Abstract

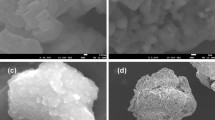

It is usually difficult to deposit a dense ceramic coating with fully bonded splats by plasma spraying at a room temperature. Following the recent research progress on the splat interface bonding formation, it was found that there is a well-defined relationship between the critical bonding temperature and the melting point of spray material. Thus, it can be proposed to control the lamellar bonding through the deposition temperature. In this study, to examine the feasibility of the bonding formation theory, a novel approach to the development of ceramic coating with dense microstructure by plasma spraying through materials design with a low melting point is proposed. Potassium titanate K2Ti6O13 was selected as a typical ceramic material of a relatively low melting point for plasma spraying deposition of dense coating with well-bonded splats. Experiment was conducted by using K2Ti6O13 for both splat and coating deposition. Results show that the splat is fully bonded with a ceramic substrate at room temperature, and the K2Ti6O13 coating presents a dense microstructure and a fracture surface morphology similar to sintered bulk ceramic, revealing excellent interlamellar bonding formation. Moreover, both the hardness test and erosion test at 90° further confirmed the formation of the isotropic ceramic coating with fully bonded lamellae.

Similar content being viewed by others

References

A. Vardelle, C. Moreau, J. Akedo et al., The 2016 Thermal Spray Roadmap, J. Therm. Spray Technol., 2016, 25(8), p 1376-1440

A. McWilliams, High-Performance Ceramic Coatings: Markets and Technologies, BBC Research, 2016

J.R. Davis, Handbook of Thermal Spray Technology, ASM International, Materials Park, 2004

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, Wiley, Chichester, 1995

C.-J. Li and A. Ohmori, Relationship Between the Structure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2002, 11, p 365-374

R. McPherson and B.V. Shafer, Interlamellar Contact Within Plasma-Sprayed Coatings, Thin Solid Films, 1982, 97, p 201-204

A. Ohmori and C.-J. Li, Quantitative Characterization of the Structure of Plasma Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, 1991, 201, p 241-252

S. Kuroda, T. Dendo, and S. Kitahara, Quenching Stress in Plasma Sprayed Coatings and Its Correlation with the Deposit Microstructure, J. Therm. Spray Technol., 1995, 4(1), p 75-84

S. Boire-Lavigne, C. Moreau, and R.G. Saint-Jacques, The Relationship Between the Microstructure and Thermal Diffusivity of Plasma-Sprayed Tungsten Coatings, J. Therm. Spray Technol., 1995, 4(3), p 261-267

L. Chen, G.J. Yang, C.-X. Li, and C.-J. Li, Edge Effect on Crack Patterns in Thermally Sprayed Ceramic Splats, J. Therm. Spray Technol., 2017, 26(3), p 302-314

S. Kuroda and T.W. Clyne, The Quenching Stress in Thermally Sprayed Coating, Thin Solid Films, 1991, 200, p 49-66

Y. Arata, A. Ohmori, and C.-J. Li, Electrochemical Method to Evaluate the Connected Porosity in Ceramic Coatings, Thin Solid Films, 1988, 156, p 315-325

M. Vippola, J. Vuorinen, P. Vuoristo, T. Lepisto, and T. Mantyla, Thermal Analysis of Plasma Sprayed Oxide Coatings Sealed with Aluminium Phosphate, J. Eur. Ceram. Soc., 2002, 22, p 1937-1946

C.-J. Li, X.-J. Ning, and C.-X. Li, Effect of Densification Process on the Properties of Plasma-Sprayed YSZ Electrolyte Coatings for Solid Oxide Fuel Cell, Surf. Coat. Technol., 2005, 190, p 60-64

R. McPherson, A Model for the Thermal Conductivity of Plasma-Sprayed Ceramic Coatings, Thin Solid Films, 1984, 112, p 89-95

C.-J. Li, W.-Z. Wang, and Y. He, Dependency of Fracture Toughness of Plasma-Spray Al2O3 Coatings on Lamellar Structure, J. Therm. Spray Technol., 2004, 13(3), p 425-443

C.-J. Li, G.J. Yang, and C.X. Li, Development of Particle Interface Bonding in Thermal Spray Coatings: A Review, J. Therm. Spray Technol., 2013, 22(2-3), p 192-206

G. Dwivedi, V. Viswanathan, S. Sampath, A. Shyam, and E. Lara-Curzio, Fracture Toughness of Plasma-Sprayed Thermal Barrier Ceramics: Influence of Processing, Microstructure, and Thermal Aging, J. Am. Ceram. Soc., 2014, 97(9), p 2736-2744

C.-J. Li, Y. Li, G.-J. Yang, and C.-X. Li, A Novel Plasma-Sprayed Durable Thermal Barrier Coating with the Well-Bonded YSZ Interlayer Between Porous YSZ and Bond Coat, J. Therm. Spray Technol., 2012, 21, p 383-390

V. Viswanathan, G. Dwivedi, and S. Sampath, Engineered Multilayer Thermal Barrier Coatings for Enhanced Durability and Functional Performance, J. Am. Ceram. Soc., 2014, 97(9), p 2770-2778

G. Dwivedi, K. Flynn, M. Resnick, S. Sampath, and A. Gouldstone, Bioinspired Hybrid Materials from Spray-Formed Ceramic Templates, Adv. Mater., 2015, 27(19), p 3073-3078

J. Rong, K. Yang, Y. Zhuang, J. Ni, H. Zhao, S. Tao, X. Zhong, and C. Ding, Phase and Microstructure Evolution and Toughening Mechanism of a Hierarchical Architectured Al2O3-Y2O3 Coating Under High Temperature, J. Therm. Spray Technnol., 2018, 27, p 358-370

Y.-Z. Xing, C.-J. Li, C.-X. Li, and G.-J. Yang, Relationship Between the Interlamellar Bonding and Properties of Plasma-Sprayed Y2O3-ZrO2 Coatings, Thermal Spray 2009: Expanding Thermal Spray Performance to New Markets and Applications, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., ASM International, Materials Park, 2009, p 939-944

H.B. Guo, R. Vaßen, and D. Stöver, Atmospheric Plasma Sprayed Thick Thermal Barrier Coatings with High Segmentation Crack Density, Surf. Coat. Technol., 2004, 186, p 353-363

Y.Z. Xing, C.J. Li, Q. Zhang, C.X. Li, and G.J. Yang, Influence of Microstructure on the Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia Deposits, J. Am. Ceram. Soc., 2008, 91(12), p 3931-3936

G.J. Yang, C.X. Li, S. Hao, Y.Z. Xing, Y.Z. Xing, and C.-J. Li, Critical Bonding Temperature for the Splat Bonding Formation During Plasma Spraying of Ceramic Materials, Surf. Coat. Technol., 2013, 235, p 841-847

S.W. Yao, C.-J. Li, J.J. Tian, G.J. Yang, and C.X. Li, Conditions and Mechanisms for the Bonding of a Molten Ceramic Droplet to a Substrate After High-Speed Impact, Acta Mater., 2016, 119, p 9-25

R. Murakami and K. Matsui, Evaluation of Mechanical and Wear Properties of Potassium Acid Titanate Whisker-Reinforced Copper Matrix Composites Formed by Hot Isostatic Pressing, Wear, 1996, 201, p 193-198

D. Yu, J. Wu, L. Zhou, D. Xie, and S. Wu, The Dielectric and Mechanical Properties of a Potassium-Titanate-Whisker-Reinforced PP/PA Blend, Compos. Sci. Technol., 2000, 60, p 499-508

Z. Lu, Y. Liu, B. Liu, and M. Liu, Friction and Wear Behavior of Hydroxyapatite Based Composite Ceramics Reinforced with Fibers, Mater. Des., 2012, 39, p 444-449

Y. Qi, Y. He, C. Cui, S. Liu, and H. Wang, Fabrication and Biocompatibility In Vitro of Potassium Titatnate Biological Thin/Titanium Alloy Biological Composite, Front. Mater. Sci., 2007, 1, p 252-257

H. Yoshida, M. Takeuchi, M. Sato, L. Zhang, T. Teshima, and M.G. Chaskar, Possium Hexatitanate Photocatalysts Prepared by Flux Method for Water Splitting, Catal. Today, 2014, 232, p 158-164

A.S. Varezhnikov, F.S. Fedorov, I.N. Burmistrov, I.A. Plugin, M. Sommer, A.V. Lashkov, A.V. Gorokhovsky, A.G. Nasibulin, D.V. Kuznetsov, M.V. Gorshenkov, and V.V. Sysoev, The Room-Temperature Chemiresistive Properties of Potassium Titanate Whiskers Versus Organic Vapor, Nanomaterials, 2017, 7, p 455-465

R. Dominiko, L. Dupond, M. Gabersaek, J. Jamnik, and E. Baudrin, Alkali Hexatitanate-A2Ti6O13 (A = Na, K) as Host Structure for Reversible Lithium Insertion, J. Power Sources, 2007, 174, p 1172-1176

X. Cheng, Q. Dong, Z. Li, X. Guo, and W. Duan, Influence of Potassium Titanate Whisker on the Mechanical Properties and Microstructure of Calcium Aluminate Cement for In Situ Combustion, J. Adhes. Sci. Technol., 2018, 32, p 343-358

C.J. Li and J.L. Li, Evaporated-Gas-Induced Splashing Model for Splat Formation during Plasma Spraying, Surf. Coat. Technol., 2004, 184(1), p 13-23

S.W. Yao, G.J. Yang, C.X. Li, and C.J. Li, Improving Erosion Resistance of Plasma-Sprayed Ceramic Coatings by Elevating the Deposition Temperature Based on the Critical Bonding Temperature, J. Therm. Spray Technol., 2018, 27(1-2), p 25-34

P. Ponce-Pena, M.A. Gozalez-Lozano, M.A. Escobedo-Bretado, P. de Lira-Gomez, E. Garcia-Sanchez, E. Rivera, and L. Alexandrova, Synthesis and characterization of Potassium Hexatitanate Using Boric Acid as the Flux, Ceram. Int., 2015, 41, p 10051-10056

L.S. Wang, S.L. Zhang, T. Liu, C.J. Li, C.X. Li, and G.J. Yang, Dominant Effect of Particle Size on the CeO2 Preferential Evaporation During Plasma Spraying of La2Ce2O7, J. Eur. Ceram. Soc., 2017, 37(4), p 1577-1585

S. Zhang, T. Liu, C. Li, S. Yao, and C. Li, Atmospheric Plasma-Sprayed La0.8Sr0.2Ga0.8Mg0.2O3 Electrolyte Membranes for Intermediate-Temperature Solid Oxide Fuel Cells, J. Mater. Chem. A, 2015, 3(14), p 7535-7553

S.H. Leigh, C.K. Lin, and C.C. Berndt, Elastic Response of Thermal Spray Deposits Under Indentation Tests, J. Am. Ceram. Soc., 1997, 80, p 2093-2099

F. Kroupa, Nonlinear Behavior in Compression and Tension of Thermally Sprayed Ceramic Coatings, J. Therm. Spray Technol., 2007, 16(1), p 84-95

G.-R. Li, H. Xie, G.-J. Yang, G. Liu, C.-X. Li, and C.-J. Li, A Comprehensive Sintering Mechanism for TBCs-Part I: An Overall Evolution with Two-Stage Kinetics, J. Am. Ceram. Soc., 2017, 100(5), p 2176-2189

C.-J. Li, G.-J. Yang, and A. Ohmori, Relationship Between Particle Erosion and Lamellar Microstructure for Plasma Sprayed Alumina Coatings, Wear, 2006, 260(11-12), p 1166-1172

A. Kobayashi, Enhancement of Functional Ceramic Coating Performance by Gas Tunnel Type Plasma Spraying, J. Therm. Spray Technol., 2016, 25(3), p 411-418

R.J. Damani and P. Makroczy, Heat Treatment Induced Phase and Microstructural Development in Bulk Plasma Sprayed Alumina, J. Eur. Ceram. Soc., 2000, 20(7), p 867-888

T. Chraska, Z. Pala, R. Musalek, J. Medricky, and M. Vilemova, Post-Treatment of Plasma-Sprayed Amorphous Ceramic Coatings by Spark Plasma Sintering, J. Therm. Spray Technol., 2015, 24(4), p 637-643

A. Ohmori, C.-J. Li, and Y. Arata, Influence of Plasma Spray Conditions on the Structure of Al2O3 Coatings, Trans. Jpn. Weld. Res. Inst., 1990, 19, p 259-270

M. Vardelle, A. Vardelle, and P. Fauchais, Study of Trajectories and Temperatures of Powders in a D.C. Plasma Jet—Correlation with Alumina Sprayed Coatings. Proceedings of the 10th International Thermal Spraying Conference, Essen, May 1983, German Welding Society, 1983, p 88-92

L.-M. Martinez and C. Angell, A Thermodynamic Connection to the Fragility of Glass-Forming Liquids, Nature, 2001, 410, p 663-667

Acknowledgments

The present project is financially supported by National Science Foundation (No. 51171144) and the National Basic Research Program of China (No. 2012CB625104).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, CJ., Zhang, QL., Yao, SW. et al. Plasma Spraying of Dense Ceramic Coating with Fully Bonded Lamellae Through Materials Design Based on the Critical Bonding Temperature Concept. J Therm Spray Tech 28, 53–62 (2019). https://doi.org/10.1007/s11666-018-0818-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0818-8