheeses). Choose materials that provide the right balance of airflow for your specific cheese type. It’s essential to consider the sustainability of your cheese packaging materials. Opt for eco-friendly options like biodegradable films, recyclable materials, or reusable containers to minimize your environmental impact and appeal to eco-conscious consumers [38]. The type of cheese and its specific characteristics play a vital role in determining the most suitable packaging materials (Table 1).

Common methods of applying edible coatings to cheeses

It’s imperative to consider the specific requirements of each cheese type and consult with experts or cheese technologists to determine the most suitable coating solutions [39]. Factors such as the type and size of the cheese, the desired ageing process, the favorite coating thickness, moisture control, and expected appearance can influence the choice of coating solution for a particular cheese type.

Dip coating is a straight-forward method where the food product is submerged in the coating solution for a specific amount of time. The coating solution adheres to the surface of the product, and excess solution is allowed to drain off, resulting in a thin coating on its surface. The cheese is then removed and allowed to drain, forming a thin coating on its surface. This method is often used for smaller cheeses or individual portions [39]. Also, rolling is a technique used for applying dry coatings, such as herbs, spices, or powdered ingredients. The cheese is rolled in the desired coating, ensuring adherence on the surface. Roll coating involves the food product being rolled or tumbled in a coating material. The coating material is often contained in a drum or on a conveyor belt with an adjustable speed. As the food product passes through, the coating adheres to its surface. Moreover, brush coating involves manually applying the coating solution on the cheese’s surface using a brush, sponge, or pastry brush. It allows for more control over the thickness and distribution of the coating process, making it suitable for smaller or delicate items.

Furthermore, spray coating is a versatile method that allows for precise application of the coating solution. It is commonly used in industrial settings, where the cheese product is passed through a conveyor system while a spray system delivers a fine mist of the coating solution. Spray coating ensures uniform coverage and can be adjusted for different coating thicknesses [40]. Correspondingly, vacuum infusion is a technique used to enhance the penetration of the coating solution into the cheese’s surface, resulting in a more uniform and thorough coating [41]. By subjecting the product to reduced pressure in a vacuum chamber, the coating solution is drawn into the food’s surface more effectively. Vacuum infusion is particularly useful for porous or absorbent food items. Similarly, laminating involves applying an edible film or wrap on the food product’s surface. The film adheres to the product, providing a protective barrier and enhancing its shelf life. Laminating is commonly used for items like cheese, where the film helps maintain its freshness and prevents drying out [2]. Also, enrobing involves fully coating a food product by passing it through a curtain or waterfall of the coating material. The product moves on a conveyor belt while the coating material is continuously poured or sprayed over it.

Edible coating materials that are commonly used on cheese

Edible coatings can be formulated using a wide range of edible materials derived from natural and synthetic polymers. The specific choice of film-forming agents depends on factors such as the cheese type, desired properties of the coating (e.g., flexibility, adhesion, barrier properties), and regulatory considerations. The choice between natural and synthetic polymers may be influenced by factors such as availability, cost, compatibility with the food matrix, and consumer preferences for natural ingredients. Different manufacturers or cheese producers may have their preferred coating materials or formulations based on their specific requirements and processes [42]. These are some of the most commonly utilized natural and synthetic polymer ingredients in the development of edible coatings.

Natural polymers

Proteins

Proteins derived from plant sources (such as soy protein, wheat gluten, or pea protein) or animal sources (such as gelatin, whey protein, or casein) can be used as film-forming agents in edible coatings [43]. These coatings provide a protective film that helps retain moisture, prevent oxidation, improve structural integrity, film-forming ability, barrier properties, and improve the cheese’s appearance. Protein-based coatings are commonly used on a variety of cheese types [44]. Soy protein is derived from soybeans and is widely used in the food industry. Soy protein isolates or concentrates contain a good balance of essential amino acids and have functional properties suitable for film formation [45]. Wheat gluten is a protein complex extracted from wheat. It consists of glutenin and gliadin proteins and is mainly used in baking applications. However, wheat gluten can also be employed as a film-forming agent in edible coatings due to its ability to form a cohesive and elastic film [46]. Pea protein is obtained from yellow peas and has gained popularity as a plant-based protein source. It has high protein content and provides a good amino acid profile. Pea protein isolates or concentrates can be used, and contributing to their barrier properties and film stability [47]. Zein is a natural protein derived from corn. It forms clear, glossy films and is commonly used as a film-forming agent in edible coatings. Zein films have good adhesion properties and can provide a protective barrier for various food products [48].

Gelatin is a protein obtained from collagen, commonly sourced from animal bones and connective tissues. It forms transparent and flexible films. Gelatin films have good adhesion and can contribute to the desired texture of the coated product [49]. Whey protein is a by-product of cheese production and is known for its excellent nutritional profile. It contains a mixture of proteins, with beta-lactoglobulin and alpha-lactalbumin being the major components. Whey protein isolates or concentrates can be used to form edible coatings [50]. Casein is the primary protein found in milk, accounting for about 80% of total milk proteins. It is available in different forms, such as sodium caseinate or calcium caseinate and used as film-forming agent in active edible coating [51].

Polysaccharides

Polysaccharides obtained from sources like cellulose derivatives (methylcellulose, ethyl-cellulose), starch, pectin, alginate, or chitosan are widely used in edible coatings. They can form films or coatings with good water vapor barrier properties and have the ability to improve the mechanical strength and stability of the coatings. Cellulose derivatives, such as methylcellulose or ethyl-cellulose, are used as edible coatings to provide a protective barrier and control moisture migration in cheese. These coatings help maintain the desired texture and prevent surface cracking, cellulose derivatives are commonly used on soft and semi-soft cheeses like Brie, Camembert, or Blue cheese [52]. Gum Arabic is a natural polysaccharide derived from the sap of Acacia trees [53]. It forms clear and glossy films and is widely used as a film-forming agent in various food applications, including edible coatings. Gum Arabic provides good adhesion and barrier properties [54]. Carrageenan is a natural polysaccharide extracted from red seaweed [55]. It has excellent gel-forming properties and can be used as a film-forming agent in edible coatings.

Carrageenan films have good moisture retention capabilities and can provide a smooth and uniform coating [56]. Agar is a natural polysaccharide derived from red algae. It forms gel-like films and can be used as a film-forming agent in edible coatings. Agar films have good water-holding capacity and can provide a protective barrier for the coated food [57]. Pectin is a natural polysaccharide found in fruits, particularly in the peels and cell walls. It can be used as a film-forming agent in edible coatings; pectin films have good water vapor barrier properties and can contribute to the preservation of food quality [58]. Alginate is a natural polysaccharide extracted from brown seaweed and is often used as an edible coating material for cheese. It forms a gel-like film that provides a protective barrier against moisture loss and microbial growth. Alginate coatings can be used on various cheese types [59]. Chitosan is a natural polymer derived from chitin, which is found in the exoskeleton of crustaceans. It has antimicrobial properties and can be used as an edible coating material to inhibit microbial growth on cheese surfaces. Chitosan coatings are typically used in combination with other materials and are suitable for various cheese types [60].

Lipid-based Coatings

Edible lipid-based coatings, oil-based emulsions, edible oils, such as vegetable oils or mineral oils, or natural waxes, such as beeswax, carnauba wax, and shellac, are commonly used as edible coatings for cheese. Shellac is a natural resin derived from the lac beetle; beeswax is a natural wax produced by bees; and carnauba wax is a natural wax obtained from the leaves of the carnauba palm tree [61]. These coatings provide a protective barrier against moisture loss, maintain texture, enhance the flexibility of the coating, and prevent unwanted microbial contamination. They also give the cheese a glossy appearance. Waxes are often used on hard and semi-hard cheeses like Gouda, Cheddar, or Parmesan to coat cheese surfaces [62].

Synthetic polymers

Polyvinyl alcohol (PVA) is a synthetic polymer that forms transparent and flexible films [63]. Polyethylene glycol (PEG) is a synthetic polymer that can form films with good mechanical properties [64]. Polyvinyl pyrrolidone (PVP) is a synthetic polymer with film-forming properties. It is soluble in water and can form clear films, making it suitable for certain food coating applications. Synthetic polyesters, such as poly (lactic acid) (PLA) or polyhydroxy butyrate (PHB), can be used as film-forming agents, and they offer good barrier properties [65].

Composite materials

Composite edible coatings can be created by combining different polymers, synthetic or natural polymers to achieve specific properties. For example, a blend of polyvinyl alcohol, polysaccharides or proteins can lead to improved film-forming ability and mechanical strength [17, 66].

Drawbacks of the protein, polysaccharides and lipid based packaging

Protein, polysaccharide, and lipid-based packaging materials offer various advantages; they also have some drawbacks as the following.

Protein-based packaging drawbacks

Protein-based films or coatings may have lower barrier properties compared to synthetic packaging materials. They may allow oxygen or moisture transfer, which can lead to quality deterioration of the cheese over time. Correspondingly, protein-based materials can be sensitive to environmental factors such as temperature and humidity. High humidity can cause proteins to absorb moisture and become less effective as barrier materials. Moreover, some individuals may have allergies or sensitivities to certain proteins, and the presence of protein-based packaging materials can trigger allergic reactions in susceptible individuals [67].

Polysaccharide-based packaging drawbacks

Polysaccharide-based films or coatings can be sensitive to moisture, leading to changes in their structure and barrier properties. This sensitivity can affect their effectiveness in preserving the quality of the cheese. Also, Polysaccharide films may have lower mechanical strength compared to synthetic polymers. They can be more prone to tearing or puncturing, which can compromise the integrity of the packaging and the protection it provides. As well, polysaccharides often require specific processing conditions and additives to form films or coatings with desired properties. These processing challenges can increase the complexity and cost of production [68].

Lipid-based packaging drawbacks

Lipid-based materials, such as edible lipids or lipid coatings, can be prone to oxidation when exposed to oxygen. This can lead to off-flavors and rancidity in the cheese. Besides, lipid-based films or coatings may have lower mechanical strength compared to synthetic packaging materials. They may be more susceptible to damage or punctures during handling and transportation. Furthermore, lipid-based materials can have melting points close to room temperature, making them sensitive to temperature variations. High temperatures can cause the packaging to soften or melt, compromising its barrier properties [69]. However, many of these disadvantages are overcome by composite type of edible packaging, blending, and layered structures materials.

Mold cultures

For soft cheeses, such as Brie, Camembert, or Blue cheese, one of the most commonly used edible coating materials is mold cultures. These cultures consist of specific strains of Penicillium or other mold species that are intentionally applied to the surface of the cheese. The mold grows and forms a natural, edible rind on the cheese, contributing to its characteristic flavor, texture, and appearance. The mold cultures help protect the cheese, control moisture levels, and add unique sensory qualities. This natural rind formation is an integral part of the production process for many soft cheeses [70].

Additives of edible coatings used for cheese products applications

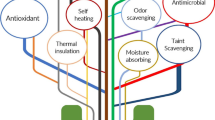

Edible coatings for various cheese products can be formulated using a variety of additives to enhance their functionality and performance. These additives serve different purposes and contribute to the overall properties of the edible coating. There are some common additives used in edible coatings for cheese as shown in (Fig. 1). These additives help inhibit the growth of spoilage-causing microorganisms and extend the shelf life of the cheese. Natural antimicrobial agents like essential oils (such as oregano or thyme oil), plant extracts (such as rosella or garlic), organic acids (such as lactic acid or acetic acid), and bacteriocins (such as nisin) [71].

Metal NPs as synthetic antimicrobial agents (such as TiO2, ZnO, SiO2, and CuO nanoparticles) can be incorporated into the edible coating [72]. Antioxidants are used to delay or prevent the oxidation of fats and oils in cheese, thereby helping to maintain the quality and flavor of the product. Common antioxidants include vitamin E, ascorbic acid (vitamin C), and rosemary extracts [72]. Plasticizers are used to improve the flexibility and pliability of the edible coating [74]. They help prevent cracking or brittleness and enhance the adherence of the coating to the cheese surface. Common plasticizers include glycerol, sorbitol, and polyethylene glycol [76].

Colorants can be added to the edible coating to enhance the visual appeal of the cheese. Natural colorants like beetroot extract, turmeric, or spirulina can be used to impart desired colors to the coating [77]. Flavor enhancers can be incorporated into the edible coating to improve or complement the taste of the cheese. Examples include natural flavor extracts, herbs, spices, essential oils or cheese-specific ingredients like cheese cultures or cheese flavors [78]. Also, pH adjusters are used to maintain the desired pH level of the edible coating, which can influence its stability and functionality. Acids or bases are added as needed to achieve the desired pH range. Common pH adjusters include citric acid, acetic acid, or sodium bicarbonate [79]. Texture modifiers can be added to the edible coating to impart specific textural attributes or control the texture of the coating. Examples include gums (such as xanthan gum or guar gum) or modified starches.

Quality parameters of the edible coating

The characterization of edible coatings involves assessing various properties to evaluate their performance and suitability for specific applications [80].

Edible coatings analysis

Edible coatings should provide an effective barrier against moisture, oxygen, and other gases to protect the coated product from quality deterioration. Techniques like water vapor transmission rate (WVTR) measurements and oxygen permeability testing can be employed to assess the barrier properties of the coating [81]. The edible coatings may possess antimicrobial properties to inhibit the growth of spoilage or pathogenic microorganisms. Testing methods, such as (microbial enumeration, mechanical attributes, thermal stability and surface morphology) were used for evaluating the edible coatings. The microbial enumeration can be employed to assess the antimicrobial activity or effectiveness of the coating [82]. As well, the edible coating’s durability against handling, deformation, and stress during storage and transportation are also determined by its mechanical attributes, such as tensile strength, flexibility, and elasticity. These attributes can be measured using devices such as a universal testing machine or a texture analyzer. Furthermore, the thermal properties of the edible coating, including glass transition temperature (Tg) and thermal stability, influence its behavior during storage, processing, and application. Differential scanning calorimetric (DSC) or thermogravimetric analysis (TGA) can be employed to characterize the thermal properties of the coating. Moreover, the surface morphology of the edible coating influences its appearance, adherence to the substrate, and interaction with the coated product. Scanning electron microscopy (SEM) or atomic force microscopy (AFM) can be used to visualize and analyze the surface structure and roughness of the coating. The water solubility or water absorption characteristics of the edible coating affect its stability and performance in different food environments [83]. These properties can be evaluated by measuring the weight change of the coating after exposure to water or by conducting a water solubility test. Correspondingly, the optical properties of the edible coating, such as transparency, gloss, and color, contribute to the visual appeal of the coated product. These properties can be assessed using colorimeters, spectrophotometers, or visual inspection [84].

Functions of edible coatings on the cheese

Edible coatings are thin layers of edible materials that are applied to the surface of food products, including cheese, to provide various benefits such as extending shelf life, improving texture, enhancing appearance, and preventing microbial spoilage [85]. The employing edible coatings on cheese involve several key functions:

Barrier function

One of the primary functions of edible coatings on cheese is to create a barrier between the cheese and its surrounding environment. This barrier helps to reduce moisture loss, control gas exchange, and prevent the transfer of contaminants. The coating acts as a physical barrier, preventing the entry of oxygen, moisture, and other gases that can cause spoilage and affect the quality of the cheese [2].

Moisture control

Edible coatings can help regulate the moisture content in cheese by reducing moisture loss or absorbing excess moisture. This is particularly important for certain types of cheese that are prone to drying out or becoming too moist. The coating material can act as a moisture barrier, slowing down moisture migration between the cheese and the environment [86].

Microbial Protection

Edible coatings can provide a protective layer that inhibits the growth of spoilage microorganisms and extends the shelf life of cheese. Some coating materials have antimicrobial properties or can release antimicrobial compounds, such as essential oils, that can inhibit the growth of bacteria, yeasts, and molds [87].

Texture improvement

Coatings can enhance the texture and mouth-feel of cheese by reducing surface moisture and preventing the formation of undesirable textures, such as the development of a dry or tough rind. Coatings can also help maintain the desired moisture content, preventing excessive softening or hardness of the cheese [88].

Appearance enhancement

Edible coatings can improve the appearance of cheese by providing a glossy or matte finish and enhancing its visual appeal. Coatings can also help retain the natural color of cheeses or provide a decorative effect by incorporating colorants or other additives [89]. The specific mechanism of edible coatings on cheese may vary depending on the composition of the coating material, the type of cheese, and the desired objectives. Different coating materials, such as edible waxes, lipids, proteins, polysaccharides, or composite materials, may be used to achieve the desired effects. The coatings are typically applied by spraying, dipping, or brushing onto the surface of the cheese, and they can be formulated to be easily removed before consumption or consumed along with the cheese, depending on the intended.

Edible coatings for cheese can provide various functional properties that help enhance the quality and shelf life of the product as revealed in (Fig. 2). It’s important to note that the specific functional properties of edible coatings may vary depending on the application method, and formulation used. Some of the functional properties of edible coatings for cheese include permeability, mechanical and antibacterial properties [17]. By providing moisture and oxygen barriers, edible coatings can help extend the shelf life of cheese by reducing spoilage and maintaining its quality for a longer duration. Edible coatings can help inhibit the growth of molds on the surface of cheese. By acting as a physical barrier, they provide protection against mold spores and reduce the risk of mold-related spoilage [90]. This is especially important for cheeses that are prone to mold development.

Edible coatings can act as a barrier to moisture transfer, helping to prevent moisture loss from the cheese and maintain its desired moisture content. Moreover, edible coatings can help control the texture of cheese by reducing surface moisture and preventing the formation of undesirable crusts or rinds [17]. This property is essential in preventing the cheese from drying out and becoming tough or crumbly and its beneficial for certain types of cheeses that require specific textures, such as soft or semi-soft cheeses. Edible coatings can also act as a barrier to oxygen, reducing oxygen exposure to the cheese. This property is crucial in protecting the cheese from oxidation, which can lead to flavor deterioration and quality loss. Edible coatings can create a physical barrier that helps inhibit the growth of spoilage-causing microorganisms and extends the shelf life of the cheese. It can reduce the risk of contamination and maintain the cheese’s freshness and safety [91].

Edible coatings can improve the appearance of cheese by providing a glossy or matte finish, enhancing its visual appeal and marketability by adding colors, patterns, or designs. This can be particularly useful for special occasions or for creating unique branding and presentation options [92]. Edible coatings can help retain the flavor of the cheese by preventing the loss of volatile compounds during storage by creating a protective barrier that minimizes the loss of these compounds responsible for the cheese’s distinctive smell. This property ensures that the cheese maintains its characteristic taste and aroma throughout its shelf life [93]. Edible coatings can be formulated with specific ingredients, such as antimicrobials, antioxidants, probiotic bacteria or flavor enhancers, to meet specific product requirements. This allows for customization based on the desired properties of the cheese [94].

Edible coatings can serve as an eco-friendly packaging alternative to traditional plastic wraps or films. They can contribute to reducing plastic waste and environmental impact, as they are typically biodegradable and can be consumed along with the cheese [95]. Edible coatings can provide convenience to consumers by eliminating the need to remove or peel off additional packaging materials before consuming the cheese. They offer a ready-to-eat presentation with minimal preparation required [96].

The applications of edible coating on different types of cheeses

Edible packaging fulfills two functions by being both functional and edible. It can increase the shelf life and quality of cheese while remaining safe to consume. The creation of edible cheese packaging corresponds with the increased demand for sustainable packaging solutions as well as the goal to reduce plastic waste. Biopolymers produced from natural sources, such as plant starches, proteins, lipids, polysaccharides, or composite materials, are frequently utilized in edible packaging. These materials can be produced into films or coatings that provide critical barrier features like moisture and oxygen resistance to protect the cheese from rotting and keep it fresh. Table 2 summarized some recent various applications of edible coatings for cheese, including their composition, functions properties, and applications.

Conclusion and future prospects of edible coating for cheese

Edible coatings on cheese offer several benefits. They can prevent moisture loss, which helps to maintain the cheese’s moisture content and prevent it from drying out. These coatings also act as a barrier to oxygen, reducing the risk of oxidation and off-flavor development. Additionally, edible coatings can provide a protective shield against microbial contamination, thereby enhancing the safety and extending the shelf life of cheese. Furthermore, edible coatings can contribute to the sensory attributes of cheese. They can improve the cheese’s appearance by providing a glossy or matte finish and enhancing its visual appeal. Edible coatings can also help to control moisture migration, maintain the desired texture, and prevent texture defects such as surface cracking or hardness. Research and development in the field of edible coatings for cheese are ongoing, focusing on improving coating materials, application techniques, and functionality. Researchers are exploring the incorporation of antimicrobial agents or natural extracts into coatings to enhance cheese safety and quality. They are also investigating the use of edible coatings to enable the controlled release of flavors or additives, enhancing the taste experience for consumers. As research continues and technology advances, edible coatings hold the potential to further revolutionize the cheese industry, ensuring the availability of high-quality cheese with extended freshness and improved sustainability.

Various types of biopolymers may be utilized for shelf life extension of cheese while maintaining their quality attributes. There are many examples of biopolymers were used in cheese coating such as, (chitosan, Whey protein, Alginate, corn starch or potato starch, and Pullulan), these coatings can help maintain the moisture content of cheese and prevent the growth of spoilage microorganisms, thereby extending its shelf life by providing preserving quality.

There is significant research and development in the field of edible coatings for cheese, the practical implementation and widespread adoption of these technologies may take time. Factors such as regulatory considerations, cost-effectiveness, and scalability of production processes will also play a role in determining the future of edible coatings in the cheese industry. While edible coatings offer several benefits for cheese, there are also some challenges and future prospects associated with their use.

-

I.

The use of nanomaterials in food products should be tested carefully due to safety reasons [140] and their use in edible coatings for cheese applications should be further explored.

-

II.

Edible coatings may not be compatible with all types of cheese. Each cheese variety has its own unique characteristics, and finding the right coating that complements the cheese’s flavor, texture, and moisture content can be a challenge. The coating should not negatively impact the sensory attributes or alter the taste of the cheese.

-

III.

Despite the fact that edible coatings can help extend the shelf life of cheese by reducing moisture loss, they need to strike a delicate balance. If the coating is too impermeable, it can trap moisture within the cheese, leading to undesirable microbial growth and spoilage. On the other hand, if the coating is not effective enough, it may fail to provide sufficient moisture protection.

-

IV.

Applying edible coatings to cheese can be a complex process. Achieving uniform coverage and ensuring proper adhesion of the coating to the cheese surface can be challenging. The application method used must be carefully selected to ensure consistent and even coating distribution.

-

V.

Edible coatings need to comply with food safety regulations and be approved for use in cheese production. Compliance with regulatory requirements can pose challenges, especially when using novel or unconventional coating materials.

-

VI.

The acceptance of cheese with edible coatings can vary among consumers. Some individuals may find the presence of coatings unappealing or have concerns about the safety or taste of the coating material. Overcoming consumer perception and gaining acceptance for coated cheeses can be a hurdle.

-

VII.

Coated cheeses may need to comply with labeling regulations, including accurate and clear ingredient declaration. If the coating contains allergens or other substances of concern, appropriate labeling should be provided to inform consumers.

-

VIII.

Edible coatings are often considered food additives, and their use must comply with regulations and guidelines specific to food additives. These regulations typically define permitted coating materials, their maximum allowable concentrations, and any restrictions or specifications regarding their use.

-

IX.

Cheese manufacturers are expected to follow good manufacturing practices, which include maintaining proper hygiene, sanitation, and quality control measures during the production process. These practices help ensure the safety and quality of the coated cheese products.

References

K.F. Chai, A.Y.H. Voo, W.N. Chen, Bioactive peptides from food fermentation: a comprehensive review of their sources, bioactivities, applications, and future development. Compr. Rev. Food Sci. Food Saf. 19(6), 3825–3885 (2020)

A.I. Nájera, S. Nieto, L.J.R. Barron, M. Albisu, A review of the preservation of hard and semi-hard cheeses: quality and safety. Int. J. Environ. Res. Public Health. 18(18), 9789 (2021)

J. Owusu-Kwarteng, F. Akabanda, D. Agyei, L. Jespersen, Microbial safety of milk production and fermented dairy products in Africa. Microorganisms. 8(5), 752 (2020)

S.M. El-Sayed, H.S. El-Sayed, A.M. Youssef, Recent Developments in Encapsulation Techniques for Innovative and high-quality Dairy Products: Demands and Challenges (Bioactive Carbohydrates and Dietary Fibre, 2024), p. 100406

J. Proulx, G. Sullivan, L.F. Marostegan, Pulsed light and antimicrobial combination treatments for surface decontamination of cheese: favorable and antagonistic effects. J. Dairy Sci. 100, 1664–1673 (2017)

M.A. Farag, T.J. Ashaolu, H. Guirguis, I. Khalifa, (2023). Implementation of HACCP in the production of Egyptian cheeses: a review. eFood, 4 (2), e69

D. Daniloski, D. Gjorgjijoski, A. Trajkovska Petkoska, Advances in active packaging: perspectives in packaging of meat and dairy products. Adv. Mater. Lett. 11(5), 1–10 (2020)

S.S. Nair, J. Trafiałek, W. Kolanowski, Edible packaging: a Technological Update for the sustainable future of the Food Industry. Appl. Sci. 13(14), 8234 (2023)

M. Goswami, K. Mondal, V. Prasannavenkadesan, V. Bodana, V. Katiyar, Effect of guar gum-chitosan composites edible coating functionalized with essential oils on the postharvest shelf life of Khasi mandarin at ambient condition. Int. J. Biol. Macromol. 254, 127489 (2024)

M. Farahani, F. Shahidi, F.T. Yazdi, A. Ghaderi, Antimicrobial and antioxidant effects of an edible coating of Lepidium sativum seed mucilage and Satureja hortensis L. essential oil in uncooked lamb meat. Food Control. 158, 110240 (2024)

S.Z. Iqbal, A. Haider, F. ur Rehman, G. Cui, M. Waseem, M. Iqbal, A.M. Khaneghah, (2024). Application of carboxymethylcellulose in combination with essential oils nano-emulsions edible coating for the preservation of kiwifruit. Int. J. Biol. Macromol., 129947

A.A. Talesh, S. Amiri, M. Radi, M. Hosseinifarahi, (2024). Effect of nanocomposite alginate-based edible coatings containing thymol-nanoemulsion and/or thymol-loaded nanostructured lipid carriers on the microbial and physicochemical properties of carrot. Int. J. Biol. Macromol., 129196

da A.C.P. Silva, J.R. Barbosa, da C. Silva Araújo, J.T.S. Batista, E.M.P.X. Neves, D.N.P. Cardoso, L. Lourenço, A new edible coating of fish gelatin incorporated into açaí oil to increase the post-harvest shelf life of tomatoes. Food Chem. 438, 138047 (2024). D. F. H

R. Pholsin, K.A. Shiekh, S. Jafari, I. Kijpatanasilp, T.N. Nan, I. Suppavorasatit, K. Assatarakul, Impact of pectin edible coating extracted from cacao shell powder on postharvest quality attributes of tomato (Lycopersicon esculentum Mill.) Fruit during storage. Food Control. 155, 110023 (2024)

N. Kumar, D. Daniloski, N.M. D’cunha, N. Naumovski, A.T. Petkoska, Pomegranate peel extract–A natural bioactive addition to novel active edible packaging. Food Res. Int. 156, 111378 (2022)

R. Sharma, S.M. Jafari, S. Sharma, Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control. 112, 107086 (2020)

S. Jafarzadeh, A. Salehabadi, A.M. Nafchi, N. Oladzadabbasabadi, S.M. Jafari, Cheese packaging by edible coatings and biodegradable nanocomposites; improvement in shelf life, physicochemical and sensory properties. Trends Food Sci. Technol. 116, 218–231 (2021)

T. Fadiji, M. Rashvand, M.O. Daramola, S.A. Iwarere, A review on antimicrobial packaging for extending the Shelf Life of Food. Processes. 11(2), 590 (2023)

M.W. Iqbal, T. Riaz, I. Yasmin, A.A. Leghari, S. Amin, M. Bilal, X. Qi, Chitosan-based materials as edible coating of cheese: a review. Starch-Stärke. 73(11–12), 2100088 (2021)

N. Bagheripoor, S. Khoshgozaran-Abras, S. Sohrabvandi, N. Khorshidian, A.M. Mortazavian, N. MollaKhalili, S. Jazaeri, Application of active edible coatings to improve the shelf-life of cheese. Food Sci. Technol. Res. 24(6), 949–962 (2018)

S.M. El-Sayed, O.A. Ibrahim, A.M. Kholif, (2020). Characterization of novel Ras cheese supplemented with Jalapeno red pepper. J. Food Process. Preserv., 44(7), e14535

G. Burkhalter, Catalogue of Cheese, Bulletin 141 (International Dairy Federation, Brussels, 1981)

J. Harbutt (ed.), World Cheese Book (Dorling Kindersley, London, 2009)

H.E. Walter, R.C. Hargrove, Cheeses of the World (Dover Publications Inc., New York, 1972)

IDF, Bulletin 485 (International Dairy Federation, Brussels, 2012)

P. Kindstedt, Cheese and Culture: A History of Cheese and its Place in Western Civilization (Chelsea Green Publishing, 2012)

S.M. El-Sayed, A.M. Youssef, Eco-friendly biodegradable nanocomposite materials and their recent use in food packaging applications: a review. Sustainable Food Technol. 1, 215–227 (2024)

A.L. Brody, B. Bugusu, J.H. Han, C.K. Sand, T.H. McHugh, Innovative food packaging solutions. J. Food Sci. 73(8), 107–116 (2008)

A. Eldesouky, A.F. Pulido, F.J. Mesias, The role of packaging and presentation format in consumers’ preferences for food: an application of projective techniques. J. Sens. Stud. 30(5), 360–369 (2015)

M. Mastromatteo, A. Conte, A. Lucera, M.A. Saccotelli, G.G. Buonocore, A.V. Zambrini, M.A. Del Nobile, Packaging solutions to prolong the shelf life of Fiordilatte cheese: bio-based nanocomposite coating and modified atmosphere packaging. LWT-Food Sci. Technol. 60(1), 230–237 (2015)

M.M. Shinde, M. Malik, K. Kaur, V.K. Gahlawat, N. Kumar, P. Chiraang, A. Upadhyay, (2024). Formularization and characterization of guar gum and almond gum based composite coating and their application for shelf-life extension of okra (Hibiscus esculentus). Int. J. Biol. Macromol., 129630

K.A. O’Callaghan, (2016). Assessment, development, and optimisation of packaging systems for cheese products using smart packaging technologies

M.C. Gaspar, M.E. Braga, Edible films and coatings based on agrifood residues: a new trend in the food packaging research. Curr. Opin. Food Sci. 50, 101006 (2023)

A. Salimi, F. Khodaiyan, G. Askari, S.S. Hosseini, A zero-waste approach towards a sustainable waste management of apple: extraction of value-added products and their application as edible coating. Food Hydrocoll. 147, 109304 (2024)

A.M. Youssef, F.M. Assem, H.S. El-Sayed, S.M. El-Sayed, M. Elaaser, M.H. Abd El-Salam, Synthesis and evaluation of eco-friendly carboxymethyl cellulose/polyvinyl alcohol/CuO bionanocomposites and their use in coating processed cheese. RSC Adv. 10(62), 37857–37870 (2020)

A.M. Youssef, H.S. El-Sayed, S.M. El-Sayed, M. Fouly, M.A. El-Aziz, Novel bionanocomposites based on cinnamon nanoemulsion and TiO2-NPs for preserving fresh chicken breast fillets. Food Bioprocess Technol. 16(2), 356–367 (2023)

S. Khoshgozaran, M.H. Azizi, N. Bagheripoor-Fallah, Evaluating the effect of modified atmosphere packaging on cheese characteristics: a review. Dairy. Sci. Technol. 92, 1–24 (2012)

L. Motelica, D. Ficai, A. Ficai, O.C. Oprea, D.A. Kaya, E. Andronescu, Biodegradable antimicrobial food packaging: trends and perspectives. Foods. 9(10), 1438 (2020)

R. Suhag, N. Kumar, A.T. Petkoska, A. Upadhyay, Film formation and deposition methods of edible coating on food products: a review. Food Res. Int. 136, 109582 (2020)

B. Fotovvati, N. Namdari, A. Dehghanghadikolaei, On coating techniques for surface protection: a review. J. Manuf. Mater. Process. 3(1), 28 (2019)

R. Rajan, J. Riihivuori, E. Rainosalo, M. Skrifvars, P. Järvelä, Effect of viscose fabric modification on the mechanical and water absorption properties of composites prepared through vacuum infusion. J. Reinf. Plast. Compos. 33(15), 1416–1429 (2014)

S.C. Shit, P.M. Shah, (2014). Edible polymers: challenges and opportunities. Journal of Polymers, 2014

M. Lacroix, K.D. Vu, (2014). Edible coating and film materials: proteins. Innovations in food Packaging (277–304). Academic

Polymers, 13(5), 769

P. Singh, R. Kumar, S.N. Sabapathy, A.S. Bawa, Functional and edible uses of soy protein products. Compr. Rev. Food Sci. Food Saf. 7(1), 14–28 (2008)

N. Gontard, S. Guilbert, J.L. CUQ, Edible wheat gluten films: influence of the main process variables on film properties using response surface methodology. J. Food Sci. 57(1), 190–195 (1992)

J. Cheng, L. Cui, Effects of high-intensity ultrasound on the structural, optical, mechanical and physicochemical properties of pea protein isolate-based edible film. Ultrason. Sonochem. 80, 105809 (2021)

T. Wittaya, Protein-based edible films: characteristics and improvement of properties. Struct. Function food Eng. 3, 44–70 (2012)

E. Poverenov, R. Rutenberg, S. Danino, B. Horev, V. Rodov, Gelatin-chitosan composite films and edible coatings to enhance the quality of food products: layer-by-layer vs. blended formulations. Food Bioprocess Technol. 7, 3319–3327 (2014)

A. Vasiliauskaite, J. Mileriene, E. Songisepp, I. Rud, S. Muizniece-Brasava, I. Ciprovica, M. Malakauskas, Application of edible coating based on liquid acid whey protein concentrate with indigenous Lactobacillus helveticus for acid-curd cheese quality improvement. Foods. 11(21), 3353 (2022)

L.F. Ríos-de-Benito, M. Escamilla-García, B. García-Almendárez, A. Amaro-Reyes, Di P. Pierro, C. Regalado-González, Design of an active edible coating based on sodium caseinate, chitosan and oregano essential oil reinforced with silica particles and its application on panela cheese. Coatings. 11(10), 1212 (2021)

I. Sebti, F. Ham-Pichavant, V. Coma, Edible bioactive fatty acid – cellulosic derivative composites used in food-packaging applications. J. Agric. Food Chem. 50(15), 4290–4294 (2002)

H. Moustafa, N.A. Darwish, A.M. Youssef, Rational formulations of sustainable polyurethane/chitin/rosin composites reinforced with ZnO-doped-SiO2 nanoparticles for green packaging applications. Food Chem. 371, 131193 (2022)

A.M. Khalil, S.M. El-Sayed, A.M. Youssef, (2023). Valorization of polylactic acid bionanocomposites enriched with CuO-TiO2 for packaging applications. Biomass Convers. Biorefinery, 1–10

Journal of the Indian Chemical Society, 99(9), 100613

M.M. Jayakody, M.P.G. Vanniarachchy, I. Wijesekara, Seaweed derived alginate, agar, and carrageenan based edible coatings and films for the food industry: a review. J. Food Meas. Charact. 16(2), 1195–1227 (2022)

S.M. Abdo, M. Youssef, E. Nagar, I. Mohamed, H.E. El-Kholy, S. A., A.M. Youssef, Processing and characterization of antimicrobial bioplastic films based on green microalgae Scenedesmus obliquus extract-loaded polyurethane. Int. J. Biol. Macromol. 257, 128711 (2024)

H. Rohasmizah, M. Azizah, (2022). Pectin-based edible coatings and nanoemulsion for the preservation of fruits and vegetables: a review. Appl. Food Res., 100221

T. Senturk Parreidt, K. Müller, M. Schmid, Alginate-based edible films and coatings for food packaging applications. Foods. 7(10), 170 (2018)

A.W. Ayoub, S.M. Sayed, M.A. Ammar, Y.A. Hefnawy, A.M. Youssef, Novel Edible Bionanocomposites Films Based on Lemon Grass Nanoemulsion and ZnO-NPs (for Extending the Shelf Life of Chilled Chicken Meat, 2023)

A.M. Youssef, S.M. El-Sayed, Bionanocomposites materials for food packaging applications: concepts and future outlook. Carbohydr. Polym. 193, 19–27 (2018)

J.M. Milani, A. Nemati, Lipid-based edible films and coatings: a review of recent advances and applications. J. Packaging Technol. Res. 6(1), 11–22 (2022)

F. Razmjoo, E. Sadeghi, M. Rouhi, R. Mohammadi, R. Noroozi, S. Safajoo, Polyvinyl alcohol–zedo gum edible film: physical, mechanical and thermal properties. J. Appl. Polym. Sci. 138(8), 49875 (2021)

K. Halake, M. Birajdar, B.S. Kim, H. Bae, C. Lee, Y.J. Kim, J. Lee, Recent application developments of water-soluble synthetic polymers. J. Ind. Eng. Chem. 20(6), 3913–3918 (2014)

J. Muller, C. González-Martínez, A. Chiralt, Combination of poly (lactic) acid and starch for biodegradable food packaging. Materials. 10(8), 952 (2017)

International journal of biological macromolecules, 122, 969–996

J.M. Milani, B. Tirgarian, An overview of edible protein-based packaging: main sources, advantages, drawbacks, recent progressions and food applications. J. Packaging Technol. Res. 4, 103–115 (2020)

Green Chemistry, 24(2), 480–492

M. Zubair, R.A. Pradhan, M. Arshad, A. Ullah, Recent advances in lipid derived bio-based materials for food packaging applications. Macromol. Mater. Eng. 306(7), 2000799 (2021)

N. Awasti, S. Anand, (2020). The role of yeast and molds in dairy industry: An update. Dairy processing: advanced research to applications, 243–262

A. Valdés, M. Ramos, A. Beltrán, A. Jiménez, C.M. Garrigós, State of the art of antimicrobial edible coatings for food packaging applications. Coatings. 7(56), 1–23 (2017)

A.A. Anvar, H. Ahari, M. Ataee, Antimicrobial properties of food nanopackaging: a new focus on foodborne pathogens. Front. Microbiol. 12, 690706 (2021)

Coatings, 9(9), 583

P. Zhang, Y. Zhao, Q. Shi, Characterization of a novel edible film based on gum ghatti: Effect of plasticizer type and concentration. Carbohydr. Polym. 153, 345–355 (2016)

N. Laohakunjit, A. Noomhorm, Effect of plasticizers on mechanical and barrier properties of rice starch film. Starch-Stärke. 56(8), 348–356 (2004)

G.T. Sigurdson, P. Tang, M.M. Giusti, Natural colorants: Food colorants from natural sources. Annual Rev. food Sci. Technol. 8, 261–280 (2017)

L. Sánchez-González, M. Vargas, C. González-Martínez, A. Chiralt, M. Chafer, Use of essential oils in bioactive edible coatings: a review. Food Eng. Rev. 3, 1–16 (2011)

De M. Villiers, Buffers and pH adjusting agents. Practical Guide Contemp. Pharm. Pract. Compd. 4, 223–229 (2009)

A.R. Hammam, Technological, applications, and characteristics of edible films and coatings: a review. SN Appl. Sci. 1, 1–11 (2019)

N. Kumar, A. Upadhyay, S. Shukla, V.K. Bajpai, M. Kieliszek, A. Yadav, V. Kumaravel, (2023). Next generation edible nanoformulations for improving post-harvest shelf-life of citrus fruits. J. Food Meas. Charact., 1–32

M. Aaqil, C. Peng, A. Kamal, T. Nawaz, J. Gong, Recent approaches to the Formulation, uses, and Impact of Edible Coatings on Fresh Peach Fruit. Foods. 13(2), 267 (2024)

Food Engineering Reviews, 15(4), 718–747

H. Moustafa, A.M. Youssef, S. Duquesne, N.A. Darwish, Characterization of bio-filler derived from seashell wastes and its effect on the mechanical, thermal, and flame retardant properties of ABS composites. Polym. Compos. 38(12), 2788–2797 (2017)

M.J. Costa, L.C. Maciel, J.A. Teixeira, A.A. Vicente, M.A. Cerqueira, Use of edible films and coatings in cheese preservation: opportunities and challenges. Food Res. Int. 107, 84–92 (2018)

N. Kumar, T. Pratibha, A. Petkoska, E. Khojah, R. Sami, A.A. Al-Mushhin, Chitosan edible films enhanced with pomegranate peel extract: study on physical, biological, thermal, and barrier properties. Materials. 14(12), 3305 (2021)

R.F. Teixeira, B. Filho, C. A., C.D. Borges, Essential oils as natural antimicrobials for application in edible coatings for minimally processed apple and melon: a review on antimicrobial activity and characteristics of food models. Food Packaging Shelf Life. 31, 100781 (2022)

Z. Lu, M.D. Saldana, Z. Jin, W. Sun, P. Gao, M. Bilige, W. Sun, Layer-by-layer electrostatic self-assembled coatings based on flaxseed gum and chitosan for Mongolian cheese preservation. Innovative Food Sci. Emerg. Technol. 73, 102785 (2021)

M.M. Silva, F.H. Reboredo, F.C. Lidon, Food colour additives: a synoptical overview on their chemical properties, applications in food products, and health side effects. Foods. 11(3), 379 (2022)

E. Díaz-Montes, R. Castro-Muñoz, Edible films and coatings as food-quality preservers: an overview. Foods. 10(2), 249 (2021)

E.A. Baldwin, R. Hagenmaier, J. Bai (eds.), Edible Coatings and Films to Improve food Quality (CRC, 2011)

A. Nussinovitch, M. Hirashima, Use of Hydrocolloids to Control Food Appearance, Flavor, Texture, and Nutrition (Wiley, 2023)

S. Rout, S. Tambe, R.K. Deshmukh, S. Mali, J. Cruz, P.P. Srivastav, de M.S. Oliveira, (2022). Recent trends in the application of essential oils: The next generation of food preservation and food packaging. Trends in Food Science & Technology

L. Kumar, D. Ramakanth, K. Akhila, K.K. Gaikwad, (2022). Edible films and coatings for food packaging applications: a review. Environ. Chem. Lett., 1–26

D. Battini, M. Calzavara, A. Persona, F. Sgarbossa, Sustainable packaging development for fresh food supply chains. Packaging Technol. Sci. 29(1), 25–43 (2016)

S. Ma, Y. Zheng, R. Zhou, M. Ma, Characterization of chitosan films incorporated with different substances of konjac glucomannan, cassava starch, maltodextrin and gelatin, and application in Mongolian cheese packaging. Coatings. 11(1), 84 (2021)

A. López-Córdoba, Feasibility of using carvacrol/starch edible coatings to improve the quality of paipa cheese. Polymers. 13(15), 2516 (2021)

Z. Lu, M.D. Saldana, Z. Jin, W. Sun, P. Gao, M. Bilige, W. Sun, Layer-by-layer Electrostatic self-assembled Coatings Based on Flaxseed gum and Chitosan for Mongolian Cheese Preservation, vol. 73 (Innovative Food Science & Emerging Technologies, 2021), p. 102785

F. Ahmadimaram, T. Mostaghim, S. Shahriari, Evaluation of alginate/collagen edible coatings with betanin and cumin to improve the shelf life of lighvan cheese. J. Food Biosci. Technol. 11(2), 69–84 (2021)

J. Siriwardana, I. Wijesekara, (2021). Analysis of the effectiveness of an antimicrobial edible coating prepared from sweet whey base to improve the physicochemical, microbiological, and sensory attributes of swiss cheese. Advances in Agriculture, 2021, 1–13

S.M. El-Sayed, H.S. El-Sayed, O.A. Ibrahim, A.M. Youssef, Rational design of chitosan/guar gum/zinc oxide bionanocomposites based on Roselle calyx extract for Ras cheese coating. Carbohydr. Polym. 239, 116234 (2020)

A. Guimarães, Ó. Ramos, M. Cerqueira, A. Venâncio, L. Abrunhosa, Active whey protein edible films and coatings incorporating Lactobacillus buchneri for Penicillium nordicum control in cheese. Food Bioprocess Technol. 13, 1074–1086 (2020)

A. Poonia, A.T. Petkoska, (2023). Whey Valorization: Innovations, Technological Advancements and Sustainable Exploitation. 1st ed. 2023 Edition (Springer): ISBN 9819954584

A.M. Youssef, F.M. Assem, M.E. Abdel-Aziz, M. Elaaser, O.A. Ibrahim, M. Mahmoud, M.H. Abd El-Salam, Development of bionanocomposite materials and its use in coating of ras cheese. Food Chem. 270, 467–475 (2019)

B.S. Alvarez, N. Damiani, M. Czerner, J.F. Martucci, L.B. Gende, (2019). Application of active and edible films of sodium caseinate to extend the shelf-life of Argentine Pategrás cheese

del S. González-Forte, L. Amalvy, J. I., N. Bertola, (2019). Corn starch-based coating enriched with natamycin as an active compound to control mold contamination on semi-hard cheese during ripening. Heliyon, 5(6)

de G.O. Elguea-Culebras, A.I. Bourbon, M.J. Costa, N. Muñoz-Tebar, M. Carmona, A. Molina, A.A. Vicente, Optimization of a chitosan solution as potential carrier for the incorporation of Santolina chamaecyparissus L. solid by-product in an edible vegetal coating on ‘Manchego’cheese. Food Hydrocoll. 89, 272–282 (2019)

J. Bonilla, P.J. Sobral, Gelatin-chitosan edible film activated with Boldo extract for improving microbiological and antioxidant stability of sliced Prato cheese. Int. J. Food Sci. Technol. 54(5), 1617–1624 (2019)

N.H. Youssef, Role of chitosan and some plant parts wraps as alternative interior edible coat surrounding semi-hard cheese in inhibiting fungal growth and mycotoxins migration. Res. Crops. 20(4), 869–879 (2019)

L. Lin, Y. Gu, H. Cui, Moringa oil/chitosan nanoparticles embedded gelatin nanofibers for food packaging against Listeria monocytogenes and Staphylococcus aureus on cheese. Food Packaging Shelf life. 19, 86–93 (2019)

F. Yangilar, Effect of the fish oil fortified Chitosan edible film on microbiological, chemical composition and sensory properties of Göbek Kashar cheese during ripening time. Korean J. food Sci. Anim. Resour. 36(3), 377 (2016)

E. Setyowati, A. Manab, Gouda cheese microbial controlling during ripening using composite edible film containing lysozyme. Int. J. Curr. Microbiol. App Sci. 5(5), 748–756 (2016)

N. Kavas, G. Kavas, Physical-chemical and antimicrobial properties of Egg White protein powder films incorporated with orange essential oil on Kashar cheese. Food Sci. Technol. 36, 672–678 (2016)

G. Kavas, N. Kavas, D. Saygili, The Effects of Thyme and Clove Essential oil Fortified Edible Films on the Physical, Chemical and Microbiological Characteristics of Kashar Cheese (J. Food Qual, 2015). (in press)

C. Pena-Serna, A.L.B. Penna, J.F. Lopes Filho, Zein-based blend coatings: impact on the quality of a model cheese of short ripening period. J. Food Eng. 171, 208–213 (2016)

A.S. El-Sisi, A.E.M. Gapr, K.M. Kamaly, Use of Chitosan as an edible coating in RAS cheese. Biolife. 3, 564–570 (2015)

F. Yangilar, Chitosan/whey protein (CWP) edible films efficiency for controlling mould growth and on microbiological, chemical and sensory properties during storage of Göbek Kashar cheese. Korean J. Food Sci. An. 35, 216–224 (2015)

Y.R. Wagh, H.A. Pushpadass, F.M.E. Emerald, B.S. Nath, Preparation and characterization of milk protein films and their application for packaging of Cheddar cheese. J. Food Sci. Technol. 51, 3767–3775 (2014)

R.D. Andriani, M.E. Sawitri, K.U.A. Awwaly, A. Manab, The effect of antimicrobial addition to protein whey based edible film on the Gouda cheese physical quality during ripening. J. Teknologi Pertanian. 14, 123–130 (2013)

M. Henriques, G. Santos, A. Rodrigues, D.M.G.S. Gomes, C. Pereira, M. Gil, Replacement of conventional cheese coatings by natural whey protein edible coatings with antimicrobial activity. J. Hyg. Eng. Des. 3, 34–47 (2013)

M.S. Arab, H. Lashkari, M. Niakosari, M.H. Eskandari, Development of Mozzarella cheese freshness indicating film by embedding purple carrot extract in gelatin and persian gum matrix. Iran. Food Sci. Technol. Res. J. 18(6), 167–180 (2023)

V.G. Kontogianni, E. Kasapidou, P. Mitlianga, M. Mataragas, E. Pappa, E. Kondyli, L. Bosnea, Production, characteristics and application of whey protein films activated with rosemary and sage extract in preserving soft cheese. LWT. 155, 112996 (2022)

S.P. Silva, S.C. Ribeiro, J.A. Teixeira, C.C. Silva, Application of an alginate-based edible coating with bacteriocin-producing Lactococcus strains in fresh cheese preservation. LWT. 153, 112486 (2022)

R. Torrijos, T.M. Nazareth, J. Calpe, J.M. Quiles, J. Mañes, G. Meca, Antifungal Activity of Natamycin and Development of an Edible Film Based on Hydroxyethylcellulose to Avoid Penicillium Spp. Growth on Low-Moisture Mozzarella Cheese. LWT 2022, 154, 112795

H.S. El-Sayed, S.M. El-Sayed, A.M. Mabrouk, G.A. Nawwar, A.M. Youssef, Development of eco-friendly probiotic edible coatings based on chitosan, alginate and carboxymethyl cellulose for improving the shelf life of UF soft cheese. J. Polym. Environ. 29, 1941–1953 (2021)

S. Mousavi, L. Najafian, M. Farsi, Effect of carboxymethyl cellulose and sodium alginate-based edible coating containing wild garlic (Allium ursinum L.) extract on the shelf-life of lactic cheese. Food Hygiene. 10(1), 73–89 (2020)

J. Mileriene, L. Serniene, M. Henriques, D. Gomes, C. Pereira, K. Kondrotiene, M. Malakauskas, Effect of liquid whey protein concentrate–based edible coating enriched with cinnamon carbon dioxide extract on the quality and shelf life of eastern European curd cheese. J. Dairy Sci. 104(2), 1504–1517 (2021)

I. Pratiwi, A. Susilowati, A. Pangastuti, (2021, July). Incorporation of purslane extract (Portulaca oleracea) to chitosan edible film as a packaging material to prevent damage of mozzarella cheese during storage. In IOP Conference Series: Earth and Environmental Science (Vol. 828, No. 1, p. 012026). IOP Publishing

P.A. Freitas, R.R. Silva, de T.V. Oliveira, R.R. Soares, N.F. Soares, (2020). Biodegradable film development by nisin Z addition into hydroxypropylmethylcellulose matrix for mozzarella cheese preservation. Int. J. Food Stud., 9(2)

S. Nottagh, J. Hesari, S.H. Peighambardoust, R. Rezaei-Mokarram, H. Jafarizadeh-Malmiri, Effectiveness of edible coating based on chitosan and Natamycin on biological, physico-chemical and organoleptic attributes of Iranian ultra-filtrated cheese. Biologia. 75, 605–611 (2020)

J.B. Molina-Hernández, A. Echeverri-Castro, H.A. Martínez-Correa, M.M. Andrade-Mahecha, Edible coating based on achira starch containing garlic/oregano oils to extend the shelf life of double cream cheese. Revista Facultad Nac. De Agronomía Medellín. 73(1), 9099–9108 (2020)

S.S.A. El-Sayed, W.Z. Mkkhail, H.M. Sobhy, A.F. Zayan, H.E.D. Aboul-Anean, Production and prolong shelf life of karish (white Egyptian cheese) using edible coating films. Plant. Archives. 20(2), 8443–8449 (2020)

S. Jafarzadeh, J.-W. Rhim, A.K. Alias et al., Application of antimicrobial active packaging film made of Semolina flour, nano zinc oxide and nano-kaolin to maintain the quality of low-moisture mozzarella cheese during low-temperature storage. J. Sci. Food. Agric. 99, 2716–2725 (2019). https://doi.org/10.1002/jsfa.9439

G. Ksouda, S. Sellimi, F. Merlier, A. Falcimaigne-Cordin, B. Thomasset, M. Nasri, M. Hajji, Composition, antibacterial and antioxidant activities of Pimpinella saxifraga essential oil and application to cheese preservation as coating additive. Food Chem. 288, 47–56 (2019)

A.M. Youssef, S.M. El-Sayed, H.S. El-Sayed, H.H. Salama, F.M. Assem, M.H. Abd El-Salam, Novel bionanocomposite materials used for packaging skimmed milk acid coagulated cheese (Karish). Int. J. Biol. Macromol. 115, 1002–1011 (2018)

S.R. Brown, S.M. Kozak, D.J. D’Amico, Applications of edible coatings formulated with antimicrobials inhibit Listeria monocytogenes growth on queso Fresco. Front. Sustainable Food Syst. 2, 1 (2018)

E. Divsalar, H. Tajik, M. Moradi, M. Forough, M. Lotfi, B. Kuswandi, Characterization of cellulosic paper coated with chitosan-zinc oxide nanocomposite containing nisin and its application in packaging of UF cheese. Int. J. Biol. Macromol. 109, 1311–1318 (2018)

A.M. Youssef, S.M. El-Sayed, H.H. Salama, H.S. El-Sayed, A. Dufresne, Evaluation of bionanocomposites as packaging material on properties of soft white cheese during storage period. Carbohydr. Polym. 132, 274–285 (2015)

L.M. Bento, M. Silva-Pereira, K. Chaves, R. Stefani, Development and evaluation of a smart packaging for the monitoring of ricotta cheese spoilage. MOJ Food Process. Technol. 1, 3–5 (2015)

M. Mastromatteo, A. Conte, M. Faccia, M.A.D. Alessandro, Nobile, A.V. Zambrini, Combined effect of active coating and modified atmosphere packaging on prolonging the shelf life of low-moisture mozzarella cheese. J. Dairy. Sci. 97, 1–9 (2013)

EFSA Scientific Committee, Scientific opinion on genotoxicity testing strategies applicable to food and feed safety assessment. EFSA J. 9(9), 2379 (2011)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Sayed, S.M., Youssef, A.M. Emergence of cheese packaging by edible coatings for enhancing its shelf-life. Food Measure (2024). https://doi.org/10.1007/s11694-024-02564-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11694-024-02564-0