Abstract

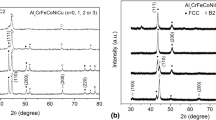

In this study, FeCoCrAlNi high entropy alloy (HEA) anti-wear coating was prepared on 304 stainless steel by plasma spraying. The results show that the HEA powder and coating phase is mainly the BCC phase. The microstructure of the splat exhibits a disk shape without obvious splashes, and the coating presents a dense microstructure with a typical lamellar structure. The average microhardness of the coating is 411 HV1.0 which is almost 1.5 times that of the 304 stainless steel substrate. Compared with the substrate, the HEA coating exhibits a better wear resistance property under a high load (20 N) at room temperature and 800 °C. The wear mechanisms for the FeCoCrAlNi coating were oxidation wear and mild abrasive wear at room temperature, and mild abrasive wear, oxidation wear, adhesive wear and the formation of oxide films at high temperature. These results indicate that HEA can be a promising high-temperature anti-wear coating material under severe working conditions.

Similar content being viewed by others

References

J. Chen, R.-M. Asmussen, D. Zagidulin, J.-J. Noël and D.-W. Shoesmith, Electrochemical and Corrosion Behavior of a 304 Stainless-Steel-Based Metal Alloy Wasteform in Dilute Aqueous Environments, Corros. Sci., 2013, 66, p 142-152.

G.-F. Sun, Y.-K. Zhang, M.-K. Zhang, R. Zhou, K. Wang, C.-S. Liu and K.-Y. Luo, Microstructure and Corrosion Characteristics of 304 Stainless Steel Laser-Alloyed with Cr-CrB2, Appl. Surf. Sci., 2014, 295, p 94-107.

J. Xu, X. Wu and E. Han, Acoustic Emission Response of Sensitized 304 Stainless Steel During Intergranular Corrosion and Stress Corrosion Cracking, Corros. Sci., 2013, 73, p 262-273.

X. Liu, X. Lu, Y. Song, S. Xia, R. Ren, Y. Wang, D. Zhao and M. Wang, Plasma-Sprayed Graphene Nanosheets/ZnO/Al2O3 Coatings with Highly Efficient Microwave Absorption Properties, J. Therm. Spray Techn., 2021, 30, p 1524-1534.

X. Lu, S. Bhusal, G. He, D. Zhao, C. Zhang, A. Agarwal and Y. Chen, Efficacy of Graphene Nanoplatelets on Splat Morphology and Microstructure of Plasma Sprayed Alumina Coatings, Surf. Coat. Technol., 2019, 366, p 54-61.

B. Malvi and M. Roy, Elevated Temperature Erosion of Plasma Sprayed Thermal Barrier Coating, J. Therm. Spray Techn., 2021, 30, p 1028-1037.

P. Ctibor, V. Stengl and Z. Pala, Structural and Photocatalytic Characteristics of TiO2 Coatings Produced by Various Thermal Spray Techniques, Journal of Advanced Ceramics, 2013, 2, p 218-226.

Y. Deng, W. Chen, B. Li, C. Wang, T. Kuang and Y. Li, Physical Vapor Deposition Technology for Coated Cutting Tools: A Review, Ceram. Int., 2020, 46, p 18373-18390.

L. Baptiste, N.-V. Landschoot, G. Gleijm, J. Priede, J. Schade Van Westrum, H. Velthuis and T. Kim, Electromagnetic Levitation: A New Technology for High Rate Physical Vapour Deposition of Coatings Onto Metallic Strip, Surf. Coat. Technol., 2007, 202, p 1189-1193.

H. Zhang, Y. Pan and Y. He, Synthesis and Characterization of FeCoNiCrCu High-Entropy Alloy Coating by Laser Cladding, Mater. Des., 2011, 32, p 1910-1915.

M.-J. Tobar, C. Álvarez, J.-M. Amado, G. Rodríguez and A. Yáñez, Morphology and Characterization of Laser Clad Composite NiCrBSi-WC Coatings on Stainless Steel, Surf. Coat. Technol., 2006, 200, p 6313-6317.

X.-D. Xu, S. Guo, T.-G. Nieh, C.-T. Liu, A. Hirata and M.-W. Chen, Effects of Mixing Enthalpy and Cooling Rate on Phase Formation of AlxCoCrCuFeNi High-Entropy Alloys, Materialia, 2019, 6, p 100292.

Y.-F. Ye, Q. Wang, J. Lu, C.-T. Liu and Y. Yang, High-Entropy Alloy: Challenges and Prospects, Mater. Today (Kidlington, England), 2016, 19, p 349-362.

J. Wu, S. Lin, J. Yeh, S. Chen, Y. Huang and H. Chen, Adhesive Wear Behavior of AlxCoCrCuFeNi High-Entropy Alloys as a Function of Aluminum Content, Wear, 2006, 261, p 513-519.

C. Tung, J. Yeh, T. Shun, S. Chen, Y. Huang and H. Chen, On the Elemental Effect of AlCoCrCuFeNi High-Entropy Alloy System, Mater. Lett., 2007, 61, p 1-5.

M. Chuang, M. Tsai, W. Wang, S. Lin and J. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys, Acta Mater., 2011, 59, p 6308-6317.

S. Zhu, Z. Zhang, B. Zhang, Y. Yu, Z. Wang, X. Zhang and B. Lu, Microstructure and Properties of Al2O3-13wt.%TiO2-Reinforced CoCrFeMnNi High-Entropy Alloy Composite Coatings Prepared by Plasma Spraying, J. Therm. Spray Techn., 2021, 30, p 772-786.

H. Liang, H. Yao, D. Qiao, S. Nie, Y. Lu, D. Deng, Z. Cao and T. Wang, Microstructures and Wear Resistance of AlCrFeNi2W0.2Nbx High-Entropy Alloy Coatings Prepared by Laser Cladding, J. Therm. Spray Techn., 2019, 28, p 1318-1329.

S.-A. Firstov, V.-F. Gorban, N.-A. Krapivka, M.-V. Karpets and A.-D. Kostenko, Wear Resistance of High-Entropy Alloys, Powder Metall. Met. C., 2017, 56, p 158-164.

A. Meghwal, A. Anupam, B.-S. Murty, C.-C. Berndt, R.-S. Kottada and A.-S.-M. Ang, Thermal Spray High-Entropy Alloy Coatings: A Review, J. Therm. Spray Techn., 2020, 29, p 857-893.

J. Xiao, T. Li, Y. Wu, J. Chen and C. Zhang, Microstructure and Tribological Properties of Plasma-Sprayed CoCrFeNi-based High-Entropy Alloy Coatings Under Dry and Oil-Lubricated Sliding Conditions, J. Therm. Spray Techn., 2021, 30, p 926-936.

A. Meghwal, A. Anupam, V. Luzin, C. Schulz, C. Hall, B.-S. Murty, R.-S. Kottada, C.-C. Berndt and A.-S.-M. Ang, Multiscale Mechanical Performance and Corrosion Behaviour of Plasma Sprayed AlCoCrFeNi High-Entropy Alloy Coatings, J. Alloy. Compd., 2021, 854, p 157140.

T. Li, Y. Liu, B. Liu, W. Guo and L. Xu, Microstructure and Wear Behavior of FeCoCrNiMo0.2 High Entropy Coatings Prepared by Air Plasma Spray and the High Velocity Oxy-Fuel Spray Processes, Coatings, 2017, 7, p 151.

M. Löbel, T. Lindner, T. Mehner and T. Lampke, Microstructure and Wear Resistance of AlCoCrFeNiTi High-Entropy Alloy Coatings Produced by HVOF, Coatings, 2017, 7, p 144.

E.-F. Sukur and G. Onal, Graphene Nanoplatelet Modified Basalt/Epoxy Multi-Scale Composites with Improved Tribological Performance, Wear, 2020, 460, p 460-461.

S. Singh, V.-K. Meena, M. Sharma and H. Singh, Preparation and Coating of Nano-Ceramic on Orthopaedic Implant Material Using Electrostatic Spray Deposition, Mater. Des., 2015, 88, p 278-286.

B. Hahn, D. Park, J. Choi, J. Ryu, W. Yoon, B. Lee and H. Kim, Effect of the HA/β-TCP Ratio on the Biological Performance of Calcium Phosphate Ceramic Coatings Fabricated by a Room-Temperature Powder Spray in Vacuum, J. Am. Ceram. Soc., 2009, 92, p 793-799.

L. Chen and G. Yang, Epitaxial Growth and Cracking of Highly Tough 7YSZ Splats by Thermal Spray Technology, J. Adv. Ceram., 2018, 7, p 17-29.

L. Tian, J. Wang, Q. Zhang, R. Li and C. Liu, Microstructure Characterization of AlCoCrFeNiTi High-Entropy Alloy Coating Produced by Atmospheric Plasma Spraying, Mater. Res. Express, 2019, 6, p 116416.

L. Wang, F. Zhang, S. Yan, G. Yu, J. Chen, J. He and F. Yin, Microstructure Evolution and Mechanical Properties of Atmosphere Plasma Sprayed AlCoCrFeNi High-Entropy Alloy coatings Under Post-Annealing, J. Alloy. Compd., 2021, 872, p 159607.

Y. Mu, L. Zhang, L. Xu, K. Prashanth, N. Zhang, X. Ma, Y. Jia, Y. Xu, Y. Jia and G. Wang, Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying, Entropy-Switz., 2020, 22, p 740.

S. Zhang, C.-L. Wu, C.-H. Zhang, M. Guan and J.-Z. Tan, Laser Surface Alloying of FeCoCrAlNi High-Entropy Alloy on 304 Stainless Steel to Enhance Corrosion and Cavitation Erosion Resistance, Opt. Laser Technol., 2016, 84, p 23-31.

Y. Wang, Y. Yang, H. Yang, M. Zhang, S. Ma and J. Qiao, Microstructure and Wear Properties of Nitrided AlCoCrFeNi High-Entropy Alloy, Mater. Chem. Phys., 2018, 210, p 233-239.

Q. Fan, C. Chen, C. Fan, Z. Liu, X. Cai, S. Lin and C. Yang, Effect of High Fe Content on the Microstructure, Mechanical and Corrosion Properties of AlCoCrFeNi High-Entropy Alloy Coatings Prepared by Gas Tungsten Arc Cladding, Surf. Coat. Technol., 2021, 418, p 127242.

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau and S.-Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299-303.

Z. Lei, X. Liu, Y. Wu, H. Wang, S. Jiang, S. Wang, X. Hui, Y. Wu, B. Gault, P. Kontis, D. Raabe, L. Gu, Q. Zhang, H. Chen, H. Wang, J. Liu, K. An, Q. Zeng, T. Nieh and Z. Lu, Enhanced Strength and Ductility in a High-Entropy Alloy Via Ordered Oxygen Complexes, Nature, 2018, 563, p 546-550.

G.-F. Sun, K. Wang, R. Zhou, Z.-P. Tong and X.-Y. Fang, Effect of Annealing on Microstructure and Mechanical Properties of Laser Deposited Co-285+WC Coatings, Opt. Laser Technol., 2015, 66, p 98-105.

M. Calmunger, G. Chai, R. Eriksson, S. Johansson and J.-J. Moverare, Characterization of Austenitic Stainless Steels Deformed at Elevated Temperature, Metallurgical and materials transactions, Phys. Metal. Mater. Sci., 2017, 48, p 4525-4538.

L. Gardner, A. Insausti, K.-T. Ng and M. Ashraf, Elevated Temperature Material Properties of Stainless Steel Alloys, J. Constr. Steel Res., 2010, 66, p 634-647.

Acknowledgments

This research work was financially supported by National Natural Science Foundation of China (Grant Numbers: 51501121, 51475315, 51775360, 51701134, 52071124), National Key R&D Program of China (2017YFB1103601), and NSAF (Grant No. U2030102) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Liu, X., Lv, F., Li, H. et al. Microstructure and High-Temperature Tribological Behavior of Plasma-Sprayed FeCoCrAlNi High Entropy Alloy Coatings Under Higher Load Condition. J Therm Spray Tech 31, 1276–1284 (2022). https://doi.org/10.1007/s11666-022-01359-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01359-3