Abstract

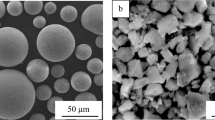

Yttria-stabilized zirconia (YSZ) is used extensively as a ceramic top coat of thermal barrier coating (TBC) system in land-based gas turbines and aero engines. TBC enables modern engines to operate at significantly higher gas temperatures. TBCs are subjected to solid particle erosion at elevated temperature, especially during the operation of aero engines in sandy terrain. Thus, the objective of the present investigation is to evaluate the impact erosion response of these coatings as a function of various eroding conditions. Toward that purpose, YSZ TBC was deposited on Ni base alloy using air plasma spraying technique. The microstructural features of the coating are evaluated, and coated samples are subjected to erosion test employing a high-temperature air jet erosion testing machine at various temperatures, at different impact velocities, and at different impact angles. The results show a brittle erosion response of TBC at all temperatures. The erosion rate of TBC is generally independent of temperature under the normal impact, and it increases with temperature under oblique impact at high impact velocity. Intersplat adhesion governs the erosion mechanism.

Similar content being viewed by others

References

N. Curry, N. Markocsan, L. Östergren, X.-H. Li and M. Dorfman, Evaluation of the Lifetime and Thermal Conductivity of Dysprosia-Stabilized Thermal Barrier Coating Systems, J. Therm. Spray Technol., 2013, 22, p 864–872.

S.G. Sapate and M. Roy, Solid Particle Erosion of Thermal Sprayed Coatings, Therm. Sprayed Coat. Their Tribol. Perform., 2015 https://doi.org/10.4018/978-1-4666-7489-9.ch007

W. Algenaid et al., Influence of Microstructure on the Erosion Behaviour of Suspension Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2019, 375, p 86–99.

F. Cernuschi et al., Solid Particle Erosion of Standard and Advanced Thermal Barrier Coatings, Wear, 2016, C, p 43–51.

F. Cernuschi et al., Solid Particle Erosion of Thermal Spray and Physical Vapour Deposition Thermal Barrier Coatings, Wear, 2011, 271, p 2909–2918.

M.P. Schmitt, B.J. Harder and D.E. Wolfe, Process-Structure-Property Relations for the Erosion Durability of Plasma Spray-Physical Vapor Deposition (PS-PVD) Thermal Barrier Coatings, Surf. Coat. Technol., 2016, 297, p 11–18.

M.P. Schmitt, A.K. Rai, D. Zhu, M.R. Dorfman and D.E. Wolfe, Thermal Conductivity and Erosion Durability of Composite Two-Phase Air Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2015, 279, p 44–52.

C.S. Ramachandran, V. Balasubramanian and P.V. Ananthapadmanabhan, Erosion of Atmospheric Plasma Sprayed Rare Earth Oxide Coatings Under Air Suspended Corundum Particles, Ceram. Int., 2013, 39, p 649–672.

D. Shin and A. Hamed, Influence of Micro–Structure on Erosion Resistance of Plasma Sprayed 7YSZ Thermal Barrier Coating Under Gas Turbine Operating Conditions, Wear, 2018, 396–397, p 34–47.

Z. Qu et al., An Investigation on Erosion Behavior of Nanostructured 7YSZ Coatings at Elevated Temperature, Surf. Coat. Technol., 2016, 299, p 129–134.

N. Ramanujam and T. Nakamura, Erosion Mechanisms of Thermally Sprayed Coatings with Multiple Phases, Surf. Coat. Technol., 2009, 204, p 42–53.

B.Z. Janos, E. Lugscheider and P. Remer, Effect of Thermal Aging on the Erosion Resistance of Air Plasma Sprayed Zirconia Thermal Barrier Coating, Surf. Coat. Technol., 1999, 113, p 278–285.

J.R. Nicholls, M.J. Deakin and D.S. Rickerby, A Comparison Between the Erosion Behaviour of Thermal Spray and Electron Beam Physical Vapour Deposition Thermal Barrier Coatings, Wear, 1999, 233–235, p 352–361.

M.P. Schmitt et al., Effect of Gd Content on Mechanical Properties and Erosion Durability of Sub-stoichiometric Gd2Zr2O7, Surf. Coat. Technol., 2017, 313, p 177–183.

S. Mahade et al., Tailored Microstructures of Gadolinium Zirconate/YSZ Multi-Layered Thermal Barrier Coatings Produced by Suspension Plasma Spray: Durability and Erosion Testing, J. Mater. Process. Technol., 2019, 264, p 283–294.

S. Mahade et al., Erosion Performance of Gadolinium Zirconate-Based Thermal Barrier Coatings Processed by Suspension Plasma Spray, J. Therm. Spray Technol., 2017, 26, p 108–115.

D. Wang, Z. Tian, L. Shen, Z. Liu and Y. Huang, Effects of Laser Remelting on Microstructure and Solid Particle Erosion Characteristics of ZrO2–7 wt.%Y2O3 Thermal Barrier Coating Prepared by Plasma Spraying, Ceram. Int., 2014, 40, p 8791–8799.

P.-C. Tsai, J.-H. Lee and C.-L. Chang, Improving the Erosion Resistance of Plasma-Sprayed Zirconia Thermal Barrier Coatings by Laser Glazing, Surf. Coat. Technol., 2007, 202, p 719–724.

M. Roy, K.K. Ray and G. Sundararajan, Erosion-Oxidation Interaction in Ni and Ni-20Cr Alloy, Metall. Mater. Trans. A, 2001, 32, p 1431–1451.

M. Roy, K.K. Ray and G. Sundararajan, The Influence of Erosion-Induced Roughness on the Oxidation Kinetics of Ni and Ni-20Cr Alloys, Oxid. Met., 1999, 51, p 251–272.

M. Roy, Solid Particle Erosion Behavior of WC Coating Obtained by Electrospark Technique and Detonation Spraying, Tribol. Trans., 2014, 57, p 1028–1036.

Roy, M. & Davim, J. P. Thermal Sprayed Coatings and their Tribological Performances. http://services.igi-global.com/resolvedoi/resolve.aspx? Doi: https://doi.org/10.4018/978-1-4666-7489-9 (IGI Global, 1AD).

R.G. Wellman and J.R. Nicholls, A Review of the Erosion of Thermal Barrier Coatings, J. Phys. Appl. Phys., 2007, 40, p R293–R305.

S. Krämer, J. Yang, C.G. Levi and C.A. Johnson, Thermochemical Interaction of Thermal Barrier Coatings with Molten CaO–MgO–Al2O3–SiO2 (CMAS) Deposits, J. Am. Ceram. Soc., 2006, 89, p 3167–3175.

D.E. Mack, T. Wobst, M.O.D. Jarligo, D. Sebold and R. Vaben, Lifetime and Failure Modes of Thermal Barrier Coatings in Thermal Gradient Rig Tests with Simultaneous CMAS Injection, Surf. Coat. Technol., 2017, 324, p 36–47.

G. Sundararajan and P.G. Shewmon, A New Model for the Erosion of Metals at Normal Incidence, Wear, 1983, 84, p 237–258.

M. Roy, M. Subramaniyam and G. Sundararajan, Room Temperature Erosion Behaviour of a Precipitation Hardened Stainless Steel, Tribol. Int., 1992, 25, p 271–280.

G. Sundararajan, The Solid Particle Erosion of Metals and Alloys, Trans. Indian Inst. Met., 1983, 36, p 474–495.

G.D. Portu et al., Solid Particle Erosion Behaviour of Laminated Ceramic Structures, Wear, 2020, 442–443, p 203147.

M. Roy, Elevated Temperature Erosive Wear of Metallic Materials, J. Phys. Appl. Phys., 2006, 39, p R101–R124.

M. Roy, A. Pauschitz, J. Wernisch and F. Franek, Effect of Mating Surface on the High Temperature Wear of 253 MA Alloy, Mater. Corros., 2004, 55, p 259–273.

K. Anand, S.K. Hovis, H. Conrad and R.O. Scattergood, Flux Effects in Solid Particle Erosion, Wear, 1987, 118, p 243–257.

M. Roy, K.K. Ray and G. Sundararajan, An Analysis of the Transition from Metal Erosion to Oxide Erosion, Wear, 1998, 217, p 312–320.

A. Pauschitz, M. Roy and F. Franek, Mechanisms of Sliding Wear of Metals and Alloys at Elevated Temperatures, Tribol. Int., 2008, 41, p 584–602.

B. Venkatesh, B. Malvi, M. Roy and P. Sarkar, Effect of Welding Conditions on Erosive Wear of Hard-Faced Co-Based Alloy Layer , Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 2018, 232, p 1377–1389.

H.E. Eaton and R.C. Novak, Particulare Erosion of Plasma-Sprayed Porous Ceramic, Surf. Coat. Technol., 1987, 30, p 41–50.

R. He, Z. Qu, Y. Pei and D. Fang, High Temperature Indentation Tests of YSZ Coatings in Air Up to 1200°C, Mater. Lett., 2017, 209, p 5–7.

F.L. Shang, X. Zhang, X.C. Guo, P.F. Zhao and Y. Chang, Determination of High Temperature Mechanical Properties of Thermal Barrier Coatings by Nanoindentation, Surf. Eng., 2014, 30, p 283–289.

G.N. Morscher, P. Pirouz and A.H. Heuer, Temperature Dependence of Hardness in Yttria-Stabilized Zirconia Single Crystals, J. Am. Ceram. Soc., 1991, 74, p 491–500.

R.G. Wellman, M.J. Deakin and J.R. Nicholls, The Effect of TBC Morphology on the Erosion Rate of EB PVD TBCs, Wear, 2005, 258, p 349–356.

M. Roy, Y. Tirupataiah and G. Sundararajan, Effect of Particle Shape on the Erosion of Cu and Its Alloys, Mater. Sci. Eng. A, 1993, 165, p 51–63.

M. Roy, Dynamic Hardness of Detonation Sprayed WC-Co Coatings, J. Therm. Spray Technol., 2002, 11, p 393–399.

Acknowledgment

The authors are grateful to the director, DMRL, for granting permission to carry out this work in DMRL and for permitting to publish this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Malvi, B., Roy, M. Elevated Temperature Erosion of Plasma Sprayed Thermal Barrier Coating. J Therm Spray Tech 30, 1028–1037 (2021). https://doi.org/10.1007/s11666-021-01189-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01189-9