Abstract

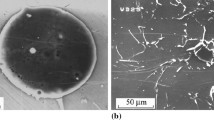

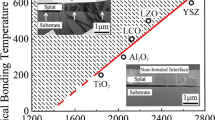

Interlamellar bonding is an important factor controlling the mechanical, thermal and electrical properties of plasma sprayed ceramic coatings. In order to understand the formation of limited interlamellar bonding, a theoretical model is proposed based on the concept of the intrinsic bonding temperature. The numerical simulation of the interface temperature between a molten splat and underlying splats was performed for splats with uniform and non-uniform thickness, in order to reveal the conditions for the interlamellar bonding formation. The interlamellar bonding ratio was theoretically estimated based on the bonding forming conditions. The features of interlamellar bonding revealed by the simulation agree well with the experimental observations. The bonding ratio of plasma sprayed coatings is significantly influenced by the distribution of splat thickness. According to the distribution of Al2O3 splat thickness in the coating, the theoretical estimation of bonding ratio yielded a value of 0.41 for the plasma sprayed Al2O3 coating at the ambient atmosphere conditions, which is reasonably consistent with the observation value. Therefore, the limited interlamellar bonding can be reasonably explained based on the sufficient condition that the maximum interface temperature between a molten splat and underlying splats is larger than the intrinsic bonding temperature.

Similar content being viewed by others

References

C.-J. Li and A. Ohmori, Relationships Between the Microstructure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2002, 11(3), p 365-374

A. Ohmori and C.-J. Li, Quantitative Characterization of the Structure of Plasma-Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, 1991, 201(2), p 241-252

C.-J. Li, G.J. Yang, and C.X. Li, Development of Particle Interface Bonding in Thermal Spray Coatings: A Review, J. Therm. Spray Technol., 2013, 22(2–3), p 192-206

R. McPherson and B. Shafer, Interlamellar Contact within Plasma-Sprayed Coatings, Thin Solid Films, 1982, 97(3), p 201-204

C. Moreau, P. Cielo, M. Lamontagne, S. Dallaire, J.C. Krapez, and M. Vardelle, Temperature Evolution of Plasma-Sprayed Niobium Particles Impacting on a Substrate, Surf. Coat. Technol., 1991, 46(2), p 173-187

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia—Part I. First Splat Solidification, Thin Solid Films, 2001, 397(1), p 30-39

Y. Arata, A. Ohmori, and C.-J. Li, Study on the Structure of Plasma Sprayed Ceramic Coating by Using Copper Electroplating, in Proceedings of International Symposium on Advanced Thermal Spray Technology and Allied Coatings, 1988, p 205-210

S. Kuroda and T. Clyne, The Quenching Stress in Thermally Sprayed Coatings, Thin Solid Films, 1991, 200(1), p 49-66

C.-J. Li, A. Ohmori, and R. McPherson, The Relationship Between Microstructure and Young’s Modulus of Thermally Sprayed Ceramic Coatings, J. Mater. Sci., 1997, 32(4), p 997-1004

C.-J. Li, W.Z. Wang, and Y. He, Dependency of Fracture Toughness of Plasma Sprayed Al2O3 Coatings on Lamellar Structure, J. Therm. Spray Technol., 2004, 13(3), p 425-431

R. McPherson, A Model for the Thermal Conductivity of Plasma-Sprayed Ceramic Coatings, Thin Solid Films, 1984, 112(1), p 89-95

S. Boire-Lavigne, C. Moreau, and R. Saint-Jacques, The Relationship Between the Microstructure and Thermal Diffusivity of Plasma-Sprayed Tungsten Coatings, J. Therm. Spray Technol., 1995, 4(3), p 261-267

C.-J. Li, C.X. Li, and M. Wang, Effect of Spray Parameters on the Electrical Conductivity of Plasma-Sprayed La1−xSrxMnO3 Coating for the Cathode of SOFCs, Surf. Coat. Technol., 2005, 198(1), p 278-282

Y.Z. Xing, C.-J. Li, C.X. Li, and G.J. Yang, Influence of Through-Lamella Grain Growth on Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia as an Electrolyte in Solid Oxide Fuel Cells, J. Power Sources, 2008, 176(1), p 31-38

L. Pawlowski, The science and engineering of thermal spray coatings, Wiley, London, 2008

J.R. Davis, Handbook of Thermal Spray Technology, ASM International, 2004

X. Shi, M. Shu, Q. Zhong, J. Zhang, Q. Zhou, and B. Quoc, Binh, Investigations of Local Corrosion Behavior of Plasma-Sprayed FeCr Nanocomposite Coating by SECM, J. Therm. Spray Technol., 2016, 25(3), p 595-604

A. Ganvir, N. Curry, N. Markocsan, P. Nylen, S. Joshi, M. Vilemova, and Z. Pala, Influence of Microstructure on Thermal Properties of Axial Suspension Plasma-Sprayed YSZ Thermal Barrier Coatings, J. Therm. Spray Technol., 2016, 25(1–2), p 202-212

Y. Zhang, M. Hyland, T. Anh Tuyet, and S. Matthews, Effect of Substrates Temperatures on the Spreading Behavior Of Plasma-Sprayed Ni and Ni-20 wt.% Cr Splats, J. Therm. Spray Technol., 2016, 25(1–2), p 71-81

A. Kobayashi, Enhancement of Functional Ceramic Coating Performance by Gas Tunnel Type Plasma Spraying, J. Therm. Spray Technol., 2016, 25(3), p 411-418

Q. Wei, J. Zhu, and W. Chen, Anisotropic Mechanical Properties of Plasma-Sprayed Thermal Barrier Coatings at High Temperature Determined by Ultrasonic Method, J. Therm. Spray Technol., 2016, 25(3), p 605-612

A. McWilliams, High-Performance Ceramic Coatings: Markets and Technologies, BCC Res., 2016, 1

A. Afrasiabi and A. Kobayashi, Hot Corrosion Control in Plasma Sprayed YSZ Coating by Alumina Layer with Evaluation of Microstructure and Nanoindentation Data (H, E), Vacuum, 2013, 88, p 103-107

S. Panwar, P.T. Umasankar, K. Balasubramanian, and B. Venkataraman, High-Temperature Stability of Yttria-Stabilized Zirconia Thermal Barrier Coating on Niobium Alloy—C-103, Bull. Mater. Sci., 2016, 39(1), p 321-329

R. Henne, Solid Oxide Fuel Cells: A Challenge for Plasma Deposition Processes, J. Therm. Spray Technol., 2007, 16(3), p 381-403

C.-J. Li, X.J. Ning, and C.X. Li, Effect of Densification Processes on the Properties of Plasma-Sprayed YSZ Electrolyte Coatings for Solid Oxide Fuel Cells, Surf. Coat. Technol., 2005, 190(1), p 60-64

A. Vardelle, M. Vardelle, R. McPhereson, Study of the Influence of Particle Temperature and Velocity Distribution within a Plasma Jet Coating Formation, Proceedings of the 9th International Thermal Spraying Conference, DVS German Welding Research Institute, p 155-161

C. Lyphout, P. Nylen, and L.G. Östergren, Adhesion Strength of HVOF Sprayed IN718 Coatings, J. Therm. Spray Technol., 2012, 21(1), p 86-95

C.-J. Li and G.J. Yang, Relationships Between Feedstock Structure, Particle Parameter, Coating Deposition, Microstructure and Properties for Thermally Sprayed Conventional and Nanostructured WC-Co, Int. J. Refract. Met. Hard Mater., 2013, 39, p 2-17

G. Mauer, D. Sebold, and R. Vaßen, MCrAlY Bondcoats by High-Velocity Atmospheric Plasma Spraying, J. Therm. Spray Technol., 2014, 23(1–2), p 140-146

C. Henkes and H. Olivier, Particle Acceleration in a High Enthalpy Nozzle Flow with a Modified Detonation Gun, J. Therm. Spray Technol., 2014, 23(4), p 625-640

A. Ohmori, C.-J. Li, and Y. Arata, Influence of Plasma Spray Conditions on the Structure of Al2O3 Coatings, Trans. Jpn. Weld. Res. Inst., 1990, 19, p 259-270

C.-J. Li and A. Ohmori, The Lamellar Structure of a Detonation Gun Sprayed Al2O3 Coating, Surf. Coat. Technol., 1996, 82(3), p 254-258

R. Kawase, H. Nakajima, K. Maehara, M. Koyama, and H. Abe, Influence of spraying parameters on detonation coating properties, Proceedings of International Symposium on Advanced Thermal Spraying Technology and Allied Coatings, Osaka, 1988, p 55-60

P. Fauchais, M. Vardelle, A. Vardelle, and J. Coudert, Plasma Spraying of Ceramic Particles in Argon-Hydrogen dc Plasma Jets: Modeling and Measurements of Particles in Flight Correlation with Thermophysical Properties of Sprayed Layers, Metall. Mater. Trans. B, 1989, 20(2), p 263-276

Y.Z. Xing, C.-J. Li, Q. Zhang, C.X. Li, and G.J. Yang, Influence of Microstructure on the Ionic Conductivity of Plasma-Sprayed Yttria-Stabilized Zirconia Deposits, J. Am. Ceram. Soc., 2008, 91(12), p 3931-3936

S. Hao, C.-J. Li, and G.J. Yang, Influence of Deposition Temperature on the Microstructures and Properties of Plasma-Sprayed Al2O3 Coatings, J. Therm. Spray Technol., 2011, 20(1–2), p 160-169

S. Sampath, X. Jiang, J. Matejicek, A. Leger, and A. Vardelle, Substrate Temperature Effects on Splat Formation, Microstructure Development and Properties of Plasma Sprayed Coatings Part I: Case Study for Partially Stabilized Zirconia, Mater. Sci. Eng., A, 1999, 272(1), p 181-188

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia–Part II. Interfaces and Subsequent Splat Solidification, Thin Solid Films, 2001, 397(1), p 40-48

G. Heintze and S. Uematsu, Preparation and Structures of Plasma-Sprayed γ-and α-Al2O3 Coatings, Surf. Coat. Technol., 1992, 50(3), p 213-222

I.H. Jung, K.K. Bae, M.S. Yang, and S.K. Ihm, A Study of the Microstructure of Yttria-Stabilized Zirconia Deposited by Inductively Coupled Plasma Spraying, J. Therm. Spray Technol., 2000, 9(4), p 463-477

I.H. Jung, J.S. Moon, K.C. Song, and M.S. Yang, Microstructure of Yttria Stabilized Zirconia Deposited by Plasma Spraying, Surf. Coat. Technol., 2004, 180, p 454-457

V. Pershin, M. Lufitha, S. Chandra, and J. Mostaghimi, Effect of Substrate Temperature on Adhesion Strength of Plasma-Sprayed Nickel Coatings, J. Therm. Spray Technol., 2003, 12(3), p 370-376

G.J. Yang, C.X. Li, S. Hao, Y.Z. Xing, E.J. Yang, and C.-J. Li, Critical Bonding Temperature for the Splat Bonding Formation During Plasma Spraying of Ceramic Materials, Surf. Coat. Technol., 2013, 235, p 841-847

S.W. Yao, C.-J. Li, J.J. Tian, G.J. Yang, and C.X. Li, Conditions and Mechanisms for the Bonding of a Molten Ceramic Droplet to a Substrate After High-Speed Impact, Acta Mater., 2016, 119, p 9-25

R. McPherson, The Relationship Between the Mechanism of Formation, Microstructure and Properties of Plasma-Sprayed Coatings, Thin Solid Films, 1981, 83(3), p 297-310

V. Sobolev and J. Guilemany, Droplet-Substrate Impact Interaction in Thermal Spraying, Mater. Lett., 1996, 28(4), p 331-335

J.M. Houben, Remarks Concerning a Rational Plasma for Thermal Spraying, Preprints of 9th International Thermal Spray Conference, 1980, p 143-154

C.-J. Li and W.Z. Wang, Quantitative Characterization of Lamellar Microstructure of Plasma-Sprayed Ceramic Coatings Through Visualization of Void Distribution, Mater. Sci. Eng., A, 2004, 386(1), p 10-19

Y. Lahmar-Mebdoua, A. Vardelle, P. Fauchais, and D. Gobin, Modelling the Nucleation Process in Alumina Lamellae Deposited on a Steel Substrate, Int. J. Therm. Sci., 2010, 49(3), p 522-528

E.J. Yang, X.T. Luo, G.J. Yang, C.-J. Li, M. Takahashi, S. Kuroda, and K.H. Kim, Impact of Deposition Temperature on Crystalline Structure of Plasma-Sprayed Al2O3 Splats Revealed by FIB-HRTEM Technique, Ceram. Int., 2016, 42(1), p 853-860

E.J. Yang, C.-J. Li, G.J. Yang, C.X. Li, and M. Takahashi, Effect of Intersplat Interface Bonding on the Microstructure of Plasma-Sprayed Al2O3 Coating, IOP Conf. Ser.: Mater. Sci. Eng., 2014, 61, p 012022. doi:10.1088/1757-899X/61/1/012022

Acknowledgments

The present project is financially supported by the National Basic Research Program of China (Grant No. 2012CB625100) and National Natural Science Foundation of China (Grant No. 51171144).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, SW., Tian, JJ., Li, CJ. et al. Understanding the Formation of Limited Interlamellar Bonding in Plasma Sprayed Ceramic Coatings Based on the Concept of Intrinsic Bonding Temperature. J Therm Spray Tech 25, 1617–1630 (2016). https://doi.org/10.1007/s11666-016-0464-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0464-y