Abstract

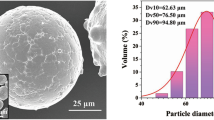

Fe-based coatings reinforced by spherical WC particles were produced on the 304 stainless steel by plasma transferred arc (PTA) to enhance the surface wear properties. Three different Fe/WC composite powder mixtures containing 0wt%, 30wt%, and 60wt% of WC were investigated. The microstructure and phase composition of the Fe/WC composite PTA coatings were evaluated systemically by using scanning electron microscope (SEM) and X-ray diffraction (XRD). The wear properties of the three fabricated PTA coatings were investigated on a BRUKER UMT TriboLab. The morphologies of the worn tracks and wear debris were characterized by using SEM and 3D non-contract profiler. The experimental results reveal that the microhardness on the cross-section and the wear resistance of the fabricated coatings increase dramatically with the increasing adding WC contents. The coating containing 60wt% of WC possesses excellent wear resistance validated by the lower coefficients of friction (COF), narrower and shallower wear tracks and smaller wear rate. In the pure Fe-based coating, the main wear mechanism is the combination of adhesion and oxidative wear. Adhesive and two-body abrasive wear are predominated in the coating containing 30wt% of WC, whereas threebody abrasion wear mechanism is predominated in the coating containing 60wt% of WC.

Similar content being viewed by others

References

Guo C, Zhou JS, Chen JM, et al. High Temperature Wear Resistance of Laser Cladding NiCrBSi and NiCrBSi/WC–Ni Composite Coatings[J]. Wear, 2011, 270(7): 492–498

Liu WH, Shieu FS, Hsiao WT. Enhancement of Wear and Corrosion Resistance of Iron–based Hard Coatings Deposited by High–velocity Oxygen fuel (HVOF)[J]. Surf. Coat. Technol., 2014, 249(25): 24–41

Zheng ZB, Zheng YG, Sun WH, et al. Effect of Heat Treatment on the Structure, Cavitation Erosion and Erosion–corrosion Behavior of Febased Amorphous Coatings[J]. Tribol. Int., 2015, 90: 393–403

Jiang CP, Xing YZ, Hao JM, et al. Effects of Heat–treatment on Crystallization and Wear Property of Plasma Sprayed Fe–based Amorphous Coatings[J]. J. Wuhan Univ. Technol.–Mater. Sci. Ed., 2013, 28(4): 643–646

Ma HR, Chen XY, Li JW, et al. Fe–based Amorphous Coating with High Corrosion and Wear Resistance[J]. Surf. Eng., 2017, 33(1): 56–62

Wang W, Zhang C, Xu P, et al. Enhancement of Oxidation and Wear Resistance of Fe–based Amorphous Coatings by Surface Modification of Feedstock Powders[J]. Mater. Des., 2015, 73: 35–41

Yang GR, Song WM, Ma Y, et al. Microstructure of Ni/WC Surface Composite Layer on Gray Iron Substrate[J]. J. Wuhan Univ. Technol.–Mater. Sci. Ed., 2011, 26(5): 861–866

Bartkowski D, Młynarczak A, Piasecki A, et al. Microstructure, Microhardness and Corrosion Resistance of Stellite–6Coatings Reinforced with WC Particles Using Laser Cladding[J]. Opt. Laser Technol. 2015, 68: 191–201

Xu JS, Zhang XC, Xuan FZ, et al. Microstructure and Sliding Wear Resistance of Laser Cladded WC/Ni Composite Coatings with Different Contents of WC Particle[J]. J. Mater. Eng. Perform.,2012, 21(9): 1 904–1 911

Wang JW, Wang HC, Wang HF, et al. Preparation of Ni60–WC Coating by Plasma Spraying, Plasma Re–melting and Plasma Spray Welding on Surface of Hot Forging Die[J]. J. Wuhan Univ. Technol.–Mater. Sci. Ed., 2012, 27(4): 640–643

Ma QS, Li YJ, Wang J, et al. Investigation on Cored–eutectic Structure in Ni60/WC Composite Coatings Fabricated by Wide–band Laser Cladding[ J]. J. Alloys Compd., 2015, 645: 151–157

Yuan YL, Li ZG. Microstructure and Wear Performance of High Volume Fraction Carbide M7C3 Reinforced Fe–based Composite Coating Fabricated by Plasma Transferred Arc Welding[J]. J. Wuhan Univ. Technol.–Mater. Sci. Ed., 2014, 29(5): 1 028–1 035

Liu R, Yao MX, Patnaik PC, et al. An Improved Wear–resistant PTA Hardfacing: VWC/Stellite 21[J]. J. Compo. Mater., 2006, 40(24): 2 203–2 215

Miracle DB. Metal Matrix Composites–From Science to Technological Significance[J]. Compo. Sci. Technol., 2005, 65(15–16): 2 526–2 540

Xu P, Lin CX, Zhou CY, et al. Wear and Corrosion Resistance of Laser Cladding AISI 304 Stainless Steel/Al2O3 Composite Coatings[J]. Surf. Coat. Technol., 2014, 238: 9–14

Lu XL, Liu XB, Yu PC, et al. Effects of Heat Treatment on Microstructure and Mechanical Properties of Ni60/h–BN Self–lubricating Anti–wear Composite Coatings on 304 Stainless Steel by Laser Cladding [J]. Appl. Surf. Sci.,2015, 355(13): 350–358

Sun GF, Zhang YK, Zhang MK, et al. Microstructure and Corrosion Characteristics of 304 Stainless Steel Laser–alloyed with Cr–CrB2[J]. Appl. Surf. Sci., 2014, 295, 94–107

Borgh I, Hedström P, Persson T, et al. Microstructure, Grain Size Distribution and Grain Shape in WC–Co Alloys Sintered at Different Carbon Activities[J]. Int. J. Refract. Met. Hard Mater, 2014, 43: 205–211

Delanoë A, Lay S. Evolution of the WC Grain Shape in WC–Co Alloys during Sintering: Effect of C content[J]. Int. J. Refract. Met. Hard Mater, 2009, 27(1): 140–148

Long JZ, Li K, Chen F, et al. Microstructure Evolution of WC Grains in WC–Co–Ni–Al Alloys: Effect of Binder Phase Composition[J]. J. Alloys Compd., 2017, 710: 338–348

Wu P, Du HM, Chen XL, et al. Influence of WC Particle Behavior on the Wear Resistance Properties of Ni–WC Composite Coatings[J]. Wear, 2004, 257: 142–147

Fernandez MR, Garcia A, Cuetos JM, et al. Effect of Actual WC Content on the Reciprocating Wear of a Laser Cladding NiCrBSi Alloy Reinforced with WC[J]. Wear, 2015, 324: 80–89

Zhou SF, Dai XQ, Zheng HZ. Microstructure and Wear Resistance of Fe–based WC Coating by Multi–track Overlapping Laser Induction Hybrid Rapid Cladding[J]. Opt. Laser Technol.,2012, 44: 190–197

Zhou SF, Dai XQ. Microstructure Evolution of Fe–based WC Composite Coating Prepared by Laser Induction Hybrid Rapid Cladding[J]. Appl. Surf. Sci.,2010, 256: 7 395–7 399

Farahmand P, Kovacevic R. Corrosion and Wear Behavior of Laser Cladded Ni–WC Coatings[J]. Surf. Coat. Technol., 2015, 276: 121–135

Ocelik V, Matthews D, De Hosson JTM. Sliding Wear Resistance of Metal Matrix Composite Layers Prepared by High Power Laser[J]. Surf. Coat. Technol., 2005, 197: 303–315

Shi MJ, Pang SJ, Zhang T. Towards Improved Integrated Properties in FeCrPCB Bulk Metallic Glasses by Cr Addition[J]. Intermetallics, 2015, 61: 16–20

Benea L, Basa S, Dănăilă E, et al. Fretting and Wear Behaviors of Ni/nano–WC Composite Coatings in Dry and Wet Conditions[J]. Mater. Des., 2015, 65: 550–558

Chakraborty G, Kumar N, Das CR, et al. Study on Microstructure and Wear Properties of Different Nickel Base Hard–facing Alloys Deposited on Austenitic Stainless Steel[J]. Surf. Coat. Technol.,2014, 244: 180–188

Guo C, Chen JM, Zhou JS, et al. Effects of WC–Ni Content on Microstructure and Wear Resistance of Laser Cladding Ni–based Alloys Coating[J]. Surf. Coat. Technol.,2012, 206: 2064–2071

Serres N, Hlawka F, Costil S, et al. Dry Coatings and Ecodesign: Part.2–Tribological Performances[J]. Surf. Coat. Technol.,2009, 204: 197–204

Van Acker K, Vanhoyweghen D, Persoons R, et al. Influence of Tungsten Carbide Particle Size and Distribution on the Wear Resistance of Laser Clad WC/Ni Coatings[J]. Wear, 2005, 258: 194–202

Dubourg L, Ursescu D, Hlawka F, et al. Laser Cladding of MMC Coatings on Aluminum Substrate: Influence of Composition and Microstructure on Mechanical Properties[J]. Wear, 2005, 258: 1 745–1 754

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Ocean Public Science and Technology Research Fund Projects of China (No. 201405013-3), the National Natural Science Foundation of China (No.51609133), the China Postdoctoral Science Foundation (No.2017M620153) and the Science & Technology Program of Shanghai Maritime University (No.20130448)

Rights and permissions

About this article

Cite this article

Fan, L., Dong, Y., Chen, H. et al. Wear Properties of Plasma Transferred Arc Fe-based Coatings Reinforced by Spherical WC Particles. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 433–439 (2019). https://doi.org/10.1007/s11595-019-2070-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2070-6